Blister Packaging Machine In Pharmaceutical Industry: The Complete Buying Guide In 2025

The implementation of blister packaging machine in pharmaceutical industry is an excellent milestone in the packaging world. It was first used in the 1960s for the packaging of contraceptive pills., and soon after that, it gained a lot of popularity due to its efficient presentation and offering perfect protection.

Well, in the pharmaceutical industry, you always look for three important factors. First, your medicine must be air-tightly packed. Secondly, it should be compliant with the user, thirdly, it must be affordable. All these factors can be met when you are using a blister packaging machine in the pharmaceutical industry.

So, this blog is all about the blister packaging machine pharmaceutical industry. Get ready to explore in-depth knowledge which includes their working principles, classification, utilization, and so much more.

1.What is a blister packaging machine pharmaceutical industry?

Blister Packaging Machine Pharmaceutical Industry- Picture Courtesy: Korber Pharma

A blister packaging machine in pharmaceutical industry is implemented for the packaging of unit dosage formulations for example tablets, capsules, ampoules, etc. The machine gives you a high level of protection for your products in the form of high barrier properties with absolute tamper-evident properties. The blister packaging pharmaceutical industry helps in the forming of small pockets where the automatic placement of products inside takes place. They are mainly formed with thermoform plastic or cold-pressing aluminum with supporting back lidding of aluminum, paper, or plastic.

2.How has a blister packaging machine pharmaceutical industry evolved?

The evolution of the blister packaging machine pharmaceutical industry is described in 3 sections:

Evolution of Blister Packaging Machine Pharmaceutical Industry

The 1st Era

The blister packaging pharmaceutical industry is traced to the early beginnings of the 1950s which was soon after the era of post-World War II. At this time, commercialization and industrialization were spurred at its peak. Therefore pharmaceutical companies, medication, with modern packaging methods were evolved, and at that time blister packaging was developed.

The 2nd Era

In the period from 1970 to the 1980s, significant improvement was noted as more advanced technology and materials were implemented such as thermoforming of plastic sheet covering of mold, and introducing customized shapes. The aluminum foil for blister packaging was first used during this era to maintain potency and efficacy.

The 3rd Era

Soon after that period, the blister packaging machine pharmaceutical industry expanded beyond than pharmaceuticals fields. It was used and installed as a packaging set up in various other industries for more protection and enhancing aesthetic values.

3.What exactly does a blister packaging machine pharmaceutical industry offer you?

There are various reasons why the blister packaging machine pharmaceutical industry is in demand. We discussed some significant points just right below:

Easy Tearing and Accessing The Medication

Easy to Tear and Take- Picture Courtesy: Pinevillepharmacy

The machine can form Push Through Pack or PTP for easy withdrawal of medications. The machine itself possesses the two key properties that offers to its customers: a foil lid that is capable of torn down when you press, and the formation of semi-rigid pocket cavities that help in the pressing out of medication when your thumb compresses it.

Retaining The Potency Of Medication

The potency of Medication- Picture Courtesy: Griffin Rutgers

The blister packaging machine pharmaceutical industry is used to offer high-quality packaging to your product as you can take one product at a time. For example, picking one tablet from one cavity. It is a far better option than in-bottle packaging where all items get exposed to air, moisture, etc when you open the cap. So it can affect the potency. But in the case of blister packaging pharmaceutical machines, it offers premium quality packaging.

No Worries About Tampering

Original Products

The blister packaging machine pharmaceutical industry is a reliable addition to the world of packaging that safely and securely places your product in each cavity with sealing. If in case anyone tries to open or access the medication; the damage layer will help you quickly to identify tampering. Therefore it presents quality products in original form.

Quick and Easy Tracking

Quick and Easy Tracking- Picture Courtesy: Maco PKG

Blister packaging machine pharmaceutical industry extends with easy trace of medication as compared to bottle packaging. You can flexibly take medication that you take regularly, with the help of stamping of dates, distinguishing codes, and sometimes days. So, you are safe from accidental intake of medicines because, you are more likely to beyond the safer side than facing the challenges of the wrong medication, or misuse of medication.

Easy To Grab

Easy to grab

The blister packaging machine pharmaceutical industry features perforated packaging that allows you to split the blister packaging card. This means you don't need any scissors or any tool to separate your tablet rather press the dotted perforation and get easy detachment.

4.What other sectors are facilitated by the blister packaging machine pharmaceutical industry?

The blister packaging machine pharmaceutical industry provides several benefits to the packaging sectors. That is why it is used in various industries. For example:

Pharmaceutical Industry

Pharmaceutical Industry- Picture Courtesy: Pioneer Packaging

The machine is mainly used for packaging pharmaceuticals, unlike other packaging modes, the blister packaging machine pharmaceutical industry gives you a sterile and rapid solution to treat sensitive medications. Various tablets, capsules, pills, gummies, lozenges, pastilles, pessaries, etc are packed in blister packs and are featured with peel-opening properties for flexible access.

Electronic Industry

Electronic Industry- Picture Courtesy: AsiaPack

Blister packaging machine pharmaceutical industry is a reliable and rapid technology used for packaging your electronic gadgets. The packaging is used as it is a safe, shock absorber during emergencies and distributions, protecting tools from thefts. For example, batteries, headphones, remote controllers, chargers, plugs, etc.

Medical Equipment Industry

Medical Industry- Picture Courtesy: Plastic inGenuity

The blister packaging machine pharmaceutical industry has gained huge popularity due to its sterile packaging processes under an affordable range. It ensures that medical tools are packed with 100% sterility and easy to unpack. There are various tools like thermometers, BP measurement devices, suture-cutting scissors, needles, spatulas, forceps, etc are reliably packed in blister packaging.

Food Industry

Food Industry

The manufacturers of food companies always care for the perishable products. Therefore, blister packaging machine pharmaceutical industry are a good option for providing unit food packaging. It keeps food items protected from moisture, light, and air. Additionally, it is increasing the shelf life with high protective barrier properties from the progression of contamination. For example, chocolate cookies, biscuits, snacks, tastemakers, nuts, and grains bars, are commonly catered by blister packaging.

Nutraceutical Industry

Nutraceutical Industry- Picture courtesy: Nutraceutical world

This is a fast-growing industry where the manufacturing and packaging of vitamins, proteins, enzymes, and related supplements are manufactured and packed. To make them safe, protected, potent, and most importantly presentable, the blister packaging machine pharmaceutical industry is utilized. Your nutraceutical supplements are guaranteed with high potency and originality with this mode of packaging.

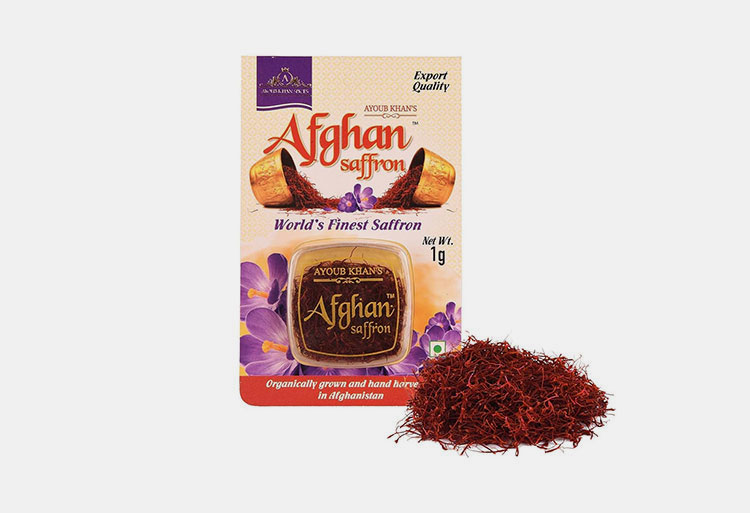

Herbal Industry

Herbal Industry- Picture courtesy: Nutraceutical world

The herbal industry is associated with herbal preparation tablets, capsules, pills, and granules, which are mainly prepared from organic sources. Therefore, the formulated product is highly sensitive to the external environment. The blister packaging machine pharmaceutical industry is used to keep your herbal preparation as fresh and effective as possible.

Veterinary Industry

Veterinary Industry- Picture Courtesy: Veterinary Practice

Various veterinary-related products including vaccination, oral solid dosage formulation, and topical solutions, are dispensed in blister packaging. This type of packaging offers promising barrier properties to veterinary items that’s why this machine is used in veterinary practices worldwide.

Toys and Household Products Industry

Toys and Household Products Industry

Toys are prone to damage during distribution, transportation, and packaging. Therefore, blister packaging machine pharmaceutical industry are used to reduce the chances of harm and breakage of expensive products. Moreover, this type of packaging makes the children and users visualize products and pick them with transparent cavities.

5.Can you describe the basic classification of the blister packaging machine pharmaceutical industry?

The classification of the blister packaging pharmaceutical industry is discussed below:

Classification based on Automation

Manual Blister Packaging Machine Pharmaceutical Industry

Hand Operated Blister Packaging Machine Pharmaceutical Industry

The manual blister packaging machine pharmaceutical industry is a simple unit used in small businesses and organizations. This is an easy operating tool used for packaging tablets, capsules, etc. In this machine, you can place the blister packaging sheet along with filled tablets over the holder die and place the aluminum foil or any back lid over it.

Now press the handle; by twisting the lever, the heat-sealing plate helps in the induction of sealing the blister takes place. After the specified time, you can pull off the lever to release the nicely formed blister pack. Now by using the cutting unit, you can trim the edges of the blister packaging to enhance the professional look of your product.

Semi-Automatic Blister Packaging Machine Pharmaceutical Industry

Allpack Semi Automatic Blister Packaging Machine Pharmaceutical Industry

This is the machine of choice if you want to have the best budget-friendly blister packaging machine for the packaging line. For moderate herbal, nutraceuticals, labs, pharmacies, etc, you can go for a semi-automatic blister packaging machine pharmaceutical industry.

Unlike, the manual, this machine is way more ideal and efficient for medical and clinical purposes as it offers packaging at a greater capacity per hour with more precision and controlled working. The machine has a compact structure therefore, you can adjust it in small spaces. There are three main tasks performed by the machine, first, blister formation, sealing, perforation around the cavity edges, and cutting. This machine is suitable for PVC, alu- alu, PP, etc materials.

Automatic Blister Packaging Machine Pharmaceutical Industry

AIPAK DPH Full Automatic Blister Packaging Machine Pharmaceutical Industry

This is a giant addition to the world of blister packaging. Automatic blister packaging machine pharmaceutical industry allows you to handle large amounts of blister packaging production involving thousands of packaging hourly. The machine is designed with a larger structure, and capable of integrated with other units. It has the capacity to work non-stop without requiring your constant monitoring or standing for the process. Moreover, it is way more suitable to bring cold-forming and thermoforming blister packaging.

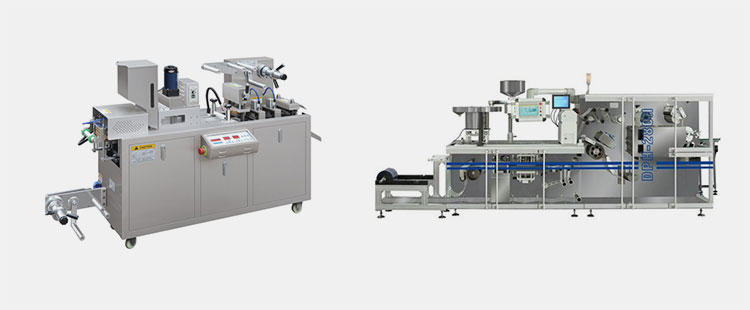

Classification Based on Design

Based on the design, the blister packaging machine pharmaceutical industry is classified into the following:

Platen-Style (Flat-Bed) Blister Packaging Machine Pharmaceutical Industry

AIPAK Platen-Style (Flat-Bed) Blister Packaging Machine Pharmaceutical Industry

The machine design is based on a platen-style die mold or a bed where the formation of blister packaging takes place. This type of machine works smoothly and subtly where a constant speed is allowed to bring the performance. The machine allows easy changeover of the blister packaging molds and you can use this option for ampoules, vials, injectables, and other various options.

A platen-style machine is mostly suggested for moderate capacities. The heated plate first provides temperature to soften the blister sheet and with the help of high compressed air the blisters formed. With the help of a flat plate, high temperature, and high pressure, you can attain the required blister packs of your choice.

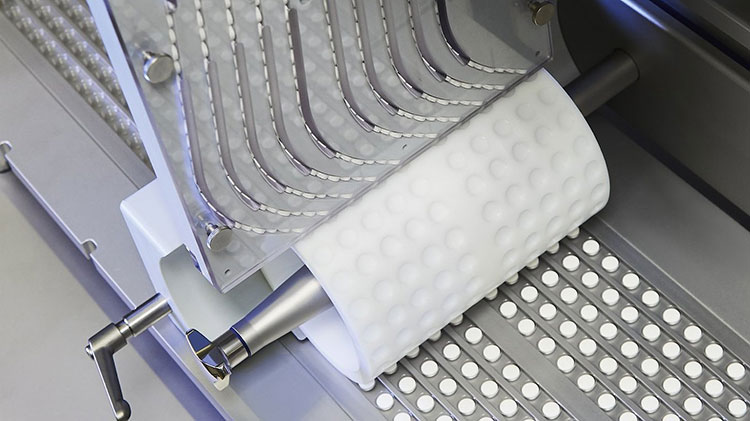

Rotary-Style (Roller-Type) Blister Packaging Machine Pharmaceutical Industry

AIPAK Rotary-Style (Roller-Type) Blister Packaging Machine Pharmaceutical Industry

This is a fast-operated machine as compared to a flat plate as there are roller that helps in the formation of blisters with sealer subjected for blister packaging. There are various stations accompanied for specific tasks therefore a mass production capacity can be handled.

Roll Plate Blister Packaging Machine

AIPAK DPH Roll Plate Blister Packaging Machine Pharmaceutical Industry

The fast-running and innovative machine follows the working adapted by flat plate and rotary blister packaging machines pharmaceutical industry. With the help of high temperature and positive pressure blown over the blister sheet the blister formation. The highly controlled automatic system is capable of fine perforation punch and cutting. This is indeed a large and modern machine with an absolutely easy operating mechanism and smooth workflow.

Classification Based on Blister Formation Type

Thermoforming Blister Packaging Machine Pharmaceutical Industry

AIPAK Thermoforming Blister Packaging Machine Pharmaceutical Industry

The machine mainly works by implication of heat. The induction of temperature leads to cause melting of the sheet and allows it to produce the cavity of desirable shape. The materials to be packed are positioned and the upper lidding is sealed. The machine offers you a cost-effective method with high production capacity. In the case of moisture-sensitive materials, this machine may not be a good option as it can affect the potency and structural integrity.

Cold Forming Blister Packaging Machine Pharmaceutical Industry

AIPAK DPH high-Speed Alu-Alu Automatic Blister Packaging Machine Pharmaceutical Industry

The machine working principle is based on the induction of high pressure and force that ensure the formation of blisters. Here, the stamp of high force is applied without any requirement of high temperature and the formed mold is used for positioning of the formulated products. Once the cavities are filled, a thin sheet is covered followed by high stamping of the force to form a protective covering or back lid. This machine is suitable for moisture-sensitive products but somehow costs you high.

6.What is the difference between flat type and roll plate blister packaging machine pharmaceutical industry?

The prime structure and design components of the blister packaging machine pharmaceutical industry are almost the same with slight variations such as flat type and roll type plate. We have talked about significant differences just right below:

Type of machine

AIPAK DPP Flat & DPH Roll Plate Blister Packaging Machine Pharmaceutical Industry

In the flat-type blister packaging machine pharmaceutical industry the heating stamp design is based on a flat-type plate which is punched on the machine directly to produce blister pockets. Whereas, a roll plate blister packaging machine pharmaceutical industry blister molding plates are based on a roll plate that rotates to produce blister cavities over the film material.

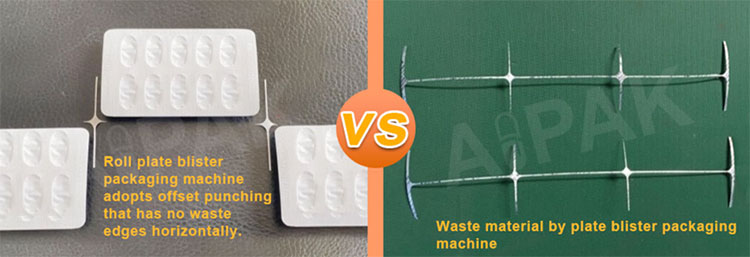

Working Speed & Material Waste

Working Speed & Material Waste

In the case of flat plate blister packaging, it is capable of producing uniform and fast blister cavities for various products.  . Whereas, a roll-type blister machine, is a bit complex machine but gives you a tremendous production capacity. This is a versatile machine and capable of managing a broad range and shapes of blister cavities for your packaging items. Also, roll plate packaging helps in no wastage of blister packaging materials as it has efficient offset punching.

Drawback

Flat type VS roll type blister packaging machine pharmaceutical industry

A flat-type blister packaging machine pharmaceutical industry nevertheless works extremely well with the finest format but the production speed is estimated as low. On the other side, the roll-type blister packaging machine gives complex shape formatting but with a percentage of error in its finishing.

7.What are the important parts of blister packaging machine pharmaceutical industry?

AIPAK DPP- Blister Packaging Machine Pharmaceutical Industry Parts

This is a super sleek constructed machine that is based on multiple working units; each unit is confined to a specific job. We have demonstrated the parts of the machine in the above picture by cleared labeling so you can understand them properly with roles in the content below:

| Heat Forming Device

|

This is a unit meant to induce or generate heat which is required for the formation of the blister. The heat-forming device is capable of inducing heat with a temperature of several hundred degrees centigrade and it is all based on the type of material you’re subjecting to the machine. |

| Anti-Scald Cover |

If you observe the unit, it is a perforated covering. The prime reason for this covering is to emit heat from the system without causing harm to you. Therefore, high-level temperatures can’t let the user burn or cause any kind of injury, this is only meant for our protection. |

| Material Feeder

|

This is a kind of hopper that is meant for storing and supplying the product to be packed inside the formed blister cavities safely and in a consistent manner. |

| Visualizing Window

|

You can see the status inside the machine, if the material loaded is perfect, or moving of the roll is working fine, etc, with the help of a visualizing window. In case of any technical issues, just press the window and directly view the components inside for troubleshooting. |

| PLC Touchscreen

|

You can input the programming, speed, production capacity, temperatures, time duration, etc directly using a digital touchscreen system. This is known as a PLC touch screen or you can term it a ‘Programmable Logic Controller’. Today, almost every modern blister packaging machine pharmaceutical industry is facilitated with this unit for ease of use. |

| Material Supporting Channels

|

Your subjected film roll is unwinding smoothly as it is mainly adjusted and supported by material supporting channels. The several working steps such as cavity formation, placement, sealing, etc are now happening uniformly and in a subtle way just because of the proper alignment of materials adjusted in a machine. |

| Heat Sealing Bars

|

The hot plate which is composed of die mold of different shapes and sizes is meant to soften the foil and form the shape or pockets in the form of a blister. The upper section of the bar is meant to induce pressure and heat for firm sealing of the back lid to secure the formulation. |

| Blister Pack Outlet

|

This part of the machine is mainly responsible for discharging the prepared blister packaging out of the machine. Here, once you receive the completed product, it would be assuring all steps are followed and the packaging is entirely secure for a long time. |

| Electric Eye Detector

|

The modern machineries are facilitated with an electric eye detector to monitor the error or misalignment of the film roll. If the product is missing, there won't be further process steps taking place. This unit helps in the identification of errors and wrong processing. |

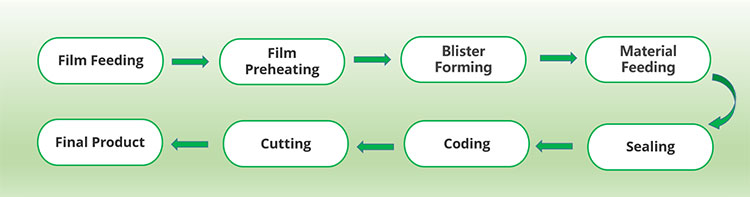

8.What is the working step of a blister packaging machine pharmaceutical industry?

Working Step Of A Blister Packaging Machine Pharmaceutical Industry- Picture Courtesy: Pharmaland

| Film Feeding

|

The film feeding is the first process step where a loaded film of PVC or any material starts extending towards the next sections of the machine to form the cavities or blisters. The loading channel unrolls the film fed over it. At this stage, a consistent and subtle operation takes place, and the smooth supply of the film ensures a steady workflow. |

| Film Pre-Heat | The thermal rays are provided onto the film which mostly ranges from 160 to 200°C to soften the sheet and facilitate an easy cavity formation. |

| Blister Formation | With the help of a vacuum and hot air blower system, the blister or cavities are formed. The presence of mold allows the specific shape of the cavities. The positive pressure and compressed air play an important role in this stage to get a desirable shape. |

| Product Feeding | If your product is a tablet, capsule, pill, or any other pharmaceutical item, it is now positioned inside each formed cavity. |

| Sealing | The back lidding is also automatically supplied by the machine which is adjusted and sealed over the formed cavities. With the help of heat sealers, the covering is fixed and firmed tightly followed by sealing. The fixed sealing now offers maximum protection to products packed inside. |

| Coding | The back of the blister packaging is now coded by the machine which mainly mentions with batch number, and important information such as manufacturing date, expiry date, etc., |

| Cutting and perforation stamp | With the help of the machine’s cutter, the final separation of the whole pack takes place. Also, each tablet or material edges are stamped with perforation bars which is mainly helpful to detach the tablet or any item. |

| Final Product | The prepared blister packaging is now discharged from the machine. |

9.What type of medicines can a blister packaging machine pharmaceutical industry pack?

Whenever you think of medicines, an image of blister packaging surely comes to your mind. Nowadays, blister packaging is synonymous with medicinal packaging. All kinds of pills and more are dispensed in blister packaging for utmost protection and product visibility.

Consequently, it is safe to say that a blister packaging machine pharmaceutical industry has a great deal of flexibility when it comes to packaging medicinal products. It easily handles all sorts of products with easy change of parts. Here is a list of different medicines packed by a blister packaging machine:

Tablets

Tablets- Picture courtesy: Tornados Studio

You certainly would have seen this machine in various pharmaceutical sectors for packaging tablets. It is a common means to enclose diverse tablets varying in their shape, form, color, coating, and mode of administration. With this equipment, you can seal uncoated, film-coated, sugar-coated, chewable, and, effervescent tablets.

Capsules

Capsule-Picture Courtesy: APTAR

They are the most widely dosage of medicines besides tablets. Many individuals prefer it over tablets because they are easily swallowed and are taste-neutral. Hence, you may find a variety of capsule forms in the market, for instance, hard-gel, soft-gel, pullulan, starch, cellulose, HPMC, and more. All these of them are loaded in blisters by the blister packaging machine pharmaceutical industry.

Lozenges & Troches

Lozenges & Troches

What do you immediately think of when someone says “sore throat”? Indeed, it is lozenges. These are small, medicated toffee or tablets for treating sore throat and cough. Their primary form of packaging is a blister that is formed by a blister packaging machine.

Suppositories

Suppositories

These medications are administered invasively to manage rectal or vaginal disorders. Subsequently, they need a high level of protection. Cold-formed aluminum blisters are typically used for packaging suppositories. With this packaging, you can protect your product from degradation from air, water content, temperature, and sunlight.

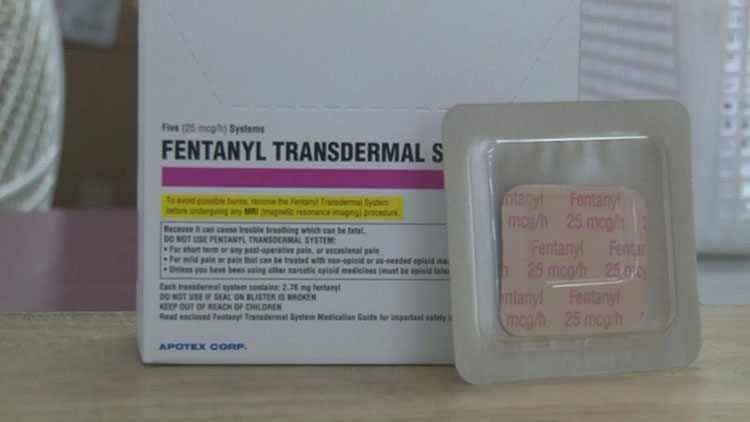

Transdermal Patches

Transdermal Patches- Picture Courtesy: WOWK

These medication forms are a recent and creative approach to delivering drugs into systematic circulation over time. You just have to put this patch on your skin to treat blood pressure, motion sickness, and migraines. You can get transdermal patches beautifully sealed in blisters from the market.

10.What is the difference between a strip packaging machine and a blister packaging machine pharmaceutical industry?

AIPAK Strip Packaging Machine & Blister Packaging Machine Pharmaceutical Industry

Both these machines are common equipment for unit-dose packaging in the pharmaceutical field, but they lie on the opposite side of the spectrum when their structure, function, and end-packaging form are considered. So, let’s discuss the major differences between a strip packaging machine and a blister packaging machine pharmaceutical industry one by one.

| Feature | Strip Packaging Machine | Blister Packaging Machine Pharmaceutical Industry |

| Definition | This equipment encloses medicinal products between two layers of foil. The pills or other materials are positioned amid a web of films and then these film layers are sealed around products. | This machine uses a molding device to create cavities that are filled with medicines. Ultimately, these cavities are sealed by foil or paper material. |

| Packaging Films | The strip packaging formed by this device is manufactured from aluminum foil, cellophane, or plastic film. | It typically forms blisters with the application of PVC, paperboard, COP, PVDC, aluminum foil, or, Aclar. |

| Sealing Approach | You’ll see that packaging films are sealed with heat only without creating a cavity in this instrument. | Both heat and pressure are used to form cavities and then seal them with lidding materials using this machine. |

| Protective Potential | Although a strip packaging machine is known for its excellent moisture and light protection, still you can’t get mechanical protection from strip packs because they lack rigidity. | A blister packaging machine pharmaceutical industry is highly recommended when you want protection against physical damage, breaking, cracking, splitting, and more. Because blisters restrict the movement of the inner contents. This machine also offers suitable protection from air and moisture. |

| Product Visibility | It normally produces opaque packaging. Thus, you can’t see the inner content and check its quality. | It uses transparent PETG or PVC that allows you and others to view products before buying. |

| Products | This machine packs a small number of products like mini-tablets, capsules, and effervescent tablets. | It is quite popular due to the handling of diverse product types, for example, pills, lozenges, suppositories, and transdermal patches. |

| Speed | It is slower than its blister counterpart. Because tablets are dropped one by one into the material web, which takes more time. | In this machine, the pills are loaded into blister cavities all at once and then concurrently sealed in a few microseconds. |

| Patient Convenience | As the strip packaging machine tightly seals medicines between film layers, thus you have to retrieve the inner contents by tearing the film. | This machine creates packaging in which pills are easily accessed by patients. They just have to press the outer lid to remove packed materials. |

Conclusion

Blister packaging machine pharmaceutical industry is a high-quality solution implemented for packaging sectors of not just pharmaceuticals but also for medical, nutraceuticals, herbal, veterinary, and so many other products. AIPAK blister packaging machine pharmaceutical industry establishes accurate and reliable machineries that help in the formation of stable and firm blister packaging to protect your products under an affordable range. You can avail of our one-stop solutions for small, moderate, and larger enterprises for a broad range of products. Want to know more about blister packaging solutions? Just message us now! AIPAK experts will shortly be in touch with you to start conversations.

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine