Blister Packing Machine:the Ultimate Buying Guide in 2025

Do you have small batches of products requiring outstanding,yet affordable retail packaging?

Is your product too good to hide?

In fact,attractive packaging is important to make your product stand out.

Blister packaging is a method that seals your product between a blister formed transparent plastic sheet and a bottom plate that makes your product appealing.

Now this is a complete guide to introduce the great machine that makes this work come true:the blister packing machine.

Spend a few minutes reading through ,you will get to know everything about this blister packing machine before purchasing the most suitable one.

Let’s drive to the subject directly.

1.What is Blister Packaging?

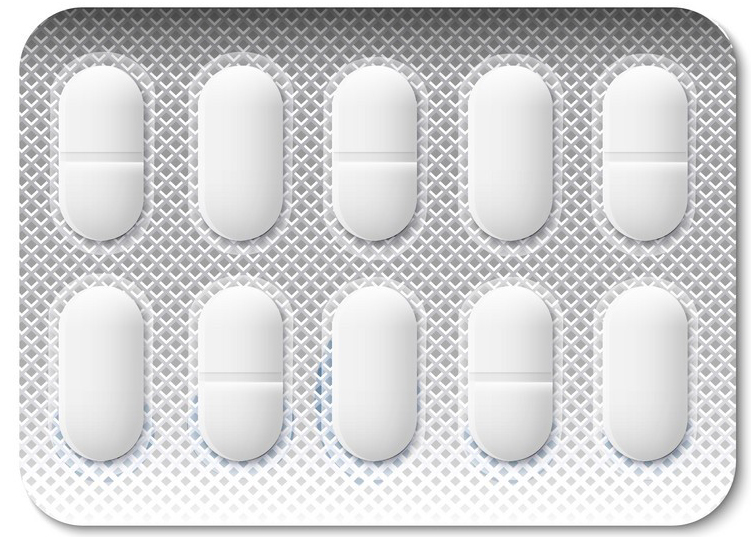

The Blister Packaging has been widely known terminology for a few sorts of already defined plastic bundling utilized for drugs, goods for the consumers, and food items as well.

The essential part of a pack the blister is a hole or pocket produced using a formable web, normally a Thermo shaped plastic. This normally has the backside of paper board or an opening or the lidding seal of the plastic and aluminum foil. A type of blister that folds into the blister itself is regularly called a clamshell.

Packs of the blister are helpful for securing items against outside elements, for example, stickiness and pollution for expanded time frames.

Blister opaque likewise ensure light touchy items against UV rays. A bundle holding and showing stock in a reasonable plastic case fixed to a sheet of cardboard Thousands of items, from radios, rubber bands are sold in packs of the plastic1s tight-fitting sandwiches of cardboard and plastics.

A strategy for securing single dosages of prescriptions inside a clear hole or cell produced using a vault formed plastic Obstacles.

The boundary between this blister packaging one portion from another shield the prescription from dampness and shields it from being broken or harmed during transportation or capacity.

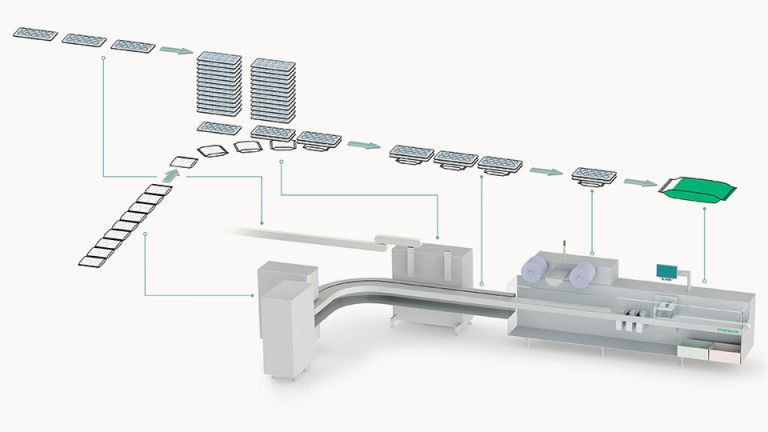

Every part of the capsules and tablets can be independently delivered or opened up without influencing capsule in the next section of the same blister packaging.

2.What are the Advantages of Blister Packaging?

The more the advantages of something the better the efficiency of that thing. When you talk about to the advantages of blister packing, it offers you many of them as defined below.

Protection of the Medication

Packaging of the blister not just shields from light, oxygen, dampness, and toxins, yet in addition secure against mismanaging and altering.

Since the item is safely fixed from an external perspective, its time frame of realistic usability is expanded, making it protected and appropriate for long short stockpiling and displaying.

Advantages blister packaging in the usage of the supplements

Despite the sort of blister bundling you picked, the blister has numerous advantages for supplement brands and buyers.

Added assurance

While a few tablets and capsules can withstand slamming and breaking around in a bottle of medicine, others are more delicate to development and can break if not packed into any other thing very carefully.

Packaging types like blister offers more protection for the capsules and the tablets and soft gels. The individual sections shield the pills from colliding with one another and splitting up.

The Freshness of the Medication

Some enhancement fixings are exceptionally touchy to humidness and oxygen. With the bottles bundling, each time a buyer opens the container, the pills inside are presented to both dampness and oxygen, diminishing their time span of usability.

Whereas on the other way around, In the case blister packaging offer buyers to get to their pills without uncovering.

Fresh Medicine in the blisters

Accommodation for movement

Another extraordinary preferred position of blister packaging is they're anything but difficult to go with. Not just are they regularly lighter than plastic containers, yet they are additionally commonly simpler to store in little spaces.

Transporters may decide to go with only one sheet of pills, for instance, and leave the rest at home. Also, the additional it's makes them ideal for voyaging.

Consistence

Probably the best-preferred position of blister packaging is that it's useful for shoppers to monitor the number of pills they have taken. It's additionally simple to print days on the backside of the aluminum.

This way, it is a helping hand for the patients to ensure they're taking their everyday supplements.

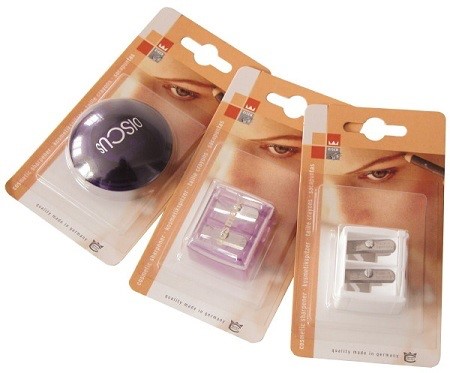

Transparency of the blister packed material

Transparency of the blister packed material is truly vital to certain buyers. They need to see the specific size and state of the tablet that you will be taking each day.

Blister Packaging is one extraordinary approach to show your shoppers what your item resembles. You can likewise utilize the occasion to get an edge over the competitors with tones and help your image to get better in the market.

Advertising

By using the blister packaging offers an assortment of shades and shapes. Card choices related issues incorporate the brands of clean zones, guidelines, data, and so forth Gives.

It permits inclusion in an appealing and simple to follow way.

These assist items with showing up sources fabricate the brand and increase the loyalty of the customers.

Cost-effectiveness by using such packaging

Higher bundling speeds and decreased costs make blister packaging a more practical solution. Blisters packs dispose of the requirement for extra cartons, in this manner lessening the expense of packing too.

Customization

All plastic packing in the blister is thermo formed, so makers can play with each plan of the item. Does not matter the size, shape, or number of things contained in the pack of a blister, it very well may be altered to fit the requirements of the item.

3.Are there any Limitations of Blister Packaging?

In spite of the way that it has a lot of preferences there are additionally a few limitations that can't be disposed of.

Time Taking

Since aluminum is utilized for the whole bundle, the entire cycle takes significantly additional time when contrasted with the time taken with plastic.

Patients can push the Medicines

Another hindrance of such bundling is that it utilizes foil posterior and patients can push the meds through the foil, however it is kid-safe.

Fixing Process is Hard

The fixing cycle to stick the plastic much time a lot of time and if the appropriate machine isn't utilized, it could bring about an increment in the expense as well.

Cut the finger

As it is sharp from the edges. So, you might injure yourself during the packing of blister packs.

4. A Statistic shows Why Blister Packaging is important in Child Resistant Packaging?

Have you ever imagine something like a kid being poisoned due to eating the tablets and going to the hospitals.

Child Resistance (singstoyou.com)

Here are some of the facts stated.

The US and EU measurements tell a terrible story: 3,000 kids harming each year in Europe due to the bad packing of the medicine and being the reason for poisoning, while in the US 67,000 kids are hurried to the emergency center because of medication harming every year.

There is nothing of the sort as kid's evidence, yet kids can be saved by using safe packing can have a major effect on item security.

Little kids up to age 4 specifically run the daily base of the danger of being harmed or hurt because of gulping unsafe items, meds, and medications.

Yet in addition, things like cleansers, beautifying agents, liquor, pesticides, batteries, little sharp articles like needles and staples, and a whole lot more.

Packing arrangements that offer a solid first line of security by making it very hard for small kids to open the bundle.

Your child swallow your medicine

5. What is Blister Packing Machine?

Electrostatic type of the machine which is used for the packing of blisters, preform bottle packing, which is filled with items and sealed is called blister packing Machine.

AIPAK Blister Packing Machine

It has moving and fixed parts that help seal products in preformed cavities.

Blister packing machine is a very well reputed machine in the industry of medicine or lets say pharmaceutical world.

You may use it to pack things like injection, tablets and capsules etc.

Mechanical movements facilitate the formation of cavities in the belt material, filling and sealing with appropriate materials.

The sealing materials can be aluminum or sealed film.

The blister is most common for small consumer, food and pharmaceutical products.

These machines utilize pressure and heat through using a die to form a pocket or pocket with a plastic sheet.

6.What is the Specification of Blister Packing Machine?

| Electric Requirements | 220VAC, 3 phase, 50/60 Hz |

| Power consumption | 10 KVA (almost) |

| Air | 90 psi, 14.2 SCFM |

| Cooling water consumption at 12C | 240 liter per hour (4.0 l/min) |

| Dimensions | 85.6 inches high, 182 inches wide, 72.5 inches deep |

| Weight of machine with tooling | 1850kg approximately |

| Speed | 15-60 cycles/min |

7.What Materials can be used for the Blister Packaging?

Blister packing is generally utilized across the drug business as a unit portion bundling arrangement that assists individuals with taking the right measure of medicine at the perfect time.

The backing material is connected to the rear of the thermo formed plastic holder. Two sided blister packs that don't utilize a blister board backside patron yet rather utilize another bit of plastic is regularly called clamshells.

Blister packaging is made using several types of rugged polymers, including:

- Polyethylene Terephthalate (PET)

- Polyvinyl Chloride (PVC)

- Polyvinylidene Chloride (PVDC)

- Polychlorotrifluoroethylene (PCTFE)

- Cyclic Oefin Polymers (COP)

Polyethylene terephthalate (PET)

PET is among those plastics which are a significant piece of your regular day to day existence.

It is a significant business polymer having applications going from bundling, textures, films, shaped parts for the car, hardware. Furthermore, some more.

You can locate this renowned clear plastic around you as a water jug or soft drink bottle compartment. PET is a major part of the blister packaging.

Medicine Packed in PET

Polyvinyl chloride (PVC)

PVC or polyvinyl chloride is the most widely recognized rankle bundling material. The primary bit of leeway of utilizing PVC is ease. PVC sheets of 0.25 to 0.3mm are utilized for making rankle packs.

PVC in Pharmaceuticals

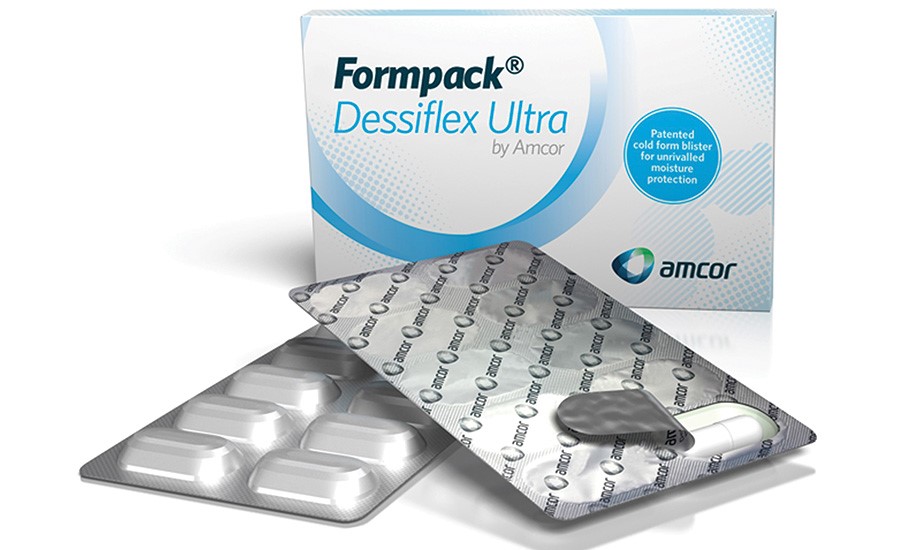

Polyvinylidene chloride (PVDC)

PVDC or polyvinylidene chloride is utilized alongside PVC sheets to improve the hindrance properties of the bundling. This gives magnificent insurance from oxygen and dampness.

Polychlorotrifluoroethylene (PCTFE)

Polychlorotrifluoroethylene or PCTFE is another type of overlay for bundling. PCFTE is essentially utilized as a dampness obstruction. Contrasted with all the polymers, PCFTE accompanies the base estimation of water fume penetration. p

Cyclic olefin polymers (COP)

COP or Cyclic olefin polymers just as Cyclic olefin co polymers improves the thermo forming in packs of blister and even gives great hindrance properties.

COP, when utilized with different polymers, for example, polypropylene and polyethylene, permits makers to make rankle packs with profound pockets. These are fundamental for pressing meds.

Cyclic olefin polymers (COP)

Blister packing makers likewise utilize cold structure bundling produced using PVC, aluminum, and Polyamide.

8.Which Industries are Blister Packing Machine widely used?

Pharmaceutical Industry

For packing of the capsule and other possible things the pharmaceutical industry use the blister packing machine.

Food Processing Industry

For the purpose of packing the food to let not any contamination food industries also uses these packing.

Food Blister Packs

Chemical Industry

Chemicals are also packed into such type of the packing. As it is already defined in the article about advantages so chemical doesn’t have any harm packing in the blister.

Cosmetics Industry

Last but not least, your cosmetic industry might be helped with such type of packing.

Cosmetic in blister

9.What is the Special Application of Blister Packing Machine in Pharmacy?/Why Blister Packaging is Popular Choice for Pharmaceutical Manufacturers?

Blister Packages are made sure to shield items from dampness and gas, to guarantee a long time span of usability, both in stores and medication cupboards. Life span is key for customers who need to save prescriptions close by for when issues emerge.

Drug blister packing is practical and simple to deliver in a high volume. Accordingly, it is an extraordinary decision for a portion of the more mainstream producer.

Supportive to clients since they give a spotless space for details to be worked out and simple-to-follow.

Blister packages are too easy to utilize. For the most part, all purchasers require to do is pop the pill out of the bundle, which should be possible rapidly. In addition purposes, there are friendly arrangements and extra safety features with child-proof highlights.

There is a wide scope of tones/colors that can be developed to include by using the blister packing. Makers can utilize that to help make their items stand prominent on racks.

Likewise the card blister packs incredible for showcasing on the grounds that they permit either the makers or retailers themselves to incorporate ads to help assemble a brand and increment client devotion.

10.Why should you Invest in Blister Packing Machine?

These are some of the major reasons you should invest in the blister packing machine:

- Lesser weight and for that reason easy to transfer to another place.

- Another reason to invest in this machine is no chance of getting in of any kinds of the impurities into the product.

- There is no way the product packed with this machine may get humid.

- One more reason, is being the cost-effectiveness of the packing by using a blister packing machine.

- Maintenance of the blister product is very easy using this machine compared to the plastic packing.

- As it is always in the transparent packs it would be easier for you to do look at the product and decide if it is fine for your usages or not.

- Tablets and capsules are so well sealed with the blister packing machine.

11.Are there any Disadvantages of Blister Packing Machine?

Below defined are the disadvantages of blister packing machine;

Thermo forming disadvantages

The defensive properties are not solid due to the PVC's helpless boundary against dampness and oxygen entrance.

Not appropriate for light-touchy medications as a result of the straightforwardness of PVC.

Cold Forming disadvantages

The pack is misty, making the assessing framework, which dismisses the flawed pack blister, hard to handle, and cost.

The expense of cold shaping aluminum film is higher than PVC.

The bigger size of the cards of blister builds the material expense.

12.How many types of Blister Packing Machine are there?What are they?

Without the correct kind of blister packing machine, every one of your tries will be worthless.

Anyway, what's the main concern?

It is imperative to be aware of the different kinds of blister packing gear accessible at market places.

For the extent of this part, the order standards will be founded on these key factors:

Presently, we should go directly into the details.

Material Type and Blister Packing Machine.

Here is the reality:

What type of material you use decides the type of blister packing machine you need.

I am mindful that producer may utilize a scope of materials for various kinds of packing for capsules, or some other item. Be that as it may, for the extent of this segment, the fundamental spotlight will be on:

- PVC/Alu

- Alu/Alu

- Alu/PVC/Alu

Things being what they are, how precisely do the kinds of material influence the machine plan and structure?

1- PVC/Al Blister Packing Machine

Likewise called the plastic aluminum pack of a blister, this machine utilizes the PVC as shaping film and aluminum as the lidding or the covering material.

AIPAK PVC/Al Blister Packing Machine

This accordingly infers that the machine relies upon thermo forming strategies to make holes/ cavities in the plastic film material.

Relying upon the warming component, this is the means by which it works

- The machine warms plastic material or in other words, called PVC

- Forms film item to an appropriate shape

- Cools down the material to guarantee plastic becomes unbending once more

- Fills pits with proper material

- Seals the pits/ cavities with aluminum foil

Going for these kinds of rankle sealer machines ensure the accompanying key advantages

- A minimal effort thermoforming measure

- Easy to make complex holes relying upon the tooling plan

- Easy to inspect items through the transparency of PVC/plastic henceforth, you can undoubtedly dismiss harmed capsules or tablets

- Most machines utilize widespread feeders, for example, roundabout brushes and planetary instigators. It doesn't need extraordinary plans.

Then again, embracing the PVC blister packing machine has the accompanying demerits

- PVC doesn't offer an ideal boundary to oxygen and dampness

- Due to its transparency, it isn't appropriate for light delicate items

2- Alu/Alu Blister Packing Machine

Dissimilar to the PVC blister packing machine, Alu/Alu blister backing machines utilize a cold framing strategy. This infers that the plan of the machine is marginally extraordinary as I had referenced before.

It utilizes the process of stamping to shape holes on the aluminum cover. At the filling station, it utilizes an aluminum foil as a material of the covering.

Obviously, for the instance of Al, you don't need the aluminum film already heated.

AIPAK Alu/Alu Blister Packing Machine

Typically, you may select Al/Al rankle sealer machines where you need

- It does offer 100% obstruction against dampness and light

- Extend item timeframe of realistic usability

Then again, you need to manage various difficulties when utilizing Al blister packing machines.

These include:

- Not as the PVC blister packing machines, the fastness of the process of Al blister packing machines is moderate

- Inspecting items require the latest machines because of the clear type of aluminum. Consequently, it well may be costly.

- Aluminum blister packaging is way more costly than PVC

- Operational cost and trouble are high because of the enormous cavity of the blister.

Alu/PVC/Alu Blister Packing Machines

You can likewise allude to this gear as a tropical blister packing machine. The machine is exceptional for an additional aluminum shaping and fixing station.

Here, when the machine thermoforms PVC Alu packs, it seals it again with a tropical aluminum.

Because of their one of a kind plan, you can likewise consider it a Thermo-cold framing.

AIPAK Alu/PVC/Alu Blister Packing Machines

The fundamental points of interest of the tropical rankle pressing machine include

- Ease and ease of activity since the machine can embrace a widespread feeder framework.

- Transparent PVC/Al makes it simple to investigate items

- Offers complete hindrance to light, oxygen, and water

- Guarantees added security to the items

Then again, here are the primary burdens of these machines

- The high cost of creation because of an additional aluminum film

- An extra framing and fixing station build the size of the rankle pressing machine

- Closely identified with these older models is the working instrument cycle of the blister pack.

13.What is the Difference Between Blister Packing Machine and Strip Packing Machine?

Blister Packing

Blister Packing is a type of unit portion bundling in which a semi inflexible hole recently framed is loaded up with items/ and lidded with a warm sealable support material.

Strip Packaging

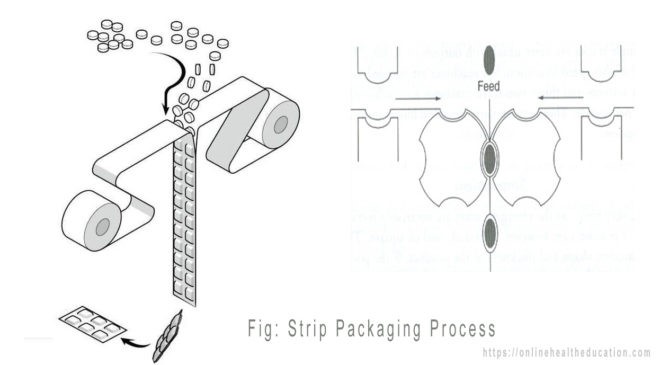

Strip Packaging

Strip bundling is an elective type of unit portion bundling in which a drug item is encased between two traps of warmth seal capable adaptable film through either a warmed responding plate or a warmed crease roller.

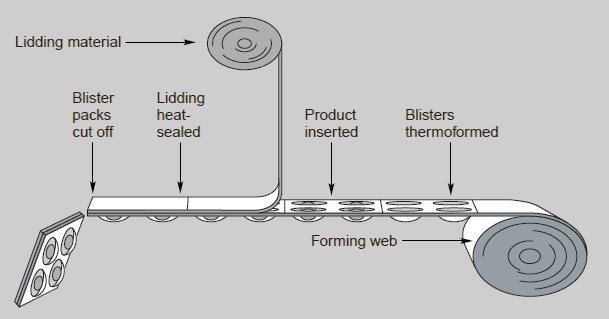

Blister Packaging Process

Blister packs are made by using a structure fill-seal strategy. From the start, Semi-unbending hole is shaped by either thermo framing or cold framing cycle and afterward loaded up with item and lidded with a warmth seal capable sponsorship material.

Photo Credit: pharmaeducation.net

Strip Packing Process

Strip packs are conformed to the tablet when it is taken down to the fixing territory within two traps of a warm seal-able adaptable film through either a warmed responding plate or a warmed pleat roller.

Photo Credit: pharmaeducation.net

| Blister Packing | Features | Strip Packing |

| A- Automatic strip blister pack machine

B- PVC blister pack of tablets C- LFA high quality blister strip packing machine D- Self checking molding aluminum blister packing machine |

Machine | A- Auto soft double AI striper

B- High speed tablet striper C- Auto AI / AIU Machine and foil striper D- Rotary type tablet strip packing machine E- High Quality Stripier |

| Higher | Packing Speed | Lower |

| No difficulties during blister packing | Difficulties | Wrinkling of the sealing place

Perforation of pocket |

| Item can be taken out by pushing | Using Pattern | Item can be taken out by tearing |

| 2 Basic types

Thermoform Cold Stretching |

Type | There isn’t any type |

| Less space occupied | Space | More space is occupied |

| Either cold or thermoform | Cavities | No such thing |

| Higher | Patient Compliance | Lesser |

| More better and popular type of the packing | Popularity | Less better and popular too |

14.What are the Main components of Blister Packing Machine?

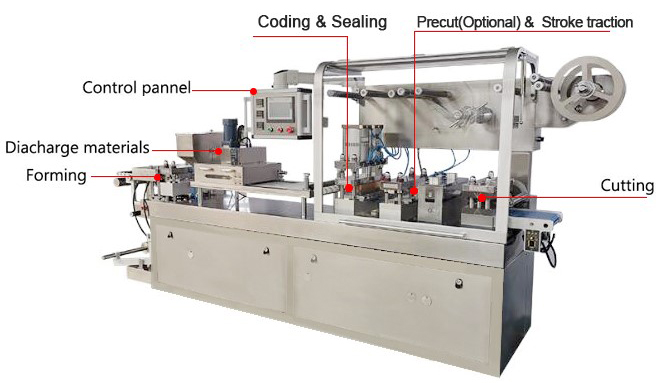

The blister packing machine relies upon the accompanying parts to aid the bundling cycle.

Touch screen for Controlling

It has a touch screen human machine interface for natural and simple administration of all the bundling processes.

Contact screen board

You can play out the accompanying errands relying upon the plan of the human machine interface board.

- Checking of the production insights and status

- Solving the problem with the machine by approaching the information which may incorporate parts and segments

- Arranging the tasks by entering in the correct production determinations and boundaries.

Tooling System of Blister Packs

You are going to discover the tooling framework of blister packs in various plans and design for the accompanying purposes:

- Thermo framing

- Cold framing

- Constant or irregular production

You can likewise arrange for a difference in parts dependent on the production of your customers well.

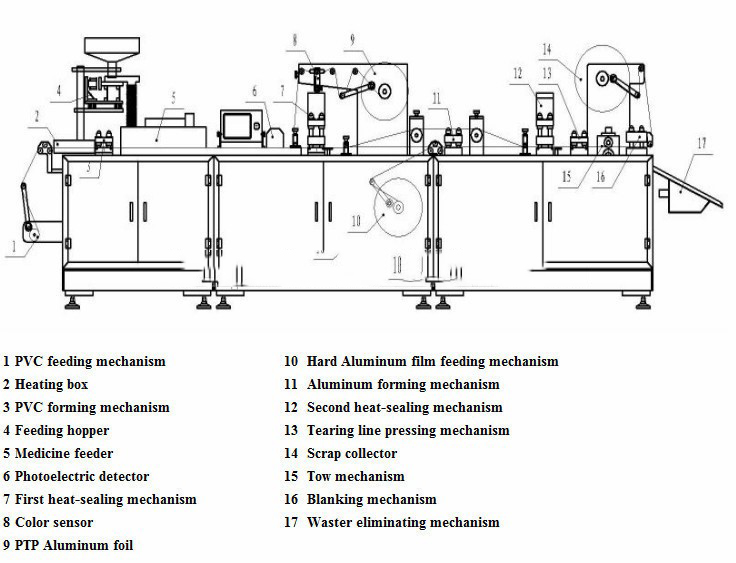

PVC Feeding Roller or Aluminum Foil

Feeding Roller

This part is used for pushing the material.

The roller keeps on moving and they also make a link with other parts to run the machine effectively.

To achieve an astonishing turn of events, the machine uses a motor framework that will ensure that:

- The structure is totally modified and you can essentially control the assignments from the human-machine interface.

- The machine has a reliable framework for taking care of.

- It has the simplest blending structure for capable packaging needs.

- It tends to the different issues of the materials feeding system.

Electric Motor

This is the portion of the machine that empowers of the moving components of the machine.

It helps in sending the motion of the moving parts through the belts, gears, and shaft of the machine.

It is additionally fit for controlling the velocity of the parts to fit into to the prerequisites of blister packing.

Turning Rollers

These are the components that aid the items feeding in the machine by applying pressure on the materials.

Along with the moving framework, it takes care of material to the blister packaging framework.

Warming Box

It is the primary component of the machine which gets materials from frameworks of the feeding.

By warming material for bundling to a reasonable temperature, it gets prepared for shaping in the following stage.

It comprises of Upper warming plate changing jolt, turning cycle, support, framing die the holder, and warming plate section among others.

Parts of the Machine

Material Forming (Cavity Forming) System

This is the part of machine that structures holes where you will stack the materials.

It comprises of 18 unique parts that cooperate to produces appropriate shapes on the materials for placing the items.

You can change all parts of material shaping framework appropriately to accommodate your packing necessities.

Guide Rail

This is the portion of the machine that deals with the materials from one period of the pressing cycle to the accompanying.

It has six parts;

- Guide Rail plate

- Coordinated guide rail

- Guide rail support

- Turning roller

- Changing handle

- Guide rail foot seat

Items Feeding System

This part of the machine opening of the pressing materials using the appropriate things.

The taking care of the speed of the blister packing machine is directed by the speed of material feed.

It has unfilled acknowledgment stuff to ensure the machine doesn't fill the pits that are empty.

Warmth Sealing System

This seals the filled cavities during the blister packing process run.

It comprises of 17 sections among them being bearing seats and cam cases which aids the system of warmth fixing.

Fixing station

Fixing station

Fixing Material Feeder

This part holds the materials that you should cover the hole that consists of the items.

It turns at a specific speed however permitting the fixing materials to move to the keeper rail.

The velocity at which the fixing material moves relies upon the accompanying elements:

- Speed of revolution of the material framing feeder

- Shaping instrument rate

- Hole for filling the items

- Review of the unfilled Cavity

Squeezing Mechanism System

It presses the fixing and structure material together to shape a lasting seal.

Squander Material Winder

It is liable for winding the materials waste from the framing material and the fixing machine.

Tow Mechanism

It assists in the development of fixed blister packs starting with one phase then onto the next in this manner taking into account effective bundling and fixing.

Blanking Mechanism

It is liable for cutting totally took care of blister packs from the principal material.

The cavities number on each set will choose the size of the blanking instrument.

You can in like manner fuse an indention instrument which assists with printing the pack number during the process of assembling.

Product Chute

This is the segment that directs the eventual outcome out of the blister packing machine.

Lubrication System

It is a computerized framework that oils or oils the moving pieces of the blister packing machine.

15.How does Blister Packing Machine Work?

The working standards of a blister packaging machine are similar to whether or not it's Alu or PVC type.

To begin the process of this machine, switch it on so the loosening up station can begin moving along with other moving segments.

Blister packing machine has two units

Unit 1 Deliver the shaping materials for the blister packaging.

Unit 2 arranges the material which is used to cover the product which is called the lid.

These two units deliver the stuff at the same speed.

Then the molded sheets will move to the essential period of getting ready.

Process1: Heating or Warming Unit

The temperature here is dictated by the sort of material being utilized for bundling.

The machine warms the structure film until it turns out to be anything but difficult to frame.

Both trays are utilized in the recuperating cycle to accomplish uniform warming.

The temperature is attempted to set somewhere close to one hundred twenty to one hundred forty in Celsius for Polyvinyl chloride stuff.

For polypropene molding sheets, You can the temperature from one hundred forty to one hundred fifty in Celsius.

You can move that stuff to the blister packing machine after just maintaining the temperature that is required

Process 2: Pocket Framing on the Films

The thermoforming blister packing machine utilizes compacted air or the die plates to frame the wanted holes for the tablet to place into them.

The machine at that point cools down the film leaving an inflexible cavity.

Cold shaping uses a stamping procedure or punching pins for the making of the holes for placing capsules by using the blister packing machine.

Cooling is not required for this situation since the warmth was not utilized in the development of the cavities.

Coming up next is the authentic working rule of a Blister Packing Machine.

Checking and Filling the cavities

In this processing, the Machine fills the cavity with the Item and check if any cavity is left that have no item in it.

Process 3: Sealing Station of Packing

This is an essential stage in this machine working.

This is because there should be precise arranging and synchronizing between the two Units.

Exactly when the outlining films show up now, the lidding or covering materials should be set up to cover the openings with things. This should cover the entire surface before it moves to the fixing unit and warming process.

The equipment maintains the fixing temperature to help apply a reasonable force that empowers the solid fixing of things.

In any case, the warmth should not mix with the item's respectability.

Process 4: After packing trimming and printing of blister product

After overseeing the item, the item will move to another unit so the significant information can be printed on the product.

The information that should appear on the pack is the assembling date, the date on which the item expires, and the batch number.

After the printing, the blister packs will go to the managing unit

Now, the unlocked rankle packs will be naturally dismissed by the machine.

Additionally, the piece gatherer will roll the excess shaping film and lidding materials.

16.Can you print anything after the Blister Packing Process?

You can print a wide and subjective scope of Printed Blister Pack, which is a generally utilized packing material in the drug business. These packs are manufactured consistently with the recommended business principles utilizing the latest innovation.

Imprinted as per:

- Text

- Design

- Color Shades

- Warning signs

Details on Packages

17.What is the Difference between the Thermo forming and Cold Forming Process?

Thermo forming

| Thermo forming | Cold Forming Process |

| Thermo forming is a method that includes warming sheets of PVC before addition into a rankle machine.

This is ordinarily accomplished by passing the sheets among upper and lower warming plates. At the point when a sheet enters a thermo forming rankle machine, it is delicate and malleable and can be compelled to assume the state of a shape through the use of pressure. Sometimes, a mechanical stamp will be utilized including with the pressure as well, especially when the state of the shape is troublesome or complex. |

Cold shaping is a method that doesn't include any utilization of warmth.

Dissimilar to the thermo forming strategy that utilization clear PVC, this procedure utilizes slender sheets of cover film that contain aluminum. To make packing out of these sheets, a blister packing machine will normally utilize a stamp to compel it into a structure. The aluminum-based film will in the general stretch and hold the shape after the stamp has been taken out. This sort of rankle pack is regularly used to contain drugs since the aluminum-based film will in general keep dampness from entering the packing. |

Advantages of thermo forming blister pack

Thermo forming blister pack

The most fundamental material for the shaping web is PVC or Polyvinyl Chloride, for simplicity of thermo framing and minimal effort.

The item is visually inspected through the plastic usually a transparent one.

The faulty card of a blister can be dismissed compete for the reviewing camera or eyes.

The simplicity of the activity.

Disadvantages of a thermo forming blister pack

The defensive properties are not solid due to the PVC's helpless hindrance against dampness and oxygen entrance.

Not appropriate for light-delicate medications due to the opaque of PVC.

Advantage of cold forming blister packaging

The utilization of aluminum offers an almost complete obstruction for moisture,light and oxygen, permitting an expiry date.

Disadvantages of the cold forming blister pack

- Slow speed

- Defective blister card

- Expensive more

19.Can you use Blister Packing Machine to package Liquid and Paste?

As you have always heard about the blister packing machine for packing the capsules and tablets.

You might have asked yourself if does also pack the liquid as well as paste items?

The answer to this question is a very big YES.

But, for this, you might need the latest features in your machine.

Turning type Automatic Blister Packing Machine for sweet chocolate syrup, jam, cheddar, margarine, other liquid, and pastes as well, and nectar to our important clients.

By utilizing forefront hardware, our experts produce these machines in adherence to the worldwide guidelines of value.

In the case of the Liquid, Blister Packing Machine works comparably to the blister packing machine which is solid, with some sharp change so the machine is reasonable for fluid and paste items, for example, nectar syrup ketchup jam and body and makeup care item including cream, moisturizer, cleanser, lipsticks, fragrance and so on.

Just by embraces the most current kind of high-power transmission system to mastermind the chain and drive the primary driving shaft.

Liquid Blister Packing Machine

20.How to choose a Most Suitable Blister Packing Machine for your Capsule,Tablet and Pill?

These are some points to consider:

Design Features of the Machine

This ought to advance the better working of the machine by permitting adaptability during the process of production.

This gear should ensure basic and simple running and simple and fast part changeover as indicated by item needs.

An adaptable machine has the ability to permit both thermoforming as well as cold shaping.

This implies that PVC/ALU and Alu/Alu have the ability to utilize it without rolling out significant improvements in the process to make of blister packs.

2- Blister Packaging Machine Automatic System

AIPAK Blister Packing Machine

This is ideal for the enormous scope of blister packs.

It will consequently take care of materials, structure holes for placing the tablets in the cavities then seal, and print out the packs.

This kind of machine has a control board also called PLC board where all tasks are controlled.

Items like ampoules may have YAMAHA and ABB robots taking care of the framework.

These working machines guarantee the blister packs cycle is consistent.

Aside from this that, machine presents sensors that distinguish a consistent production cycle.

For instance, it does have a camera, a vacant rankle cavity, and temperature and movement discovery sensors.

These sensors improve productivity and consistency in the process of blister packs.

The Drive System

This is a basic element on the grounds that the cycle relies upon the mechanical movement of the portable segments.

A decent drive component in this machine is an element important to be considered.

The machine ought to have distinctive recurrence step-less speed guidelines and servo foothold.

These will permit speed change and frame work synchronization with the goal that it can work easily.

The machine should have the option to shape packs, fill items, seal and cut the packs of blister.

21.What should you Take Care when Operating the Blister Packing Machine?

While working this machine, security for an expert and the machine is significant.

Try not to contact warming, fixing, and cutting stations since they are hot and can cause burning of your that body part.

Don’t Touch It

Guarantee you hold your hand-off the cutting station since it may make genuine injury you.

Ensure you don't contact moving parts like shaping, fixing, and cutting stations.

The gear ought to have security interlock entryways that keep the expert from getting to the item handling region.

Unsafe

This is on the grounds that a few items might be unsafe, and admittance to that zone may prompt item defilement.

All-electric gadgets in the machine should not be contacted since they can cause stun or burning.

Try not to contact the blister packing machine since this can bring about genuine injury.

All engine components should have lockable entryways.

This will diminish any potential wounds that may happen during the rankle bundling measure.

Likewise, this machine ought to have an alert framework.

Notwithstanding these, it ought to give simple admittance to the stop button on the off chance that there is a crisis.

22.What Quality Certification should Blister Packing Machine Meet with?

Food and Drug Administration (FDA) Quality Standards

The Food and Drug Administration is an administration office set up in 1906 with section of the Federal Food and Drugs Act. This organization is isolated into parts that manage a greater part of the association's commitments including food, medicine, pharmaceutical drugs and many more.

The Food and Drug Administration (FDA) oversees the companies that make items like medication devices, Food products, tobacco products and ensure that everything according to the quality standard. Approval of the product by the Food and Drug Administration before it can be sold into the market.

If any product in launched in the market and this product is not according to the quality standard of the FDA, then FDA has the ability to overdraw this product from the market.

Current Good Manufacturing Practices (CGMP) Quality Standards

CGMP is known as the Current Good Manufacturing Practice guidelines authorized by the FDA. CGMP gives guidelines to the organizations about making process, design, and monitoring of the product.

In CGMP "C" stands for current that gives flexibility to the organizations to allow them to use the current best processing and scientific methods and to use modern technologies as there is always room for improvement.

ISO certification quality standards

ISO is an overall alliance of public guidelines bodies. It is a non-governmental association that involves principles participants from in excess of 160 nations. The American National Standards Institute.

ISO certification guarantees that an administration framework, documentation technique, or fabricating process has all the thing that is required for normalization and quality confirmation

CE Quality Standards

CE stands for Chartered Engineers certification. The CE mark on an item demonstrates that the maker or shipper of that item asserts its consistency with the significant EU enactment.

It is a criminal to fasten a CE imprint to an item that isn't agreeable or offer it available to be purchased. CE mark on the product make sure that the product is according to the EU standard of safety and health protection

23.Are there any New Advancements on Blister Packing Machine now?

Medication well being isn't simply identified with the lives of thousands of families, yet in addition the lives of medication organizations as well.

Blister Packs

More Intelligent Machines

As a significant gear of medication packing, the nonstop advancement and discovery of the innovation of machine can not just improve the production proficiency of medication packing business, yet in addition, improve and also ensures the safety and the danger further diminished.

These days, you will see some rankle bundling machines are more savvy and shrewd than previously.

For instance, high-speed blister packaging and automatic cartoning line of businesses have a much better feeding system.

The cantilever aluminum-plastic rankle bundling and programmed cartoning line have the new pivoting pull head and astute transport line drug plate lining innovation, which can accomplish 600 plates for each min can be steadily lined and shipped off the cartridge magazine.

The constant advancement of mechanization innovation incredibly improves the productivity, yet in addition further diminishes the manual activity in the part of medication wellbeing, making the productivity cleaner and more secure.

Advancement in the design of the Machine

What's more, to additionally decrease the danger of medication wellbeing, a few endeavors keep on changing in item design.

For example one of the major change in the blister packing machine is the availability of a better purification system which makes sure not even single contamination gets in.

New pharmaceutical blister packaging equipment offers flexibility and integration.

Flexibility in the Machines

AIPAK Blister Packing Machine

Machine adaptability alludes to the framework's capacity to deliver new kinds of items, and its capacity to change the request in which tasks are executed.

In the case of the blister packing machine, the new advancement gives you the chance of the advancements.

Mechanical Integrity

Mechanical Integrity (MI) can be characterized as the administration of the basic cycle of the machine to guarantee it is planned and introduced effectively, and that it works and is looked after appropriately (for example no breaks and all components are good for administration).

Integrity is also offered by the blister packing machine.

24.How to troubleshoot Common Problems of Blister Packing Machine?

Some off the issues that you can recognize when you troubleshoot a blister packing machine include:

1- Backing Material Thickness problem

Problem

This could influence the respectability of the bundle to shape a total hindrance around various items.

Aside from that, the nature of the backing materials could conduct the variety in material thickness.

Solution

You can solve this problem by thinking about a uniform material thickness and program the machine appropriately.

2- Missing Products in the Holes

Problem

This can be possible because there are some problems in the blister Packing machine or there are some parts that are not working properly or Speed of filling product into the holes is too high.

Solution

You can solve this problem by checking the blister packing machine properly and by fixing or replacing the part of the machine that is not working properly for example, turning the roller for appropriate filling of holes.

You can also change the speed of the turning roller from the control board of the machine.

3- Sealing Problem of the Product

Problem

This can result in the stripping off the seal from the PVC.

The primary causes of this issue are that because there are not enough heat and the pressing force.

Solution

You can solve this issue by solving the heating mechanism of the machine and the pneumatic system.

You can also adjust the pneumatic and the heating system of the component properly from the control board.

25.How to Maintain Blister Packing Machine?

If you want to run your machine for the long run, bear in mind these key factors of the machine.

Check the bolts

You have to keep checking the bolts of all pieces of the packing machine consistently to stay away from detachment.

Clean Everything

You will focus on the waterproof, dampness confirmation, against erosion of electrical components and will do the cleaning for the electric control system and wiring of the machine will also be protected by doing this.

Open the Heated Parts

At the point when the machine is halted, you should open the two warmth fixing rollers to keep the packing materials from being harmed by burning.

Oiling of the Blister Packing Machine

You should consistently add oil to the stuff cross-section or mesh gear of the blister packing machine, the oil filling opening of the machine will stay fine plus the parts will also stay lubricated.

Don’t Drop the Gease on Machine

Whenever you are filling the greasing up oil, you must take care not to drop any droplet of the oil on the belt, in order to avoid any type the slipping, loss of revolution or maturing harm of the belt.

After closure, you will clean the metering part so as to guarantee that the blanking plate and revolving table are cleaned enough in each move to keep them away from any type of rusting.

Clean Often

You likewise should clean oftentimes for the warmth sealer body to guarantee that the seal surface is clear.

You need to clean routinely the photoelectric following head, that is, the electric eye to guarantee the little mistake of cursor following.

Try to do the Routinely cleaning of the residue in the electric control box to protect bad contact and different deficiencies.

Blister Packaging Machine Related Products

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours