Screw Capping Machine:The Ultimate Buying Guide In 2025

Over the past few years, there has been great innovation in the packaging industry. Packaging of any product is very essential for consumer satisfaction and the safety of the product. When we talk about the filling of liquid in bottles the next important thing that captures our attention is the sealing of these bottles to protect the product inside from any kind of damage.

The pharmaceutical industry is one big industry with a wide range of products. Being in the pharmaceutical industry your ultimate wish is to expand your business and increase your productivity in a minimal period. To compete with the growing industry you need to come up with new and improved products. The packaging of these products is equally important and to ease you in process of packaging we offer different and most advanced equipment.

Nowadays filling of liquid substances in air-tight bottles has gained so much importance and to ensure the best quality product inside the bottle, the packaging of the bottle plays an integral role. One biggest inventions in the packaging of bottles is a Screw Capping Machine. The capping of bottles is very important for the safety and freshness of the filling liquid.

Here I will explain to you the pros and cons of an ideal Screw Capping Machine. After reading this blog you will have a clear mindset about the purchasing of the Screw Capping Machine and will be able to make a wise decision.

Let’s start!

1.What is a Screw Capping Machine?

AIPAK Automatic Screw Capping Machine

When dealing with the filling of liquids in the bottles you must need a capping machine to tightly close the lid of the bottle, so that no liquid will ooze out of the bottle. The screw capping machine will fit the lid over the bottle and tightens it with great consistency.

In almost all industries dealing with liquid material, screw capping machine is a must-have. The efficiency and consistency of the screw capping machine are unmatchable.

2.What are the advantages of a Screw Capping Machine?

The screw capping machine has a wide range of advantages that makes it an integral part of almost all industries.

Practical Demonstration of Capping of Bottle by Screw Capping Machine- Image Courtesy: Levapack

I will explain to you few important benefits of screw capping machines.

- Consistency:

The screw capping machine is fully automatic, thus the capping of all the bottles occurs most consistently. None of the caps is loose or misfit. This cannot be possible with manual or hand capping of the bottles.

- Safety of Product:

The automatic capping ensures the safety of the product inside. Since the cap is tightly bound to its place there is no chance for the entry of any foreign material inside the bottle.

- Consumer Satisfaction:

The tightly packed bottle made it reliable for the consumer's use, and also increases the sale of your product.

- Time-Saving:

It saves you the time and labor of hand capping of the bottles. It takes a lot of time and human labor to individually cap each bottle.

- Adjustability with other Equipment:

The screw capping machine is very simple to put in use with other equipment, it fits perfectly with your bottle filling machine and readily cap the bottle to avoid any loss of product.

- Multi-Function:

The screw capping machine is very versatile in its function, by using a single machine you can cap bottles of different diameters with capsizes and types depending upon the shape of the bottle.

- No need for Human Labor:

The screw capping machine is fully automatic and doesn’t require any special assistant to operate machine. You just need to set the parameters through the control panel and make sure the supply of caps and bottles to be capped, after that machine is responsible for its functioning.

- Security of Product:

The screw capping machine gives confidence to the buyer about the safety and security of the bottled product. As everyone understands that a tightly capped bottle is safe and doesn’t have any health risks.

- High Production Rate:

The screw capping machine works at a very high speed and caps your bottles in a very short time as compared to manual capping of the bottles. Thus, it increases the production quality.

- Health Safety:

The screw capping machine also saves you from any of the injuries that may occur while manual capping of the bottles.

3.What are the limitations of a Screw Capping Machine?

Like any other machine screw capping machine also has some drawbacks that may affect productivity. Some common limitations of the screw capping machine are:

- Most of the industries use the liner capping machine specifically for the capping of the bottles and it has a low speed and production rate as it only caps the single bottle at a time, thus it takes a lot of time to cap the bottles.

- The other limitation of the liner capping machine is that it can’t adjust with continuous changing of bottles, it is very difficult to perform capping of differently sized bottles with the screw capping machine

- In the liner machine, you will need to change the head of the screw capping machine each time when you want a specific type of capping, and this will cost an additional amount of money to replace the head each time.

4.What are the different parts of a Screw Capping Machine?

A fully automatic screw capping machine has many different parts that are linked to each other to work in a coordinated manner to perform the capping of bottles and containers.

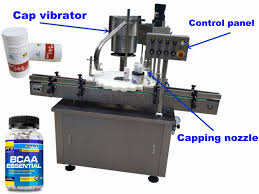

Major Components of a Screw Capping Machine- Image Courtesy: Precisiontork

Following are the important parts of a fully automatic screw cap machine.

- Belts:

These are the very important part of the screw capping machine that supports and guard the bottles or containers during the capping process. They are also called conveyor belts or conveyor systems as they transport the containers from one unit of the screw capping machine to the other during and after the capping procedure. These are in continuous motion that’s why made up of hard thick material like rubber or steel so that they can provide firm support and holds the containers tightly.

- Chute:

The lid is placed firmly on the bottle by the use of cap chutes. The chutes hold the lid tightly and when the container comes it places the cap over the container.

Chute-Image Courtesy: Changeparts

- Clutches:

It is responsible for providing the required torque to the caps, and incoordination, with the chunks it will fix the cap on the containers or bottles.

Clutch-Image Courtesy: Changeparts

- Chunks:

These are the special heads that hold the container tightly in its place while the capping is done. This is a very important part of the screw capping machine as it holds the container firmly otherwise the container may slip through the conveyor belts that will cause the loss of product and problems during the capping. They also apply the necessary torque on the container to create the seal.

Chunks- Image Courtesy: Changeparts

- Cap Feeders and Sorters:

This part of the screw capping machine is responsible for the feeding of different caps in the screw capping machine, and the cap sorter will differentiate among the caps depending upon their shape. The shape of the cap feeder is similar to the geometry of the screw capping machine.

- Cylinders:

It is an important component of the automatic capping machine that is responsible for holding and cut off the caps.

- Gear Boxes and Motor:

These are the main power supply of the screw capping machine. They provide the necessary energy required to run a machine. They work in a coordinated fashion to operate the screw capping machine smoothly and complete the capping process.

- Grip Disk:

The name of the part truly represents its function. It holds the container in the upward position to avoid any spill of the material and also supports the containers while they wait for their turn during the capping process.

- Guarding Clamp:

They are for the protection of the parts of the screw capping machine from any external damage, and it also holds and joins the different parts of the screw capping machine altogether.

- Pulleys:

Their function is to assist in the movement of cans, bottles, and containers during the capping process. It is known as the transport system of the screw capping machine. There are different sizes of pulleys available in the market. The size of the pulley will depend upon the type of machine you will use. These pulleys are in close connection with conveyer belts and gears for the transport of the materials.

Pulleys-Image Courtesy: Changeparts

- Shafts and Sprockets:

Like the pulleys, gears, clutch, and chute they are also an important part of the screw capping machine used to assist the capping process by applying the rotary force during the transmission process. Although they are not used in liner capping machines but are important in other types of capping machines.

Shafts-Image Courtesy: Changeparts

5.What is the working mechanism of a Screw Capping Machine?

The working of an automatic screw capping machine depends entirely upon the type of machine being used. With few exceptions, all the types function in such a manner to reduce your workload with their automatic control panel. You just need to set the parameters and tune the parts of the machine, the rest of the work will be performed by the screw capping machine itself.

I will simplify the working principle for your better understanding.

Pictorial Representation of Working of Screw Capping Machine-Image Courtesy: cnchengxiang.com

- Cap Feeding and Sorting:

The caps are feed into the screw capping machine through the cap feeding system, all these caps are then sorted by the cap sorter according to their geometry, all the break, and de shaped caps are removed by the sorter, only the perfect caps will be allowed to move through the cap chute.

- Placement of Lid over the Bottles:

When the cap reaches the cap chute through gravity it will remain intact in the chute until the bottle is detected and the chute releases the cap and tightens it over the container. The bottles or containers will continuously come in a row and the process of capping goes on. After capping the bottles will move to the next station through the conveyer belt system.

- Tightening of Caps:

After placing the cap firmly the next step is to tighten the cap at its place to ensure the safety of the process. The capped containers are moved through the spindle wheels the necessary torque is applied to the bottle to create the seal. The process continues and doesn’t stop after the placement of the cap.

The capped bottles are now ready to proceed to the next step of the packaging line.

6.What are the different types of Screw Capping machines?

The screw capping machines are divided into different types depending upon the mode of operations and cappers. I will individually explain each type to give you a comprehensive view of each type.

Based on the mode of operations there are two major types of screw capping machines.

- Automatic Screw Capping Machine

- Semi-Automatic Screw Capping Machine

Automatic Screw Capping Machine:

AIPAK Automatic screw capping machine

This type of machine is the most advanced type among the capping machine, this will be a great addition to your packaging line. There is a touch screen control panel that has different parameters. You just need to set the parameters as per your requirement and then the machine is responsible for the rest of the task.

One thing you need to do is provision of caps to the machine. Your only task is to watch the process of capping and keep an eye on the provision of caps during the process.

There are no chances of hand contamination, also the machine caps the bulk of bottles in minimal time hence suitable for mass production at large-scale units.

- Semi-Automatic Screw Capping Machine:

The screw capping machine has different variations ranging from a simple portable one to a frame-fitted machine. The major difference between a semi-automatic machine from a fully automatic is that you have to place the cap on each container manually and then the machine will apply the necessary torque on the capped bottles to seal it tightly.

The manual placement of caps over the bottles is somehow tiresome and needs human labor. Also, it creates the chances of hand contamination. But the screw capping machine is quite portable and can be easily moved from one place to another, thus it is ideal for small-scale production units.

Semi-Automatic Screw Capping Machine-Image Courtesy: Liquid Packaging Solutions

Depending upon the cappers the fully automatic machine is divided into the following types.

- Chuck Capper Automatic Machine

- Spindle Capping Machine

- Inline Capping Machine

Chuck Capper Automatic Machine:

The screw capping machine uses an ahead or a chuck device to place the lid over the lid. It has a rubber band attached to it that applies the force to tightly close the cap.

Chunk Capper Automatic Machine-Image Courtesy: aaapackaging

The size of the chuck depends upon the size of the cap, and it differs with different capsizes. Most preferably it is used for small-size bottles.

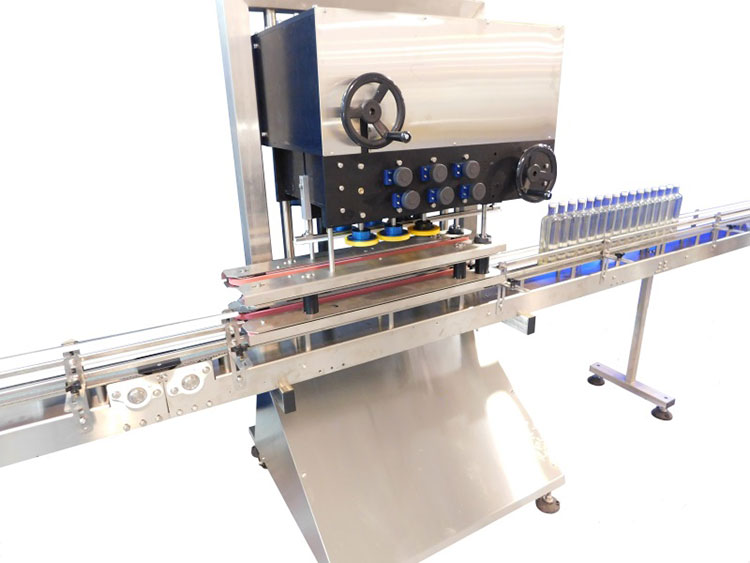

- Spindle Capping Machine

This type of automatic machine has replaced the chuck with a rotating wheel to tighten the cap over the bottle. The spindle capping machine is fully automatic and it is easy in the supply of caps by auto feeding of caps, thus the process of capping doesn’t stop at all.

Spindle Capping Machine-Image Courtesy: .apacks

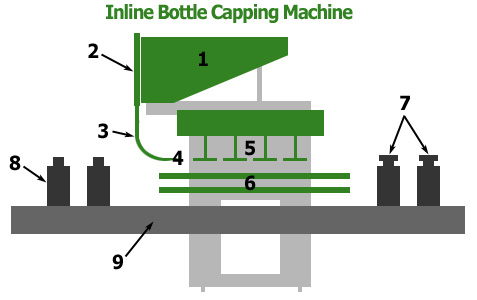

- Inline Capping Machine

This is the most commonly used type of automatic screw capping machine. It uses the spring to apply the required torque and then release the force accordingly.

Inline Screw Capping Machine-Image Courtesy: lazarcapper

7.What are the industrial applications of a Screw Capping Machine?

Almost every industry has some kind of liquid product that needs to be filled in the containers and bottles, and these bottles are needed to be capped accordingly. So in almost every industry, you will find the use of the screw capping machine. Following are some of the most common industrial applications of the Screw Capping Machine.

- Food and Beverage Industry:

This is a huge industry and the use of screw capping machines in the food industry is limitless. All your carbonated drinks, juices, water bottles, coffee, energy drinks, jams, jellies, oils, vinegar, soya sauce, canned food, milk, and yogurt is packed in containers or bottles that make the product safe and fit for your use and also increases the shelf life of the product. All this is possible only because of the screw capping machine that caps the product so tightly that no foreign substance can gain entry inside the product.

Different Soda Bottles Capping Around the World-Image Courtesy: Conde Nast Traveler

- Cosmetic Industry:

All the perfumes, creams, lotions, deodorant, gel, sanitizers, liquid soap, and shampoo bottles are capped using the screw capping machine.

Cosmetic Product Bottles-Image Courtesy: Pinterest

- Pharmaceutical Industry:

The pharmaceutical industry produces different types of liquid syrups, ointments, and other medicines that need to be packed in containers and bottles, and these are then tightly capped using the screw capping machine.

Capping of Pharmaceutical Drug Bottles-Image Courtesy: IndiaMart

Pesticide Industry:

All agriculture products especially insecticide are packed in air-tight containers because of their harmful and health hazard nature. The screw capping machine tightly packs these containers to make them safe for use.

Pesticide Bottles Packed by Screw Capping Machine-Image Courtesy: Shreeram Containers

8.What problems may occur in a Screw Capping Machine?

When it comes to capping of bottles it’s definitely a task that requires the most of the effort especially the high level of observation through the process. Although the machine is fully automatic and performs the capping process in a coordinated fashion but some problems may arise during the process that needs to be checked. It is necessary for you to understand and overcome the problems of screw capping machine to avoid any hindrance in the final production.

Some of major issues that may occur include:

- Overflow of Liquid Product from the Bottle:

Sometimes it may happen that the product over flows the bottle, it is usually because of high pressure of the gripper. This problem usually arises during the changeable packaging. The grip on the bottle during the cap tightening may be more than the required, thus the bottle squeezes and the product overflows.

This issue can be simply resolved by losing the pressure over the bottle through the control panel or pressure holder. If remains unchecked this may cause the inconsistency in the amount of the filled product.

- Damaging of Caps:

Sometimes it may occur that after leaving the machine the caps of bottles are being damaged, this problem is because of the much close contact and high speed of the spindle wheels.

To resolve this issue you must check the distance between the spindle wheels, also changing the hardness of spindle wheels may be useful in solving the problem.

- Sliding of the Bottles:

Sometimes it may occur that the bottles may slide over the machine because of improper position of spindle capper and conveyer. The other reason for this problem may be the too high or too little pressure of the gripper.

To resolve this issue you need to check if the level of the spindle capper and conveyer belt is right according to the ground floor. Also the check the level of pressure by the gripper belts and stabilizer bars.

- Missing of Caps:

One big issue with the machine that may occur is the missing of bottle caps. This problem will lead to spill of liquid material from the bottles as well as the low production rate.

You need to solve this problem by making sure the smooth and continuous supply of caps to the machine. Also carefully observe the path of the caps and look for the point where the caps are falling off the machine. By doing so you can make sure the continuous delivery of caps to the machine.

- Lifting of Bottles:

This one issue is similar to the lifting of the bottles. In this case the bottles may be lifted from the point of the capping because improper adjustment of conveyer belt. Also the irregular pressure of gripper may account for this problem. So, check for these parameters during the lifting of bottles.

These problems are little but can cause hindrance in the working of the screw capping machine. So you need to be very vigilant during the process of capping and solve any issue at its point of origin.

9.What are the main points for the maintenance of the Screw Capping Machine?

Once you buy a required screw capping machine it is very important to keep an eye on how you can make your machinery long lasting.

Some measurements that may help you in this regard include:

- Always clean the machine thoroughly after each use.

- Lubricate the parts of the machine to avoid the friction.

- Keep the right spare parts of the machine with you.

- Never save extra on spare parts of the machine because they are the important tools at the time of need.

- Hire an expert technician to operate the machine

10.What are the specifications of a Screw Capping Machine?

Before you go for the final decision of buying a Screw Capping Machine you must be aware of some of the technical requirements of the machine so that you can compare the model of the machine with your requirements and will explain your demands to the manufacturer in a better way.

- Different capping machines have different electrical requirements, the machine with a high production load will work on high volts. So, you must ask the manufacturer about the power supply needed to operate the machine.

- The size of the cap varies according to the size of the bottle and the container. So you must ask for a variety of capsizes from the manufacturer.

- The types of caps are also an important factor to be considered while purchasing the machine. Always go for the machine which can deliver different caps.

- If you are running a large-scale industry where the production is high and you need a large mass of capped containers then you will need the bigger machine with more weight and height, but for a small scale industry, a machine of low weight and capacity is suitable.

- You will need to determine the torque needed for the tightening of the caps. If you will explain to the manufacturer about the requirement of torque you need then he will guide you about the best type of capping machine.

- In most automatic screw capping machines there is an option to control the pressure needed for tightening the caps, so this will assist you in managing the air pressure as per your requirements.

Conclusion:

So a Screw Capping Machine is a great addition to your business, it saves you from the trouble of manual capping, and hiring of labor for manually capping the bottles and containers. It also saves you from the loss of the product through spilling. It saves your time and capped a large number of bottles and containers.

So now you are aware of all the aspects of the screw capping machine you are free to make your decision.

For any assistance and query, we are always there to help you.

Capping Machine Related Products

Capping Machine Related Posts

Capping Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours