Your Best High Containment Roller Compactor

- Delivering world-class dry-granulation

- Improve material flow characteristics

- Increasing product yields and minimizing product fines

AIPAK Pharmaceutical Roller Compactor

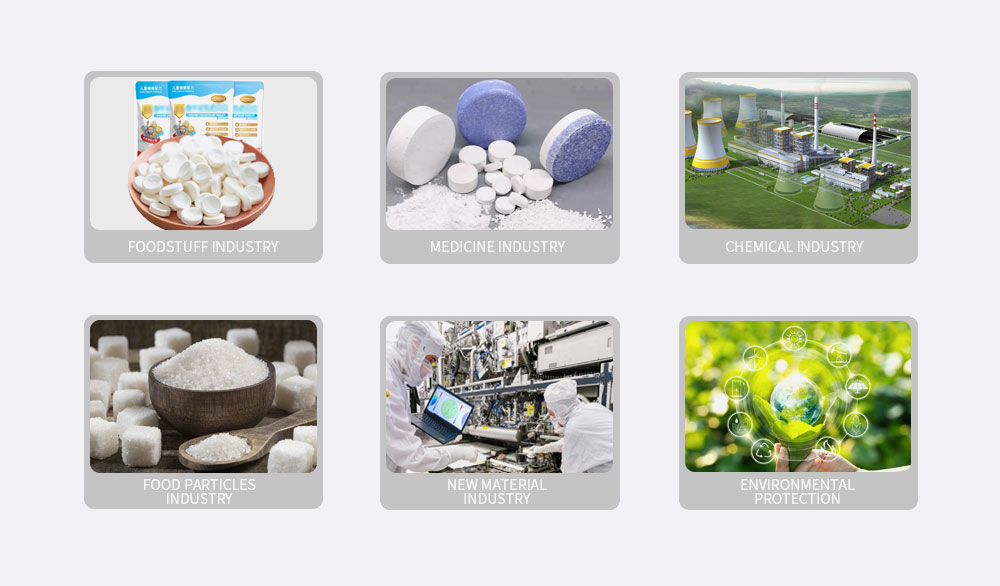

Pharmaceutical roller compactor is also called dry granulator. It is a new high efficient type granulating equipment that can make powder to granules directly, and the working process does not need adding water, stirring or drying. It is widely used in pharmaceutical, chemical and food industry. It has a lot of advantages, so it in widely used in all kinds of industries for treating active materials, especially suitable for heat-sensitive drugs.

Application Of LG Series Roller Compactor For Health Care Products Spirulina/Probiotics Capacity 50kg 100kg 200kg 300kg 500kg 1000kg

It is widely used in pharmaceutical, chemical and food industry. It has a lot of advantages, so it in widely used in all kinds of industries for treating active materials, especially suitable for heat-sensitive drugs.

AIPAK Pharmaceutical Roller Compactor Working Principle

The Buyer's Guide

Pharmaceutical Roller Compactor:The Ultimate Buying Guide In 2025

In the pharmaceutical industry, there are two methods for dry granulation:Slugging and roll compaction.

Slugging: was used during 1950-1970 but nowadays roller compactor is the preferred tool as it offers high-degree production capacity with a simplified and continuous production line.

Pharmaceutical roller compactor, which is also referred as Chilsonator, employed to force fine powders in between two counter-rotating rollers that press the raw ingredients into compact solid in the form of flake, sheet, or strip. A roller compactor is also known as a 'dry granulator'.

Read this detailed blog if you are interested in purchasing a pharmaceutical roller compactor machine for implementation in pharmaceutical manufacturing purposes.

You will find structural and functional properties, working principles, operating, advantages, integration, and much more about pillow packaging machines.

Have a deeper look at incredible rollers!

1.What is a pharmaceutical roller compactor?

Pharmaceutical roller compaction is a process of dry granulation in which the compaction of dry powders is changed into a solid mass commonly known as the ribbon.

Pharmaceutical roller compactor

This process uses three key components.

- A feeding system that carries and converts the raw material into the powder through a set of counter-rotating rollers. In this process, the use of liquids and high temperatures are avoided.

- The powder is then compacted by applying force between the counter-rotating rolls to a ribbon in a compaction unit.

- The ribbon is then milled down into a specified particular granule size which uses a size reduction unit such as an oscillating mill.

The main purpose of dry granulation is to increase the flow of materials and to prevent particle segregation and also ensure a better flow of distributed material; an important factor in the production of tablets and capsules using production equipment of high speed.

The key processing parameters in the dry granulation are powder feeding, compaction pressure applied, and the gap diameters. The powder is fed into the rollers and is subjected to high pressure and is dependent on the feed rate of powder, gap diameter, and force.

The powder will be ‘compacted’ into a pre-defined ribbon thickness. To ensure that the result is suitably uniform, precise process control is critical for granule properties. This is determined by the pressure at which the powder is forced through the counter-rotating rollers.

2.Why compaction?

Compaction of powders is of prime importance due to certain reasons:

1.TO PRODUCE UNIFORM BLENDS OR MIXTURES

The mixtures of different discrete particles lean towards the classification in transport or handling as there is a difference in particle size, shape, and density. A pharmaceutical roller compactor produces granules with the confidence of dose uniformity that prevents particle segregation and also provides consistent analysis.

2.TO PRODUCE A UNIFORM PARTICLE SIZE RANGE

The uniform particle size of the product can be selected according to the requirements of an individual and their needs.

3.TO CONTROL DUST

Generally, dust is a wasteful and unpleasant form to handle. The product loss along with cross-contamination can also be eliminated.

4.TO ADJUST FLOW PROPERTIES

The flowing process of granular materials resist bridging and caking easily and, in many cases, higher flow rates and even fill can be achieved.

5.TO CONTROL BULK DENSITY

Transport, storage, or packaging may be desirable for increased bulk density and marked increases can also be achieved and controlled within certain limits.

6.TO CONTROL PARTICLE HARDNESS

The requirement of a product is important; therefore, the characteristics of particle hardness can also get adjusted to suit the needs of a product. Crush strength and disintegration can be important properties brought under more rigid control.

7.TO IMPROVE SOLUTION OR DISPERSION RATES

One of the most important properties of granular materials is that they absorb liquids more readily than many of the powders do. Hence the dissolving and dispersing of granular materials are easy and quick. Some materials under proper conditions can also be adjusted to sink or float as desired.

3.What is the principle of working of pharmaceutical roller compactor?

Process Parameters: Force and Gap

The working principle of a pharmaceutical roller compactor is simple. In this process, force is applied to the powder which is compacted betwee two counter-rotating rollers which is the first and most important step in the dry granulation.

Pharmaceutical Roller Compactor

Sometimes, the pressing force is shown in the bar which represents pressure within the hydraulic system, and it is not an appropriate measuring unit for the force that is being applied onto the powder.

Depending on the amount of powder that is conveyed to the rolls. It will be compacted to a predefined thickness of a ribbon at a given force.

Roller Compactor Machine

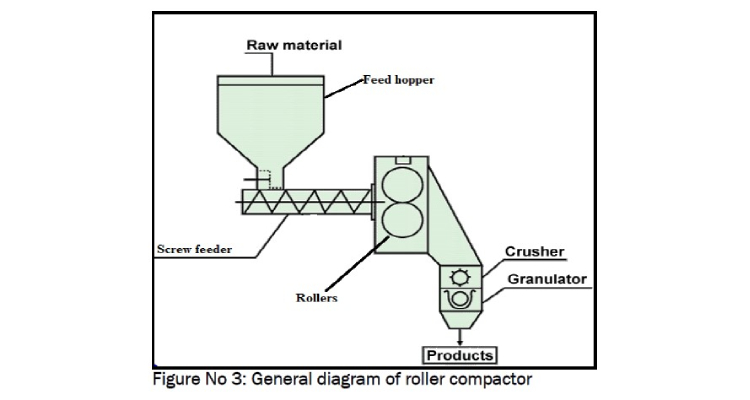

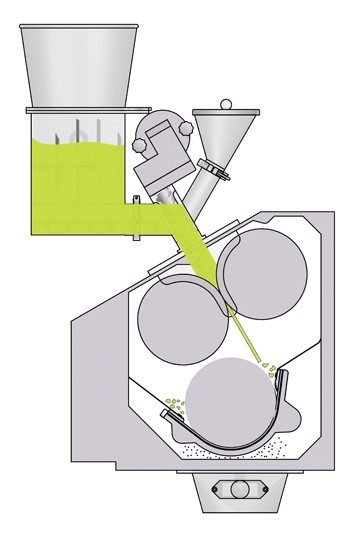

A pharmaceutical roller compactor consists of three major units.

- A FEEDING SYSTEM: in which the powder is converted to the compaction area between the rolls.

- A COMPACTION UNIT: where force is applied to the powder which is compacted between the two counter-rotating rolls to a ribbon.

- A SIZE REDUCTION UNIT: where the ribbon is milled down into a specified particular granule size in order to achieve the desired particle

- Working principle of pharmaceutical roller compactor- Video Courtesy- Solid Online

4.What are the components of the pharmaceutical roller compactor?

The parts of the pharmaceutical roller compactor machine are as followed.

Schematic diagram of pharmaceutical roller compactor

Major Components of pharmaceutical roller compactor

The major components of pharmaceutical roller compactor are as followed;

A. Hopper

- Screw Feeder

- Rollers

- Flake Crusher

- Pre & Fine Granulator

A.HOPPER

The ingredients are fed into the hopper of the pharmaceutical roller compactor machine which is present at the top that allows material into the circulating chopper. The rotor arm facilitates the material in a downward direction uniformly via hopper toward screw feeder.

Feeder- pharmaceutical roller compactor

B.SCREW FEEDER

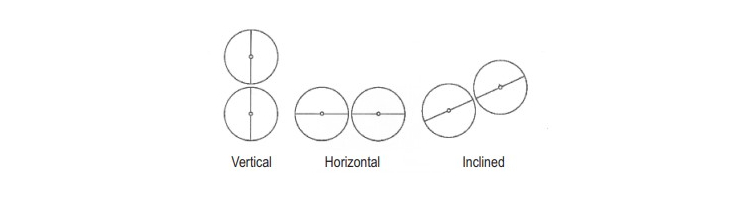

A screw feeder carries material toward the roller in the meantime it also deaerates material in order to avoid air entrapment during compaction. There are generally three types of screw feeders used in industrial practices. For instance, vertical, inclined, and horizontal screw feeders.

C.ROLLERS

Rollers play an essential role in the compaction process as it presses the material in the gap area between the pharmaceutical roller compactors. There are various kinds of rollers such as flat, punch, and pocketed available in the market.

Rollers- pharmaceutical roller compactor

1) Configuration of Rollers

- FLAT ROLLERS:

These rollers are suitable for sticky materials that cling to the surface of rollers.

- PUNCH SHAPED ROLLERS:

Punch-shaped rollers are recommended to treat light, voluminous and fluidizing ingredients.

- POCKETED ROLLERS:

Pocketed rollers are suitable for that product that can easily be cleaned from rolls.

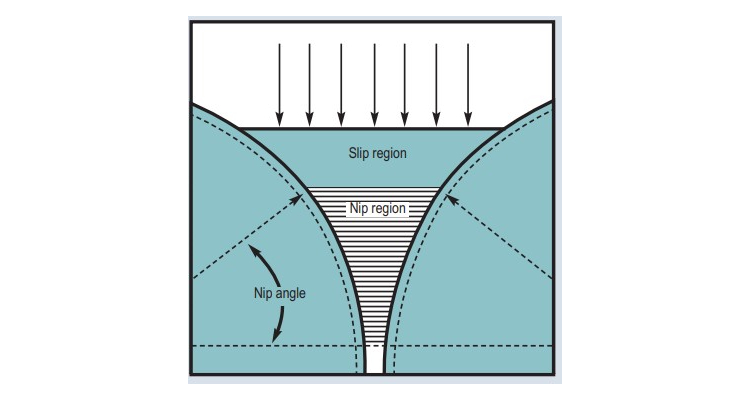

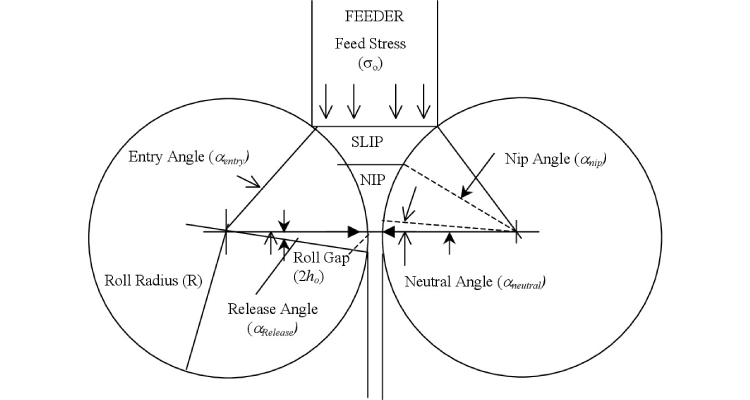

2) Regions of Roller

There are three basic regions of rollers: slip region, nip region, and extruding region.

- SLIP REGION- FEEDING ZONE

As its name shows when powder enters into slip region it allows sliding motion between the rollers.

Roller regions- pharmaceutical roller compactor

- NIP REGION- COMPACTION ZONE

In this region, the material is trapped between the roller and moves with the speed of the roller surface. The compaction force between rollers deforms the particles. An angle forms between the feeding zone and compaction zone known as the nip angle. For better compaction, the ‘nip angle’ must be efficiently large.

- EXTRUSION REGION- RELEASE ZONE

In this region, the gap between rollers begins to increase and a pattern of compact ribbon is released from the rollers.

Roller Compaction Process

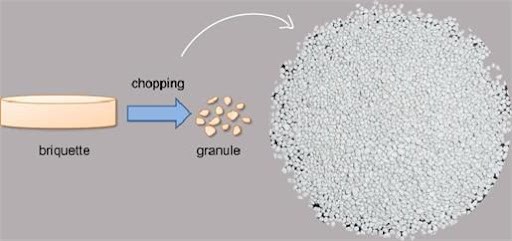

D.FLAKE CRUSHER

Compacted flakes are crushed by using a flake crusher. A flake crusher has six blades that cut the flakes that are coming from rollers in the form of a ribbon. At this point, the speed of the flake crusher is of prime importance. It requires optimization that may impart in the refinement of granules.

E.PRE & FINE GRANULATOR

It receives the fine pieces of ingredients that fall from hoppers and generates them into fine granules. The size of granules is determined by suitable mesh size.

5.What are the new techniques and advancements of pharmaceutical roller compactor machines?

A pharmaceutical roller compactor is versatile equipment that is extensively used in pharma industries. The day-by-day modification and advancement of the pharmaceutical roller compactor make this machine the most sophisticated The new process and tools are discussed below:

A) ROLLER COOLING AND HEATING UNIT

It has been observed that low melting point substances are melted in rollers due to friction between them. Not only this, but it also generated heat.

Thus, in modern pharmaceutical roller compactors, you will find cooling or re-heating rollers. This is attained by circulating water via rollers that help to maintain the temperature.

B) VACUUM DE-AERATION

Most often air entrapment between powder particles creates problems during compaction. This is tackled by the introduction of a vacuum de-aeration system. It creates a vacuum as well as absorbs the particles to be compressed from the screw-feeder over the filter. It enables the transportation of voluminous and fluidizing substances.

C) PNEUMATIC DRY GRANULATION

This extends the flowability of material by improving the re-compatibility of granules.

In this method, by using circulating gas in rotating perforated-cylinder fine granulated particles from pharmaceutical roller compactor are pneumatically fractioned and recirculated in rollers. This is a cost-effective method as it reduces the loss of material during compaction.

6.What are the advantages of pharmaceutical roller compactor?

1.SUITABLE FOR MOISTURE AND HEAT-SENSITIVE DRUGS

An important advantage of dry granulation over wet granulation is that there is no presence of water or any organic solvents, a major factor in the methodology of drugs that are either moisture or heat sensitive.

2.COMPOUNDS WITH A LOW MELTING POINT

It is also suitable for those compounds that have either a low melting point or can easily degrade with time during the heating process as the method does not need or involve any drying step.

3.IMPROVES DISINTEGRATION PERFORMANCE OF TABLETS

Pharmaceutical roller compaction results in granules that form porous tablets thus allowing water to penetrate more easily into the tablet. This leads to improved disintegration behaviour of tablets.

4.ENVIRONMENTALLY FRIENDLY & COST-EFFECTIVE

The process of roller compaction is efficient and environmentally friendly. The automated process of this technique is efficient and simple which also results in low operational cost.

5.NO DUST PRODUCTION

Obnoxious dust problems can be avoided or minimized by applying roller compaction procedures. The die filling during tableting is improved due to no dust production.

6.CAPPING OF TABLETS

The pharmaceutical roller compaction process also helps in minimizing tablet capping defects.

7.NON – FREE-FLOWING POWDERS

The advantage of the pharmaceutical roller compactor is that it offers a greater capacity to convert the granules into fine powder. Roll compaction/dry granulation can be used if the drug or the excipient is poorly flowing or sensitive to heat or moisture.

8.DENSIFICATION OF POWDERS

It is also used for the densification of dry powders prior to encapsulation.

9.GREATER PROCESS ACCURACY

When compared to slugging which is another method for dry granulation, roller compaction offers better consistent powder flow hence resulting in more consistent compaction.

10.EASIER SCALABILITY

For the roller compaction operations, the product batches of both pilot and commercial can occur on the same machine which benefits in the expansion of production without bearing additional machinery investment or cost.

11.LOWER OPERATIONAL COSTS

There are many advantages of using pharmaceutical roller compaction. The process of roller compaction or dry granulation does not involve the wetting or drying stages of material; therefore, the operational costs are always lower when compared to wet granulation operations.

7.Pharmaceutical roller compactor uses are?

PHARMACEUTICAL APPLICATIONS

A pharmaceutical roller compactor is used prior to tableting. Hence, a prime interest is to get good quality tablets. This method is used when a drug or excipient has poor flow ability or is more sensitive to heat or moisture. Furthermore, it may also be used for densifying powders prior to gel encapsulation. The importance of pharmaceutical roller compactors used in pharma are discussed below:

1.PROPER FORMULATION OF DRUGS

At times, the granules which have low and inconsistent bulky particles are accompanied by fine particle sizes. The materials may exhibit poor flow properties and poor formulation, which may result in the hampering of the tablet processing. The roll compactor process allows overcoming these difficulties by granulating the particles into the desired size.

2. GRANULATION OF THERMOLABILE DRUGS

The drugs which are sensitive to heat and can easily decompose when exposed to the application of moderate heat are known as Thermolabile drugs. The dry granulator comes in handy while granulating the thermolabile drugs as it does not change the texture and properties while granulating them.

3.PREPARATION OF ACTIVE INGREDIENTS & EXCIPIENTS

The roll compactors are also used to blend the active ingredients and excipients to make it as dosage forms. The pharmaceutical roller compactor has many advantages and can convert the granules into a fine powder, the blending of active ingredients can also increase in bulk density and uniformity of the granules required for tablet manufacturing.

4.COMPACTION OF HERBAL DRY EXTRACTS

Herbal dry extracts often possess hygroscopic properties due to their hydrophilic components like sugars or organic acids. Due to their hygroscopic properties, the extracts show poor flow and compression attributes which makes compaction an essential process prior to the production process of a tablet.

8.Granulation? dry or wet granulation?

Granulation, a mechanical process that is performed to alter the physical properties of the powder blend. Granulation produces larger granules and removes fines and increases the flowability of powder in the formulation.

The whole process is influenced by flow characteristics, particle size, and density of powder.

This process is efficiently applied when raw ingredients or blend possesses behavior properties that impede other production processes. Such as poor flow, poor compressing, segregation of particles, and inappropriate particle sizes.

To check the good flowability of powder- you need to assess the angle of incidence. For instance, a small angle on the powder means good flowability and is suitable for direct compression- a high angle means poor flowability and your material is not suitable for direct compression.

There are three reasons to granulate your formulation:

- 1. To increase the flowability of formulation:

- To improve your formulation more and more compressible

- Ensure a uniform propagation of active pharmaceutical ingredients in your formulation.

There are two different methods for the manufacturing of granules are used. - Dry Granulation

- Wet Granulation

1- DRY GRANULATION

Dry granulation is the process of obtaining granules without requiring liquid.

In the dry granulation process, a desired quality of granules is generated by using two methods as compacting and milling.

Dry granulation is generally needed for material sensitive to moisture or heat.

2- WET GRANULATION

The process of incorporating a liquid solution into your formulation to bind the particles is known as wet granulation. A non-toxic binder is sprayed over the formulation in order to aggregate the particles.

Most often, binders are alcoholic, or water-based which acts as an adhesive. These binders are inter-connected with each other by a liquid bridge system- referred to as an agglomerate. This process may require a downstream drying process in order to minimize the moisture in the granules.

9.Why you prepare granules? What are the steps used in dry granulation?

Pharmaceutical granules are prepared:

- to avoid segregation of powders

- to prepare a uniform mixture

- to improve the flowability of powder

- to prepare dust-free formulations.STEPS IN DRY GRANULATION

- Compaction of powder

- milling of powder

- screening of powder

10.Industrial applications of pharmaceutical roller compactor applications, including the following:

1. THE PHARMACEUTICAL INDUSTRY

In the pharmaceutical industry, a pharmaceutical roller compactor machine is primarily used to improve flowability in powders and protect particle segregation.

Thus, facilitating fast and consistent feeding in the manufacturing of tablet processing. Due to this property, pharmaceutical industries are better able to obtain good quality pharmaceutical tablets and capsules with constant and stable weight, strength, and uniform distribution of APIs.

2.THE CHEMICAL INDUSTRY

Like the pharmaceutical industry, the chemical industry also requires the usage of pharmaceutical roller compactor machines to improve the physical properties of powder material.

Using dry compaction can greatly impact production. For instance, dry compaction is seen in the production of battery mass, fine chemicals, silica, and carbon black, etc.

3.AGRICULTURE INDUSTRY

In the agriculture industry, pharmaceutical roller compactor machine is widely used to break up the lumps in fertilizers to make fertilizer pellets, minerals, animal feed, and increase value to products by minimizing dust, as well as an agglomeration of goods.

4.THE FOOD & BEVERAGE INDUSTRY

The food and beverage industry entirely rely on pharmaceutical roller compactor machine for the manufacturing of powder-based products, instant blending, extraction of flavors, and much more.

- NUTRACEUTICAL INDUSTRY

You must know every substance has a unique structural and physical characteristic. In the preparation of nutraceutical items, you mostly encountered sensitive materials that require intricate handling to preserve the action and integrity of the active ingredient.

Pharmaceutical roller compactors can deal with moisture or heat-sensitive material with perfect processing outcomes in the manufacturing of nutraceutical products. Such as multi-vitamins, protein milk powders, food supplements, etc.

6.VETERINARY INDUSTRY

Like other industries, the veterinary industry also requires a roller compactor for the preparation of veterinary medicinal products. Formulation of veterinary tablets requires dry granulation. The tablet formulation for animals is of the same susceptibility ratio of facing challenges as human tablets.

For instance, tablets defects, powder processing, etc. Powder treated by roller compactor improves flowability and makes the formulation process much convenient and easier.

7.DETERGENT INDUSTRY

The formulation of detergent contains 95% of powder include anionic and non-ionic organic compounds. The detergent process requires drying, mixing, and densification. The mixture of detergent is processed by a roller compactor which is a continuous process in the production of detergent. Moreover, compression also increases the dissolution time and disintegration of detergent.

8.CEMENT INDUSTRY

Cement industry require roller compactor machine for pressing brittle material such as limestone, shale, gypsum, iron ore etc.

This roller compactor is designed conferring principle of bed grinder and high-pressure load that directly applied on material via double rollers that exerts internal stress on particle and cracks them.

9. HERBAL DRY EXTRACT

Herbal dry extracts commonly comprises of hygroscopic properties due to hydrophilic constituents such as sugars or organic compounds. These substances promptly require compression prior to tableting as extract demonstrate poor flowability ratio.

Roller Compactor for Cement industry

11.What is the impact of pharmaceutical roller compactor on the process parameters?

The parameters of roller compaction pharmaceuticals have high effects on the feasibility of the process such as ribbon quality, the flowability of the powder, and uniformity of the blend.

Certain critical parameters should be optimized to improve the quality of the products such as the force of compaction, roller speed, screen size, roll-gap, and acceleration of feeder screw. Thus, the efficiency of the pharmaceutical roller compactor is dependent upon the structure of equipment and functional parameters.

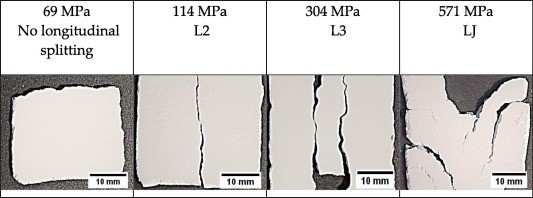

1) FORCE OF COMPACTION:

For the treatment of loose powders, a sufficient compaction force is needed. Because by applying this pressure powder becomes more densified and attached to form a ribbon. By increasing the pressure up to a certain limit may result in improving ribbon density, the mean particle size of granule, and flowability. Hence, optimum compaction facilitates good quality granules that may vary with different ingredients. Furthermore, over the force of compaction ribbon may break that ultimately results in the poor quality of granules formation.

This may create tablet compression problems such as reduced hardness, capping, as well as high friability. Furthermore, the force of compaction may influence the substance temperature, therefore this parameter must be considered prior to initiating the process.

2) ROLL GAP:

Roll gap, which is a distance between rolls to their nearest point. A roll gap is a crucial parameter of the pharmaceutical roller compactor. It is a pressure applied on the rolls and the number of components that are crossed between them. Like a force of compaction, roller gap also exhibits a critical impact on ribbon density, flowability of granules, uniformity of granule, and hardness. The force of compaction increases with decreasing roller gap.

Schematic diagram of pharmaceutical roller compactor

3) SCREW SPEED:

A screw speed is another critical factor that must be considered when using a pharmaceutical roller compactor. The average range of screw speed depends upon the flowability rate of material, speed of roller and roller gaps.

When screw speed is lesser, material in the nip region reaches insufficiently that resulting in the formation of ribbon with reduced strength.

On other hand, when screw speed is high it causes a high densified zone in the nip region and results in melting or caking of raw ingredients. Thus, high speed is not a solution to deal with poor flow materials. For this, you just need to balance vertical and horizontal screws. Furthermore, the feed rate must be equal to the rate of discharge.

4) ROLL SPEED:

Roll speed is inversely associated with the dwell time that affects the density of the ribbon. The roller speed is always needed to be adjusted in accordance with the speed of the feeder screw and the flowability of the powder. If you have high roller speed it will lead to inadequate passing of material through rollers therefore inadequate compaction is achieved that ultimately results in blending segregation that loses content uniformity.

Roller Compactor

5) MILLING:

Ribbon size reduction is achieved by applying force to get desired size granules. The granule size is of prime importance for uniform particle size, distribution, excellent flowability, and compressibility. The size of the mill screen orifice is directly impacted on particle size distribution that can impact on granule’s uniformity as well as flowability. If you find unnecessary fines in the milling process it will densify the blend and ultimately affects flowability. Excessive fines subsequently affect the uniformity and cause tablets hardness during compression.

12.What are the possible failures of roller compaction and how to tackle the problems?

To find a problem while operating a system is not an exceptional practice. You possibly find some unwanted events while operating the pharmaceutical roller compactor machine.

But we have tried our maximum to solve your problem with the pharmaceutical roller compactor by enlisting some remedies that can be done on the operator level. Such as:

1.COMPACTION/DWELL TIME IS TOO SHORT:

- Appropriate compaction is always required to press the particles completely. When compaction time is too short, it will result in inadequate compaction that increases the chances of particle segregation and non-uniformity in the blending process.

REMEDY

To troubleshoot this problem, you will be required to slow down the rollers' speed of the pharmaceutical roller compactor.

2.AIR ENTRAPMENT

Air entrapment in powder material is another and most challenging process, particularly in fine powders.

REMEDY

Use a deaeration system to minimize the chances of air entrapment in the pharmaceutical roller compactor.

3.LEAKAGE OF POWDER

Sometimes leakage of powder occurs during the compaction process.

REMEDY

The solution to this problem is to tighten the sealing unit of the pharmaceutical roller compactor. This unit is developed to separate the process chamber and machine operator.

4.TOO HARD RIBBON COMPACTION

Sometimes the compaction results in the formation of a hardened ribbon.

REMEDY

To tackle this problem, you just need to reduce the roller force and screw speed.

5.EXCESSIVE FINES

The large particle size leads to cause this problem.

REMEDY

To avoid this problem, use a finer screen or sheet to mill the compacts.

- CHALLENGING MATERIAL

There are certain types of materials that are unable to form desirable granules while treated from a pharmaceutical roller compactor. Because they are prone to segregate.

REMEDY

To troubleshoot this problem, you may need to pass the material from the machine over and over again. - MELTING OF MATERIAL

Some material melts when passing through rollers. Because they are heat sensitive and friction force let them to melt.

REMEDY

To deal with this problem, you may require cool rollers, by using nitrogen gas or water circulation over rollers.

8.STICKINESS OF MATERIAL ONTO THE ROLLS

Some material tends to stick to compaction roll due to insufficient lubrication level.

REMEDY

You may add the appropriate amount of lubricant in compacting material prior to compaction.

13.How to operate pharmaceutical roller compactor?

PRE-START-UP

- Turn ‘ON’ the main switch of the pharmaceutical roller compactor.

- The panel is ‘ON’ and the screen displays the menu.

- Enter ‘Log in’ and ‘PASSWORDS’. Set all parameters of the machine and enter the desired values.

- Now the machine will run the system automatically.

START-UP

- Connect water inlet and outlet connection.

- Load the material via the material transfer unit. The de-aeration of a product via a screw feeder takes place during the compaction process.

- Start pressure rollers that compact the material in the gap area into a strip of flakes.

- Depending upon compaction pressure you may determine the thickness and hardness of the flake. You must check the hardness of flakes by continuous intervals.

- From the roller unit, flakes are cut into small granules. Small flakes fall into granulator units such as Unit ‘A’ coarse granulator- Unit ‘B’ fine granulator.

- Collect the granules in a polythene-lined bag integrated below the discharge chute. Fine granules are collected in a separate bag and again fed into the feeder and repeated the process.

END-UP

- After completing the process- Switch ‘OFF’ the main unit and machine.

14.What are the different types of pharmaceutical roller compactor used in pharma?

Types of pharmaceutical roller compactor is divided into two basic categories:

A)- Based on design

B)- Based on capacity

A) BASED ON DESIGN

1- Fixed Gap

In a fixed gap pharmaceutical roller compactor, the amount of powder particles introduced into the compaction unit between rollers is inconsistent that resulting in the application of various forces onto the powder bed.

2- Floating Gap

In a floating gap, the distance between rollers changes according to the amount of powder. The amount of powder particles into the compaction unit and between rollers is consistent.

B)- ON THE BASIS OF CAPACITY

1- PHARMACEUTICAL ROLLER COMPACTOR- R&D

This is suitable for the small lab to medium production. This type of pharmaceutical roller compactor is mainly available in smaller sizes that carry throughput from 8kg/hour to 40kg/hour.

The ingredient compaction capacity of pharmaceutical roller compactor may vary that depends upon different manufacturing industries.

This is a compact form of pharmaceutical roller compactor that can easily be moved from one place to another.

Small-Scale pharmaceutical roller compactor

2. MEDIUM-SCALE PHARMACEUTICAL ROLLER COMPACTOR

Medium pharmaceutical roller compactor may use in the pharmaceutical, R&D, healthcare sector with maximum throughput from up to 150kg/hour.

Medium Size pharmaceutical roller compactor

- LARGE-SCALE PHARMACEUTICAL ROLLER COMPACTOR

A large-scale pharmaceutical roller compactor is used in pharmaceutical production for compact on and granulation of particles. It may yield a production throughput up to 250- 400kg/hr.

Pharmaceutical roller compactor unit – Picture Courtesy- HOSOKAWA ALPINE

Industrial scale pharmaceutical roller compactor

15.What are the structural specifications of the pharmaceutical roller compactor?

The structural specification of the pharmaceutical roller compactor machine is especially compliant with the needs of the pharmaceutical, chemical, and food industries. Such as:

- Construction of pharmaceutical roller compactor is done with stainless steel.

- Full instrument automation and excellent system design.

- PLC touch screen visualization and command.

- An adjustable roller gap.

- Temperature modulation and estimation in the nip region.

- Availability of roller cooling system- suitable for heat-sensitive compounds.

- Well-equipped dust-free construction.

- Well-equipped with vacuum de-aeration (removed air must be filtered and dust-free ensuring the safety of the working environment).

- Pneumatically operated lifting unit for screw feeder cleaning.

- A special design for abrasive materials such as metal or diamond powders.

- Roller surface in various shapes improves the feeding behavior of the product.

A sealing device optimizes the compaction process and improves the rate of yields and minimizes the chances of segregation.

16.How to clean and maintain the pharmaceutical roller compactor machine?

1) CLEANING

Cleaning SOP should prepare before installing the machine.

The cleaning procedure will depend on the type of application such as; a chemical that runs 24 hours for 7 days a week does not require cleaning every day. But dealing with different colors dyes or powder may require cleaning batch to batch to prevent contamination. Cleaning can be done using purified water, 2% non-ionic detergent solution, and nylon scrubber.

2) MAINTENANCE

Working with roller compacter, manufacturers determine what type of maintenance is required by a machine as well as how often you require to provide the services.

Lubrication is a major consideration required for various parts of pharmaceutical roller compactor machines such as roller press, bearing, rotor, etc.

They are most often shipped in pre-greased form therefore this machine does not require re-greasing.

A large-scale pharmaceutical roller compactor has grease fitting and drains plugs that enable you to grease or lubricate the components without disassembling the rolls or removal of machine parts.

The bearing of the machine is sealed therefore, it does not need periodic lubrication.

A mill motor and bearings of a pharmaceutical roller compactor are the exceptional parts of the machine that require regular lubrication.

17.What are recommended precautionary measures you must follow when operating a pharmaceutical roller compactor?

There are the following mentioned precautionary measurements that users must follow when operating a pharmaceutical roller compactor.

- PERSONAL PROTECTIVE EQUIPMENT/ PPES

PPEs, such as safety goggles, protective gown, shoe cover, and face mask should never be ignored when operating a pharmaceutical roller compactor machine.

- VENTILATED AREA

All working procedures performed on a pharmaceutical roller compactor must be carried out under a well-ventilated area with an appropriate exhaust unit in order to maintain a dust-free and cleaned environment. - ESTABLISHING PROPER ELECTRICAL WIRING

All electrical connections must be secured and properly grounded. - SCREWING OF HYDRAULIC SYSTEM

Before starting the machine monitor the pressure connections and fix the screwing hydraulic system to avoid leakage and external damage. - PRE- SETTING OF MACHINE

Always pre-set the pharmaceutical roller compactor gap as required by the roller-gap control function. The gap must not be below 1.0mm.

18.What is the future prospect of a pharmaceutical roller compactor?

Pharma roller- compactors are exclusively designed to meet the dry-granulation process and are specifically used in various industrial sectors such as pharmaceutical, chemical, food industry, etc.

The comprehensive analysis of the pharma pharmaceutical roller compactor provides deep data about market dynamics and the development of the manufacturing industry.

In 2020, the global market size of pharma pharmaceutical roller compactor was estimated at USD million and it is estimated to cross beyond that by 2027 with the following CAGR of 2021 to 2027.

19.What are the important buying consideration steps for a pharmaceutical roller compactor?

1.SURFACE AREA FOR INSTALLATION EQUIPMENT

Before purchasing a pharmaceutical roller compactor, you must consider the space requirement of your plant. The required space should be the best fit for the height and width of the pharmaceutical roller compactor. For this purpose, sketch details of the pharmaceutical roller compactor can help you to determine the detailed assembly of the machine. If you have smaller space, you must look for a compact or smaller version of the machine. In the same way, for spacious and large manufacturing units you may go for large machines.

Roller compactor- Picture Courtesy- Pharmaceutical Networking

2. DUST CONTROL

A successful pharmaceutical roller compactor machine must be safe and provide comfort to your workers with excellent good dust control features. Before buying for pharmaceutical roller compactor, you must scrutinize how this machine can pick up and protect you against dust. The amount of airflow depends upon the location and specific design of the machine that fully specifies the dust control on your application.

Pharmaceutical roller compactor

a) If you are dealing with only one powder then the dust controller unit may facilitate recycling the collected dust to the feed hopper.

- b) If your ingredients are high cost and can’t be recycled ensure that the dust controlling unit must not draw off too much dust with help of processed gas as well as a dust filtering system.

3.NOISE CONTROL

Before buying a pharmaceutical roller compactor you must consider the noise controlling properties for the user’s safety. Generally, roller motor and screener may generate noise from its parts. By considering noise levels, specify a low noise machine or may use a noise-cover for the motor.

However, you must be aware that motor cover may affect and compromise the function of the motor unless you provide adequate ventilation to keep the motor cool.

Noise Cancellation Device

4.ENERGY EFFICIENCY

Energy consumption is the major issue in powder compacting technology. Hence you must look for an efficient compacting tool that may improve energy management with optimized procedures and boost your product manufacturing competence.

5.SPARE AND REPAIR

Good manufacturing companies always provide seek customer compliance and exchange quality services to save time and cost in the worst cases. They always provide tools and repair your system reliably and rapidly to minimize downtime of your process production line.

6.COMPETITIVE VENDOR

You buy what you pay!

You must look for the quality product rather than the cost of equipment. A competitive vendor always provides good services, machinery, pre-and post-sale services including satisfactory transportation, installation, etc.

CONCLUSION

In a nutshell, applications of pharmaceutical roller compactors have become increasingly revolutionizing in the development and production sector of industry. Further improvement in technical and structural processes of pharmaceutical roller compactor may improve work potential and capacity of dealing powders. Pharmaceutical roller compactor machine ranges from small equipment to extremely heavy units for pharma, chemical, agriculture, and food industries.

It is of prime importance to choose this machine from a company that has excellent and proven experience that enables reliable work performance and feasible maintenance.

Hence a pharmaceutical roller compactor is well-acknowledged and advanced equipment utilized worldwide that may help to boost your business and allow you to stand among competitive companies.

Don't forget to share this post!

Granulator Machine Related Products

Granulator Machine Related Posts

Granulator Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine