Your Top Blister Packaging Machine

Servo Motor Driven

Simple Operation

High Output

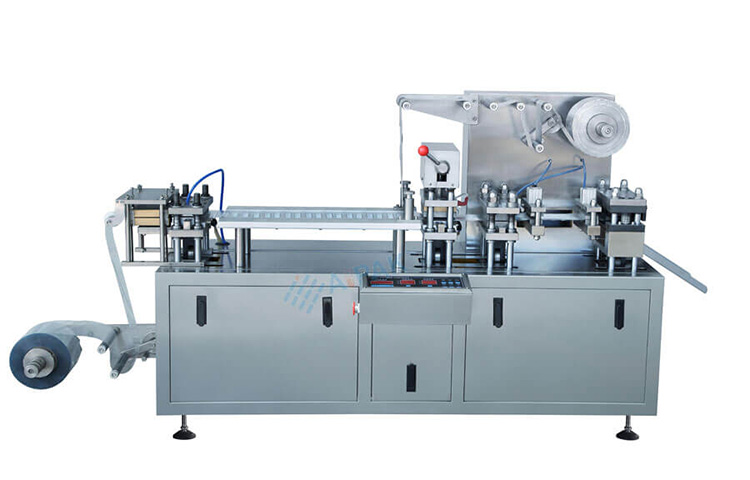

AIPAK Blister Packaging Machine

AIPAK blister packaging machine is fully accordant with GMP requirement, applicable to medicine packaging, such as variety specification of sugar coated tablet, capsule, soft capsule and so on. It's also suitable for packing small hardware, electronic element, medical devices and foods which the shape is similar with above pharmaceuticals. With innovative design,adopt servo drive, precise control, low noise, fast production speed, stable performance of each module, convenient mold replacement, and low maintenance cost of partition, high output, AIPAK blister machines are the most ideal packaging equipment in large and medium size pharmaceutical enterprises, healthcare products and food industry.

Various Blister Packaging Machine Feeding Devices

The Buyer's Guide

Blister Packaging Machine: The Complete Importing Guide in 2025

Packaging machine is one of the essential equipment in the pharmaceutical industry, among which the blister packaging machine is widely used for packaging capsules, tablets, pills, suppositories, etc., and has become the mainstream of solid medicine packaging.

So, if you want to meet your various packaging forms, you should get an automatic blister packaging machine.

And import the right blister packaging machine,blister packaging equipment will attach such great importance to your pharmacy manufacturing.

Reading this import guide, you will get everything about this machine. It covers everything you want to know about the blister packaging machine, from the working principle, classification, machine qualifications, benefits, etc.

Let’s get started now:

1. What is Blister Packaging?

Blister packaging is to make transparent plastic film or sheet into a blister, then use hot pressing, bonding and other methods to seal the products in a cavity between the blister and base plate.

2. Where is blister packaging used?

AIPAK DDP-180H Blister Packaging Machine

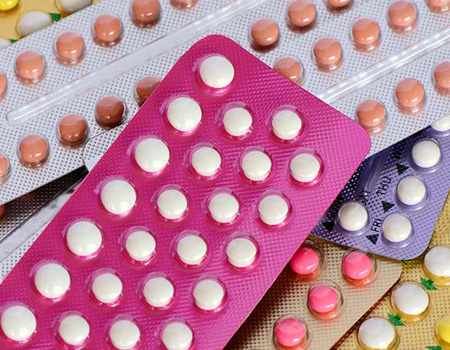

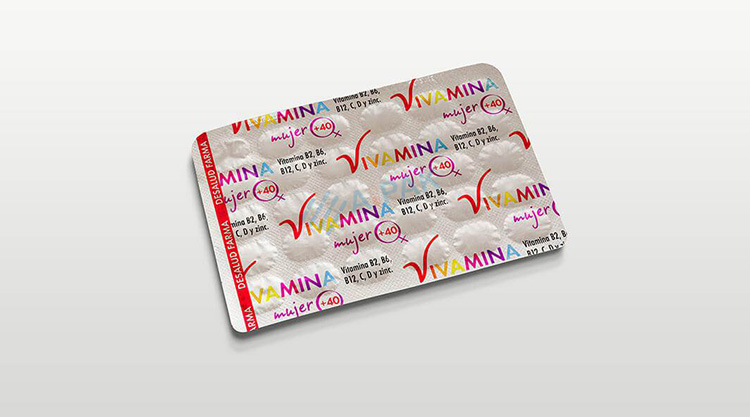

Initially, you will get blister packaging to pack your pharmaceuticals, yes, it has been used in many aspects in pharmacies including:

- You can pack your tablets, capsules, suppositories from tablet press and filling or suppository machines.

- You can seal your tablets, capsules, ampoule and syringes to resistant change or damage.

Blister Packaging Syringes

- You can print the information that let the patients know their individual dosage to make sure they follow their treatment plan.

- You can pack your products to protect moisture, oxygen, light, and any form of contamination.

Apart from that, you will make blister packaging to pack other products including: food, cosmetics, stationery, toys, gifts, tools, electromechanical parts, etc.

Cosmetics Blister Packaging Cards

3. What are the benefits of blister packaging?

i. Freshness

You will have individual compartments for the items used one at a time that can keep them ready whenever the customer needs.

That is, medications and herbs and other environmentally sensitive items may benefit from blister packaging for this reason.

ii. Good protection

You will see blister packaging has good sealing ability, can be waterproof, moisture-proof, dust-proof, rust-proof, so that could extend the protection period.

Besides, blister packaging has created conditions for VCI packaging, as the prevention effect will be better with VCI.

Using a Medication Blister Pack

iii.Dosage or serving size

For medicines and certain foods, these packages evenly portion out an item so that the consumer does not use too much of the product at once.

Some seasoning blends benefit from blister packs because the company has already predetermined the amount needed for certain recipes.

That is to say, medicine dosing is easier to understand and safer for the consumer when this type of package is used.

iv. Visibility

You can see with the plastic front, these containers allow consumers to view the product before purchasing.

This also provides reassurance to the amount of product contained is as advertised and that all pieces are accounted for.

Even though customers can view the item, they cannot touch them.

As such, the product is safeguarded from thieves and tampering.

Individual compartments for Drugs

v. Security

Blister packaging is the ideal solution for products that need to stay immobilized, as the individualized and generally small compartments do not allow the products to move within the packaging.

In other words, this design protects items from damaging caused in transit.

vi. Customization

You have known that all plastic blisters are thermoformed, so every design is unique to the product being sold.

That is, whatever the size or number of items contained in the blister packaging, it can be customized to fit the needs of the products.

4. Are there any drawbacks of blister packaging?

Blister packaging has so many benefits but also has a drawback as the following reasons:

- Not all pharmaceutical medications can be used for blister packaging

- You will it will make the patients confuse who used to fixed dosage as it will be hard to take the correct dosage for the not blister packed medicine, which will also increase the risk of disease treatment.

Pills Confusion

- You will also find even the nurse in the nursing home will also find it different to determine the correct medicine dosage since they need to distinguish from the un-packed dosage .

- You will find the whole process of sealing the filled cavities take a little long time.

- Since the back is foil, the packed medicine can be press through the foil through

- You will see the whole aluminum packaging process is longer than normal plastic packaging.

- It will increase your packaging cost if only for small scale manufacturing as it is an expensive machine.

5. What materials are used in blister packaging?

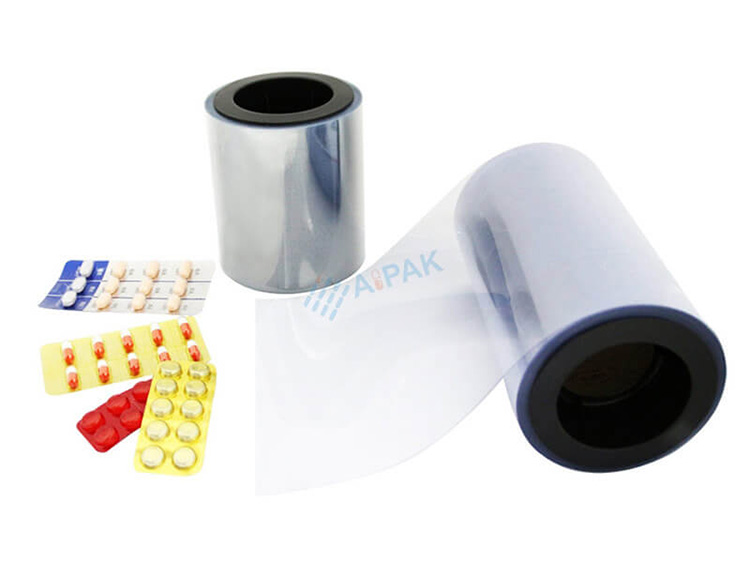

Packaging Film

You will use the plastic film for blister packaging as it has sufficient barrier performance to oxygen, carbon dioxide and water vapor, high transparency and mechanical strength not easy to crack.

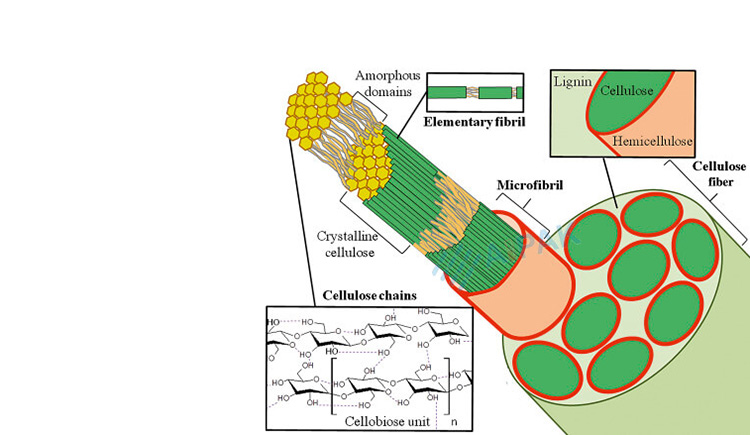

In addition, you will also use the rigid plastic films include cellulose, polystyrene, vinyl resin, polyvinyl chloride, polyvinylidene chloride, etc. for blister packaging.

While Cellulose such as cellulose acetate, cellulose butyrate, cellulose propionate are widely used as they all have excellent transparency and thermoformability, good heat sealing and could resistant to grease.

But the heat sealing temperature of cellulose is generally higher than that of other plastic sheets. Directional tensile polystyrene has excellent transparency, good heat sealing, but poor impact resistance. It is easy to be broken, even worse at low temperature.

The price of vinyl resin is generally cheaper than polystyrene, some are hard and some are soft, and they have better transparency. Besides, it is good in heat sealing with coated cardboard, but the cold resistance and impact strength will be improved when adding plasticizer.

Cellulose used for food packaging

At present, the most widely used pharmaceutical blister packaging material is PVC plastic sheet. Because the drug is very sensitive to moisture and light penetration, it is required to have good barrier performance against water vapor, light and the peculiar smell of plastic sheet.

However, the PVC used currently is not ideal in moisture resistance, you’d better use the polyvinylidene chloride (PVDC) or its composite materials in the future.

Another kind of blister packaging material is vacuum aluminized film.

It is a kind of film that precipitates aluminum vapor on the base film under high vacuum. At present, pets, CPP, PVC, OPP, PE, etc. are widely used.

In addition to the characteristics of the original base film, the vacuum aluminizing film, as the base film, also has a beautiful decoration and better barrier performance. The light transmittance, oxygen permeability and moisture permeability are only a few tens or even one percent of the original base film.

Substrate

You will get the most used white cardboard for blister packaging. It is made of bleached kraft wood pulp, or can be made of by the recycled board covering the base layer with white paper.

When using the white cardboard you need to consider the size, shape and quality of the packaging

The thickness range of the whiteboard substrate is 0.35-0.75mm, while the normally used board is 0.45-0.60mm.

White Board For Packaging

Besides, make sure the surface of the substrate is white and glossy, with good printability, and the heat sealing coating could be firmly coated, the substrate and the blister can be closely combined after the heat sealing coating is melted, so as to prevent the contents from falling out.

And you can also choose B-type or E-type coated corrugated paper, coated aluminum foil and various composite materials as the substrate.

Coating material

The coating material you are should be compatible with the substrate and blister, and the temperature should be relatively low, so that it can be sealed quickly without damaging the blister film.

Normally you could use soluble vinyl resin and water-resistant acrylic resin as they have good luster, transparency and heat sealing ability.

6. What is the difference between PVC and PVDC?

You will get to know PVC stands for Polyvinyl chloride and PVDC is polyvinylidene chloride, both are primary materials used in pharmaceuticals.

PVC

As PVC forming film is almost free of softening agents and plasticizer, it is also called rigid PVC.

While no plasticizer, PVC blister owns good structural rigidity and physical protection to the pharmaceutical dosage form.

You will find it is hard to collapse when you press upon the formed web and the blister cavity is just accessible by the push-through effect. And that is also why you need to choose PVC sheet thickness between 200µ to 300µ depending on the cavity size and shape.

PVC Blister packaging

You can see the rigid PVC is very clear, stiff material with low water vapor transmittance. But also has excellent thermoformability, high flexural strength, good chemical resistance, low permeability to oil, fat and flavoring ingredients, easy instability. Last but not least, you will save costs.

Now PVC has almost 100% on the market among the plastic component as its so many qualifications have made rigid PVC become the ideal choice for blister packaging.

While you will find the thermoformed PVC film has a thickness of about 10 mil.

The main disadvantage is poor barrier against moisture ingress and oxygen ingress, but also PVC has a negative environmental connotation due to its chlorine content and highly toxic dioxins.

PVDC

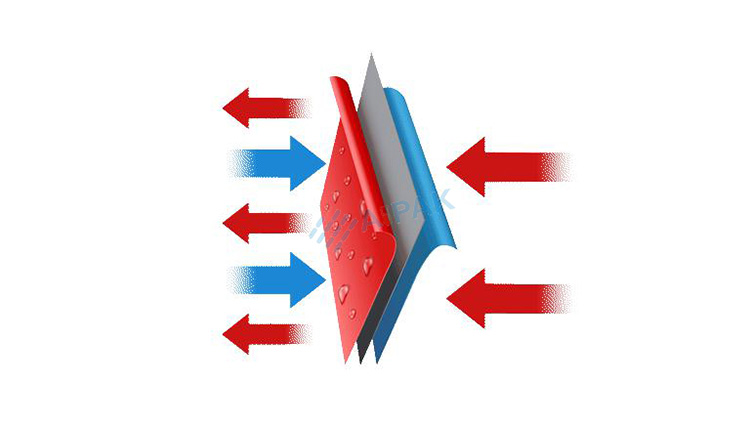

PVDC also called coated PVC. As the laminations or coatings of PVC, PVDC has played an important role in blister packaging. It reduces the gas and moisture permeability of PVC blister packaging by

5-10 times.

You will find the coated PVC films is 8-10 mils thickness while the coated PVDC is 1-2mils.

PVDC offers a wonderful barrier to both oxygen and water vapor, the gas barrier properties are unaffected by relative humidity.

You will find almost all PVDC products on the market are actually copolymers of vinylidene chloride (VDC) and other comonomers while the relative amount of VDC in the copolymer dictates some key properties.

That is, with more VDC, the barrier properties are generally better, with less VDC, flexibility usually improves.

However, the amount and type of comonomer as well as other additives and processing technology used, will influence other properties such as sealing, surface properties, transparency, glossy coefficient of friction, etc.

7. What should be considered when using PVDC for blister packaging?

PVDC is so excellent in blister packaging, so there are some advice when using :

- For the blister machine using PVC film, you no need to change the equipment if PVDC composite material is used instead.

- You should make the PVDC face to the inside and direct contacts with the package during the process of using PVDC composite material

- If the blister machine has requirements on the unwinding direction of the base material (high-speed blister machine with automatic roll change), in order to ensure that the PVDC surface is on the inside, you must negotiate with the PVDC supplier in advance.

- You should place the PVDC in a room at 22 + 5 ℃ for 3-5 days before using, as its performance can reach to the best as so

- You need to seal the unused PVDC with black PE film and then store it in the warehouse.

8. What are the main parts of the Blister Packaging Machine?

You could like to know the main parts of the blister pack machine have determined its packaging process.

Now you can see its many parts as below:

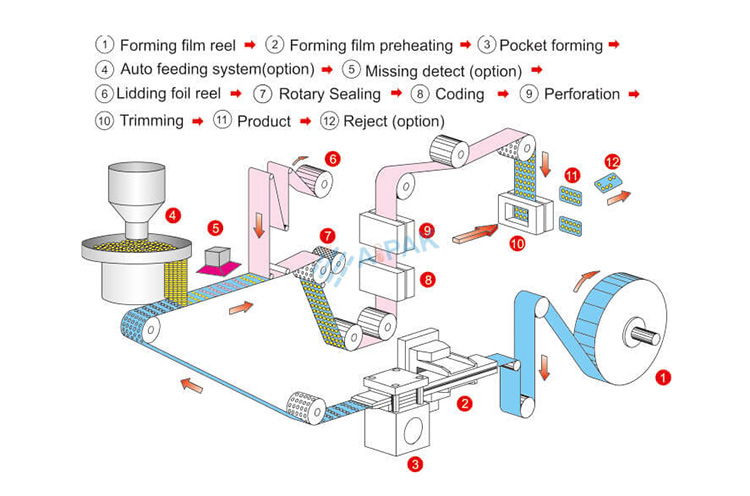

Flow charts of Automatic Blister Packaging Machine

Touch Screen Panel

You can see from the surface that these parts assist to control the whole packaging process.

Apart from that, you will know the touch screen helps in other aspects including:

- You can record the productivity and process condition.

- You will read the manual instruction to troubleshooting problems during the packaging process.

- You could input the parameters or specifications to make high efficient working.

PVC feeding or Aluminium foil Roller

You will see this foil roller provide the blister packaging material and make the product go to the platform to be packed.

The electric motor system is the key point parts of the blister packing machine as it controls the movement of all parts of this machine.

Besides, this component also management the speed of all active parts to make it meets the needs of the whole blister packaging process.

PVC Feeding Mechanism

You can see this PVC feeding works with the rolling system to make the products feed into the blister packaging system. The material tension is exerted so t make it work smoothly.

Heating Box

You will see the heating box is made of upper heating plate adjustment screw, heating plate, forming die holder, brace rod and turning cycle.

You can see initially, the product comes from that the feed mechanism, then the heating box will heat it into an appropriate temperature to be well prepared for the afterward step.

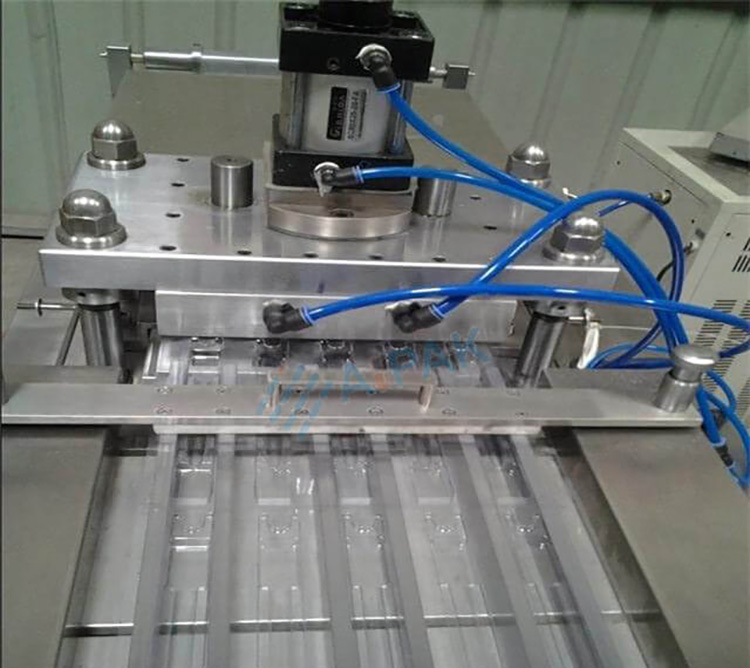

PVC Forming Mechanism

You will see the PVC forming mechanism makes form cavity in the product loaded area.

There are totally eighteen parts making the cavity on the packaging materials.

Product Feeding system

You could find the feeding system is made of feeding hopper and medicine feeder. They assist in filling the cavity with the right materials and the filling speed is affected by the feeding rate.

Besides, there is a photoelectric detector that inspect the empty cavity which not be filled from the feeding system.

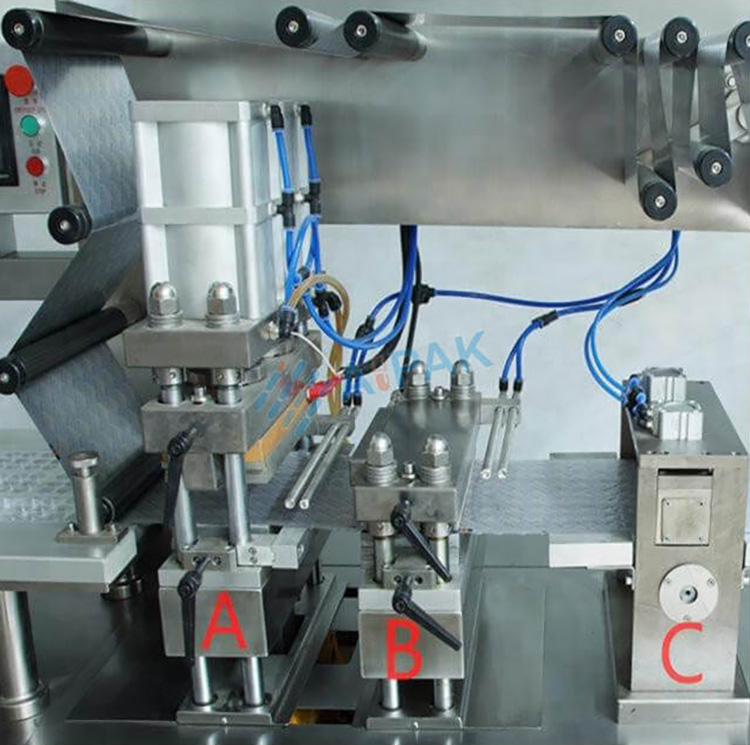

Second Heat Sealing Mechanism

The heating sealing mechanism consists of many parts, while the bearing seat and the cam case included play the critical roles in the whole heat sealing system.

You can see the filled cavities will be sealed by this heat sealing mechanism.

Tearing Line pressing mechanism

This pressing mechanism is used for pressing the forming material and sealing fit together well, then an ideal seal is made.

Scraper Collector

You could easily know that the scraper collector is used for collecting scraper from the sealing machine and forming materials.

Tow mechanism

As for efficient sealing and packaging process, the towing mechanism is helpful in making the sealed packages go to the next station.

Blank Mechanism

The number of cavities decides the size of the blank mechanism, as it helps in cutting the formed blister packages.

Finished Product Chute

You can see at the last stage of the packaging process, all finished products will be loaded down from this chute.

9. Is there is any difference between the drug Blister Packaging machine and other Blister Packing Machine?

Yes, they are different in size and the products they handle.

Drug blister packaging machine is small as it mainly used for hospitals, labs or some medium factories.

The other blister packaging machine can be used in many areas such as chemical, foodstuff, cosmetic and electric, household companies.

10. How many types of blister packaging are there?

As the structure and working principle various, you can choose three types of blister packaging machine including:

AIPAK DPP-260H1 Blister Packaging Machine

Roller blister packaging machine

First, you need to use the heating device to heat and soften the forming film, then you need to suck out the blister on the roller type forming die roller by the vacuum negative pressure.

After that, you should use the filling device to fill the package into the blister, and then, you will through the roller heat sealing device to seal the covering film with adhesive on one side on the surface of the material with a blister, and then you will seal the package into the blister.

Finally, you will print the batch number and press out the brake line through the printing and stamping device, and last you will use the punching and cutting device to cut into a single size of package.

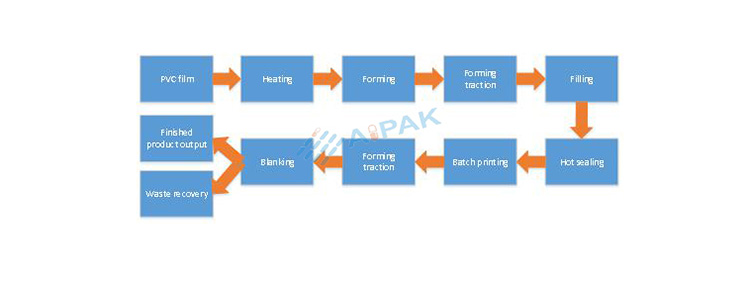

Flat blister packaging machine

You will know the working principle of the flat blister packaging machine:

First, you will use the flat heating device to soften the formed film.

Secondly, you will use the forming device to blow the softened film into the blister by compressed air.

Thirdly, you will make the filling device to fill the package into the blister, and then sent to the sealing device.

After that, you will seal the covered film with the formed film under the appropriate temperature and pressure.

Finally, you will print the batch number and press out the beak line by the typing and stamping device, last you will use the punching and cutting device to cut into a single specified size of the packaging.

Blister packaging process flow chart

Roller plate blister packaging machine

You will find the roll plate blister packaging machine is just evolved from the roll and flat type blister packaging, that is, it has combined the flat blister forming device to blow molding with roll blister sealing device to seal.

So you will get to know its working principle is just as above two.

11. What is the working principle of the blister packaging machine?

From the above blister packaging machine types, you will know the working principle is similarly the same.

Generally, you have known the machine can be divided into two parts, one part is to provide the forming materials, the other part is to send the sealing materials.

While the two parts will work together with relevant speed to supply materials.

Heating

First the forming materials will move to the heating box to be heated. This step you will need to adjust the temperature according to the packaging material types until the forming materials are softened, during which the upper and lower plate should join in to make even heating.

Cavity Forming

As blister packaging machine type varies,the cavity-forming process will be different, using die plate or compressed air to form the ideal cavities.

Then you will cool the PVC to make a rigid cavity.

Customized Blister Packaging

Empty Cavity Detection

This step, you will need to use the machine to check if there is an empty cavity to make all products are filled.

Sealing Station

This step is the most important in the whole blister packaging.

You will need to seal the cavities with products using the sealing materials. Remember to sealing closely the whole surface as the next step is the heat sealing system.

While you should also increase the temperature to make sure the products are firmly sealed.

Besides, the temperature or heat must not affect the product performance.

Printing and Cutting

First, you will use the printing device to print the batch number, expiry date or whatever you the product should show.

Then after printing, you will need to place the packages to the cutting device to make they are cut into individual units.

Last, you will load all the finished products.

While at the same time, you will reject the not sealed packages by the waster eliminating mechanism. And use the scraper collector to collect all the left PVC films and sealing materials.

12. What are the operation methods of blister packaging?

You will see there are three methods can be used to complete the blister packaging process including:

Hand operation

First, you need to perform the plastic sheet and pre-print, cut the substrate.

Manual Blister Packs

Then you will manually put the packages into the cavities and cover the substrate, and then you will use the heating sealer to seal the blister and substrate.

Moreover, some do not require high temperature and humidity in the circulation environment, so you could seal with stapler instead of heat sealing.

Semi-automatic operation

You should first put the roller or single sheet into the semi-automatic blister packaging machine, the machine operation is continuous or intermittent.

The number of mold die depends on the size and production of the product, generally adopt the multi-row type.

After the film is cooled by the mold, you need manually put the product into the blister, then cover the printed substrate of roller or single sheet on the blister, last make heat seal and cut.

Automatic operation

AIPAK DPP-120H Blister Packaging Machine

In automatic operation, in addition to the above packaging process, printing, manual loading, box loading and other processes can also be connected with the production line.

This automatic packaging production line is suitable for mass production of a single variety, its advantages are high productivity, low cost, and in line with the health requirements.

13. What is Aluminum Plastic Blister Packaging Machine?

AIPAK DPP-260H1 Blister Packaging Machine

The Aluminum plastic blister packaging machine is also called a PVC blister packaging machine.

As the forming film is using PVC and cavity packages using aluminum.

You will apply thermoforming technology to make form the cavities.

While the machine is specially designed and manufactured for small pharmaceutical factories, health product factories, food factories, hospital preparation rooms, etc.

And it is mainly used for packaging capsules, tablets, pills, suppositories, milk tablets, candy, hardware and other solid drugs and food.

14. What is the advantage of Aluminum Plastic Blister Packaging Machine?

You will see the aluminum-plastic blister packaging machine has below advantages:

- It has temperature control detection of heating plate, overload protection of main motor, material position detection of PVC and PTP package.

- Mechanical friction wheel is superior to mechanical fixed ratio reducer in speed reduction and speed regulation.

- Adopt the same (spline) shaft transmission of four mold box to improve the transmission rigidity and work synchronization.

- The overall structure is an open layout, with good visibility, simple and convenient machine maintenance and adjustment.

- It is convenient to use a modular mold, replace, install and adjust. Multi specification production with the same machine and low mold cost.

- PLC microcomputer control, touch screen operation, digital display, prompt for fault diagnosis, easy and reliable operation, convenient maintenance.

15. Does Aluminum Plastic Blister Packaging Machine have any drawbacks?

Yes, just as some other equipment, the blister pack machine has drawbacks:

- Free protect to oxygen and moisture.

- Not suitable for product that sensitive to light as the PVC materials is transparent.

16. How many types of Aluminum Plastic Blister Packaging are there?

Aluminum plastic blister packaging machine can be divided into roller type and flat type according to forming and hot pressing sealing methods.

Whereby the effect of flat type positive pressure forming is better than that of drum type vacuum forming.

The heat sealing can also be divided into a drum and flat type hot-pressing sealing, and drum-type is better than that of flat type g in speed and reliability.

AIPAK DPP-150E Blister Packaging Machine

17. What is the Alu-Alu Blister packaging machine?

Alu-Alu blister packaging machine also known as cold forming.

It is a machine that added a set of mechanical forming device and directional feeder on the aluminum-plastic blister packaging.

The aluminum machine will form through the mechanical strength of the composite aluminum foil, and feed by directional feeder.

AIPAK Alu-Alu Blister Packaging Machine

18. What are the merits of Alu-Alu Blister packaging machine?

You will see the merits of Alu-Alu blister packaging machine as follow:

- Through the Servo traction, you will see the operation is stable, synchronous and accurate, and the stroke length can be adjusted at will according to the plate size within the design scope through PLC control panel (digital display).

- You will set the corresponding blanking times according to the length of travel and the feeding difficulty of the filled materials.

Advantage of Blister Card

- You can free displacement to adjust each station and an independent indentation station (optional) can be added to ensure the clarity of indentation and batch number.

- You will see the suspended operation platform, which is completely isolated from the transmission mechanism and meets the requirements of the new GMP standard, is easy to clean and maintain.

- You could set automatic alarm and shutdown for PVC finished and broken pieces, and you will see the machine is equipped with arc transparent protective cover and emergency stop safety device.

- The whole machine ≤ 1.7m that can enter the elevator and split purification workshop.

- Last all parts in contact with the drugs are made of stainless steel and non-toxic materials that meet the requirements of GMP.

19. How to choose the best printing inks for the Blister packaging process?

You will consider from the printing process of medical aluminum foil and the special requirements of drug packaging, the printing ink used for aluminum foil must have below characteristics:

Aluminum Blister Packaging

- Good adhesion to the aluminum foil, the printed text pattern is firm and clear.

- The solvent is fast to release, the heat resistance is good.

- Good friction resistance, good luster, the pigment is non-toxic.

- The chemical composition contained in the ink cannot cause migration and pollution of the packaged drugs.

- Practical viscosity should meet the requirements of the aluminum foil printing process.

20. How to troubleshoot common problems during blister packaging?

Blister packaging machine is easy to have problems in blister forming, hot press sealing and other aspects in use.

Here you can find how to solve these problems:

AIPAK DPP-260H2 Blister Packaging Machine

Blister forming

You may encounter the forming blister size or shape do not meet the requirements you want, then you may check below aspect:

- Whether PVC film (hard film) is qualified.

- Whether the temperature of the heating device is too high or too low.

- Whether the surface of the heating device adheres to PVC.

- Whether the molding die is qualified, whether the molding hole is smooth, and whether the hole is unobstructed.

- Whether the cooling system of the forming die works normally and effectively.

- Whether the vacuum degree and exhaust rate of roller negative pressure forming can reach the normal value, and whether the pipeline has abnormal loss.

- Whether the compressed air of flat positive pressure molding is clean and dry, whether the pressure and flow can reach the normal value, and whether the pipeline has abnormal loss.

Hot sealing

You may be challenged by not clear mesh or the depth is various as the hot sealing is completed under certain temperature and pressure, then you can troubleshoot as below:

- Whether the aluminum foil is a qualified product, and whether the hot sealing surface is coated with the required hot-melt adhesive.

- Whether the temperature of the heating device is too high or too low.

- Whether there is abnormal resistance in the operation of PVC tape or aluminum foil.

- Whether the heat sealing mold is qualified, whether the surface is flat and smooth, and whether they formed blister on the PVC belt can be smoothly sleeved into the hole of the heat sealing roller (plate).

- Whether the cooling system of the heat sealing mold works normally and effectively.

Stop Operation

You may need to stop the operation if encounter below problem including:

- Safety protection cover is opened.

- Insufficient compressed air pressure.

- PVC film or aluminum foil used up.

- The packaged drugs are used up.

- Mechanical overload of some stations.

- Circuit overload.

21. How to inspect the medical blister packaging quality?

Inspection requirements for blister packaging

You have known that the main packaging object of blister packaging is solid drugs, to isolate the contained pharmaceutical preparations from the outside.

on the one hand, prevent the volatilization, escape and leakage of the active ingredients of drugs.

Since the volatile pharmaceutical ingredients can be dissolved in the inner side of the packaging materials and spread to the other side under the effect of osmotic pressure, such as solid pharmaceutical preparations containing aromatic ingredients and volatile active ingredients, whose active ingredients are volatile and penetrate some materials.

On the other hand, you will be easy to understand that blister packs can prevent the outside air, water, foreign matters and microorganism from entering and contacting with the medicine.

As there is oxygen, water, a large number of microorganisms and foreign particles contained in the air, you may find they will lead to the oxidation, hydrolysis, degradation, pollution and fermentation of drugs after entering the packaging.

While the PTP aluminum foil and PVC hard disk or PVC / PVDC composite hard disk used for blister packaging will directly contact with the drug, so you should pay special attention to the testing of the material.

The testing items include appearance, barrier performance, tensile strength, impact strength, heat shrinkage and other mechanical properties, as well as health indicators, etc.

You will see below key test items of blister packaging:

Barrier test

The barrier test is the key test item of blister packaging, including the oxygen permeability test and the water vapor permeability test of materials.

Although the standard does not mention the oxygen permeability test of aluminum foil, the indicator is closely related to the number of pinholes.

Therefore, if the number of pinholes of aluminum foil can meet the requirements of the standard, the oxygen permeability generally can meet the use requirements.

Whether it is aluminum foil or PVC material, the material barrier is high in actual use, so when choosing testing equipment, you should pay attention to choose the instrument with high testing accuracy.

In order to test the overall barrier of the blister, you will use special accessories to prepare the sample of the blister, and use the equal pressure method in the oxygen permeability test and the sensor method in the water vapor permeability test to test.

During the whole test, you need to pay special attention to the adjustment of flow rate to avoid the sudden rise and fall of pressure caused by the sharp change of the gas volume in the bubble cap, which will affect the sample state.

In fact, the detection accessories used in the blister can also be applied to the detection of small hollow containers such as capsules, which can easily expand the types of small samples that can be detected.

Thermal strength test

Like other types of packaging, sealing is an important indicator of the practicability of blister packaging, and the heat sealing strength is an important test item to reflect the sealing.

The test method of heat sealing strength is: you will select the appropriate heat sealing parameters according to the specific test standards, and use the heat sealing instrument to measure the size of 100mm × 100mm The PVC or PVC / PVDC composite hard disk is heat-sealed (the bonding layer of aluminum foil is overlapped with PVC).

And then the sample is cut into 15mm wide with a standard cutter, and the middle three strips are peeled 180 ° by a tensile machine (the peeling speed is subject to the requirements of specific testing standards).

22. How to maintain a blister packing machine?

- You will check the screws of all parts of the packaging machine regularly to avoid looseness.

- You will pay attention t the waterproof, moisture-proof, anti-corrosion of electrical parts and make clean for the electric control cabinet and wiring terminal to prevent electrical failure.

- When the machine is stopped, you will need to open the two heat sealing rollers to prevent the packaging materials from being damaged by scalding.

AIPAK DPP-260H2 Blister Packaging Machine

- You will need to regularly add oil to the gear mesh of the packaging machine, the oil filling hole of the bearing with seat and the moving parts for lubrication.

- When filling the lubricating oil, you should take care not to drop the oil on the drive belt, so as to prevent slipping, loss of rotation or aging damage of the belt.

23. How to clean the blister packaging machine?

- After shutdown, you will clean the metering part in time to ensure that the blanking plate and rotary table are cleaned in each shift to prevent them from corrosion.

- You also should clean frequently for the heat sealer body to ensure that the seal texture is clear.

- You have to clean regularly the photoelectric tracking head, that is, the electric eye, to ensure the small error of cursor tracking.

- Regularly clean the dust in the electric control box to prevent poor contact and other faults.

24. What is the new innovation In the Blister Packaging market?

Intelligence

Drug safety is not only related to the lives of thousands of families, but also the lives of drug companies.

As important equipment of drug packaging, the continuous progress and breakthrough of the technology of blister packaging machine can not only improve the production efficiency of drug packaging enterprises, but also make the drug safety better guaranteed and the risk further reduced.

Nowadays, you will see some blister packaging machines are more intelligent and smart than before.

Artificial Intelligence and relationship to Machine

For example, the high-speed blister packaging and automatic cartoning line of an enterprise has realized automatic blister forming, feeding, foam feeding, automatic detection and waste removal, and the drug plate has been automatically queued and transferred to the high-speed automatic box loader bin.

The cantilever aluminum-plastic blister packaging and automatic cartoning line have the new rotating suction head and intelligent conveyor belt drug plate queuing technology, which can achieve 600 plates per minute can be stably queued and sent to the cartridge magazine.

The continuous breakthrough of intelligent automation technology not only greatly improves the production efficiency, but also further reduces the manual operation in the aspect of drug safety, making the production cleaner and safer.

Design transformation

In addition, in order to further reduce the risk of drug safety, some enterprises continue to reform in product design.

A major breakthrough is to realize the production of internal and external package isolation. "The setting of this isolation area better isolates the production purification workshop from the non-clean area, making it difficult for bacteria to enter, which makes the drug packaging cleaner, less safety risk and more in line with GMP requirements.

Blister Packaging Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586