AIPAK Semi Automatic Capsule Filling Machine

CGN-208D Semi Automatic Capsule Filling Machine

CGN208-D type capsule filling machine is a new efficient equipment based on DTJ-C model (old type) after research and development. Easier more intuitive and higher loading in capsule dropping, u-turning, vacuum separation in comparison with the old type. The new type of capsule orientating adopts columns pill positioning design, which shortens the time in the replacement of mould from the original 30 minutes to 5-8 minutes. This semi-auto capsule filler machine is one type of electricity and pneumatic combined control, PLC and touch screen control, automatic counting electronics, programmable controller and frequency conversion speed regulating device.

Filling Accuracy±3%

Main Body 304 Stainless Steel

Mold Replacement Convenient And Fast

Get A Free Quote Now

CGN-208D1 Semi Automatic Capsule Filling Machine

CGN-208D1 semi automatic capsule filling mahcne adopts programmable control system, touch panel operation, stepless transduction speed shift, and electronic automatic counter. It can automatically complete the action of position, separation, filling, locking, etc. The dosage is accurate, and the operation is very convenient. The overall machine is made of good quality stainless steel, and the machine is suitable for capsules which filled with powder and pellet.

GMP Standard

Can Fill 000#~ 5#Capsule

Easy Operation And Safe

Get A Free Quote Now

CGN-208D2 Semi Automatic Capsule Filling Machine

CGN-208D2 new semi-automatic Capsule Filling Machine is new medical packing machinery with novel structure and artistic molding. It adopts mini computer speed-adjusting equipment, and to be controlled by the electric and pneumatic, equips electron automatic counting device. It can respectively finish the different processes separately such as arrangement, separating, filling, locking and etc. Which reduce labor intensity, improve production efficiency, raise the accuracy of filling dosage. The machine meet with GMP standard.

Touch Color Screen Parameter Adjustable

Put In Accurately Perfect Fit

Complete Machine Parts One Year Warranty

Get A Free Quote Now

CGN-208D3 Semi Automatic Capsule Filling Machine

CGN-208D3 semi automatic capsule filling machine is suitable for filling capsules with sizes000,00, 0, 1, 2, 3,4#. This semi-auto capsule filler machine Is equipped with electric and air control devices and an automatic counting Device. The entire filling process is automatic, from packing the empty Capsule, separating the empty capsule body and cap, filling the filler into the Body, and covering the cap on the filled body.

Low Requirement On The Capsule

High Probability

Compact Structure And Easy To Operate And Maintain

Get A Free Quote Now

CGN-208S Semi Automatic Capsule Filling Machine

CGN-208S is a new type of high-speed semi-automatic capsule filling machine independently developed by our company. The speed can reach 40,000 tablets/hour. This series of capsule filling machines can fill powder, granules or small tablets into hard hollow capsules, which can be used for 000#, 00#, 0#, 1#, 2#, 3#, 4#, 5# Mechanism for filling of standard capsules. The structure is novel, the bladder structure has been transformed to create efficiency, save labor, improve work efficiency, beautiful shape, in line with GMP production requirements, is the first choice for the majority of pharmaceutical manufacturers, health product manufacturers, hospitals for medium-volume production or laboratory use product.

Double Loading System, Up To 50,000 Pcs / Hour

Closing System Is More Efficient, Safety, And Smoothly

Capsule Trays Are Hard Anodized

Get A Free Quote Now

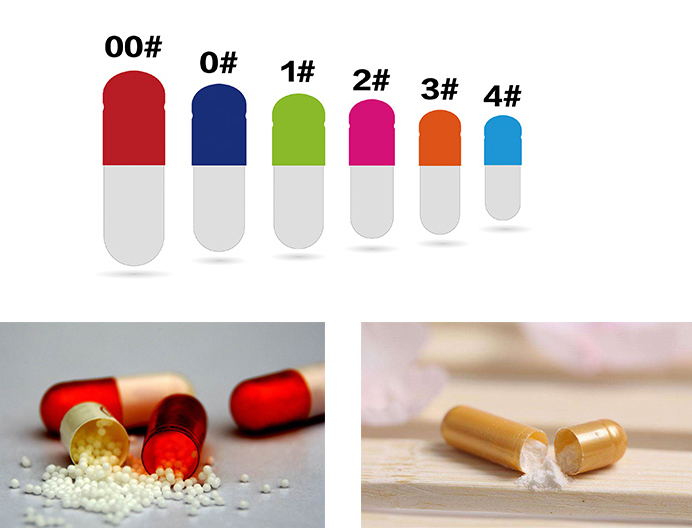

AIPAK semi automatic capsule filling machine is an integrated machine which is suitable for the medium, small pharmaceutical factory and hospital labs. It can be used for filling 000#, 00#, 0#, 1#, 2#, 3#, 4# and 5# standard capsules.All AIPAK semi aotomatic capsule filling machine adopt programmable control system, touch panel operation, step-less transudation speed shift, and electronic counter. The semi-auto capsule filling machine can complete the actions of position, separation, filling and locking.

The semi automatic capsule filling machine adjusts the speed by frequency conversion, equipped with electirc auto counting device to complete the placing, separating, filling and locking for capsule respectively.So it can decrease the working intensity and increase the working efficiency, this kind of machines meet the requirement of pharmaceutical sanitary, it is suitable for filling powder and granular material in pharmacy and health food industry into capsule.

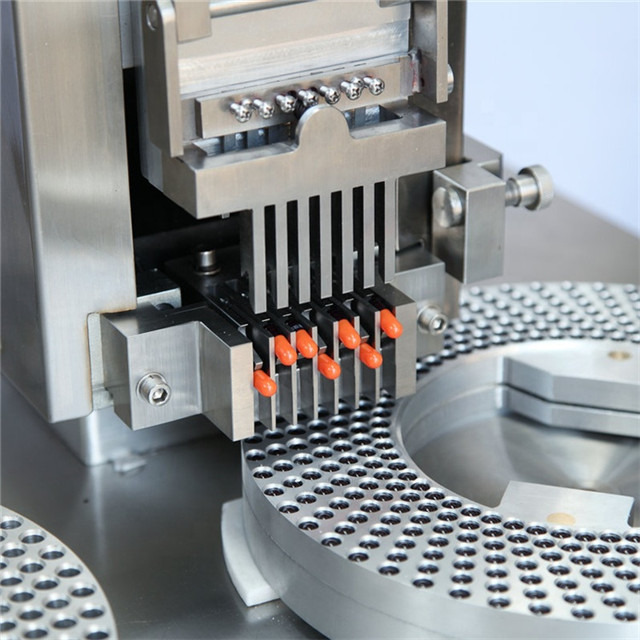

Empty capsule loading

Electronic Box

Powder filling station

Locking Station

The semi automatic capsule filling machine working principle is when the empty capsules are loaded in the capsule hopper,and the to be filled powder loaded into the other separated hopper.It is a corkscrew driven hopper,which will allow constant filling of every empty capsules.Then your operator will have to use the vacuum sucker to indivdually sort out and fill the empty capsules into the loading rings.Loading rings of the semi-auto capsule filler can be changed from #00 to#5 as per your various requirements.Then your operator will have to use the vacuum to separate the capsules.

Once your capsules are separated,the loading rings are pulled apart to release just the bottom section.The bottom section is then placed into the filling part of the machine.Once the loading ring has been placed into this section of the semi-auto capsule filler,your operator can switch on the filling.This causes the filler to slide across onto the capsules,and the capsules to rotate beneath it.The corkscrew then evenly forces the powder down into the capsules.This step ensures each capsule can be the same size and filling weight.The two loading rings are then placed back together and placed into the sealing section of the semi automatic capsule filling machine.Once they are aligned,your operator will have to close the guard and use air pressure to seal the capsules.The capsules are then can be released from the loading ring.

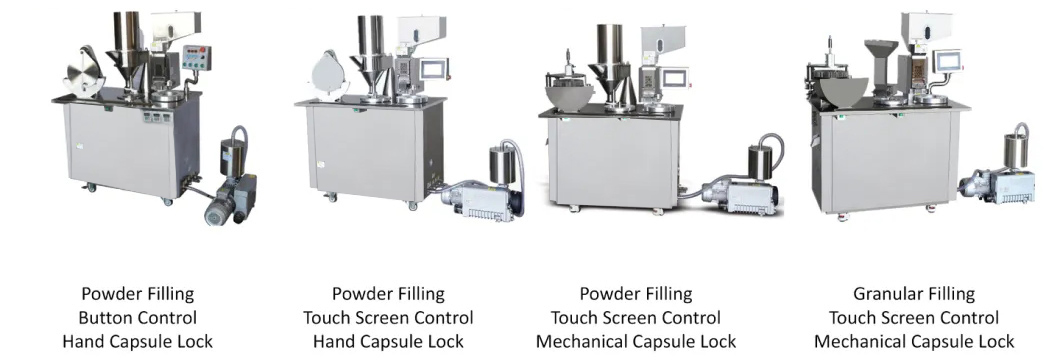

Different Model Introduction

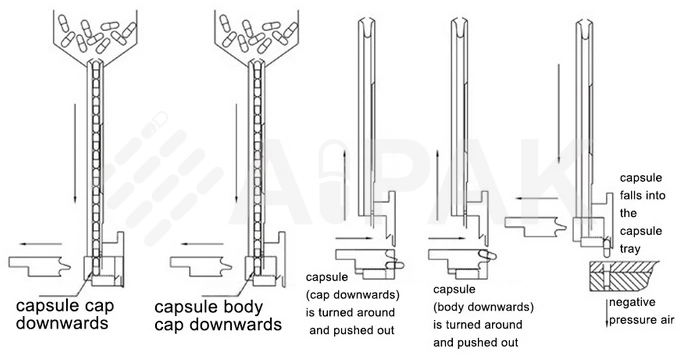

Capsule Loading Principle Diagram

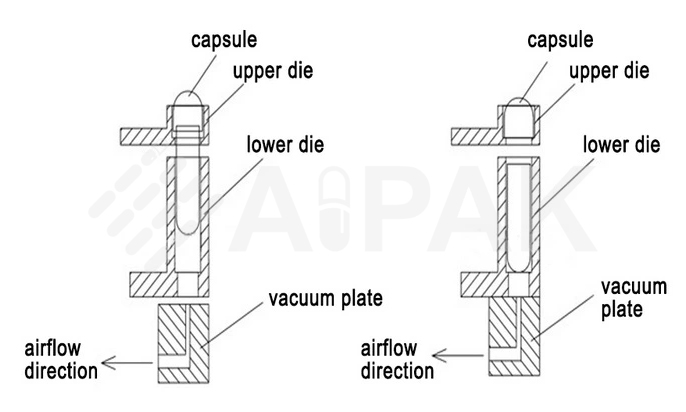

Capsule Separation Schematic

Features Of AIPAK Semi Automatic Capsule Filling Machine

Matching different size formats to fill 000#~4#capsule.

One size capsule matched one set format.

It can finish the whole filling capsule process, adjusted the capsule of cap and bottom, open the cap and bottom, filling powder, get rid of unqualified capsules, close the capsule, finished capsule.

It can finish the whole filling capsule process, adjusted the capsule of cap and bottom, open the cap and bottom, filling powder, get rid of unqualified capsules, close the capsule, finished capsule.

Satisfied GMP standard, the powder will not be pollution, save powder materials than semi automatic capsule filling machine. Easy to be clean;capsule filling machine 000.

Low wear and tear. The structure is new, improved design.

Can filling all kinds of Chinese and foreign medicine powder, and granules.

Frequency control, the operation is safety and simply.

It is suitable for filling powder, granules, pellets, tablets material in pharmacy and healthy food industry.

The Semi-automatic Capsule Filling Machine has independent empty capsule feeding.

station,powder feeding station and capsule closing station.

The machine adopt variable speed control,the operation is very easy.

The machine body and working table adopt S.S.304 material, meet the requirements of GMP.

The whole machine adopts programmable control system, touch screen panel operation, stepless frequency conversion debugging and pneumatic joint control.

In the design of the equipment, the double head semi automatic capsule filling machine is adopted. Compared with the old semi-automatic capsule filling machine, the speed, mold replacement, filling degree and maintenance of the double head automatic capsule filling machine have made obvious progress. The equipment has become more rapid, convenient, simple and stable. In the aspect of capsule locking, we use pneumatic control and automatic capsule locking to save labor time.

In terms of man-machine, our company has installed a safety door device in the bag pulling station. When the safety door is not closed, the equipment is in a static state and cannot run. In the powder filling station, a visual window is added to observe the powder loading degree. A barrier plate is installed on the lock pocket position to avoid accidents when the lock pocket is turned over. The right side of the equipment is equipped with a capsule tray rack, which is convenient for application.

The fuselage and worktable are made of stainless steel to prevent corrosion and oxidation.

The equipment can be used to fill different types of capsules, which can be used to fill hard capsules of medicines and health care products such as powders, granules and pellets.

Technical Specification Of AIPAK Semi Automatic Capsule Filling Machine

| Model | CGN208-D | CGN208-D1 | CGN208-D2 | CGN208-D3 | CGN208-DS |

| Productivity | 20,000-25,000 capsules/h | 20,000-25,000 capsules/h | 20,000-25,000 capsules/h | 25000-25000Pcs/hour | 38000-43 000capsules/h |

| Applicable capsules | #000/00/0/1/2/3/4/5 | ||||

| Filled medicine type | Not adhensive or wet powders, and small granules | ||||

| Total power | 4.0KW | 4.0KW | 4.0KW | 4.0KW | 2.12kw |

| Air pressure | 0.03m 3 /min, 0.7MPa | 0.03m 3 /min, 0.7MPa | 0.03m 3 /min, 0.7MPa | 0.03m 3 /min, 0.7MPa | 0.03m 3 /min, 0.7MPa |

| Vacuum pump | Evacuating rate, 40m 3 /h | Evacuating rate, 40m 3 /h | Evacuating rate, 40m 3 /h | Evacuating rate, 40m 3 /h | Evacuating rate, 40m 3 /h |

| Dimension(L*W*H) | 1500*780*1800mm | 1500*780*1800mm | 1500*780*1800mm | 1140×700×1600 mm | 1140×700×1600 mm |

| Weight | 380KG | 380KG | 380KG | 580Kg | 500kg |

| Warranty | 1 year | 1 year | 1 year | 1 year | 1 year |

AIPAK Semi Automatic Capsule Filling Machine Videos

AIPAK Semi Automatic Capsule Filling Machine Buyer’s Guide

Semi-Automatic Capsule Filling Machine: The Complete Buying Guide in 2024

Between manual filling machine and automatic filling machine there is a machine called semi automatic capsule filling machine.

A semi automatic capsule filling machine uses manual labor force as well as automatic function for filling of the capsule. Today, this machine is the need of every booming business in the world.

Today,I am going to use this article to explain why these machines are mandatory in your capsule filling company.

Let’s dig more in details from the machines information to the working as well as for applications.

1.What is the Global Forecast of the Capsule Filling Machine?

The Capsule Filling Machines Market represented 403 million dollars in 2019 and according to this, it is going to reach 547 million dollars by 2027 developing at a compound annual growth rate of 3.9% during this time. but as an expert, I think it is going to boost by 2027.

As you know this machine is continuously advancing every year there are some of the best technologies of this time in the Capsule filling machine and consumption of capsules is growing so because of these reasons the market of this machine is growing so fast.

There are so many features in the capsule filling machine. You can use any size of the capsule in this machine and there are so many options in the filling material like you can use liquid, solid material, any semi-solid material, or powder. It is not wrong to say you can fill any material in the capsules with this machine.

Hybrid capsule filling machines are designed differently than other machines. There are so many other features present in this machine, like weight inspection and visual inspection.

In the light of facts, you should know that hybrid capsule filling machine to grow at this time. In the coming years, the demand for hybrid capsule filling machines is going to increase. As of now, there is a high demand for this machine in America.

2.What is COVID-19 Impact on Capsule Filling Machine Market?

Since the COVID-19 infection started in 2019, the WHO announced a general wellbeing crisis. This disease has spread to more than 100 nations and caused tremendous misfortunes of lives the world over.

Particularly the worldwide assembling, the travel industry and monetary business sectors have been hit hard. The descending tension on the world economy that once gave indications of recuperation in the past period has expanded once more.

The start of the pandemic has added hazard variables to the all-around development of the world economy.

Numerous worldwide associations have called attention to the fact that the world economy is in the most extreme time frame since the monetary emergency.

Capsule filling machine market is deeply affected by this pandemic because all the sources of import and export are closed, enormous amounts of laborers remaining at home and all the global markets are closed.

The negative worldwide effects of the COVID-19 are now there, altogether influencing the Capsule Filling Machine market in 2021.

3.Is the Future of the Capsule Filling Machine Robotic?

The answer to this question is very big yes! The future of capsule filling machines is robotics. As the capsule filling machine is advancing every time there is new advanced technology in this machine.

Not only capsule filling machines, but the future of all machines is also robotics.

Using robotics machines there is zero chance of the error, robotic capsule filler machines are multi-reason it very well and may be utilized for both medication filling and gadget filling too.

The fill2weight innovation is incredibly adaptable and it tends to be utilized for a wide scope of powders.

Robotic Capsule Filler is a rapid filling and effortlessly scaled for business manufacture.

Easy to start with one spot then onto the next like from the tidy up space to the lab room. Infinitely factor portion weight is acknowledged without change of tool.

4.What is a Semi Automatic Capsule Filling Machine?

AIPAK Semi-automatic capsule filling machine

Semi Automatic Capsule Filling Machine is used for filling the capsules. It is considered at a higher level when it is compared to a manual capsule filler. It is not fully automatic, but it is very accurate in filling the material in the capsules.

Semi-automatic capsule fillers consist of a four-speed drill which permits you to fill different materials in the capsules. It can fill up to forty thousand capsules per hour.

Semi-automatic capsule filler machine has an automated capsule filling system to make sure it is fast, safe, and easy discharging of filled capsules.

5.What are the Pros/Advantages of the Semi Automatic Capsule Filling Machine?

These are the advantages of the Semi-automatic capsule filler machine.

Accuracy

It is very accurate in filling the dosage in the capsules and it is very precise in how much material you want to put in the capsules. You just must set the weight through the plc control panel, and it will put the exact same amount of material in the capsules.

Easy to use

A semi-automatic capsule filling machine is very easy to operate because it has a digital control panel where you can control anything with just the touch of the finger like you can control the production of the machine and many more.

Although it is not fully automatic it is designed that way that any man with the basic knowledge of the machine can easily operate it. There is no qualification required to use this machine.

Production rate is high

The production rate of this machine is higher than the manual capsule filler. The production rate depends on many things like how many holes in the many and which size of capsules is being used.

Semi-automatic capsule filling machine has many types which all vary in the production rate.

Advanced control panel

Parts of AIPAK semi-automatic capsule filling machine

It has a Plc control panel from which you can control any electrical and mechanical equipment of the machine. When you are using this machine there is very less chance of any error.

Machines are Safe

It is safe from the electric shock because all the electric part of this machine is covered, and these covers have danger signs on them.

You cannot open that covered part of the machine when it is in the working mode.

It is also safe from dust because all the parts of the machine are covered that way so that no dust particles can enter these parts and it also has the automatic vacuum cleaning system. It is also safe from the corrosion.

Reduce the labor cost

Semi-automatic capsule filling machines reduce the labor cost. Only one staff member is required to operate the machine.

Reliable and efficient

It is reliable and efficient because it is made according to the quality standard of cGMP and it is CE compliant. These quality standards make sure it is reliable, precise, and safe. It is very easy to maintain.

Low noise and size

Semi automatic capsule filling machines have very less noise and they have very small size, so it is easy to adjust this machine anywhere. Its power consumption is also very low.

6.What are the Cons/Disadvantages of Semi-Automatic Capsule Filling Machine?

These are the Cons of semi-automatic capsule filling machine.

Labor always required

There is always one staff required to use this machine but in the automatic capsule fillers there is no staff required to operate it. There is always one man near the machine who understands the machine and knows how to use it.

Production capacity

The production capacity is of the machine is low when we compare it to the automatic capsule filling machine.

7.What are the most important components of Semi-Automatic Capsule Filling Machine?

These are the major parts of a semi-automatic capsule filling machine.

Product Hopper

Product Hopper

Product hoppers contain the product like powder, granules, or any other lubricant you want to put in the capsules. Size of the product hopper varies with the different models of the machine. Stainless steel is used to produce product hoppers. It is also slightly movable.

PLC Control Panel

Plc control panel

t is the most important part of machine. You easily control anything on this machine from the control panel like how much product you want to put in the capsule and all the other parts of the machine.

Powder filling auger system

It is the unit which is used to fill the empty cases with the product. Every machine has a different amount of filling auger, it depends on the type of the machine.

Pneumatic System

This system is used to push the material into the capsules that are empty through the compressed air.

Loading system of capsule fillers

This system is used to fill the capsule in the holes. It also makes sure that no holes are empty, and all the capsules are precisely positioned in the tray.

Capsule filling table

It is the table where material goes into the empty cases. The speed of the capsule filling table varies.

Electric system

It is used to deliver the power to the machine. If there is any problem with the electric unit, the machine stops working. It is the part which keeps the machine in the working state.

Machine body

It is the major component of a machine, it is the part which holds all the components together. It is the steel body which wraps all the parts of the machine. It must be strong so it should bear all the vibratory forces during the process.

Capsule body tray

It is component of the machine which has two sections. It is use to split the capsules and make the filling process easy.

Rectifier

It is the part of the machine which is used to keep the capsules in the appropriate position for the filling.

Capsule opening and closing unit

It is used to open and close the capsules. It makes this process very easy. It consists of a peg ring and chute.

8.What is Semi-Automatic Capsule Filling Machine Working Principle?

Here is the working of semi-automatic fillers

The working of a semi-automatic capsule filling machine is basic and very easy. As the name shows, it includes both automatic and manual cycles.

After the machine is completely set and arranged, run some tests to make sure that the machine is fine.

In the first phase fill the material and the empty capsules in their own containers the quantity of capsules and quantity of material will rely upon the capacity of the machine.

You can set all your requirements on the PLC control panel like how much material you want to put on the capsule.

In the second phase the unfilled capsules will start moving from the container and go to the round capsules plate.

This plate has two parts. one part of the plate holds the body while the other part of the plate holds the covers.

you must separate the body and covers by yourself. After separating body and caps unfilled body of capsules are empty and ready to be filled

Keep in mind, that in the filling of capsules the tray and capsules will be moving in the round movement. This makes the filling of the case are more proficient and controls the wasting of material.

In the third phase the machine will arrange the capsules body in the tray and in the correct place for filling.

The plate starts the roundabout movement, the machine will start the filling cycle.

The dosing plate of the machine will precisely control the speed and the filling cycle. When it will complete the filling process, it will return to the first position.

In the last phase take the covered plate and put it over the body plate. When the two plates are in position, cautiously press to bolt the cases. With the assistance of a pressure, it will bolt the capsules. From that point, filled capsules are ready to deliver to its next unit. You would then be able to take the filled capsules to quality investigation, stamping and packaging.

9.Which Industries use Semi-Automatic Capsule Filling Machine?

Capsules and tablets

Semi-automatic capsule filling machine is majorly used in these industries.

- Pharmaceutical industry

- Dietary supplements manufacturer

- herbal medicine manufacturers

It is used in the drugs industry for filling different materials in the capsules. Many local manufacturers and drug stores also use this machine.

Dietary supplements and herbal medicine manufacturers also use the semi-automatic capsule filling machine. It is used locally because it has very small size and it can be fit anywhere.

The main purpose of industrial usage of this machine is because it can fill all sizes of capsules.

10.What should you look for when buying a Semi-Automatic Capsule Filling Machine?

Whenever you are looking to buy a semi-automatic capsule filling machine you must consider these things

Model of the machine

AIPAK CGN-208D semi-automatic capsule filling machine

You should always know what type of machine you want, and you always look for that model which serves your purpose accurately.

you should go for a legitimate brand of filling machine. This machine may be more costly than the local manufacturer, but you will be saved from the pressure of failure and fixes and this is probably going to get more time with machine.

Production rate of the machine

Whenever you are buying a capsule filling machine you should know how much production you want and what are your requirements. You must get the machine which suits your needs. For medium creation, this machine is best.

Quality standards

You must go for that machine which is made according to the quality standard of Cgmp and have a CE mark on it and have international organization standardization (ISO) certification. It is to make sure that the machine is accurate and has good quality.

Technology advancement

You should always look for that machine which is according to the technology of recent times and always look for the best technology.

There must be an option of advancement in the machine so you can upgrade it any time. If you want to increase the production rate so you can easily do it.

Integration with other equipment

For completing the process there is always a need for other equipment like packaging machines and marking machines. There should always be an option for connecting the hardware to the machine. It should always support other equipment.

11.How do you Compare Manual Capsule Filling Machine with Semi-Automatic Capsule Filling Machine?

Manual capsule filler-Photo credits:indiamart

These are the comparison between manual and semi-automatic capsule filling machine.

| Manual capsule filler | Semi automatic capsule filling machine |

| · The production capacity of a manual capsule filling machine is less than the semi-automatic capsule filling machine.

· When you are using this machine, you must do everything manually. · You always need a professional staff to operate this machine · It is slow and not as efficient as a semi-automatic capsule filling machine. · It is only used by drug stores and local drug manufacturer. · It can fill up to eight thousand capsules per hour. |

.The production capacity of semi-automatic capsule filling machines is high than the manual capsule filler machine.

· When you are using a semi-automatic filling machine you just have some task manually. ·You just need one staff with the basic knowledge of the machine to operate this machine. · It is fast and efficient than the manual capsule filling machine. · It is used by the local drug stores and by the small industries. · It can fill up to forty thousansd capsules per hour. |

12.How do you Compare Semi-Automatic Capsule Filling Machine with Automatic Capsule Filling Machine?

AIPAK Automatic capsule filling machine

These are comparison semi automatic and automatic capsule filler

| Semi Automatic Capsule Filling Machine | Automatic Capsule Filler Machine |

| · It is only suitable for the filling of hard capsules

· It is a combination of both automatic and manual filling machine there is always one staff required to operate it. · It is fast and accurate but not like an automatic capsule filling machine. · The production rate and capacity of semi-automatic capsule filling machines is less than the automatic capsule filling machine. · It is mainly used by the local drug manufacturer and small industries. · The size of this machine is small and very less space to use it. · It is suitable to produce the small batch of capsules |

· It is suitable for the filling both hard and soft capsules

· It is an automatic machine and no staff required to operate it. · Automatic filling machine is very fast, accurate and efficient. · The production rate and capacity of automatic capsule filling is higher than the semi-automatic machine. · It is used by the big industry like the pharmaceutical industry. · The size of the machine is very large, and a large area is needed to use it. · It is suitable to produce the large batch of capsules |

13.How can you Use Semi-Automatic Capsule Filling Machine?

It is very easy to use the semi-automatic capsule filling machine, you will easily understand how to use a semi-automatic capsule filling machine.

These are the following steps that you must follow

Step 1

press the power button to turn on the power of the machine. this button should be of green color.

Step 2

Gradually change the "vibration strength change handle" and move it in the clockwise direction.

As of now, the completing plate, which is associated with the "vibration upheld", begins to vibrate. Contact the completing plate with your hand and change the vibration strength as per your desire.

Step 3

Put the capsule shell into the "powder-filled case shell completing circle". Put the capsule cap into the capsule cap completing tray.

The completing plate is made of glass tray, on which there are numerous roundabout holes.

As of now, the capsule shell of the working stage plate moves steadily and gradually, with the goal that it can enter the opening of the stage plate individually.

Step 4

In around 30 seconds, the powder-filled container shell and case cap fall into the circular opening with the initial looking up.

Step 5

On a level plane hold the associating plate of powder stacked container shell, push it in the lower some portion of the completing plate, the powder stacked case shell in the completing plate will fall into the roundabout opening of the interfacing plate. And afterwards take out the associating plate. Similarly, take out the case cap with the case cap interfacing plate.

Step 6

A hopper which is loaded up with powder, and the associating plate of powder-filled case shell can be set in the powder square plate evenly. At that point cover the plexiglass outline coordinated arbitrarily on the powder filling container interfacing plate, put the powder into the casing with a little auger, and fill the powder with a scratching on the edge of the body.

Step 7

At the end take the caps of the capsule and make the opening of the caps facing each other and join the plate of caps and plates of body that is filled with the powder and pull down the pressing rod with the full force to lock the cap and body of the capsules and then the process is complete.

14.What Type of Material can you Fill with Semi-Automatic Capsule Filling Machine?

Dry powder

Semi-automatic capsule filling machine is suitable for all sizes of capsules for 0 to 5. You can fill these materials in capsules using this machine.

- Dry powder

- Granules

- Pellets

You can easily fill this material in the capsule using this machine.

15.What are the Technical Specifications of Semi-Automatic Capsule Filling Machine?

Everyone knows that every machine has some specifications. The specifications of the Semi-Automatic Capsule filling machines are as follows:

Output

Sizes

The Semi-Automatic Capsule machine has three different sizes like 000, 00L, 00, 0L, 0, 1, 2, 3, 4, 5.

Electric Supply

3Phase Energy Meter-Photo credit: vertex.pk

The electricity supply should be 380 V, 3 phases, 50 Hz.

So, these are the electricity supply specifications for the Semi-Automatic Capsule Filling Machine.

Working Capacity

The Semi-Automatic Capsule Filling Machine produces about 25 thousand (25000) capsules per hour.

Required Vacuum Pump

Vacuum Pump

The vacuum required for the Capsule Filling Machine is 40 m^3 per hour.

Compressed Air

The compressed air used in the Semi-Automatic Capsule Filling Machine is 0.03m^3 0.7 Mpa.

Changing Time of Mold

The machine changes its mold in almost 5 to 8 minutes.

Dimensions

The dimensions of the Capsule Filling machines are 1140*700*1600 mm.

Weight of the Machine

The total weight of the machine is almost 580Kg.

Warranty

The warranty for the Semi-Automatic Capsule filling machine given by the company is 1 year.

Filled Medicine Type

The medicine filled by the machine is not adhesive or wet powders and granules.

16.How do you maintain when using Semi-Automatic Capsule Filling Machine?

For efficient results you must maintain the semi-automatic capsule counting machine.

Since a semi-automatic capsule counting machine is a vibrating machine; you need to take following measures to maintain the machine:

- You need to check the screws of all parts of the machine frequently. If it is losing you should tighten it in time to prevent any damage or fault.

- The medicine board should be placed either horizontally or vertically to avoid deformation and or disfiguration.

- To ensure safety, the machine must be grounded. The power must be cut off after work.

- After ending the work, you should clean the machine and the mold hole from any residual drugs. You should avoid washing the machine with water.

17.How much Does Semi-Automatic Capsule Filling Machine Cost?

The cost of Semi-Automatic Capsule Filling machines are in Dollars.

Also, the cost of the Capsule Filling Machine varies from machine to machine.

The cost of the Manual Capsule filling is much cheaper than other two. And also, the production rate is very less as compared to the Semi-Automatic and Fully Automatic Machines.

Moreover, the Semi-Automatic Capsule Filling Machine is little bit expensive than the Manual Capsule Filling Machine. And the production rate is also higher as its speed is higher than the Manual one.

In the addition, there is also a bit expensive Capsule Filling Machine which is Fully Automatic Capsule Filling Machine. It has very high production rate comparative to the other two Capsule Filling Machines. It works with at great high speed which is not matchable for its competitors.

18.Which Auxiliary Equipment do you need in Semi Capsule Filling Machine?

There are many types of auxiliary equipment used in the Semi-Automatic Capsule Filling Machine. The equipment are as follows:

Automatic Capsule Feeder

The Automatic Capsule Feeder is an important equipment of the Capsule Filling Machine. This is very perfect for the production at medium and large-scale enterprises.

This apparatus is very easy to use. It is also very handy at saving time and also the cost of the labor.

The Capsule feeder is very helpful in occupying little space and also it gives you the production at a very higher rate with the great regulation.

It is also very cheap in price and gives you a great output of that small investment on the Automatic Capsule Feeder.

This apparatus is not complicated and it can be controlled easily by a semi-experienced person. So, it does not require a very trained and skillful person to work with this apparatus and to pay him extra money for that equipment.

Capsule Sorter

This equipment plays a very important role during the capsule filling in the Semi-Automatic Capsule Filling Machine.

The capsule sorter works for the betterment of capsule sizes. It eradicates oppositely mutilated capsules from the part and permits the ideal size capsules to go through.

So, it is a part of the Semi-Automatic Capsule Filling Machine and guarantees only the perfect sized and proportionate capsules.

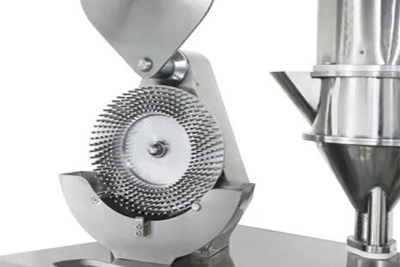

Capsule Polisher

The capsule polisher is another major equipment of the Semi-Automatic Capsule Filling Machine. It is very helpful in the betterment of the polishing quality of the capsules.

The Capsule Polisher utilizes the turning brush guideline to clean the capsules on constant premise.

Capsules are taken care of into the polishing chamber where a pivoting twisting brush eliminates the powder particles staying from the external surface of cases.

The process of capsule polishing is fully automatic and does not need any human effort to work or to polish the capsules. It is done by the pump which sips and moves on the capsule which is filled with some ingredient.

Rotating brushes in the machine do the cleaning of the capsule. So these brushes remove the dust particles from the capsule.

Printing Machine

This is another major apparatus of the Capsule Filling Machine. This equipment helps in improving the printing quality of the capsule.

So, the capsule is being printed in this portion of the machine. This is not a very complicated apparatus. It is not rocket science to understand it.

It does not have any special system to activate. So, it can be done easily by the machine. No extra human effort is required for this equipment to work.

19.Is Semi-Automatic Capsule Filling Machine is a Profitable Investment?

Yes of course, the Semi-Automatic Capsule Filling Machine is very beneficial in terms of profit. If we invest in the Capsule Filling Machine then it will help us in many ways.

Efficient Production

A large quantity of capsules can be made by the Capsule Filling Machine in very less time as compared to the manual Capsule Filling Machine. It manufactures almost 45,000 capsules in one hour which is a very big amount.

So, it is also a less time consuming in contrast with other machines that are being handled manually.

Range of Capsule Filling Machine

The range of the Semi-Automatic Capsule filling machine is very vast as it fills a large number of different container sizes that are 00, 0, 1 to 5.

So, in this way it is very profitable as it saves the cost of the producer and creates more capsules in various sizes.

Saves Work Costs

This machine is very easy to use and it also required a smaller number of workers to work. A very small staff of 2 or 3 workers can handle this machine effortlessly because this machine works smoothly without any interruption.

Low Maintenance Cost

Everyone knows that this Semi-Automatic Capsule Filling Machine requires very little maintenance which is a very big profit in terms of cost.

Vast Lifetime

The Semi-Automatic Capsule Filling machine is also very profitable as it has a very long lifespan as compared to the other machines. So, all the parts of the machine are very high quality and don’t undergo wear and tear.

Assurance of Security

The Capsule Filling Machine comes with a warranty. So, if anything happens to the product or some part of the machine is damaged and can be repairable due to the warranty of the Machine. You don’t have to worry about the damage cost.

Packaging Machine

AIPAK Capsule Packaging Machine

The last equipment of the Semi-Automatic Capsule Filling Machine is the Capsule Packaging System. This part of the machine provides help in the wrapping of the capsule.

It is also an automatic process. It can be done without any labor. So, no human effort is needed to activate this process.

Due to its automatic process, it is very profitable in saving your labor cost. This is the big advantage of this part of the Capsule Filling Machine.

20.How do you Troubleshoot Semi-Automatic Capsule Filling Machine?

The worker can face some problems regarding Semi-Automatic Capsule Filling Machine. These are not very big problems. These problems can be solved easily.

So, the problems are:

Problem in Capsule Entering

Sometimes machines face the problem of entering the capsule. This problem can be solved by some technical work.

So, this can be solved by setting the plate of the machine properly before using it. Then the capsule flow can not be stopped in the machine.

Also check the magazine before using it because it will not work properly if the problem occurs in the magazine.

And the last but not the least use the machine at high speed because it is a perfect state of the machine.

Damaged Capsule

This problem is very common and occurs during the filling of the capsule. It is because your rectifier block does not align accurately.

The solution to this problem is very simple. You have to only align the rectifier at its best position to avoid this problem.

Damaged Capsule

Transfer Problem

In this problem the cap capsule is being lost during transferring. It is due to poor alignment of cap and also due to high vacuum inside the machine.

So, to solve this problem you have to use medium vacuum instead of high vacuum. It can be done by the help of throttle.

Problem of Separating Capsule

This problem is very common in the capsule filling. It occurs due to the small leakage in the filters of the machine. And also, it may be due to the extended spring loss.

So, this may be covered by removing bad spring extensions. And the leakage can be solved by the decreasing of the vacuum slowly with time.

Variation Disturbance

The variation problem is caused by the bad maintenance of bush and also due to the gap given in between the dosing disc and supporting pad.

This problem can be solved by filling the gap between the dosing disc and supporting pad. And the good maintenance of bush can solve the variation problem that occurs in the Semi-Automatic Capsule Filling Machine during the filling process.

21.What Points to consider when buying a Semi-Automatic Capsule Filling Machine?

AIPAK CGN-208D1 Semi-automatic capsule filling machine

When you are buying a Semi-Automatic Capsule Filling Machine, you have to consider some important points.

Model OF the Machine

The first thing you have to look forward to before buying the Semi-Automatic Capsule Filling machine is to check the model of the machine.

So, you have to look forward to a reliable brand of Semi-Automatic Capsule Machine. This will help you to work for a longer period of time.

Everyone knows that the machine is expensive according to the model wise price. But it will give you the comfort and you will save yourself from the small technical faults that occur in the Capsule filling Machine.

So, you have to buy the model of the machine which is more effective as compared to the other Capsule Filling Machine.

Quality of the Machine

Quality is the second important thing to look forward to before buying a Semi-Automatic Capsule Filling Machine.

So, before buying a machine you have to examine the quality standards that are given by the different pharmaceutical companies.

These are also signs of the protection's authenticity.

The quality standards you have to look forward to are the standards of C.E, cGMP, ISO, RoHS.

Knowing about the Producer

This is the third step before buying the Semi -Automatic Capsule Filling Machine. It is very important for a buyer to look out for the manufacturer of the Capsule Filling Machine.

Because it will help in purchasing the best machine you want. And also, you have to look closer to the experience of the machine maker that is, the machine maker is very skillful in making such kinds of machines.

And check the reliability and the reputation of the producer in the market. It will help you in selecting the producer of the Semi-Automatic Capsule Filling Machine.

Capacity to Produce Capsules

So, the last step of all this process is to look out for the production capacity of the Semi-Automatic Capsule Filling Machine.

It will help you in purchasing a machine of your own choice that you wanted. Because, there is some amount in your mind about the quantity of producing capsules.

So, this decision will help you to buy the machine you wanted.

22.What are the new Available Technologies in the Semi-Automatic Capsule Filling Machine?

These new technologies are very helpful in making the machine safer and more reliable.

And also, these technologies help you to make the product efficient and to upgrade its production and performance.

Touchscreen Panel

The improved touchscreen panel of the Semi-Automatic Capsule Filling Machine helps us in controlling the system of the machine and also the production administration.

Enclosed Dosing

It helps us in making the system of the machine more efficient and compatible during the filling process of the capsule.

Cleaning System

So, the betterment in the cleaning system of vacuum in the Capsule Filling Machine helps us in the cleaning of the machine.

And moreover, it also makes the cleaning system faster and quicker than before.

Improving Lubrication System

The auto lubricant system is very popular nowadays. It helps us in the prevention of the parts of the Capsule Filling Machine because the machine lubricates itself with much more ease.

Also, it increases the life of the machine by lubricating itself.

Frequency Drive System

The variable frequency drive system of the machine helps us in controlling the speed of the motor and the Semi-Automatic Capsule Filling Machine.

By doing this it decreases the error possibility in the Capsule Filling Machine.

So, these technologies make the machine more safe, reliable and efficient for the customer. Before buying the Capsule Filling Machine remember these technologies in your mind.

23.How Semi-Automatic Capsule Filling Machine Help Boosting your Business?

It is must for you to change you within the environment for stay in the business as well as boosting it.

You can boost up your business by the Semi-Automatic Capsule Filling to make more capsules of the preferred customer sizes.

It can help in boosting up your business to produce capsules of good quality. Because of the good quality of the capsule is the very first priority of the customer.

So, if you want to earn more and raise your business , then you have to work hard or improve your quality.

The other way of boosting up your business is to work on the customer management system. It will automatically uplift your business.

To be efficient in the market can also increase your business. So, be efficient and check the needs of the customer than what the customer is waiting for on the market.

And produce the capsules of the customers choice. It will help you in improving your sale ratio which will automatically lift your business.

Also, you can sell your product at cheaper rates than others to earn a trust of the client. If you will manage to earn trust of your customer then there are a lot of chances in lifting up your business at a higher level.