Pillow Packing Machine:The Complete Buying Guide In 2025

The flexible pillow packed materials are found everywhere in supermarket, or pharmacies. Pillow packing is the most used and significantly sold packaging machine around the globe for special packing of pharmaceutical oral powders, food or cosmetic items. The main purpose of the pillow packing machine is to provide safety, integrity, and good quality product to end-users.

The design and structure of the pillow packing machine are suitable for regular and fixed shape material into pillow packaging.

If you are planning to purchase a ‘pillow packing machine’ then you’re at the right place! Read this detailed guidance blog to find out the design, working principle, troubleshooting, and integration of state-of-the-art pillow packing machine technology.

1.What is pillow packing?

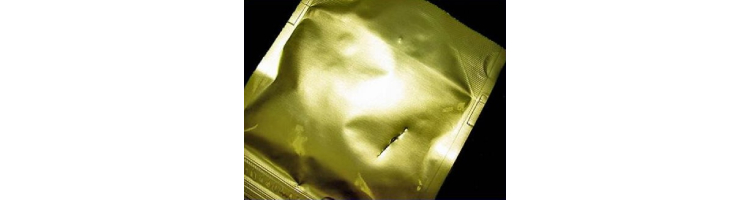

Pillow packing or pillow pouch is the one of the long running flexible packing in the market. For decades, pillow pack products like chips, biscuits, single serving coffee and smaller serving food category has been wrapped in pillow packing.

It is one of the most economical and straightforward pillow pouches currently available. The longevity of pillow packing in the market has employed remarkably well- known throughout the world.

These packaging features heat sealable top and bottom with small cut on the top to hang on metal pegs in retail stores.

Pillow pouches are good choice of packaging that is simple, effective, environment and user-friendly packing solution.

2.What is a pillow packing machine?

A pillow packing machine is an efficient machine used for packing food and non-food items of various specifications. It involves positioning, sealing, and cutting the packaged material. These types of machines are utilized in the packaging area, where finished products are packed.

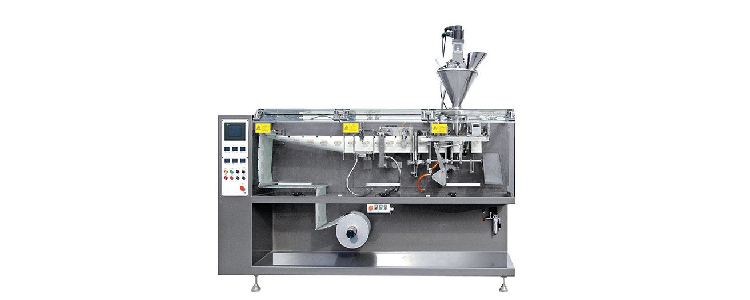

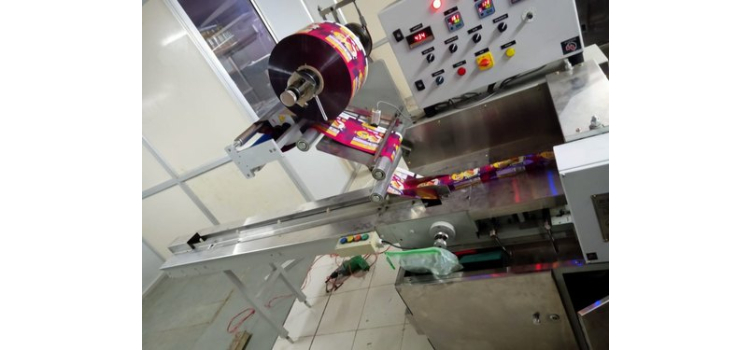

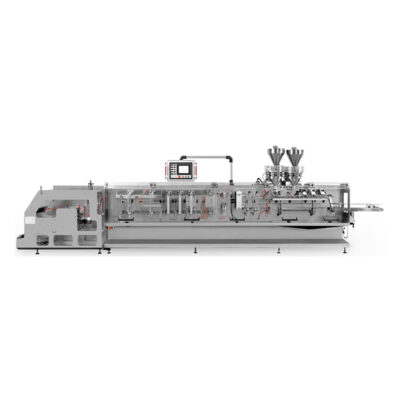

pillow packing machine

Pillow packing machine is a durable, reliable, and rapid automated packaging system that reduces labor work yet brings good benefits to suppliers as well as consumers in the form of secure packaging and health benefits. It is a well- developed product packaging equipment that is progressed with a wide variety of packaging materials.

Besides the fact that pillow packing machines utilizes an intelligent man-machine interface it makes use of double inverters for control and highly sensitive photoelectric eye color mark technology for sealing and reducing. It has multiple functionalities and advancements.

3.How can a pillow packing machine be advantageous for boosting your business?

Pillow packing machine

- Pillow packing machines offer a high degree of automation which makes the process rapid and convenient.The parameter setting is also simple and easy.

- Packaging efficiency has been another advantage of the pillow packing machine as it does feed, packing and sealing in a single step.

- The pillow packing machine offers another advantage to boost the business as it allows a very low waste rate. The automatic detection device avoids sealing the empty film and to reach the cutting process hence preventing the wastage of packaging film.

- The wide packaging range makes it more flexible to use while energy-saving and its high efficiency make it a better choice to be utilized for the packaging business.

- As the machine is controlled by software it can keep pace with time and help in boosting the packaging business and industry.

4.What are the different classifications of pillow packing machines?

These machines have a roll of flexible stuff like paper or film. These bags are made in the tube and sealed. This pillow packing machinery is broadly divided into two categories.

- Vertical Pillow Packing Machines

- Horizontal Pillow Packing Machines

- Vertical Pillow Packing Machines

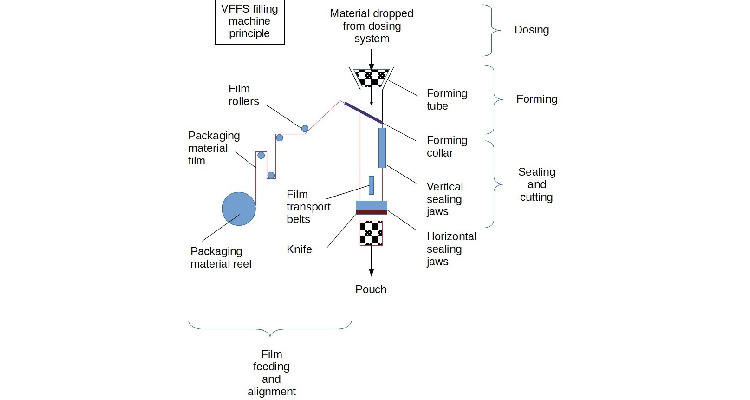

These are automated packaging systems used to pack solids and liquids. In these machines, bags are formed in a circular shape at the top of forming tube.

Vertical pillow packing machines make packs with overlap seals and transverse seals. Overlap seals are found on the bottom of the bag while the transverse seals are found on each side.

Substances enter the forming tube in vertical pillow packing machines. Friction rollers move this film to the forming tube. Forming collars then transform plane film into a circular film. Sealing jaws glues the sides of the film together while horizontal bars seal the bag at the top and bottom sides.

Application

These are used to pack chocolate bars, candies, detergents, salts, sugar, etc.

Vertical Pillow Packing Machines

There are two types of vertical pillow packing machines based on the principle

- Intermittent Motion Packaging Machines

In intermittent motion packaging systems, the movement of the film is stopped for some time when the film receives its vertical seal. Similarly, the film pauses when horizontal jaws seal the upside and downside of the bag. It is useful for functions where the pace of the procedure is not a concern. This is used for washdown functions such as packing poultry and seafood.

- Continuous Motion Packaging Machines

In these machines, vertical bars are continuously in contact with the film, so it does not pause and the same is the case with horizontal seals. The jaws work in the up and down direction so that bag gets sealed at the upper and lower part. These machine functions very quickly.

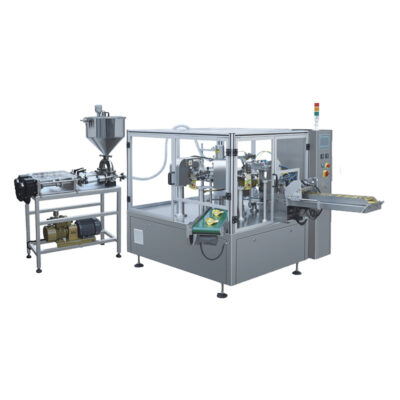

- Horizontal Pillow Packing Machines

These are widely used machines as products of various kinds and volumes are packed by these machines. Horizontal Pillow Packing Machines make the bag from the rolling stock and fill this pouch at the same time. The films move in the horizontal direction which gives the machine its name.

These machines merge three processes (formation of bag, shaping of bag and its filling) into two processes (filling of bag and sealing).

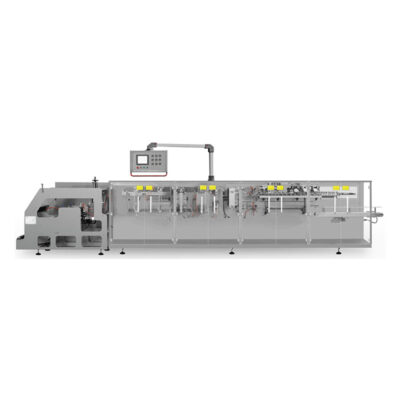

Horizontal Pillow Packing Machines

Materials are loaded on conveyor belts while bags are formed inside the forming tube. The sides of the pouch are sealed when they go through horizontally fixed sealing rollers.

Application

These machines are used to pack confectionaries, food materials, and cereal bars.

Horizontal Pillow Packing Machines

5.Difference between a vertical pillow and horizontal pillow packing machines

The pillow packing machines follow two different principles for packaging i.e., Vertical or horizontal depending upon the type of material that needs to be packaged. The difference in both types of machines is as clear as it sounds, here are some main differences

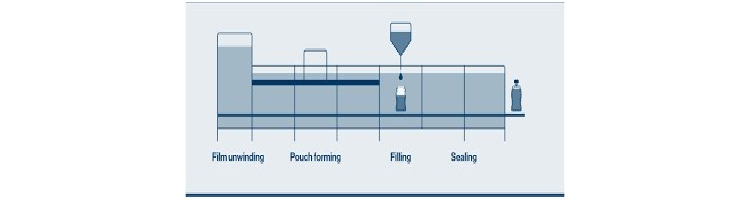

- The Vertical packaging machines are also known as Vertical Form Fill and seal (VFFS) involves forming a vertical pouch or package then filling the pouch with the product and sealing it afterward whereas in a horizontal packaging machine the material is dragged from the reel into a horizontal plane where the three functions of shaping, placing the material and sealing the pack take place.

- The type of product is the real decision-making criteria for selecting the type of machine. If a product does not need accurate placement such as rice, a vertical packaging system is preferred while for precise product packaging e.g., bread rolls in-tray then a horizontal packaging machine is the best option.

In VFFS, the vertical sealing bars apply vertical overlap seal sequentially the horizontal sealing bars creates the bottom seal in the cross jaws while in HFFS the packaging material or wrap is folded in form of a tube and the edges of the tube are sealed with the help of horizontally fixed sealing rollers.

6.What are the basic components of a pillow packing machine?

Pillow packing machine typically consists of

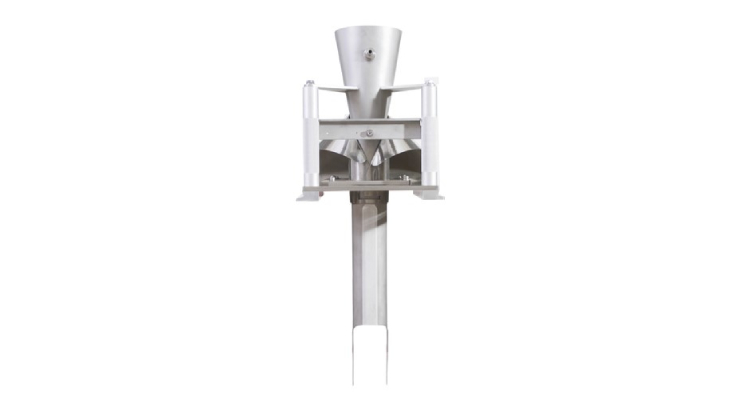

I.Feeding system- Funnel

In the feeder section of the pillow packing machine, products are loaded. These products are then packed into bags or pouches.

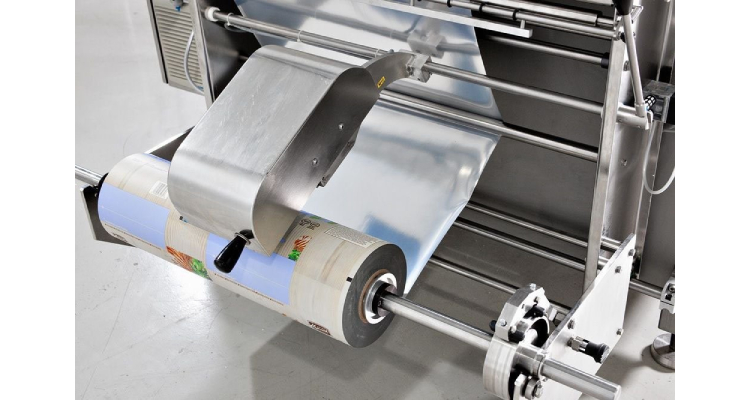

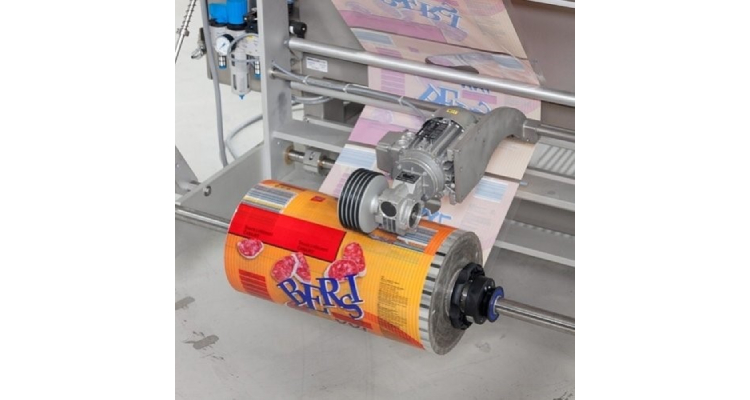

II.Film Unwind Section- Film Tracking

Film or wrapping material is unravelled in this section. In some machines, unwind section is not powered. This section uses friction breakers to uncoil the film and these breakers also supply necessary film tension.

This section has roll lifts and a vacuum cutting shaft. A vacuum cutting shaft is a horizontal shaft that is equipped with a vacuum and a flat opening. This opening fits a utility knife to cut the film

III.Dancer Arms- Film Reel

The dancer's arms have a speed feedback machine for controlling the unwinding of the film. It assembles the bags and also keeps the film from drifting away.

Dancer-arm- Pillow packing machine

IV.Registration Section

This is used to make adjustments on the end of the seal and cutting. Film registration is printed on the film. Film sliding, the tension in the film, and printing differences can cause misplacement of graphics on the bag. The registration mark is a way to make the sealing and cutting process more accurate. This also helps in tracking the position of film in the forming tube.

V.Sensors

Different types of sensors are used in pillow packing machines. These are

- Diffuse Sensor which senses the ending part of the rolling stock.

- Inductive Sensor-this examines the tension in the movement of the film

- Registration Sensor-its use is to identify the registration mark so that process of cutting and sealing occurs simultaneously.

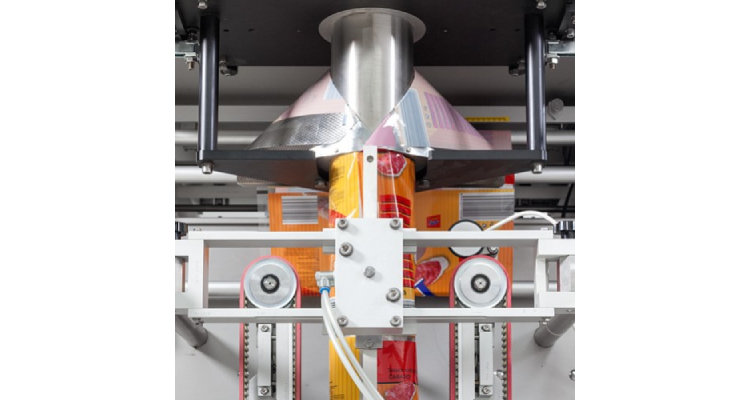

VI.Forming Tube

The forming tube is an inverted cone shape structure that alters a plane film into circular or tubular form.

The forming tube has different designs which are employed for various types of films and products. The forming tube has a long seal. This seal is formed by many heating systems present at the front of forming tube. These are about 8-12 inches in length. There are two kinds of long seals.

- Static Bars Long Seals

A static bar is a heating rod, equipped with a heating part and thermocouple. This bar comes in contact with the film when it is moving. To prevent the melting of the film, contact of film with static bar is delayed for some time. Sometimes there is two bar, facing each other which results in the placement of long seals between these bars. These create stronger overlapping seals.

- Dynamic Belt Long Seal

It is made of stainless-steel belt which is pulled by two pulleys. A heating metal plate supplies the heat to the belt. This belt comes in contact with film when it is in motion. Like the static bar, there can be two belts in the forming tube. The advantage of using two belts is that these transport the film and are regulated of increasing the speed of the film.

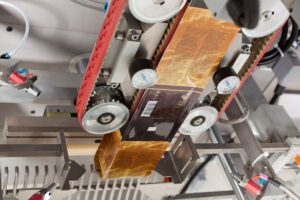

VII.Pull Belts

These provide the force for pulling the film and also keep the film under tension. The pillow packing machine is composed of two pull belts located on the left and right sides. These are vacuum belts that are used for their good grip on the film. These are used in high dust, moisture, and cold working condition so they can provide better grip to the film. Friction belts are also used for dusty conditions as they suffer from less damage.

VIII.Sealing Jaws

There are two types of sealing jaws.

- Vertical Sealing Jaw

These jaws move with the help of gears. These move in the top and bottom directions. These sealing jaws seal the two layers of the packing material.

- Horizontal Sealing Jaw

These are also called cross jaws. These are front and back sealing bars that function together. It has three functions.

- To stick the top side of a bag filled earlier.

- To glue the bottom seal of the next bag to be filled.

- To break apart two bags.

The back jaw has a knife that operates in the middle of the jaw. Sometimes either the front or back jaw is stationary or the other is movable.

IX.Printers

These machines have built-in printers. Their function is to print registration marks, manufacturing date, expiry date, bar codes, and other graphics on the film.

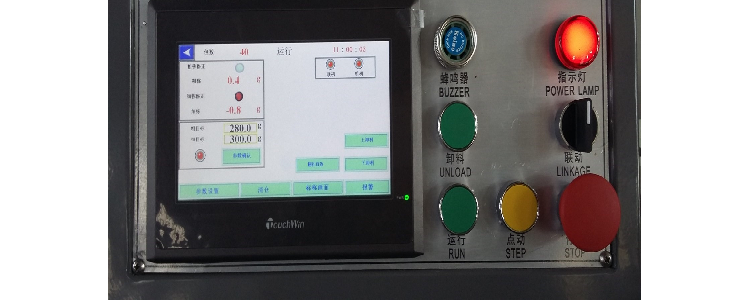

X.Human Machine Interface

The human-machine interface also known as HMI has different options for setting the parameters of the pillow packing machine like temperature, speed, etc. The length of the bag is also programmed and displayed on the HMI screen. Once the appropriate bag length is reached, the film will stop rolling.

HMI- Pillow Pouch Packing Machine

XI.Servo Drives

These are the regulator which aids in the monitoring of the filling speed and process of bag filling. It controls the main feeder of the machine. It helps in the reconfiguration of the machine very rapidly, saves time and money.

7.What are the structural features of the pillow packing machine?

pillow packing machine- Picture Courtesy- CONOVAL

- The pillow packing machine is self-automated. It easily identifies failures in itself and displays this error on the screen.

- This machine has the software for functional repairs and mechanical updates.

- It has a human-machine interface that is easy to understand and use. The parameters on this interface are rapidly and conveniently

- The pillow packing machine is equipped with autonomous PID temperature control that is appropriate for different types of wrapping materials.

pillow packing machine

- This machine is provided with a double frequency converter. The purpose of this converter is to set and cut the bag length in one place which conserves time and film.

- pillow packing machine contains highly sensitive photoelectric examining system, automatic input wrapping and cutting modifying system which makes sealing and incision of packaging material precise.

- It has an automated stop function so there is no need for sticking a knife and wasting the envelope.

8.What are the different mechanisms of packaging performed by pillow packing machines?

Different types of pillow packing machines have different working principle.

- Horizontal pillow packing machine

This packaging machine has a tooth chain transmission moved by V-belts. Speed is adjusted by speed control in the gearbox. Paper length is regulated by a timing belt. Chain drive moves the outer streak of the gearbox so that it can then rotate the film pressure roller.

Photoelectric tracking checks the production length of the paper film. Multiple chains drive the gearbox which moves the conveyor belt. This conveyor belt moves the objects which are to be packed.

The film role of this machine is placed on a shaft roller. The packaged item is loaded into the feeder. The conveyor belt transfers the packaged items to the packing location, where these objects are packed, then these objects are heated squashed into form. These packaged items are then moved to a slant sealing cutter, where heated sealing and cutting are performed. Final products are moved with the aid of a conveyor belt.

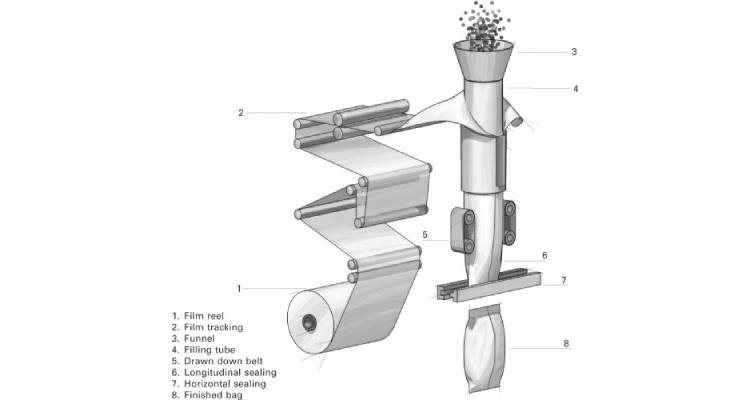

- Vertical pillow packing machine

The different steps in the working of vertical pillow packing machine are as follows:

1.Film Supply and Unwinding

This machine uses a single sheet of packaging material wrapped around a core called roll stock. This rolling stock is positioned on a cylinder tube at the back of the machine.

The film is tugged by the transport belt when the machine is in working. The transport belts are located at the side of forming tube. In some cases, sealing jaws moves the film down and carry it without transport belts.

2.Film Tension

When the film is unwinding from the roll, it goes over the dancer's arms which have a set of rollers. The movement of the dancer's arm keeps the film from drifting side to side so the film remains under tension.

3.Printing

The film goes through printers after passing the dancers. The printer prints manufacturing and expiry dates on the film. It also embosses the codes, graphics, and registration marks on the film.

4.Film Tracking

The film goes to registration tracking. It is a photoelectric system that controls the movement of the film on a pull-down belt. After this, the film moves through film tracking sensors. These sensors help in the positioning of film on the film carriage.

5.Bag Formation

As the film goes to forming tube system, it rolls on the top of forming tube and then is wrapped around the tube in such a way the two external sides of the films overlap each other. This begins the process of bag formation.

Two gears drive the film down, which is then moved to the pull-down belts present on the sides of forming tube. These belts use a vacuum to maintain the grip on the film. These belts can be used in the substitution of friction belts.

6.Bag Filling

The film is stopped briefly on the packaging machine as the bag is sealed vertically with the help of a vertical bar. This glues two layers of the film together. Then horizontal bar glues the top and bottom portion of the bag.

If the products are heat sensitive, then ultrasonics is used in a cold sealing system. In this sealing system, vibrations are used which causes friction. This friction produces heat only in the region between film sheets.

When sealing jaws are shut, the material which is to be packed falls in the center of forming tube and is placed in the bag.

7.Bag Discharge

The filling of material in the bag is followed by the cutting. A knife slices the bag by moving between sealing jaws. Then the jaws unlock and the finished bag is dropped. This bag is then moved to a container or moved by conveyors belts to weight checkers and X-ray machines.

9.What are pillow packing machine installation steps?

Installation Requirements

- Space

The installation area should have sufficient space for working and maintaining the machine. The ground should be even and durable.

Working Conditions

- Do not expose the machine to chemicals like gasoline, acids, and alkali material. Also, ensure explosive and flammable materials are not in contact with the pillow packing machine.

- Do not expose the machine to direct sunlight.

- The machine should not be in contact with other vibrating machines.

- The temperature should be in the range of 5°C to 40°C.

- The illumination of the working area should be above 300 LUX.

- Keep the machine away from blowing a fan.

- Dewdrop pressure should be approximately 30% to 90%.

Installation Steps

I.First set the machine on the flat ground after that adjust the four leveling screws so that machine should be leveled. Use worktable as the reference for setting the machine.

II.Set up the machine feeder and attach it to the left edge of the core machine with the screws. Then fiddle the leveling bolts of the feeder machine so that it is located on a leveled stage. The lower part of the feeder tube and core machine must be in line and at the same height.

III.Set up the push chain. Unlock the left wheel of the feeder and then attach the push chain with the feeder. After that, rotate the wheel so that the push chain has proper tension.

IV.Hook up the power supply. pillow packing machines consume 220 volts and 50HZ energy. Under no condition hook this machine to 380 volts. Electric wiring should be installed by properly skilled staff. Properly connect live wire, negative wire, and earth wire.

Testing

I.Ensure you have installed the power supply properly. Test live and negative wire with a pencil.

II.Set up the trip switch in the safety cabinet. Then inspect that the power meter's light on the control board is at normal.

III.To check the machine is working properly, turn the inching button.

IV.Input the packing speed to 40 bags per minute on HMI. Press the green start button. To ensure the machine is working accurately, run the machine for 3-5 minutes. After that press the red stop button.

10.What steps should be taken to operate an automatic pillow packing machine?

For operating pillow packing machine following steps should be taken

- Before operating, the accurate operation method and safety rules should be known.

- All the safety devices and warnings including shield, face lock device, operating instructions on the machine should be intact and not removed along with dirt.

- The location and usage of the emergency stop button should be clear before operating the packing machine.

- Appropriate working dress code according to the safety regulation must be followed. Loose-fitting clothes, scarves, and ties are strictly prohibited.

- All screws in every part of the machine and the presence of any loose body on the table should be checked before commencing the machine operation

- Check for any abnormal behavior, noise after the start of the machine so that maintenance workers can be contacted promptly.

- Make sure to completely turn off the machine before touching the inside or any electrical parts. Avoid extending your hand into the end sealing and heating sealing wheel while the machine is working.

- Proper cleaning and lubrication of the machine should be done once every week.

11.What do you do when the pillow packing machine gets damaged or failed to pack the pillow?

Failure is the normal part of machine operation, so you do not need to worry if you face some unexpected incidents during normal machine operation. You can easily fix these problems.

Some problems and their solutions are given below:

I.Loose Sealing

Sometimes a bag is not correctly sealed and the sealing becomes loose.

Cause

- The temperature of the sealing bar is low.

- The speed of the machine is too high.

- The inner sheet of a film does not have enough thermal resilience.

Solution

- Raise the temperature of the machine.

- Reduce the speed.

- Switch the film with a better one.

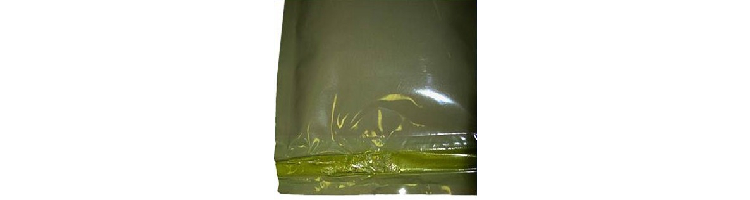

II.Wrinkles on Sealing

You can see crumples on the sealing of the bag.

Cause

- The temperature is high.

- Speed is very low.

Solution

- The temperature should be adjusted so that it is in a proper range.

- Improve the packing speed of the machine.

III.Cuts on the Product

The cutting knife cuts inside the sealing.

Cause

- The cutting knife is not on proper elevation.

- The speed of the machine is rapid.

- The motion of pushing rod and cutting knife is not executed at similar timings.

Solution

- Maintain the appropriate height of the cutting knife.

- Reduce the packing speed.

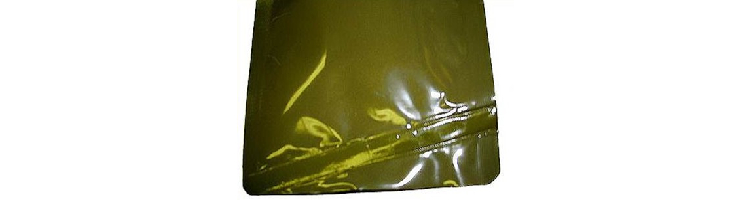

IV.Burnt Wrinkles

Sometimes you see seared wrinkles on the sealing film.

Cause

- The resilience of the outer layer of film is not appropriate.

- The temperature of the machine is too high.

- The packaging speed is too slow.

Solution

- Switch the film.

- Decrease the machine temperature.

- Increase the packaging speed.

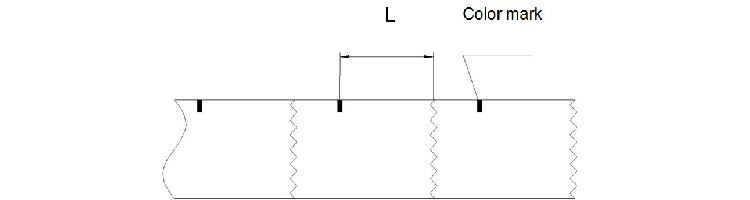

V.Deviation from Colour Mark

It happens when the cutting location of the packaging machine is not on the color mark.

Cause

- The Colour mark does not have proper brightness and is too dull.

- Slipping of the film occurs.

- The follow-up to color is not used.

Solution

- Modify the sensitivity of the color mark registration sensor.

- Modify the tension of the roller.

- On HMI display alter the setting of the ‘follow up’ method to ‘follow up cut’ procedure.

VI.Regulation of Temperature Control

It happens when the temperature regulator cannot maintain the temperature of the machine.

Cause

- The heating part is broken.

- A thermocouple is no longer working.

- A circuit breaker is burnt.

- The temperature regulator is damaged.

Solution

- Switch the heat part with a new one.

- Substitute thermocouple.

- Place new circuit breaker.

12.How to adjust operational parameters of pillow packing machines?

Operation

I.Safety Check

Before starting the machine, first, make sure that there is no dust or unknown substances on the working area, belts, and sealing bars. Also, make sure there is no person around the machine.

II.Switching on Power

First, open the safety cabinet and hook up the main switch. Ensure all the thermocouples and power lamps on the main board are normal. Also, make sure that the display of HMI is working properly.

III.Human Machine Interface

Main program parameters are adjusted on the HMI.

- When the setting option on HMI is clicked, parameter setting options like speed, length, and cutting option are seen on the screen of HMI.

- If you enter the speed which is greater than the speed of the machine error is shown on the screen and it will ask you to enter the correct speed.

- The length parameter is the total length of the bag.

- The cut position is the position at which film is cut. First, enter the value 0 to the cutting position parameter, and then cut the bag. Calculate distance L in the middle of the eye mark and cutting point. Press back and enter distance L in the cutting position parameter.

- Then press the ‘COUNTER’ option and enter the total time of the operation, total bags produce during the operation, and total bags produced during the shift.

- In FOLLOW UP option set the length setting cut. If the bags have color marks then use a follow-up setting and they do not have color marks then use length setting cut.

- In INFLATE SETTING option you will decide whether you want bag inflation or not. If yes then for how much time you will inflate the bag.

- In the QUANTITY SETTING option enter the quantity of packed bags. If the machine reaches desired quantity, then the machine will automatically shut down. If a machine for some reason gets shut down then on restarting the machine, quantity packed will start from zero.

IV.Temperature Control

There are two settings for temperature control. These are mid-sealing temperature and end-sealing temperature. The temperature setting depends upon the packaging speed, total firmness of film, and ambient temperature.

V.Eye Mark Registration

The eye mark sensor is very precise, and it requires that paper should be flat and have a steady distance from the light source. The paper is fixed in holding guide plate so that it should be even. Eye source should be in the middle of the registration mark.

VI.Start

a.Inching

Punch and hold the black INCHING switch. The machine will run and produce 30 bags per minute. If the inching button is released, then the machine will instantly halt.

b.Continuous Operation

Punch the green START button for steady machine operation. By doing this, the machine will keep on running until the emergency or stop key is pushed.

VII.Stop

a.Normal Machine Shutdown

For stopping the machine, push the red ‘STOP’ key. This will halt the machine operation with the cutting knife in the even position.

b.Emergency Stopping

For stopping machine in case of accident press mushroom-shaped ‘EMERGENCY’ key. This will end the machine operation right away. If you want to restart the machine then push the reset key.

13.What are important buying considerations for a pillow packing machine?

- For buying a pillow packing machine the most important consideration should be defining the requirement and needs of products that have to be packaged.

- It is an important decision to make ahead whether you need a vertical or horizontal pillow packing machine depending upon the type of product.

- If the product freely flows into the package and does not require a proper orientation horizontal and vertical machines can be the choice.

- Once chosen the right type of machine you should select the maintenance/service provider as it will be required for the good working of a machine to work for a long time.

- The cost of the machine and the spare parts that will be predictably required should be considered at the time of selection.

- As the packaging machine is a huge investment the wrong type of machine can cost so much.

- It should be easy to clean between different cycles of packaging products.

14.How to clean and maintain a pillow packing machine?

I.Cleaning

- First, switch off the power supply then start cleaning. This protects cleaning personnel from electric shock.

- Wipe the working clean and external casing of the machine with a wet and sanitary cloth.

- Remove the fragments of film that remain jammed in the feeding system and sealing bars with the pressurized air.

- By using a steel cord brush swipe the film pieces that are affixed to the cutting knife.

II.Inspection and Maintenance

1.First, lubricate the interlocking gear of the drive with oil. Chains of the wheel system should also be lubricated. Use a small quantity of grease to lubricate these parts.

2.You should not add oil to the pull and conveyer belts.

3.Sealing nuts and screws should also be oiled regularly.

4.Tension in the drive chain should be checked daily and if you find the chain lose then tighten it.

5Examine for loose nuts and bolts. Tighten them if necessary.

6.Clean the waste carbon material on the machine.

III.Biannual Maintenance

- Check the state of drive and conveyer belt twice a year. If they are worn out then replace them.

- Examine all the parts of forming, feeding, and sealing system and switch the old parts with the new ones. Also, switch the old drive parts.

- Inspect the electric wiring of the machine and tauten if needed.

- Twice a year electric elements should be cleaned of dust by using pressurized air.

Final Thought!

Choose the right type of pillow packing machine for your business- The entire blog aims to guide you through the process and categorization of pillow packing machines in order to understand the differences in pillow packaging types, how to use them, and selection. We recommend you begin your search and fully scrutinize for a pillow packing machine to skyrocket business revenue.

Premade Pouch Filling Machine Related Products

Premade Pouch Filling Machine Related Posts

Premade Pouch Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours