Blister Cartoning Machine: The Complete Buying Guide In 2025

Although blister packaging is considered one of the cost-effective ways to safely enclose a range of products from pills to toys and eatables. However, it is important to care for additional packaging in the form of cartoning so the product will be safe against distortion. For this reason, Blister Cartoning Machine has been designed to carry out the task of packing blisters into cartons.

You may have queries about the machine features, working principles, and components etc., that's why we have come up with this informative review. You just need to understand each question thoroughly after which you will surely be able to operate it in the right way with simple maintenance. So, what are you waiting for? Take a start and read it thoroughly!

1.What Is A Blister Cartoning Machine?

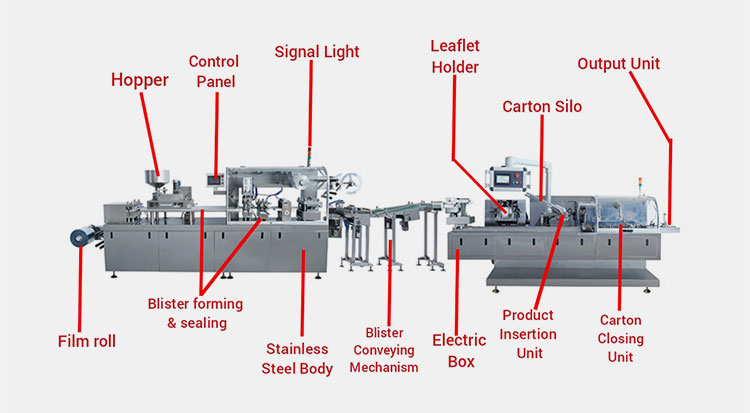

AIPAK BZX-120B Full-Automatic Medicine Plate Packing Box Production Line Machine

Blister cartoning machine is an automatic equipment designed to finish blister packs and then encase these blister packs in cartons for enhanced safety against distortion. It has durable structure with main body made up of 304 stainless steel along with control system, conveying mechanism, and packing tools.

It is capable to carton any product which is inside blister packs such as tablets, capsules, and hardware objects. The machine follow simple operational procedure for blister cartoning by forming cartons, supplying leaflets, and infusing blister packs inside cartons. The process is undertaken automatically by machine until operator intervene or fix timing gets completed.

2.Enumerate The Features Of A Blister Cartoning Machine?

In addition to smooth operation and fast packaging, the blister cartoning machine also comes with a list of useful features to enhance productivity and boost business success. Some of the important features of blister cartoning machine are penned in the following points:

Multifunctional

Blister cartoning steps- Picture Courtesy: Jornen Machinery

This machine has numerous carton handling systems to automatically carry and insert blister packs into cartons. It is comprised of multiple high-sensitivity sensors and guide systems for smooth and error-free placement and packaging.

High Production

Large number of blister cartons- Picture Courtesy: iStock

Depending upon the model, this device can process of minimum of 100 cartons that can go as high as 400 per minute. Thus, you can install it in your mass-scale packaging.

Flexibility

Blister cartons of various sizes & shapes- Picture Courtesy: Jornen Machinery

It comes with a wide range of feeder systems to handle a diverse array of cartons with multitudes of sizes and materials. You can easily process both paperboard and corrugated cartons using a blister cartoning machine.

Convenient Operation

It has user-friendly and effortless operation because of its interactive HMI and touchscreen. This component is used for inspecting real-time progress, log messages, and processing parameters.

High Accuracy

Precise blister cartoning process- Picture Courtesy: Jornen Machinery

This equipment mechanically identified missing blisters in cartons, leaflets with incorrect folding patterns, and flaws in cartons with its sophisticated sensors. So, it rejects faulty cartons without input from operators. Moreover, due to its leaflet insertion systems, you can precisely fold and place different types of product leaflets in cartons.

3.Explain The Working Principles Of A Blister Cartoning Machine?

The operation of a blister cartoning machine revolves around certain working principles which must be followed. These are explained below:

Machine Setting

First, you need to set the machine which include structural adjustment of various parts and components along with the parameters setting such as printing data, and cycle time duration etc.

Material Loading

Leaflets feeding in silo- Picture Courtesy: CVC Technologies

Prior to machine starting, it is necessary to load it with required material such as bulk of items in hopper, film roll, unformed boxes, leaflets and glue in case of hot melt glue sealing.

Blister Forming

Blister forming- Picture Courtesy: ascendpkg.com

The blister forming take place when film is unwinded from film roll. It is then turned into desired shape blister packs with the help of help and air pressure.

Blister Filling

Once blister packs are formed, they are moved ahead for filling. Precisely counted objects are sequentially placed in blisters.

Blister Sealing

Blister sealing- Picture Courtesy: accupackengineering.com

In this step, the filled blister packs are passed through through conveyor where aluminum foil is spread over blister packs. Similarly, the wrapped blister packs are sealed through the application of heat and pressure.

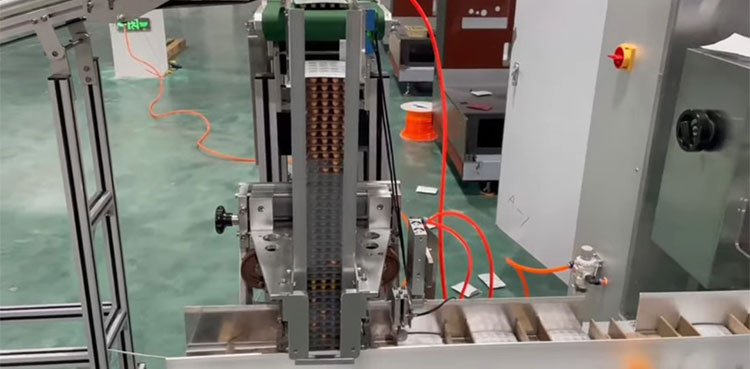

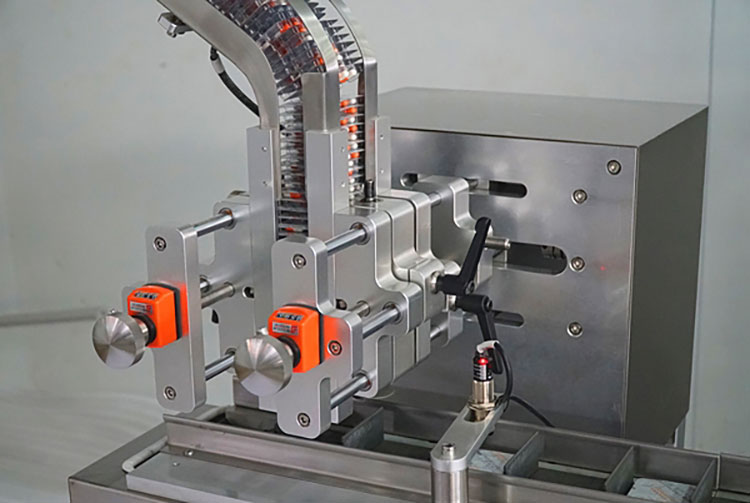

Blister Feeding

Blister feeding into machine- Picture Courtesy: wzscience.com

Once the setting and material loading of blister cartoning machine are done, you can start the operation. The initial step will be feeding of blisters. For this, you may feed the blister packs manually or integrate the machine for automatic feeding.

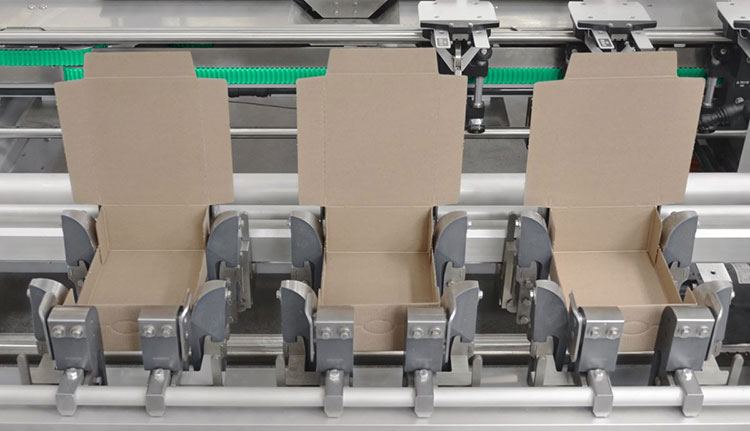

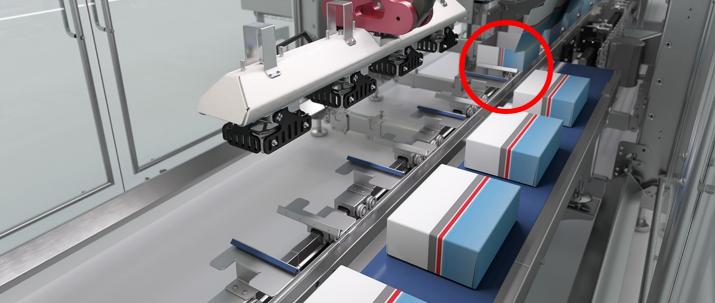

Carton Forming

Carton forming- Picture Courtesy: Syntegon

As long as the blister move ahead through conveyor, unformed cartons are sucked through the help of air and placed on conveyor belt. Similarly, box forming mechanism is activated through which the carton is opened and shaped.

Leaflet Folding

Leaflets folding- Picture Courtesy: Jornen Machinery

Moving forward, leaflet is drawn from silo towards the carton and folded to place inside the box. Each leaflet is provided to every passing box.

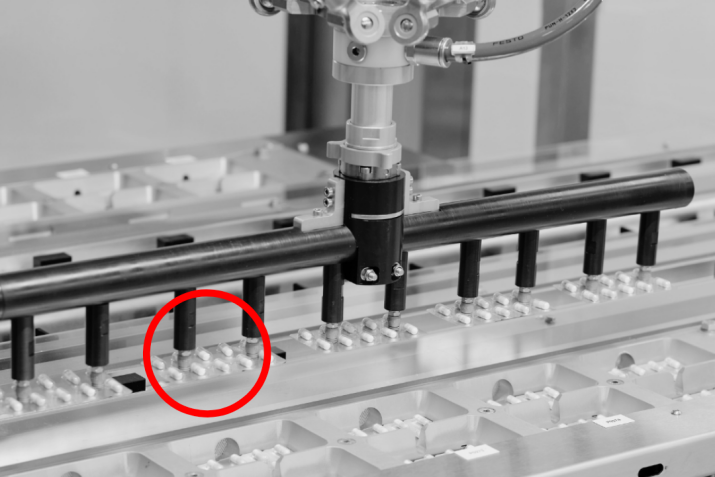

Blister Pushing into Carton

Blister pushing into cartons- Picture Courtesy: Jornen Machinery

Once leaflet is placed inside the box, blister is then pushed into the carton with the help of side tools. Before blister cartoning, they are counted by counting system in case multiple blisters are packed.

Printing and Embossing

Printing & embossing- Picture Courtesy: Jornen Machinery

This is another important step during blister cartoning process where manufacturing date, expiration date, and price is printed over box. Embossing of batch no is also done at this stage which is an optional step.

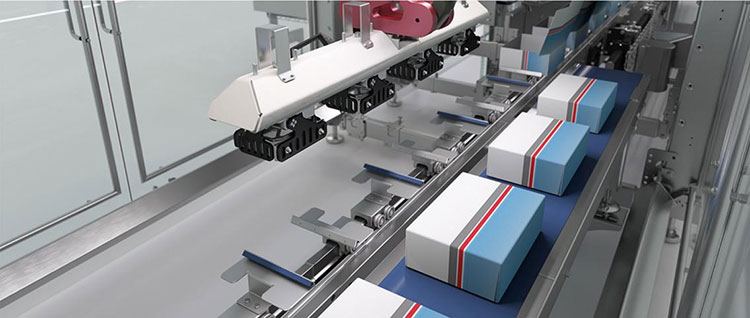

Carton Closing

Carton closing- Picture Courtesy: ROTZINGER Group

Now, the blister filled carton is closed by using tools which invert the flappers inward the carton. In case of glue sealing, hot melt glue is applied and spread over the flappers for tight sealing.

Carton Discharging

Blister cartons discharging- Picture Courtesy: wzscience.com

Finally, blister cartons are discharged out of the machine from another end and collected into a collection container.

4.Describe The Components Of A Blister Cartoning Machine?

Blister cartoning machine is composed of different parts which are described below:

Components of AIPAK WZH-120 Horizontal Boxes Packaging Cartoning Machine

Hopper

It is a stainless steel large size container where products are loaded before their packaging into blister packs.

Film Roll

Blister cartoning machine has a film roll which supply film for the formation of blisters. Along with film roll, there is another roll of aluminum foil.

Blister Forming & Sealing

It is the primary section of blister cartoning machine which blister packs are formed, supplied with items, and accurately sealed by the application of aluminum foil on upper side.

Leaflet Holder

Leaflet holder is a long narrow part of the machine which functions as a magazine for holding leaflets for blister cartoning. It supplies the instruction manuals for blister packa when they enter into machine through conveyor belt.

Control Panel

Blister cartoning machine has another significant component which is named as control panel. This control panel is a computer-like structure which has a digital touch screen display along with several knobs for switching and controlling the machine. Users can simply interact with it and regulate machines as desired by setting commands in it.

Carton Silo

The machine has a separate carton silo for storing unformed flat cartons. These cartons are loaded sequentially and picked up by an assembly for formation and blister packs infiltration.

Carton Closing Unit

The carton closing unit is another important part of the blister cartoning machine which performs the task of closing carton flaps. When blister filled cartons are moved via conveyor belt and they stop under carton closing station the tools of unit start folding the flappers to close the carton. In case of glue closing, hot melted glue is introduced on flaps for tight sealing.

Signal Light

Blister cartoning machine do have an alarm light which is also known as signal light. It is helpful to know the working condition of machine which is highlighted through multiple lights. In addition, red, green, and blue lights show emergency, smooth operation, and operator help respectively.

Blister Conveying Mechanism

Blister conveying mechanism is an individual unit integrated with blister cartoning machine through which blister packs are supplied for cartoning. This feeding of blister packs is done automatically.

Electric Box

It is an electric cabinet where bulk of electrical parts in the form of wires, fuses, and motors are located. It is a safety enclosure for encasing different heavy-duty parts.

Product Insertion Unit

As the title illustrates, this unit of the machine is used to carry out the function of inserting blister packs into cartons. In this step, instruction manuals are also attached with the blister packs.

Stainless Steel Body

The machine is made up of robust stainless-steel structure which has exceptional safety against environmental factors such as bacteria and corrosion build up. It is helpful in ensuring machine's stability throughout operation.

Output Unit

Output unit is the last section of machine which is also called discharge chute. The finished blister packs are removed from machine through this part.

5.What Are The Uses Of A Blister Cartoning Machine?

Blister cartoning machine can be used in different industries some of which are highlighted below:

Pharmaceutical Industry

Various tablets blister packs- Picture Courtesy: iStock

Blister cartoning machine is popularly used in pharmaceutical industry for the packaging of capsules and tablets blister packs. Apart from this, the machine is also used for ampoules and vails containing vaccines or injection water.

Food Industry

Various snack foods- Picture Courtesy: gracefoodpack.com

Most of the food products including sauces, spices, and confectionaries are now delivered in single serving blister packs. Therefore, many reputable suppliers used to deliver these blisters in cartons for enhanced protection for which a blister cartoning machine is suitable.

Cosmetic Industry

Various cosmetics- Picture Courtesy: fdli.org

Various cosmetics such as mascara, eyeliner, powder kits, lipgloss, and nails etc., are often packed in blisters which are further enclosed in paper boxes. This process of packaging is done by using a blister cartoning machine.

Dermatological Industry

Various dermatological products- Picture Courtesy: violethollow.com

Dermatological industry refers to the field where skin health related products are produced. These include injections and other medications for treating various skin disorders. In this way, different types of small products like vaccines, serums, and injections are packed in blister cartons for which this machine is used.

Hardware Industry

Hardware blister packs- Picture Courtesy: aapack.com

Blister cartoning is also adopted for the packaging of different types of hardware products such as toys, battery cells, USB, and home essentials. Hence, the use of blister cartoning machine is also relevant here.

6.How To Maintain A Blister Cartoning Machine?

Cleaning and maintaining a blister cartoning machine is crucial for its smooth functioning and long working life. Therefore, we have explained simple tips which you should follow on regular basis:

Operator maintaining blister cartoning machine- Picture Courtesy: richpacking020.com

Cleaning:Clean your machine everyday after the work is done. For this, it is good to disassemble the detachable parts like glue applicator. Similarly, you need to use a recommended cleaning agent to rove out all the accumulated debris, dirt, and particles left over various parts of machine. For other parts, you can use a damp cloth for wiping.

Adjustment:It involves structural adjustment and the modification of parameters. The former is important for stable operation, while as, the later is inevitable for machine operation and efficient working.

Lubrication:The machine has movable parts like conveyors and box forming mechanism. Such tools require lubrication for smooth running. So, make sure to timely remove out the old lubrication and put new one to avoid friction and parts wearing.

Parts Changeover:It is obvious that at any point, your blister cartoning machine may start malfunctioning due to parts damage. It is the right time to change the parts with new ones.

7.What Quality Standards Should A Blister Cartoning Machine Meet With?

As blister cartoning machine is meant to deal with variety of products including pharmaceutical, food, and beauty care products, it is necessary to adhere to certain quality standards. These include:

Icons of CE, ISO, & FDA- Picture Courtesy: sapheneia.com

International Organization for Standardization (ISO)

ISO is a non-governmental international body which provides guidelines to manufacturers regarding the safe production and processing of machines and goods. Thus, a blister cartoning machine should be certified by ISO.

Food and Drugs Administration (FDA)

FDA is USA agency particularly established for maintaining quality control in food and Drugs area. As the machine is also used in both fields, it must have FDA approval in form of certification.

Conformate European (CE)

For all the products which are meant to be manufactured or used in European Union countries, CE mark is obligatory. Therefore, if a blister cartoning machine is supposed to be exported to these states then the company must acquire CE mark by complying their quality standards.

Current Good Manufacturing Practices (cGMP)

Current Good Manufacturing Practices provide guidelines to ensure the quality of products. It helps in preventing contamination and reinforces quality practices.

8.Explain The Troubleshooting Of A Blister Cartoning Machine?

Are mechanical, electrical, and performance issues in your blister cartoning machine the source of worry for you? Are you tired of these problems? Are you continuously searching for solutions? Then, stop clicking and pay attention to the following points because we have detailed various issues with the blister cartoning machine and its solutions.

| i. Cartoning Misfeeding | ||

Cartoning Misfeeding Errors- Picture Courtesy: Korber Pharma |

Cause:

Carton magazine is not set and leveled accurately. Sometimes, the cartons are glued together. The vacuum pressure for feeding is not programmed properly and there is damage to the vacuum suction system. You have input the wrong settings for carton size |

Solution:

You should properly align and level the carton magazine before turning on the operation. You should check the carton sticking and separate them before loading. Also, adjust the vacuum pressure and replace old vacuum suction cups. Reprogram the carton size to match machine specifications. |

| ii. Errors in Blister Feeding | ||

Blister Feeding- Picture Courtesy: Tekpak Automation |

Cause:

In some cases, the blister guiding systems are not set properly. There is dust on the feeding system causing feed hindrances. Feeding sensors are damaged or erroneously calibrated. Blister packs have defects |

Solution:

Blister guidance system and alter the leveling of guide rails with conveyors. Cleaning of the feeding system is directly related to smoothness in blister pack feeding. Also, check and calibrate the settings and functioning of sensors for perfect blister defection. Lastly, there should be no imperfections in blister packs. So, separate the defective blister before feeding |

| iii. Leaflet Dispensing and Placement Flaws | ||

Leaflet Dispensing- Picture Courtesy: CVC Technologies |

Cause:

Presence of static particles on the leaflet. Improper alignment of leaflet feeding device. The leaflet paper is of poor quality. Unclean or damaged roller or suction component. |

Solution:

First, incorporate an anti-static device with the machine to avoid sticking of leaflets. Secondly, examine and properly position the leaflet feeder and guides. You should procure high-quality leaflet paper having the right thickness and coating. Suction cups or rollers for leaflet picking and dispensing should be clean and damage-free |

| iv. Faults in Carton Closing and Sealing | ||

Carton Closing- Picture Courtesy: ROTZINGER Group |

Cause:

A defective gluing system or clogged nozzles are one of the causes of carton sealing defects. The carton tucking mechanism is faulty. Carton materials are of substandard quality |

Solution:

You must inspect and clean the clogged nozzles. Also, the sealing and gluing temperature must be within the range of the specified limit mentioned in the machine manual. Always, check and align tucking arms or rollers for accurate carton sealing. You should examine carton material quality and thickness by conducting trial tests before actual processing |

9.Factors To Consider When Choosing A Blister Cartoning Machine?

When choosing a blister cartoning machine, it is important to consider several factors for making a sound purchase. These are as follows:

Machine Specifications

Specifications of blister cartoning machine- Picture Courtesy: Jornen Machinery

It is crucial to check the specifications of a blister cartoning machine as they vary from one type of machine to another. The common specifications include speed, production capacity, changeover time, and adaptability to support different sizes and formats of cartons.

Quality Compliance

Quality compliance icon- Picture Courtesy: kvalito.ch

The quality of machine also matters a lot. In this way, you need to check the machine's certifications which must include FDA, ISO, and GMP. Considering this factor can help you in your future safety of business processing due to the growing concern of quality control.

Supplier Reputation

Supplier icon- Picture Courtesy: trakti.com

Buying a blister cartoning machine means choosing a life long partner in form of supplier who can support you throughout your manufacturing. So, you have to be careful in examining the supplier reputation and experience.

Price

Price icon- Picture Courtesy: toplinestrategy.com

Blister cartoning machines have different prices which ask for an analysis of your budget and that of overall estimated cost of machine price along with maintenance and operation cost.

Conclusion

To wrap up this comprehensive buying guide about Blister Cartoning Machine we are glad to have delivered necessary information. We hope it has been useful in resolving your queries about the equipment. Besides, blister cartoning machine is a compact machine with simple operational procedure which is carried out automatically. It has diverse applications in fields such as pharmaceutical, food, and hardware industry. Moreover, it requires little maintenance and cleaning. So, with few formalities you can get lots of benefits. Then what are you waiting for! Just click on the link below and order your favorite blister cartoning machine now!

Don't forget to share this post!

Cartoner Related Posts

Cartoner Related Products

Cartoner Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours