Blistering Machine In Pharmaceutical Industry: The Complete Buying Guide In 2025

As we all know, medicine play a vital role in our life. Do you know why the medicine we take can be stored for so long? Blistering machines in pharmaceutical industry have been widely used to package drugs, to improve patients’ healthy life.

Do you feel a bit confused when facing numerous blistering machines in pharmaceutical industry? How to choose a suitable equipment has become a headache.

Next, let’s read the complete buying guide for blistering machine in pharmaceutical industry together

1.What is Blistering MachineIn Pharmaceutical Industry?

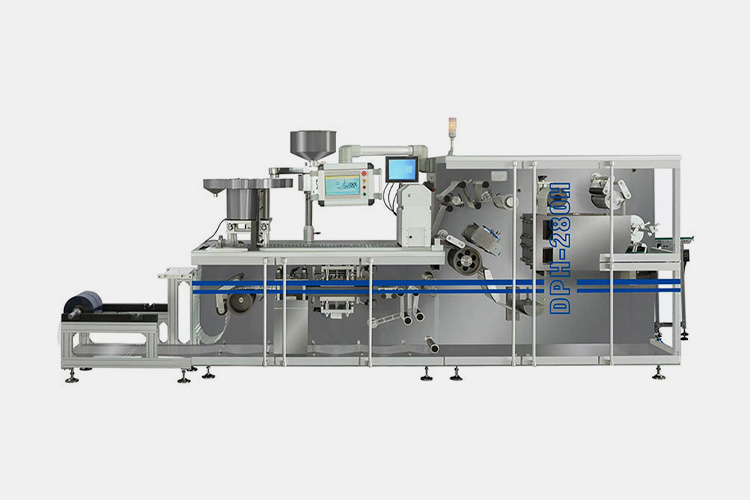

Aipak Blistering Machine In Pharmaceutical Industry

The blistering machine in pharmaceutical industry is applied to packaging medicine into a blister. The medicine packed by this equipment includes capsule, tablets and others. This machine, serving as a vital role in the pharmaceutical industry, can packaging many materials, which will introduce in the following content.

2.What are the Strengths of Blistering MachineIn Pharmaceutical Industry?

Blistering machines in pharmaceutical industry are highly favored by numerous businesses owing to their excellent advantages. Are you interested in discovering the benefits of this device?

(1)Ensuring drugs safety

Ensuring Drugs Safety - Sourced: leadfluid.com

This machine must undergo quality standard inspection before leaving the factory. Blistering packaging can ensure the safety of drugs and reduce situations such as packaging breakage.

(2)Improving efficiency

Efficiency - Sourced: CPS Energy

What is known to us all is that efficiency is an important factor in the development of factories. The use of good blistering machines in pharmaceutical industry can simplify the operation process, reduce manual involvement, and thus improve production efficiency.

(3)Meeting the customized needs of customers

Customized Blistering - Sourced: Plastics Today

Did you notice any different medication names or other information printed on the blister pack while taking the medicine? Blistering machines can meet customers’ customized needs, including unique capsule sizes and unique designs on the blister.

(4)Reducing packaging waste

This machine can achieve precise filling, reduce unnecessary packaging waste, and save resources. In addition, this machine can reduce resource waste through automatic adjustment function.

3.What Materials are Used in the Blistering MachineIn Pharmaceutical Industry?

Materials are a vital source of machine packaging. Do you know what materials can be used for blistering machines in pharmaceutical industry? To be honest, this kind of machine can package several material.

(1)PVC

PVC - Sourced: Packaging Digest

PVC is easy to process and shape, and can be used to produce drug packaging in different shapes and sizes. In addition, this material has good sealing properties, which can prevent drugs from being corroded and extend their shelf life.

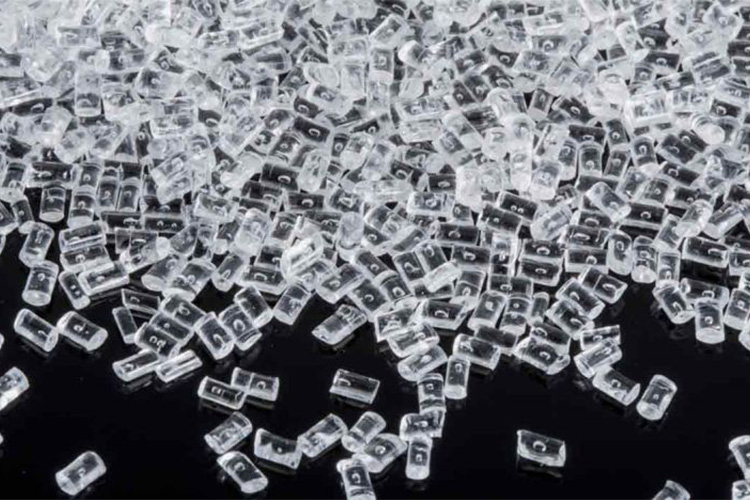

(2)COP

COP - Sourced: Zeon

COP is a kind of plastic material with high transparency, and blister with this material can allow customers to see the specific product. In addition, this material also has high tolerance and will not undergo chemical reactions with the drugs inside the blister.

(3)Aluminum Foil

Aluminum Foil - Sourced: TED Indenting House

Aluminum foil material is often used for blister, which can prevent moisture and light, ensuring the safety of drugs. Blistering machine can packing this kind of material.

(4)PET

PET- Sourced: KAA Timex LR

PET has strong shock resistance and can reduce damage to this material during packaging by blistering machines. In addition, this material can be recycled and reused.

(5)PCTFE

PCTFE - Sourced: KAA Timex LR

PCTFE has corrosion resistance and low temperature resistance, which can effectively prevent the penetration of water vapor. The use of this material in blistering machines in pharmaceutical industry can prevent drugs from getting damp.

(6)COC

This is a thermoplastic with excellent physical and chemical properties that can be used for blister packaging.

(7)PVDC

PVDC - Sourced: Haisun

PVDC exhibits excellent gas barrier properties and resistance to chemical corrosion, effectively isolating the penetration of oxygen to preserve the quality of products, such as drugs.

(8)PETG

PETG possesses robust hardness, excellent impact resistance, and high transparency, effectively safeguarding the drugs inside blister packaging from damage.

(9)Starch-based plastics

This material is made of renewable materials, which is environmentally friendly.

(10)Polyurethane adhesives

Polyurethane adhesives exhibit high strength, resistance to hydrolysis, and chemical corrosion, making them suitable for blister packaging applications.

4.How Many Types of Blistering MachineIn Pharmaceutical Industry?

Have you seen many types of blistering machines in the pharmaceutical industry at the market? Are you aware of the various types that exist? In fact, there are two classification methods for this machine. Let’s take a look at the types of machines according to these two methods.

(1)Depending on the structure

Flat palateblister machine

Flat Palate Blister Machine - Sourced:

This machine adopts positive pressure forming and flat pressure heat sealing, which has the characteristics of firm blister and flat plate, and generally applicable to non mass production.

Roller plate blister machine

Aipak Roller Plate Blister Machine

By using hydraulic transmission to convert liquid pressure into mechanical energy, the working process of the roller plate blister machine is driven, and packaging materials can be quickly and accurately packaged.

(2)Depending on automation level

Automatic blistering machine

Aipak Automatic Blistering Machine

With automated operation, automatic blistering machine in the pharmaceutical industry can produce a large number of blisters, and reduce manual involvement. It can also ensure the accuracy of the product and is suitable for factories with large-scale production.

Semi-automatic blistering machine

Semi-automatic Blistering Machine

Compared to fully automated machines, this type of machine requires manual assistance and has slower efficiency. It is more suitable for small pharmaceutical companies.It has a small footprint and volume, and some can even be placed on a desktop for easy operation.

Manual blistering machine

Manual Blistering Machine - Sourced: cecle

Manual blistering machines have much slower production efficiency, but they can also package various drugs, making them suitable for use in laboratories or small factories. But this type of machine takes up a small space and can be placed on a desktop, making it convenient to use.

5.What are the Differences Between StripPackaging Machine and Blistering Machine In Pharmaceutical Industry?

To start with, let’s take a look at strip packaging and blinding packaging, two different drug packaging methods. We can see from the following picture that there are two different forms of packaging.

Two Kinds of Drug Packaging - Sourced: iSock

Strip packaging machine and blistering machine serve as significant role in the pharmaceutical industry. What are the differences between these two equipment? You can see the table below.

Strip Packaging Machine VS Blistering Machine

| Strip packaging machine | Blistering machine | |

| Packaging speed | Its speed is relatively slow. | Its speed is relatively high. |

| Cavities | It doesn’t have cavities. | Hot forming and cold forming. |

| Packing types | Usually, it is displayed in two sealing. | Usually, it is displayed in face sealing, and mock clamshell. |

| Types of packing medicine | Usually, it can pack hard capsules and tablets. | It can pack hard capsules, soft capsules, and tablets. |

| Cost | Its cost is relatively low. Its cost is relatively high. | Its cost is relatively low. Its cost is relatively high. |

| Product protection | Its protective performance is relatively poor. | Its protective performance is relatively good. |

| Product opening method | Mainly by tearing open the packaging. | Mainly through pushing and peeing. |

| Machine size | It occupies a relatively small space. | It occupies a relatively large space. |

| Process | It is formed by using two flexible film webs, which can be directly heat sealed. | It is made using the molding-filling-sealing method. |

6.What are the Key Parts of Blistering MachineIn Pharmaceutical Industry?

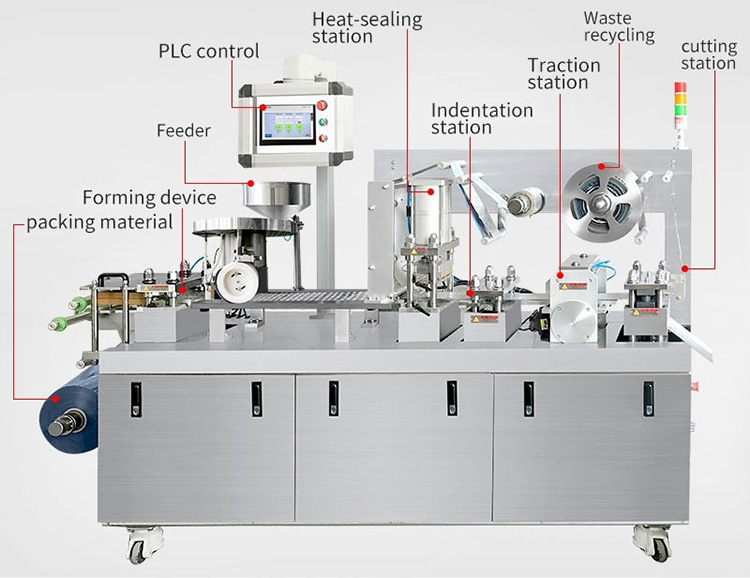

In order to understand a machine, it is crucial to know its components. Are you aware of the essential parts of this device? The picture below displays nine parts of this kind of machine.

Key Parts of Blistering Machine

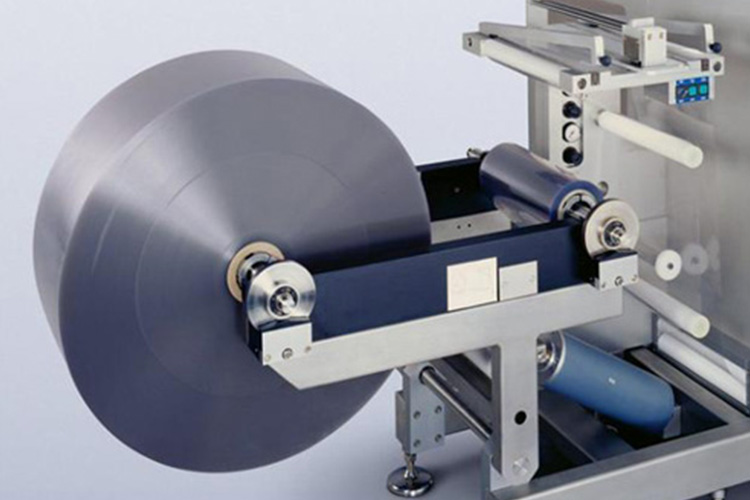

(1)Packing material

Packing material is placed on the foil coil. There are several kinds of packaging materials, including PVC, PET and others.

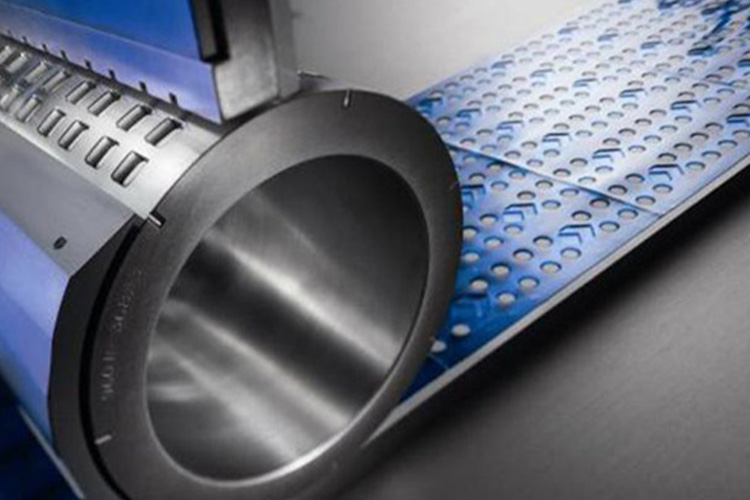

(2)Forming device

Aipak Forming Device

Blister grinding tools are usually made of metal or other hard materials and have grooves, which can be selected in different capsule sizes according to one’s own needs. It mainly shapes various materials according to the required shape.

(3)Feeder

Made of stainless steel, it is used to transport the required packaged drugs into the machine by the motor. There are specialized brushes inside this unit to prevent drug adhesion. Stainless steel hoppers not only have good sealing properties, which can prevent materials from getting damp and contaminated.

(4)PLC control

Aipak PLC Control

This device is capable of controlling the operation of the entire machine. It can adjust packaging speed, packaging materials, and other parameters. This device is usually equipped with a display screen that allows for a clear view of the process.

(5)Heat-sealing station

Aipak Heat-sealing Station

With heating element, it is used to seal the already packaged the sealing edge of the blister. This component has a sealing hot press head that can be used to adjust the problem and pressure.

(6)Indentation station

This part applies pressure to press the expiration date of the batch number that needs to be printed onto the blister. It is usually made of stainless steel and has high hardness and wear resistance. The durability of the indentation station directly affect the forming quality of the blister.

(7)Traction section

It is responsible for pulling down the roll and stamping station, and can be adjusted according to product specifications.

(8)Waste recycling

This part is mainly used to recycle the waste generated during the operation of the machine, some of which can be reprocessed and reused to avoid contaminating the final product.

(9)Cutting station

This is the final stage of this machine, which is designed to cut packaged products into their final form.

7.What is the Workflow of Blistering MachineIn Pharmaceutical Industry?

Are you interested in learning how to operate a blistering machine in the pharmaceutical industry? Let’s delve into the workflow of this machine together!

Step 1: Prepare the materials

Before running the machine, you need to prepare packaging materials such as PVC, PET. And you need to prepare capsules, tablets, etc.

Step 2: Unwinding

Unwinding

Driven by the engine, the material on the foil coil is transported to the forming station. Roll plastic sheet unfolded and transported forward.

Step 3: Forming

Due to the thermoplasticity of materials such as PVC and PET, they can be formed into the desired shape in a molding die by heating or stamping.

Step 4: Filling the medicine

Filling The Medicine - Sourced: Lenis Machine

After waiting for PVC, PET and other materials to form, you can adjust the filling speed for filling. Solid drugs can be filled automatically by a scanning device or by an automatic discharge device.

Step 5: Sealing

After filling the medicine, it is usually sealed with aluminum foil or other material. By attaching plastic film to the already filled medication and performing sealing operations, the packaging’s sealing is ensured. There are various sealing methods, including rolling type and pressure plate type.

Step 6: Printing

Printing the batch number, expiration date, and other information you need on the back of the blister.

Step 7: Cutting

The last step is cutting into individual packaging units. After the punching process is completed, the scrap removal device removes the scrap based on the signal stored in the memory device.

8.What Quality Standards Should Blistering MachineIn Pharmaceutical Industry Follow?

In order to ensure the safety of patients, blistering machines in pharmaceutical industry need to strictly comply with various rules and regulations.

(1)Meeting GMP standards

GMP Standards - Sourced: Encyclopedia

The final products produced by Blistering machines in the pharmaceutical industry need to be used for patients and are related to people’s life and health. Therefore, this machine requires strict adherence to GMP standards for calibration and maintenance before they can operate.

(2)Approving by the quality control department

Packaging materials and drugs are key factors in blister, and their quality must be strictly controlled. The materials used for this machine need to be reviewed by the quality control department, and any material must be labeled with batch number, expiration date, etc.

(3) Adhering to personal hygiene standards

Personal Hygiene Standards - Sourced: Instagram

In addition, employees also need to strictly comply with various hygiene standards. Staff who operate blistering machines need to wear protective covers, face masks, and medical gloves to strictly prevent bacterial growth and affect drug safety.

9.What are Common Issues and Solutions of Blistering MachineIn Pharmaceutical Industry?

It is normal for a machine to have minor problems. If you encounter some problems while using blistering machine in pharmaceutical industry, don’t panic and try the following solutions.

| Common issues | Solutions |

| Poor sealing | You need to check the heating and pressure issues and try adjusting them. |

| The medication was not fully packaged | Due to issues with machine components or excessive operating speed, some medications may be missed during packaging. You can check the operation of the components or adjust the operating speed, such as rotating stick. |

| Breakage of packing | Poor materials can cause problems during machine operation. You need to check the quality of plastic film and other materials, and replace them with better quality materials. |

If the above solutions still cannot solve the problem, please contact the relevant engineers at the factory for assistance.

10.What Should You Consider When Purchasing A Blistering MachineIn Pharmaceutical Industry?

Blistering machine in pharmaceutical industry is a major equipment, which affects the efficiency of the entire factory. Therefore, you need to thoroughly take into account multiple factors.

(1)Packaging materials

Packaging Materials - Sourced: Packaging Strategies

You also need to understand and materials can be packaged by the blistering machine in the pharmaceutical industry. Some machines can adapt to different materials, while others cannot.

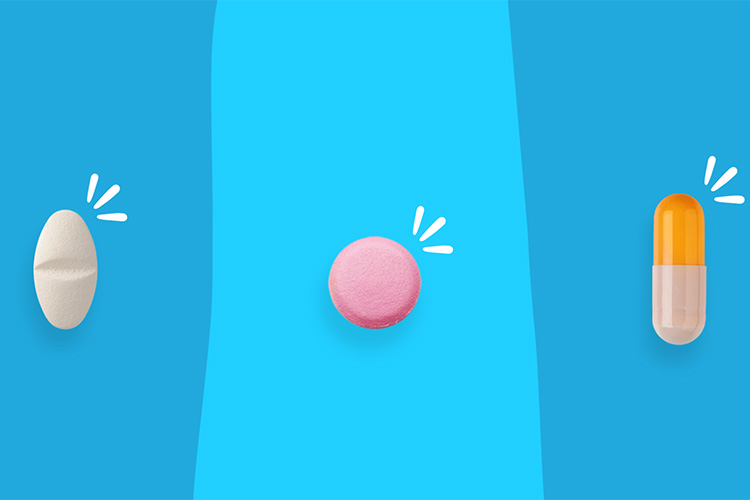

(2)Clearly define the type and size of the medication

Type and Size of the Medication - Sourced: SingleCare

You also need to clarify which type of medication you need to package, such as capsules, tablets, and others. You also need to specify the size of the medication and choose the appropriate size of blister molding tool.

(2)Machine efficiency

Based on your own production scale and production volume requirements, you need to consider the production efficiency and automation level of the machines. Besides, based on the area of the factory, you need to consider the size and weight of the machine.

(3)Capital budgeting

Capital Budgeting - Sourced: Study.com

Financial budget is also important, you need to choose machines based on your funds. The prices of machines vary, so you need to choose more and choose machines with high cost-effectiveness.

In addition, you also need to understand the shipping cost of the product. The shipping cost of large machines is high, and you need to know whether the shipping cost is borne by the buyer or the seller.

(4)Security

Only drugs produced by machines that have undergone quality inspection can meet customer needs and be allowed to circulate in the market. Therefore, you need to check if this machine meets safety standards and if it has a certificate of quality inspection.

11.How to Choose A Suitable Manufacturer of Blistering MachineIn Pharmaceutical Industry?

A good manufacturer can provide high-quality products and after-sales service, which can help customers solve many problems. Therefore, you need to think carefully and seriously.

(1)Reputation

Reputation - Sourced: Titanium Marketing

A good brand has undergone long-term testing, won the favor of customers, and accumulated a certain reputation. When selecting blistering machines in the pharmaceutical industry, it is also important to pay attention to the brand and reputation of the product. You can search and research some brands on the website to understand their development history, product origin, etc.

(2)After-sales service

After-Sales Service - Sourced: Adtance

After sales are very important. When you purchase blistering machines, you need to inquire about the manufacturer’s after-sales service, how many years of after-sales service are available, and whether they can provide professional engineers for repairs.

(3)Technical personnel

You need to inquire whether the factory is equipped with professional engineers and other technical personnel, and whether remote guidance can be provided. Can you provide timely engineer maintenance when the machine encounters problems.

12.The Future Development of Blistering MachineIn Pharmaceutical Industry.

People’s emphasis on health has led to an increase in blistering machines in the pharmaceutical industry. Let’s take a look at the future development trend of this machine.

(1)Increase in demand

Increase in demand - Sourced: The Economics Times

People are paying more and more attention to their physical health, which has spurred the development of the pharmaceutical industry, constantly researching and producing new drugs for patients to improve their health conditions. Therefore, the development prospects of blistering machines are broad.

(2)Better performance

Better Performance - Sourced: Canopy

With the increasing demand from factories, future blistering machines will undergo continuous technological upgrades to achieve superior performance. The design of bubble caps will become more diverse, allowing for the production of different types of blister.

Conclusion

Blistering machines in pharmaceutical industry are crucial for packaging of various drugs, such as capsule, tablet, etc. The superiority and importance of this machine are highly favored by many pharmaceutical companies. After reading this article, have you gained a comprehensive understanding of this machine? If you have any additional questions, please do not hesitate to contact Aipak at any time.

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine