Why the Automatic Aluminum-Plastic Blister Packing Machine Becomes The Mainstream Of Solid Pharmaceutical Packing?

With the rapid development of the national economy and some favorable policies support, manufacturing factories have a bright future. In recent years, pharmaceuticals’ aluminum-plastic blister packing machines have develop so fast.

This is because it has the characteristics of a long-term store and portable and convenient so that this machine become more and more popular for customers and pharmaceutical industries. So, the traditional glass bottle packing and bulk packing are gradually substituted, and the aluminum-plastic blister packing machine becomes the mainstream of solid pharmaceutical packing.

It is reported that an aluminum-plastic blister packing machine exists in many forms because of the different manufacturers. The performance level of domestic and abroad products also has a big difference.

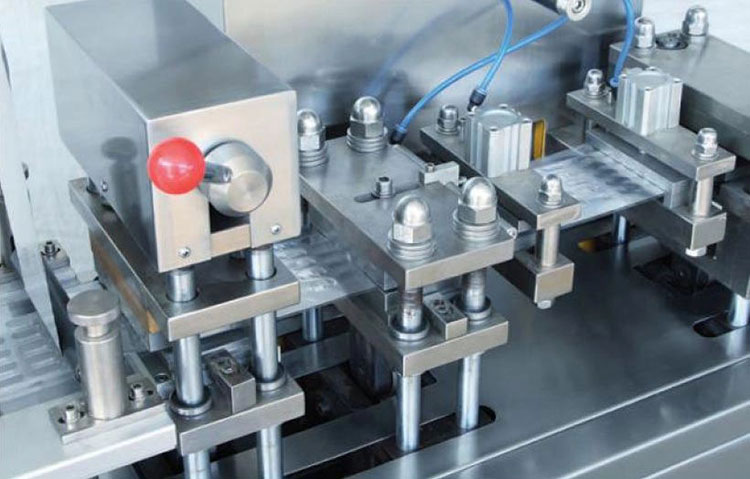

Aluminum-plastic blister packing machine can be distinguished according to two ways, molding and heat sealing, the mold is divided into drum type and flat plate type. The effect of barotropic flat plate type is better than drum vacuum molding.

The heat sealing is also divided into drum type and flat plate type and the effect of flat plate type heat is better than drum type heat sealing, but the drum type heat sealing is better than flat plate type in speed and reliability.

You should know that the good barrier properties of blister packing are due to its choice of original materials in aluminum foil and plate. The aluminum box features a highly dense metallic crystal structure and it also has good barrier properties and photophobism.

Compared to glass bottle drugs, the significant advantage for blister packing is portable and convenient, which can reduce the pollution during the process of carrying and taking. What’s more, the blister packaging also has obvious advantages in gas barrier, moisture permeability, health and safety, production efficiency, dose accuracy and prolonging the shelf life of drugs.

Another advantage of blister packing is that the fully automatic packing process ensures the safety of drug packaging to a large extent. Fully automatic blister packing machine includes blister molding, drug filling, sealing, folding and insertion of instructions, blister plate into the box and carton sealing. All the process is completed at one time, safe and healthy.

The advanced models, in addition to a high degree of automation, there are a number of safety detection devices, including packaging box and manual identification and detection, can greatly improve safety and health, and can effectively reduce drug packing in a wrong way.

With the maturity of automatic technology, the aluminum-plastic blister packing machine in the market,in addition to good barrier packing, its another advantage is that the automatic packing process can largely ensure the safety of drug packing.

Since the promulgation and implementation of the 2015 version of pharmaceutical packaging material standard and the new version of GMP requirements, the quality control of pharmaceutical packaging has been raised to a high level.

Among them, the sealing performance of aluminum-plastic blister packaging is an important index to ensure the quality of drugs, and is also an important part of the quality testing of drug packaging materials.

With the continuous implementation of the "Made in China 2025" plan, intelligent manufacturing has also become one of the main directions of various industries. Similarly, in the field of blister packing machine, intelligence has also become the key point of enterprise icebreaking.

It is understood that although there is still a long way to go intelligent, now many enterprises have made important steps in intelligent automation linkage.

According to a new survey released by US market research firm Freeddonia, the demand for blister packing for pharmaceutical products is expected to grow 6.5% annually. The growing demand for pharmaceutical aluminum-plastic blister packaging also brings new development opportunities to the aluminum-plastic blister packaging machine market.

Why is the demand for pharmaceutical blister packaging increasing by 6.5% annually. This is a question that needs to be thought and analyzed.

First, aluminum-plastic blister packing is often used in single-dose packs of solid oral prescription drugs because it is convenient and safe to dispense these drugs directly to patients, for clinical trials, for distribution as samples, or for storage in hospitals.

Second, blister packaging is also widely used in over-the-counter (OTC) tablets, capsules, and capsules of 50 capsules or less.

According to industry professionals’ analysis, there may be more prescription drugs to join the ranks of over-the-counter drugs in the future, benefiting from such a shift, in the packaging application of over-the-counter drugs, blister packaging growth prospects are optimistic.

Third, Blister packaging is a packaging method that seals the product between the blister formed by transparent plastic sheets and the bottom plate. It has been widely used in the pharmaceutical packaging industry.

In the future, the demand for blister packaging of drugs will further expand, and the annual growth rate is expected to reach 6.5%. According to a new survey released by US market research company, Freedonia, the demand for drug blister packaging will reach $4.4 billion by 2021, which is equivalent to 12.9 billion packages.

The rapid demand for aluminum-plastic blister packing has a significant relationship with the increase of patient needs, the improvement of packing material and design capacities. Moreover, the continuous improvement of aluminum-plastic blister packing machine technology also provides a driving force for the growth of blister packaging demand.

Fully automatic technology has been introduced into the aluminum-plastic blister packing industry, which provides powerful impetus for the aluminum-plastic blister packing’s development.

The automatic aluminum-plastic blister packing machine provides a new choice for the large-scale packaging of drugs in the pharmaceutical industry, improving the efficiency and reducing the cost.

At the same time, the blister packaging market is growing at an annual rate of 6.5%, which brings new opportunities and challenges to the blister packaging machine market.

Blister packaging is in great demand, which not only makes the blister packaging machine usher in a new round of market demand, but also puts forward higher requirements for the technology of blister packaging machine.

In the future development, the blister packaging machine still needs continuous technological innovation to achieve greater breakthroughs, so as to meet the needs of high quality, low cost of aluminum-plastic blister packing.

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine