Blister Packaging Equipment :The Complete Buying Guide In 2025

The blister packaging equipment is an indispensable equipment in the pharmaceutical industry, food processing and chemical industry. Its wide range of applications and uses can bring huge benefits to your business. By understanding its working principle and application, you can help you choose a more suitable model.

With the increasing demand for product safety, the latest blister packaging equipment can now meet your various production needs. Through this post of blister packaging equipment, you may understand all its information about the blister packaging and blister packaging equipment. Let's begin now!

1.What Is A Blister Packaging And What Are Their Types?

Blister packaging-sourced: hopingcn

Blister packaging is a process that uses heat pressing, bonding and other methods to turn transparent plastic film or sheet into blisters and seal the product in the cavity between the blister and the base. It is mainly suitable for various products in the pharmaceutical industry, food processing and chemical industry.

According to the application of different products, blister packaging can be divided into:

Thermoformed blister packaging

Thermoformed blister packaging-sourced: hopingcn

Thermoformed blister packaging mainly uses heated plastic sheets to make them into blister cavities that can accommodate products, and then fills and seals the products. It is versatile and can be used in different industries.

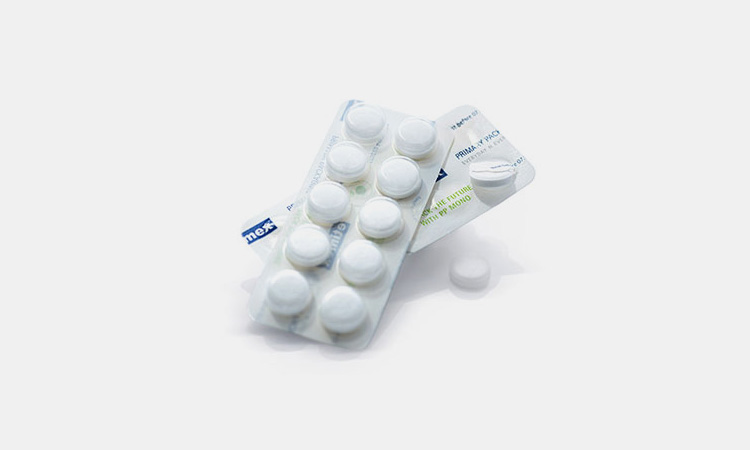

Cold-formed blister packaging

Cold-formed blister packaging-sourced: acg

Cold-formed blister packaging refers to the process of pressing an aluminum-based laminate into a blister mold under pressure at room temperature to form a mold for the blister cavity, and then filling and sealing the product. It is suitable for products that require high barrier properties and are relatively sensitive.

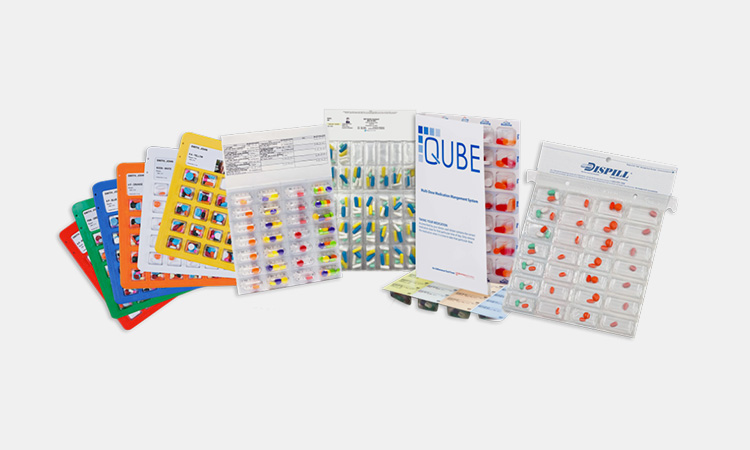

Blister card

Blister card-sourced: rxsafe

Blister card mainly refers to packaging in which the product is filled into a transparent mold with a cavity and the plastic cavity attached to the cardboard backing is sealed.

Clamshell blister

Clamshell blister-sourced: clamshell-packaging

Flip blister is a fully enclosed but detachable blister card packaging. It is widely used in packaging of electronic products and skin care products.

2.What Are The Advantages And Disadvantages Of Blister Packaging?

Blister packaging is widely used in the market and is increasingly sought after by merchants. The benefits of blister packaging are:

Product protection

Product protection-sourced: made-in-china

The materials used in blister packaging are relatively strong and durable. It can prevent your product from being damaged during transportation and handling, and can maintain the freshness of the product.

Tamper-proof

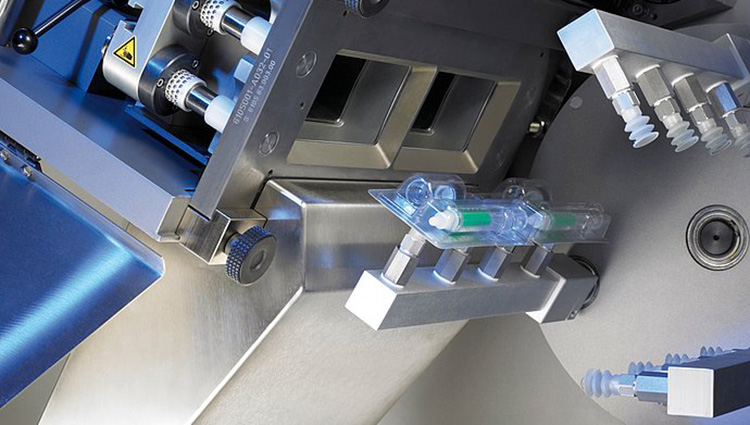

Tamper-proof-sourced: romaco

Once the blister packaging is opened, it cannot be restored. And the cavities of the blister packaging are separated, which can well ensure the independence and safety of the medicine.

Control dosage

Control dosage-sourced: pharmaworks

The good sealing ability of the blister and the independent cavity can not only extend the shelf life of the product, but also well control the dosage of the user's product.

Visibility

Visibility-sourced: pharmaeducation

Most blister packaging is made of transparent materials. And the information on the packaging is clear and standard, allowing you to understand the content information and dosage at a glance.

Blister packaging also has disadvantages. It includes:

More expensive

More expensive-sourced: brookings

The cost of using blister packaging and the machine cost are more expensive than other packaging equipment. And compared with ordinary plastic packaging, the packaging materials used for blister packaging are more expensive.

Environmental issues

Environmental issues-sourced: geeksforgeeks

The secondary recycling of packaging materials used in blister packaging is difficult and can easily cause environmental pollution.

Limited brand space

Compared with other packaging materials, blister packaging has a weaker ability to be used for brand marketing and advertising.

3.What Is A Blister Packaging Equipment?

AIPAK blister packaging equipment

Blister packaging equipment, also called as blister packaging machine, is mainly used to pack various capsules, pills, tablets, suppositories, etc. into blister packaging. Through this packaging, the product can be protected from external contamination and the freshness and effectiveness of the product can be maintained.

4.What Are The Uses Of Blister Packaging Equipment?

There are multiple uses of blister packaging equipment. They include:

Pharmaceutical industry

Pharmaceutical industry-sourced: contentstack

All pills, capsules, suppositories, ampoule, syringes, pastes, liquids, etc. in the pharmaceutical industry can be filled and packaged in blister packaging. In addition to protecting the drugs from contamination, it can also facilitate subsequent packaging, handling and transportation.

Food industry

Food industry-sourced: contentstack

All kinds of functional candies, chocolates, biscuits, frozen foods, etc. can be packaged and packaged by blister packaging equipment. It allows you to easily see the product contents in the package when selecting products.

Electronic industry

Electronic industry-sourced: sgpackaging

Various expensive or fragile electronic products, including USB flash drives, memory cards, SIM cards, etc. can be reinforced and protected by blister packaging. In addition to being protected from damage, it can also improve the grade of the product.

Daily necessities industry

Daily necessities industry-sourced: elsepack

Whether it is small skin care products such as essences, creams, lipsticks, sunscreens, etc., or toothbrushes, razors, knives, toys and other products, they can be easily packaged in blister packaging.

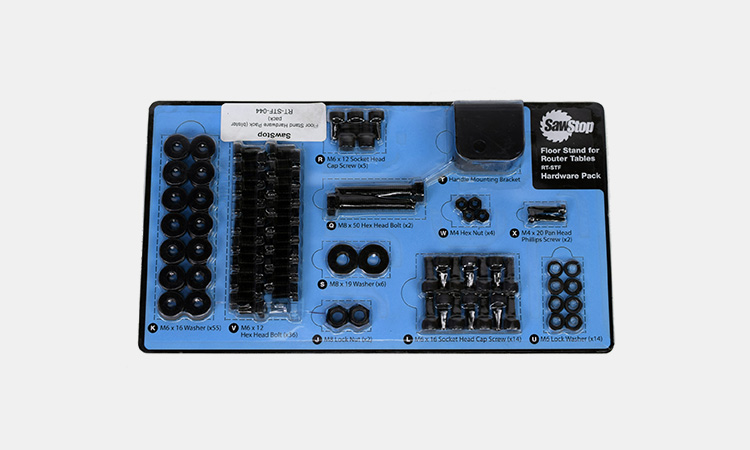

Hardware Industry

Hardware Industry-sourced: sawstopstore

The blister packaging equipment is also widely used in the packaging of various small parts such as screws, nails and bolts.

5.What Are The Materials That Can Be Used In Blister Packaging Equipment?

Not all materials can be used in blister packaging equipment. Materials used in blister packaging include:

PVC

PVC-sourced: greenpack

The advantages of PVC are stability, good processing performance, strong adaptability and practicality, heat resistance and easy molding. It is one of the most common and stable blister packaging materials.

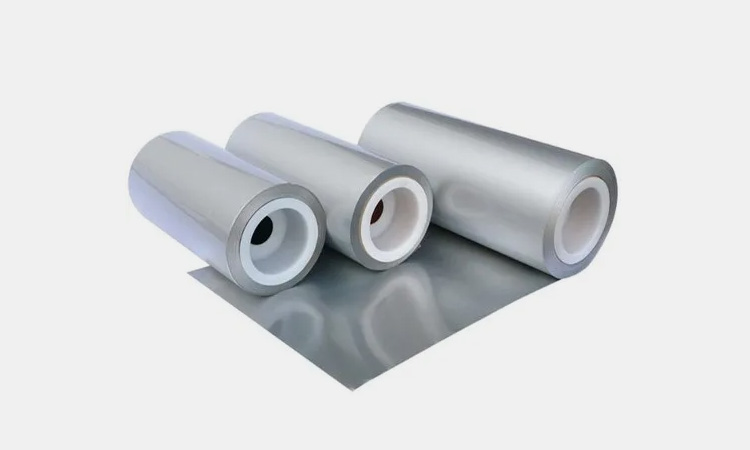

PVDC

PVDC-sourced: richpacking020

The PVDC material is mainly a blister material made by adding a PVDC coating to a PVC film. It has the advantage of being able to block oxygen and moisture. In addition to being economical, it is also a good material for packaging sensitive drugs.

COC

COC-sourced: topas

COC is an amorphous plastic specifically used for drug blister packaging. Its advantage is that it can resist water vapor permeability very well.

PCTFE

PCTFE-sourced: acg

PCTFE is a blister packaging material that is very suitable for packaging sensitive drugs. It can help drugs resist the influence of moisture and oxygen. And the physical and chemical properties are stable.

PET

PET-sourced: wallisplastic

PET is a relatively environmentally friendly material because it can be recycled and reused, has higher transparency and stronger hardness. Therefore, it can provide better protection for your products and can last longer in transportation.

PP

PP-sourced: perlenpackaging

PP is a blister packaging material with excellent heat resistance. Not only can it withstand high temperatures, but it also has strong gas barrier properties. However, its disadvantage is poor visibility. It may not be able to package products that require high visibility.

PS

PS-sourced: overseadia

The advantages of PS material are high hardness, good transparency and easy molding. It is suitable for packaging products with complex shapes and requiring stronger wrapping. However, its disadvantages are that it is not resistant to high temperatures and has strong impact.

6.What Can The Blister Packaging Equipment Bring You?

Using blister packaging equipment can bring you many benefits. It includes:

Improve efficiency and output

Improve efficiency and output-sourced: koerber-pharma

Compared with manual blister packaging, blister packaging equipment can greatly improve the efficiency and output of your product blister packaging, greatly reduce your dependence on manual labor, and reduce manual errors.

Improve patient safety

Blister packaging equipment has a low error rate and high and uniform product quality. Improve patient safety by reducing manual errors.

Production speed and flexibility

Production speed and flexibility-sourced: koerber-pharma

The more automated the blister packaging equipment is, the faster and more flexible it will be. In addition to these, it has strong adaptability.

Product quality

Product quality-sourced: koerber-pharma

By setting a standardized blister packaging procedure, the blister packaging equipment can provide high-quality product quality and improve product traceability.

Production cost

By cutting labor costs and adjusting the accuracy of blister packaging equipment, it can greatly reduce your production costs and improve resource utilization.

7.What Are The Types Of Blister Packaging Equipment?

Blister packaging equipment can be mainly divided into 3 types. The manual type, semi-automatic type and automatic type.

Manual blister packaging equipment

Manual blister packaging equipment-sourced: celce

The manual blister packaging equipment is specially designed for small pharmaceutical factories, health care products factories, food factories and preparation rooms. During use, it needs manual operation with low efficiency. However, it has a compact appearance and low noise in use.

Semi-automatic blister packaging equipment

Semi-automatic blister packaging equipment-sourced: ascendpkg

The semi-automatic blister packaging equipment is a type between manual and fully automatic. It is able to complete blister forming, sealing, perforating and cutting processes. It is able to handle all thermoforming and cold forming materials with easy operation. However, its working speed is slower than that of the fully automatic model. Faster than manual.

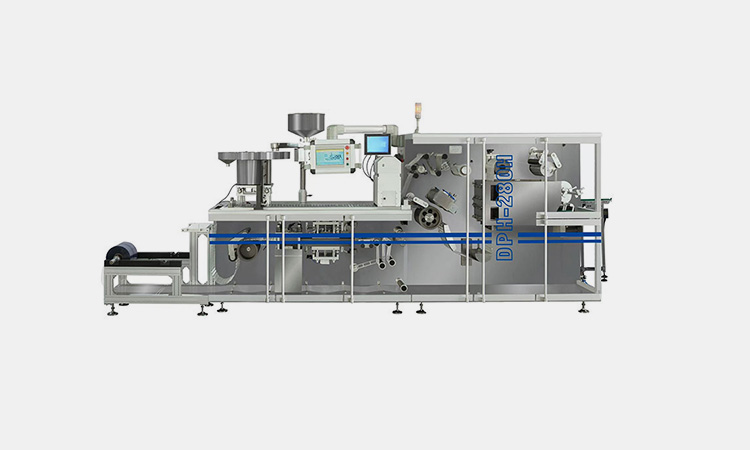

Automatic blister packaging equipment

AIPAK automatic blister packaging equipment

The automatic blister packaging equipment is able to handle all types of film and foil materials, and can complete both thermoforming and cold forming packaging. It is a tool specially designed for mass production. In addition to being able to complete blister packaging, it can also complete packaging forming, sealing, coding date or perforation, and die-cutting for you.

In addition to the difference in automation, different blister packaging equipment can be divided into flat plate blister packaging equipment and roll plate blister packaging equipment.

Flat plate blister packaging equipment

AIPAK flat plate blister packaging equipment

The flat plate blister packaging equipment has a flat plate blister forming structure. It is suitable for packaging various medicines, foods and medical devices. The flat plate blister packaging equipment also uses blister materials that are heated in the cavity and then blown into shape. Its products are relatively uniform and smooth.

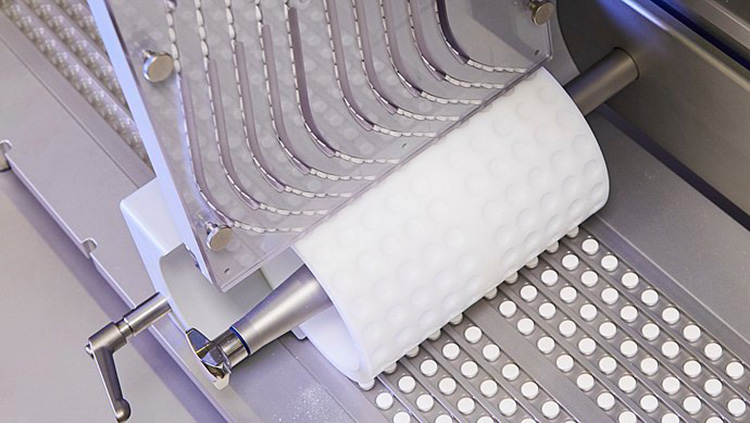

Roll plate blister packaging equipment

AIPAK roll plate blister packaging equipment

The roll plate blister packaging equipment is a kind of equipment that specially uses rollers and plates to form the cavity, and then heats the blister material to form the shape in the roller cavity. Finally, the product is filled. It is also widely used in pharmaceutical packaging, food packaging, cosmetic packaging, medical device packaging and other industries.

8.What Are The Manufacturing Process Of Blister Packaging?

The blister equipment mainly applies two manufacturing processes, and it includes:

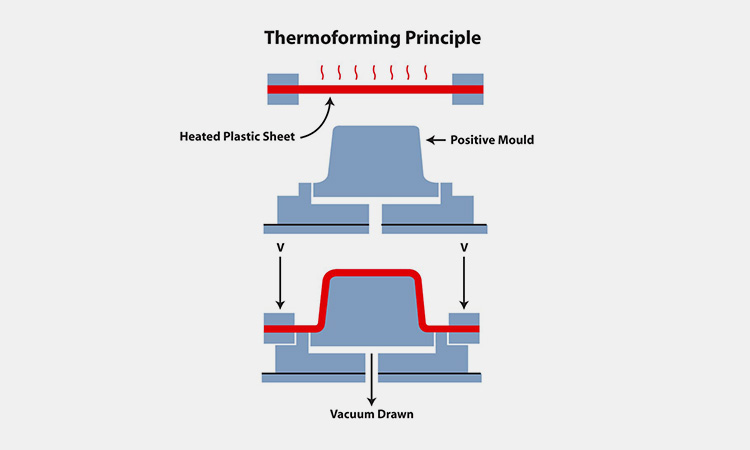

Thermoforming process

Thermoforming process-sourced: euroextrusions

Thermoforming process mainly uses heating to make blister packaging. Firstly, you need to heat the transparent PVC sheet and then put it into the mold for plasticization. When the PVC sheet becomes soft and is molded into the blister packaging shape you need, you can apply a certain amount of pressure to shape the mold, so as to continue the subsequent product packaging and sealing.

Cold forming process

Cold forming process-sourced: arnoldunformtechnik

The cold forming process is a way to directly press and plasticize the sheet without heating. Firstly, you need to select a sheet suitable for cold forming and apply a certain amount of pressure to press the film into a certain shape.

After forming, you need to use stretching force to keep the film in shape and fill and seal the product. This packaging method is simpler than the thermoforming process, but the cost is more expensive.

9.What Are The Main Components Of Blister Packaging Equipment?

After understanding the types of blister packaging equipment, you should also be curious about its components. This can deepen your understanding of this equipment.

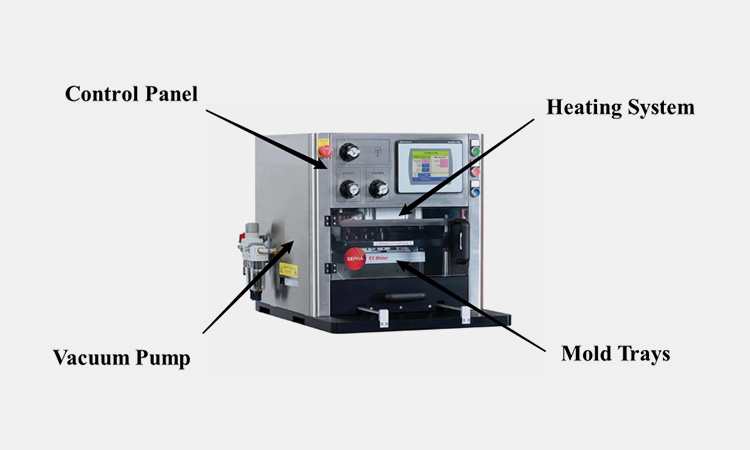

Main components of semi-automatic blister packaging equipment

Main components of semi-automatic blister packaging equipment-sourced: celce

Heating system

The semi-automatic blister packaging equipment applies the heating system to seal the blister packs for the tight and safe seal.

Control Panel

Through the simple control panel, you can adjust according to your needs. There are buttons and parameter boards for you to adjust and read. Any problems will be displayed on the screen.

Vacuum Pump

The vacuum pump is mainly responsible for providing pressure and power for the heating system and sealing system.

Mold Trays

There are multiple mold trays for your use. You can choose molds of different sizes and shapes to adapt to different product packaging.

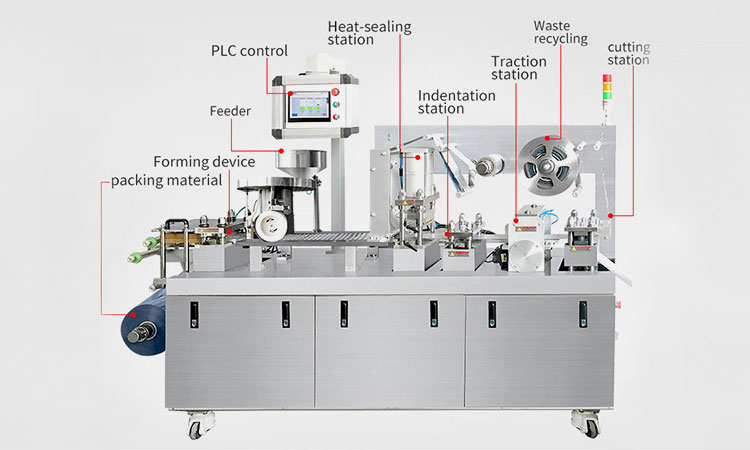

Main components of automatic blister packaging equipment

Main components of automatic blister packaging equipment-sourced: richpacking020

Packing material

It mainly includes film strip unwinder and the film rolls. When the equipment is started, the film strip unwinder will unwind the plastic film or aluminum foil to prepare for the subsequent thermoforming.

Forming device

The forming device is also called as heating station and thermoforming station. It will apply the heat to complete the film thermoforming. It mainly makes the plastic film concave by heating the air and presses it into the shape of the mold.

Feeder

The feeder is the feeding and storage space for products such as soft capsules or tablets that need to be packaged. It is connected to the vibrating plate and filling station. It may help you arrange and fill the products well.

PLC control

Through a simple touch screen, you can use PLC control to set the blister packaging mode you need. This includes filling speed, time, efficiency, etc.

Heat-sealing station

After the products has been filled into the blisters, the heat-sealing station will use heat and pressure to seal the mouth of the blisters. The sealing foil and the forming film can be sealed at a constant temperature and pressure set by you.

Indentation station

The indentation station may help you press the indentation line into the formed blister material. This allows the contour of the film to match the contour of the product exactly.

Traction station

The design of traction station is mainly to help the film to be stretched out without folding.

Waste recycling

The waste recycling helps you collect waste film or unused film.

Cutting station

The cutting station will help you cut the waste materials and then make it easier for you to put then in cartons.

10.What Are The Working Principles Of Blister Packaging Equipment?

The working principle of the blister packaging equipment is not complicated, but you need to understand it carefully.

Working principle of semi-automatic blister packaging equipment

Working principle of semi-automatic blister packaging equipment-sourced: celce

Preheating in advance

Start the machine and press the preheat button. The heating system of semi-automatic blister packaging equipment will start to heat up and preheat.

Placement

The semi-automatic blister packaging equipment requires you to manually place the blister shell that has been formed on the mold tray.

Filling

You need to manually fill the product such as capsules and tablets into the empty blister shell. Then cover it with a layer of film according to the position where it needs to be packaged.

Sealing

The filled blister shell will be pushed into the heated sealing system. The set temperature will seal the blister safely and firmly according to your needs.

Working principle of automatic blister packing equipment

AIPAK Working principle of automatic blister packing equipment

Blister forming

After the equipment is started, the roll film will be automatically fed into the blister machine. The thermoforming system will heat the blister system and soften the film. The heated film will be fed into a specific mold and blown into the shape and size you need by the heated air.

Product filling

The blown blister shell will be fed into the filling station. The automatic feeding and conveying system of the automatic blister packing equipment will accurately feed the product into the blister shell for subsequent packaging.

Heat sealing

When the product is completely filled into the blister shell, the top of blister packs will be placed with a layer of plastic film or paper material. The heat sealing system will heat seal the blister shell with the help of the positioning system. The heat sealing temperature is set at about 160 degrees Celsius for the best heat sealing effect.

Cutting and forming

The heat-sealed product blisters will be cut out separately by the cutting system to form independent blister packaging products. The unique positioning system of the automatic blister packing equipment will ensure the accuracy and neatness of your product cutting.

11.What Are The Considerations You Need To Know Before Choosing The Blister Packaging Equipment?

The purpose of understanding the blister packaging equipment is to be able to choose a suitable blister packaging equipment for your own business manufacturing and developing. Following the steps below:

Productivity

Productivity-sourced: ascendpkg

The productivity of the blister packaging equipment mainly determines your packaging quantity and output speed. It allows you to output the blister packaging you need efficiently and quickly.

Product specifications

Product specifications-sourced: ascendpkg

The product specifications of the blister packaging equipment mainly determine the size of your equipment and the floor space. This can determine the size of your blister packaging factory area.

Automation Level

Automation Level-sourced: celce

The level of product automation can determine your production efficiency and time issues. At the same time, blister packaging equipment with high productivity and high automation is suitable for the entire line, helping you achieve full automation.

Power and air pressure requirements

Power and air pressure requirements-sourced: smpnutra

Products with different powers have different requirements for air pressure. Some products with very strict requirements on air tightness and high sensitivity require your high air pressure function.

12.What Are The Troubleshooting Issues With Blister Packaging Equipment?

The Troubleshooting Issues With Blister Packaging Equipment-sourced: knowmax

If there are problems occur that you do not know how to deal with, follow this table and you can find your answers.

| Issues | Troubleshooting |

| Incomplete packaging

|

The thickness of the packaging film may have changed; |

| Improper sealing

|

It may cause the PVC seal to peel off;

Check whether the heating temperature and pressure have changed or are insufficient; |

| Missing product in the cavity

|

Check the filling station for jams or blockages;

Check whether the parts of the machine have malfunctioned or damaged; |

| Blister leakage

|

The blister packaging material used may have been damaged;

Replace new or complete blister packaging materials in time; |

Conclusion:

After reading through this complete buying guide, you may know that blister packaging equipment can meet all your needs whether for your tablets, capsules, or soft gels. As a leading manufacturer and supplier of the blister packaging equipment, AIPAK can offer you everything you need to improve your blister packaging solutions. Contact AIPAK now!

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine