Blister Packaging- Your Medicinal Bodyguard

Blister packaging is an excellent choice for many kinds of products. This is the best packaging solution whether you need to secure tablets, capsules, medical tools, vials, ampoules, or non-medical items. A little wonder is that it can be easily used for retails products also. Because it always helps you to protect your items to meet your needs and budget. We’d like to highlight some interesting information about blister packaging type.

1.What Is Blister Packaging?

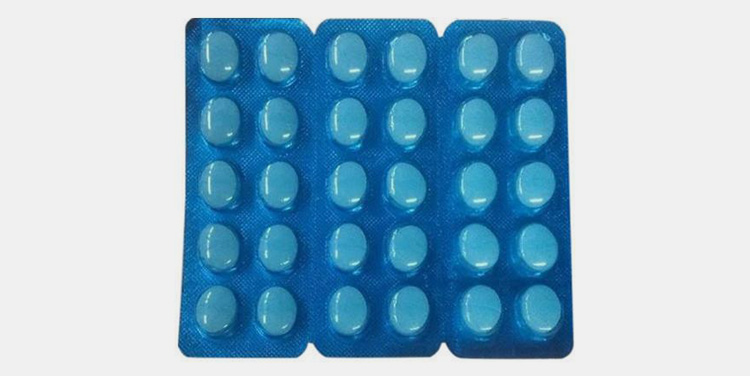

You have certainly observed blister-packed medicines many times but might not be aware with its name. This is a kind of plastic packaging commonly employed for securing various pharmaceutical and retail products. The blister is a sort of pocket that allows the product to sit in. That’s why it is also known as ‘Bubble Pack’or ‘Compliance Pack’. It is a thin shell created by thermoforming or plastic mold adhered to aluminum foil or a paperboard. It can be bonded alone which is termed a ‘clamshell closure’.

Side by side, it is often paired with beautiful, customized designs to entice passersby. It cannot just add aesthetic value to your pharmaceutical goods, but it also protects the valuable against environmental hazards and transportation shock.

2.How Does Blister Pack Improve Medication Errors?

Blister pack card comprises of single unit dose or all medications that a patient needs at a given time. Each blister is labeled with dosage, time, and medication name.

It is very useful for those people who take clusters of medicine each day and difficult to remember the administration time.

Thus, an individual can easily push a blister or cup and extract the tablet in a timely manner. This strategy is very helpful in minimizing medication errors efficiently. Moreover, strong enough to prevent accidental opening and administration.

3.Blister Packaging- Historical Glimpse

PVC - A CHILD IN 1872

In 1872, a German chemist ‘August Wilhelm von Hoffman’ created a primitive version of polyvinyl chloride (PVC). His great efforts were refined by two scientists ‘Friedrich Heinrich August Klatte (a German scientist) 1913, who utilized sunlight to induce polymerization reaction. Similarly, another scientist ‘Semon Waldo Lunsbury’ (employee of a tire manufacturing firm) worked on a plasticized form of polymer in 1926 and transformed it into a more flexible form.

We consider these innovations are the turning point behind the creation of the world’s most prevalent packaging material

BLISTER PACKING- BORN IN THE 1960S

It is a great deal of discussion that when blister pack originated first. It basically depends on the molded plastic, in fact, its primary purpose was specially intended to help customers in terms of safety and compliance.

Practically, it was used as a key element for drug delivery in 1960s with an oral- contraceptive. Before blister packing, medicines were stored in bottles. Today, blister packaging gained popularity as women used to take them discreetly in their purses. So, it was created to help consumers in order to retrieve a single dose whenever they require it. The very first blister pack medication includes an oral contraceptive (Enovid 10 mg) and Melabon (Aspirin).

4.Advantages Of Blister Packaging

This nifty device performs a great job in terms of the product’s safety, integrity, and patient compliance. Let’s have a look at its further considerable benefits:

Freshness

This is worth considering for those items which are sensitive in nature such as herbs, vitamins, and nutraceuticals. The individually packed and ready-to-use medicine is accessible in fresh form when consumers need it.

Serving Size

As your product is equally portioned in even sizes, so lesser chances of product wastage or consuming extra dosage. The company dispenses a pre-determined dose when blister packaging is used.

Customization

As plastic is easy to transform into various shapes, hence company may implement unique designs to boost their identity and aesthetic effects.

Fixed and Immobilized Packaging

Many items need to be fixed when transported from one place to another. The tough covering and packaging format of blister packaging make them remain immobilized in fixed compartments till you unpack them.

Tamper Evident

This is an important strength of blister packaging. Here, an individual unit dose is sealed and protected against tampering. Otherwise, any unwanted handling results in immediate visibility that you may easily differentiate from than original one.

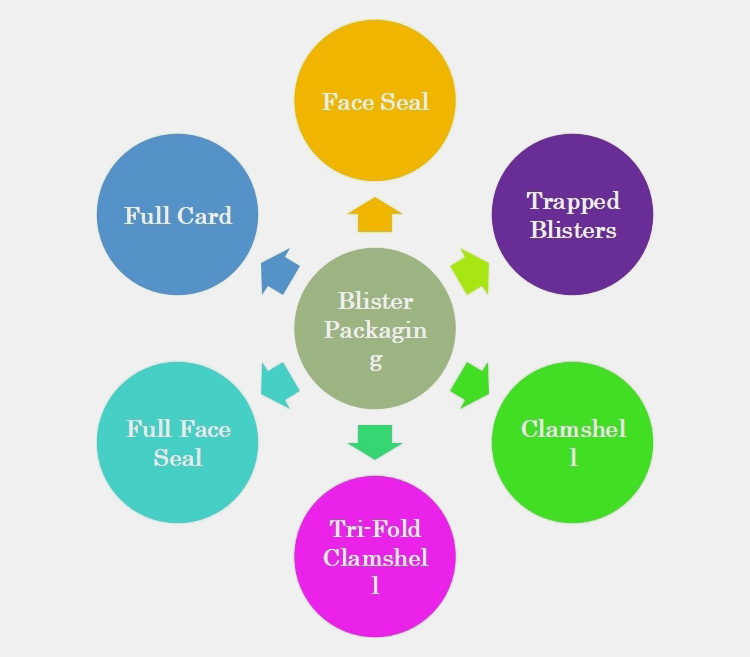

5.Blister Packaging Has Many Variants

Blister packaging has ‘Six’ special variants that make them unique.

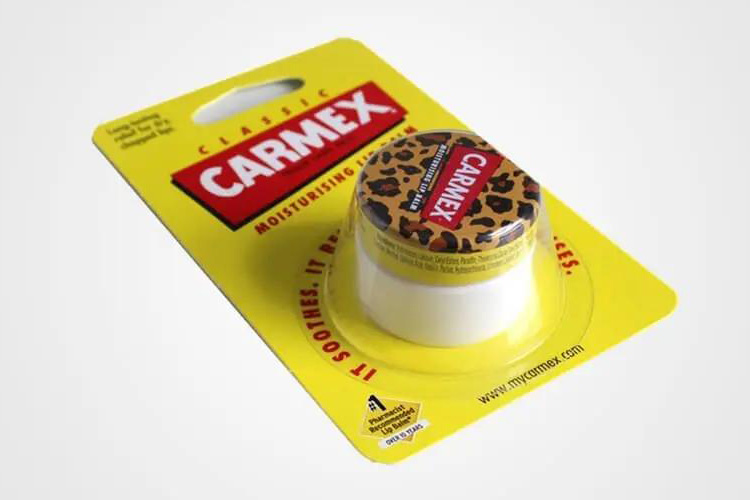

Face-Seal Blister Packaging

Perhaps, this can be the most low-end blister packaging type. Here, a plastic blister with a customized cavity wraps the top of a product and is sealed to pre-printed paperboard or a blister card. This packaging is popular to secure lightweight or cheap items such as lip balm.

Trapped Blister Packaging

In this case, a plastic cavity fits the entire product and is trapped between pieces of blister card or paperboard.

This packaging is a great option for those manufacturing companies who wish to limit the usage of plastic but wants to offer attractive packaging choices for their consumers. You might have noticed this type of packaging for memory cards like Sandisk.

Clamshell Blister Packaging

Clamshell packaging is possibly a protective and tamperproof solution for many packaging products. This is well- known for its thick covering and hard sealing, thus difficult to open. Yet, they are the most expensive form among other blister packaging types.

Tri-Fold Clamshell Blister Packaging

Perhaps, this form of packaging utilizes the same packaging format as clamshell but with added double hinge in its bottom that facilitates an easy standing of your product. The packaging does not require any support and can easily be adjusted on shelves devoid of extra hooks or support. This is an amazing solution for packaging uneven products like a computer mouse, webcam, etc.,

Full Face Seal Blister Packaging

A full-face seal offers you more protection than a face seal blister. Because it extends the plastic till the edges of blister card or paperboard. This form of packaging is more durable than face-seal blister packaging but on the other side, it is pricier as well.

Full Card Packaging

Full card packaging is almost similar to full-face blister packaging. The only difference is the addition of flanges to its end that wraps around the card. This can be secured by the use of staples.

6.MATERIAL CHOICES FOR BLISTER PACK

You have vast options for blister pack material types that meet the requirement of customers belonging to different groups. Discuss below is a short summary about material choices.

PET

Polyethylene terephthalate or PET is most affordable and economical material for blister packaging. This material is also used for making water bottles, clamshells, and other products. The material forms an impact-resistant, cleared, and recyclable packaging for pharmaceuticals, foods, and retail items.

HDPE

High density polyethylene or HDPE is utilized for various types of packaging. This is also an affordable and lightweight material but not cleared. It can produce a translucent or opaque effect, therefore it is preferable for those products which are photo-sensitive.

PP

Polypropylene or PP is mainly utilized for the packaging of food and medications. They are suitable for making blister, bottles, and bottle closures under a friendly budget. This form of material is somewhat similar to HDPE.

PVC

Polyvinyl chloride or PVC is a commonly used and approved material for the packaging of medications. This material is also utilized for foods packaging but is not frequently used as PET. The packaging material has opted whether you need unit-dose or other types.

7.Physical Properties of Blister Packaging

The significant physical properties of blister packaging are discussed below:

A Great Barrier

The packaging offers an excellent barrier property against unwanted physical hazards such as oxygen, humidity, light, temperature, etc., This is all because of a multi-layer sheet of polymer that ensures high safety to your product.

UV Protection

UV light exerts detrimental effects when it comes to the stability of the product. Because this is a culprit behind the oxidation and rancidity of the product. A metalized PVC efficiently blocks the risk of UV radiation hence improving the shelf life.

Water Resistance

A blister pack polymer has the ability to protect the inner product from water or any liquids. However, this degree of protection may vary on material and packaging pattern. Such as, if the back covering is made up of paperboard, then of course the chance of protection would be lesser than aluminum foil.

Visibility of Content

As discussed above, some blister packs offer you the property of visibility while some are opaque. This is ideal for marketing purpose as consumer can easily see the product of choice. For instance, in the case of medicine, the patient can directly see the tablets, capsules, or others and identify them.

No Product Damage

The packaging holds a high degree of protection against the accidental bump. A hard layer surrounds the product ensuring extra shielding against scratches.

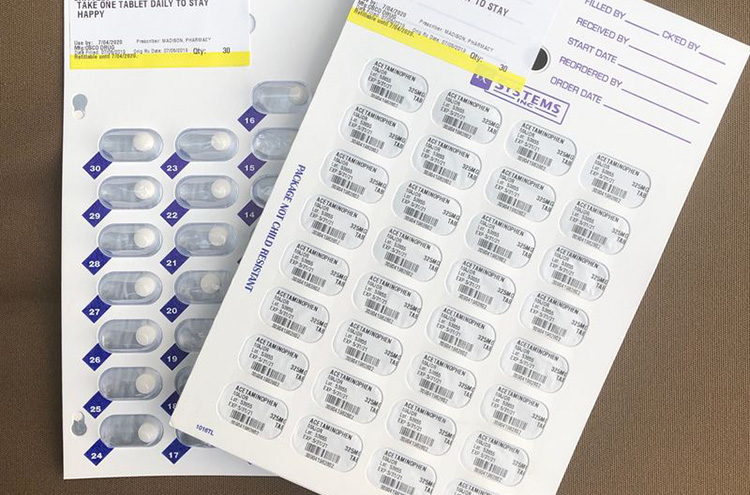

8.Blister Packaging Formats for Older Population

A significant number of the world’s population comprise people over 60 years. As age progresses the dexterity, muscle strength, hand grip, and eyesight gradually weaken leading to decreased patient’s compliance. Over all compliance of medicines prescribed to elderly four times a day was greatly reduced to 60% as compared to medicines prescribed once daily.

Moreover, medicines provided in a child-resistant container also prove to be difficult to access in patients of this group. The Association of Packaging and Processing Technologies has reported approximately 66% of patients experiencing discomfort and inconvenience while accessing the meds with over 40% reporting actual injuries while opening the container.

For all such reasons special blisters packaging was introduced that would be gentle for elderly and also retain their child resistant characteristics. These included push-out blister packs in which the tablet or capsule is forced out through the foil by the thumb. Not only these packs are elderly friendly and child resistant but also prevent degradation of the medicine due to light, moisture, and microbial content.

Other features of elderly-friendly blister pack models include scissors marks, and calendar packs to aid the geriatric population in maintaining compliance.

9.Blister Pack- A Sustainable Child-Resistant Packaging Solution

Child-resistant packaging was first introduced in the UK in 70’s and since its introduction, there was a significant reduction in children poisoning cases in developed countries according to WHO. However, child-resistant packaging does not mean that a child cannot open it but rather it is difficult to open by a child of 52 months.

Initially, bottles and jars were introduced later on the same concept was applied to blisters as they offered low production cost and easily accessible materials. Between bottles and blisters, some consider the latter to be more compliant as the chances of a child consuming medicines from bottle are high or the bottles can also be a nuisance to the elderly with arthritis or decreased handiness.

Blisters are made up of a multi-layer packaging materials mainly aluminum, PVC, PE, Alcar etc. or they are provided in a secondary container equipped with a locking mechanism.

10.Pharmaceutical Blister Packaging Market Performance

On the pharmaceutical platform, blister packaging is the most popular packaging mode. It is not only due to the product’s visibility or texturally appealing. But it also helps the manufacturing companies in minimizing the risk of errors during packaging. Due to its high demand, it has been estimated that the market value is expected to hit 17.4 billion dollars by 2024. The biggest users of blister packaging are North America and European states. Moreover, the development of healthcare also demands an increasing growth of blister packaging in developing regions such as Asia, the Middle East, Africa etc.,

CONCLUSION

No matter the type of blister packaging you need for your product. Aipak pharmaceutical’s production team is offering you the world’s best designs and types of thermoforming machines. With over 10+ years of marvelous work profile, the company deals with a broad spectrum of industrial applications, especially foods, pharmaceuticals, medical, and nutraceutical industries. Drop a message for a quick contact any time you need.

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine