Egg Powder Machine: The Complete Buying Guide in 2025

Do you know that egg powder is getting more and more popular now? What is it? Well, egg powder is a kind of powdery or granule which is obtained by drying egg liquid, it is a new type of nutritional supplement. Egg powder is famous by its convenience and nutritive value, now it is in urge demand, don’t you want to catch this business opportunity?

Feeling curious about what to do? At first you need to possess an egg powder machine, it is a drying equipment which is specially designed for producing egg powder. Besides its purpose, do you know other aspects of the egg powder machine, such as working principle, advantages, applications, etc? If you don’t, you can have a look at this helpful blog so that you can get comprehensive information of egg powder machine.

1.What is egg powder machine?

Egg powder machine is a type of processing machine of egg powder, it produces egg powder by drying egg liquids, this equipment can dry egg liquids in a short time. The machine can be used to dry egg white, egg yolk or the whole egg. Besides egg powder, the egg powder machine can also be used to produce other powdered products, for an instance, milk powder.

2.What are the advantages of egg powder machine?

Are you curious that why egg powder machine is so popular in industries? As a hot-selling equipment, egg powder machine has many advantages so that it can bring benefits to those manufacturers, next let’s discuss the advantages one by one?

Extend Shelf Life

Did you guess it? The most basic advantage of egg powder machine is that it can extend the shelf life of egg. By using a egg powder machine, eggs are turn into powdered form, which can be stored up to 12 to 18 months, as a result, the egg powder can be used for all kinds of industrial application.

Wide Range of Application

Is this amazing? In fact, egg powder machine can not only be used to produce egg powder, it can also be used to produce other food and non-food products such as coffee powder, milk powder, washing powder, fruit juice powder, tea powder, cheese powder, vitamin powder, etc. Therefore, no matter in which industry you are, egg powder machine is useful to you.

High Efficiency

Egg powder machine adopts spray drying to make egg powder, it atomizes the egg, then make it contact with hot air, the moisture content in the egg evaporates, so as to achieve the purpose of drying. The whole drying process occurs in a short time, in other words, egg powder machine has high efficiency.

Uniform Drying

Egg powder machine has perfect performance and drying effect, the products which are processed by this machine has uniform particle size, as a result, egg powder machine is suitable for industries which have high requirement for uniform product size.

Keep Material Consistency

Don’t understand why it is said that egg powder machine can keep material consistency, well, as is mentioned that the drying time is short, thus the machine can keep the color, smell and taste of the raw material, in other words, the characteristic of the raw material aren’t changed by the egg powder machine.

3.In which industries can you use an egg powder machine?

It is mentioned that egg powder machine has a wide range of application, do you want to know that it can be used in which industries? To be honest, the common industries which you can think of, all have demands for egg powder machine.

Food Industry

It is no doubt that egg powder machine is widely used in food industry, besides egg powder, it can also make tea powder, flavor powder, milk powder, cocoa, fruit powder, cheese powder, coffee powder and so on. You can say that food industry has lots of demands of egg powder machine.

Pharmaceutical Industry

Do you know that drug powder is necessary in pharmaceutical industry, for capsules, they need to be filled with drug powder, for tablets, they need to be compressed from drug powder. Egg powder machine can help to dry drug into powder form so that it is can be produced into medicines.

Nutritional Supplements Industry

The nutritional supplements, for example, vitamins, some of them come in powder form, therefore, egg powder machine is used to produce vitamin and other raw materials of nutritional supplements.

Chemical Industry

Egg powder machine also plays an important role in chemical industry, it is used to produce all kinds of chemical products, such as washing powder, paint powder, NaF, SiO2, etc. But, note that egg powder machine isn’t suitable for all chemicals, it is widely used to dry heat-sensitive products.

Plastic & Resin Industry

It is less known that egg powder machine can be used in plastic & resin industry, plastic materials and products are heat-sensitive so that they can be easily dried by this machine. Egg powder machine dries the plastic and resin materials to uniform particles for specific production requirements.

4.What is the working principle of egg powder machine?

Through the previous description, you should have realized that the egg powder machine is actually a spray dryer, the working principle of this machine is quite simple, it just works through atomization and evaporation.

At first, the egg liquid is sprayed into ultra fine mist droplets by the centrifugal atomizer, then, the hot air enters the air distributor after being filtered and heated, and next it is blown into the drying tower evenly.

In the drying tower, the atomized egg liquid is in contact with hot air, at this moment, the moisture content of the egg liquid is evaporated, it is dried into dry powder, thus the egg powder is produced.

Finally, the finished product is discharged from the bottom of the drying tower and the cyclone separator, while the exhaust gas is discharged by the fan.

5.What is the technologies process of egg powder machine?

After learning the working principle of egg powder machine, do you feel curious about the whole technologies process of this machine? The whole working process of egg powder machine includes 7 steps, which are as follows:

- The first step is stirring, whisk the eggs into egg liquid to facilitate the subsequent processing steps.

- Next step is filtering, the purpose of this step is to remove broken eggshells, yolk membranes, eggshell membranes and other substances in the egg liquid.

- After being filtered, the egg liquid goes through sterilization, to ensure the hygiene of finished product.

- The fourth step is spray drying, the principle of this step has been introduced in the last question.

- What will happen to egg powder after spray drying? Well, when the drying process is finished, the egg powder is discharged, is this the end? of course not.

- When the egg powder is dried, at this time, it is still at a relatively high temperature due to the fact that it has just been in contact with the hot air, therefore, it must be cooled.

- After the cooling step, the whole technologies process nearly comes to the end, only remains the final step, screening. The egg powder is sifted to ensure that the final product is of high quality and meets production requirements.

- At this point, the technological process of the egg powder machine is at the end, and then the egg powder is packaged by other equipment.

6.What are the different drying methods of egg powder?

You know that egg powder machine adopts spray drying method to produce egg powder, however, are there other different drying methods of egg powder? Sure, there are, next they will be introduced to you one by one.

Pasta Drying

Pasta drying is to heat the mixture of egg yolks and egg whites to realize the purpose of drying, and then the dried mixture is cooling and screening, at this moment, egg powder is produced.Note that the mixture is heated at low temperature condition.

Freezing Drying

Freezing drying, as the name implies, it is to freeze egg liquid to dry it. During the process of freezing drying, the egg powder is frozen first and then by dried in a vacuum condition. There is a benefit of this drying method that it can keep a good oxidation stability of the egg powder.

Thermal Drying

What is thermal drying? By using this drying method, the egg liquid is directly heated and then in contact with air, as a result, it is dried and made into egg powder.

In a word, although there are other drying methods to produce egg powder, spray drying is the most common drying method which is adopted by egg powder machines, it can produce egg powder effectively and efficiently.

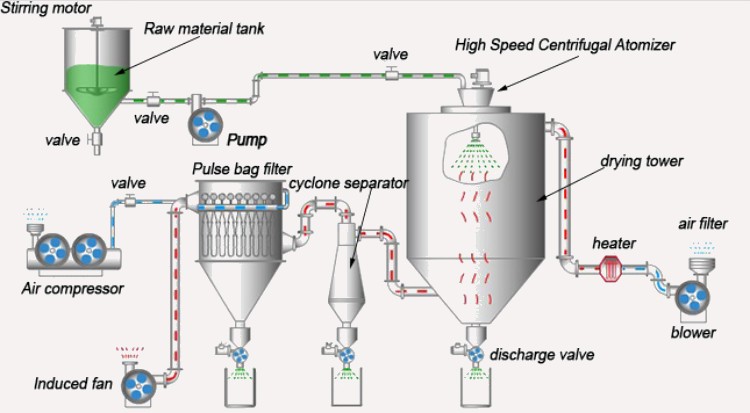

7.Which components consist an egg powder machine?

The egg powder machine is composed of many different components, each of them has its own function, and they work together to support the normal operation of the whole machine. No more talking nonsense, let's start learning some main components of the egg powder machine.

Raw Material Tank: This part is to storage the egg whites and egg yolks before they are stirred.

Stirring Motor: The function of stirring motor is to stir the egg whites and egg yolks to mix them, when the machine starts, the stirring motor begins to rotate to play its role.

High Speed Centrifugal Atomizer: This part is important to the whole drying process, it is to atomize the mixed egg liquid.

Drying Tower: It is the place where the drying process happens, the atomized egg liquid is in contact with hot air in the drying tower and dried into egg powder.

Blower: Blower is to inhale air into the machine, air is a vital element of the production process.

Air Filter: When the air enters the machine through the blower, it will pass through air filter, either. In this part, the dust and other impurities in the air are removed.

Heater: As is mentioned that, to dry egg liquid, there is a vital element, that is hot air. When the air is filtered by air filter, it is heated by heater, and then enters the drying tower.

Cyclone Separator: The function of this part is to separate solid and liquid by using the centrifugal force of the cyclone.

Air Compressor: You can guess the function of air compressor through its name, it is to compress the air and add the pressure.

Pulse Bag Filter: You can regard pulse bag filter as a cleaning system which is to remove particles and dust from the surface of internal filter by the compressed air.

Discharge Valve: When the discharge valve is open, the dried egg powder will be discharged through this component.

Induced Fan: The function of induced fan is to exhaust air when the drying process is finished.

8.How many types of egg powders can you make with an egg powder machine?

As is known that egg powder machine is versatile, it can produce different types of egg powders, do you want to know how man types of egg powders can you make by using this machine?

Egg Albumen Powder

Egg albumen power, is also called egg white powder, it is dried from the withe part of the egg. What are the benefits of egg albumen power? It increases your metabolic rate and provides you with the nutrients which your body needs. Egg albumen powder is widely applied in bakeries, confectionery, noodles and potato products.

Egg Yolk Powder

Egg yolk powder is made of the egg yolk, drying the egg yolk into powder, you can extend its shelf life and storage it for longer time, don’t need to worry that it will be spoiled.Egg yolk powder can be used as emulsifier or browning agent in the production process of sauces, bakery products and mayonnaise.

Whole Egg Powder

Whole egg powder is made of the mixture of egg white and egg yolk, the egg liquid is mixed totally by stirring, and then is dried by the egg powder machine. The whole egg powder has long shelf time, it can even be stored for 1 years. Generally speaking, the whole egg powder is often used to produce pasta and bakery products.

9.Which factors can affect the drying effect of egg powder machine?

During the drying process of egg powder machine, due to the different parameters, the drying effects are also different. So, which factors can affect the drying results? Let’s discuss together.

Spray Flow Rate

As you known, the egg liquid will be atomized under the role of spraying, therefore, the spray flow rate is an important factor that will influence the drying effect. Why? It is because that spray flow rate is a key indicator affecting the particle size of egg powder, the larger the spray flow rate, the higher the agglomeration rate of egg powder.

Feed Temperature

This is also an important factor which will cause changes of the drying effect, generally speaking, the best feed temperature is 40℃. When the feed temperature is 40℃, the agglomeration rate of egg powder reaches the minimum value,which means that the drying effect is the best at this time.

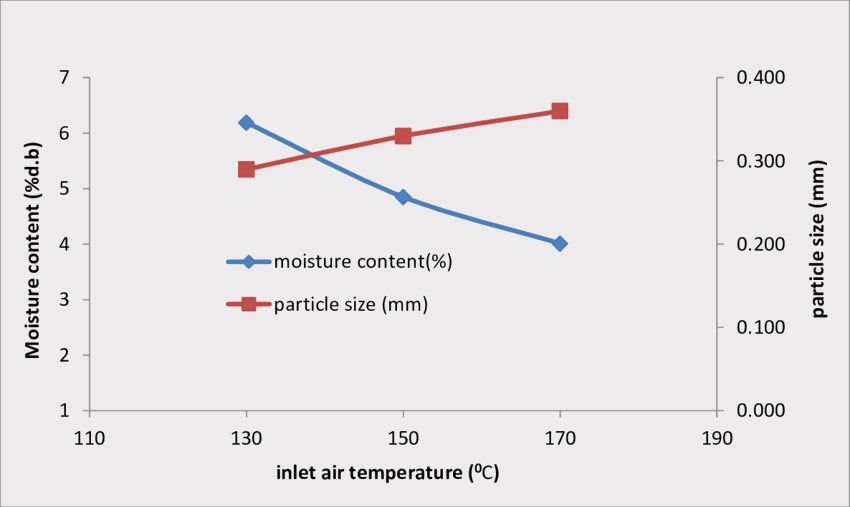

Inlet Air Temperature

Inlet air temperature is the main source of heat in the spray drying process, the most proper inlet air temperature is 180 ℃. If it is higher than 180 ℃, there may be sticky walls and burnt paste, which will seriously affect the quality of egg powder; when it is lower than 180 ℃, the egg liquid is not completely dried and not easy to form egg powder.

10.Are there any other egg powder processing machines?

It has been explained that egg powder machine is to dry egg liquid and make egg powder, however, are there any other egg processing machines which can be used as auxiliary equipment of this machine? Of course there are, these machines are as follows:

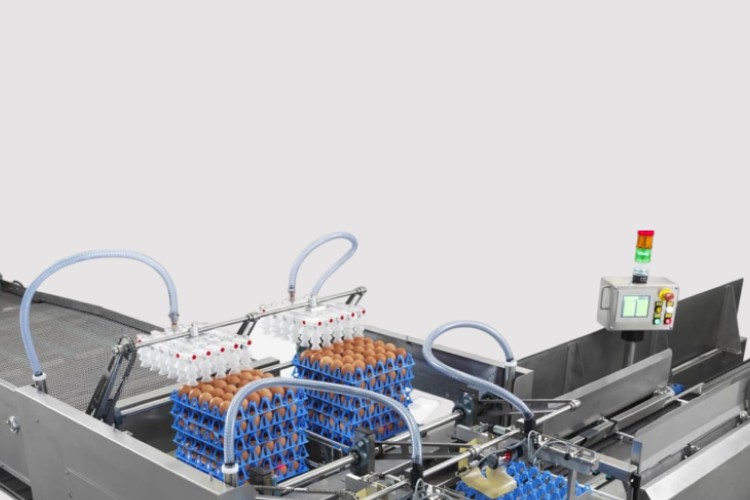

Egg Loader

Egg Loader-Photo Credit: Sime-Tek

Egg loader is used to deliver eggs, as the picture shows, this machine has a unique component which can catch the eggs which are packed in trays, and then these eggs are delivered by the conveyor belt to enter the next working procedure.

Egg loader make the delivering process of eggs more convenient, and avoid the risk of eggs being broken during transportation.

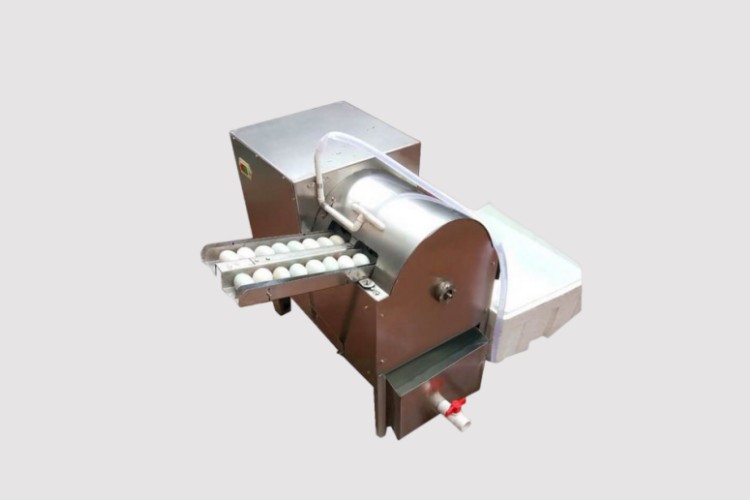

Egg Washer

Egg Washer-Photo Credit: Egg Machine

Egg washer, as the name implies, is used to clean eggs, it wash the egg shells to guarantee there are not dust and other dirt on the surface of these eggs. Why is this machine used for egg processing? It has high production capacity, can wash up to 10,000 eggs an hour, is suitable for mass production.

Egg Breaker

Egg Breaker-Photo Credit: Moba

Egg breaker can also be called as egg separator, it is used to break eggs and separate the egg white and egg yolk automatically. This machine is equipped with special designed pneumatic holders, can replace human hands. It works with high speed and high precision, which can improve the efficiency of egg processing.

Egg Pasteurization Machine

Egg Pasteurization Machine-Photo Credit: Meridian Trade Links

You know that egg powder is made of egg liquid, if you want to get high quality egg powder, at first you should ensure the egg liquid is sterile, as a matter of fact, egg pasteurization machine can play this role. This machine is an ideal solution for egg liquid processing, and it is necessary in the whole egg powder production line.

11.How to maintain egg powder machine?

If you want to exntend the service time of your egg powder machine, it is necessary to maintain it regularly. How to maintain it? Are there any precautions during the maintenance of egg powder machine? With these questions, try to find the answer in the following content.

- During the operation processof the machine, if the centrifugal nozzle makes noise, stop the machine immediately and clean the nozzle.

- If you want the centrifugal nozzle to work smoothly under high-speed rotation, it is best to use the nozzle alternately.After the machine has been working continuously for 8 hours, the nozzle needs to be replaced.

- When using the egg powder machine, it is necessary to carefully check whether the bearings and bushings, as well as the transmission parts such as shafts and gears, are abnormal. If they are, the damaged parts should be replaced in time.

- Regularly use lubricating oil to maintain moving parts such as bearings and gears.

- When you finish using egg powder machine, you need to remove the atomizing disc and wash it with water, to remove all kinds of stains on the surface.

12.What if you want to search for a perfect egg powder machine?

A high quality machine can increase the whole production efficiency, therefore, purchasing a perfect egg powder machine is important, but, how can you do that? There are some questions that you should think carefully before making decision, they are:

Production Volume

The basic thing you need to consider is the production output of the egg powder machine, firstly, estimate how much egg powder you need to produce and how long is the expectant production time. After you calculate all this, try to select a egg powder machine which can easily meet your production volume requirements.

Space Limitation

You should consider the size of your workshop, too, how large a machine can your workshop accommodate? There are many different egg powder machines which are in different sizes, you should choose one which can be installed and normally run in your workshop.

Investment Budget

The last but not the least, your investment budget is also a decisive factor of your choice. You should figure out how much can you invest for an egg powder machine, and think about your requirements for this machine, and is it necessary to buy an expensive one.

Conclusion

What are your opinions after reading this article? Do you think purchasing an egg powder machine is necessary? Do you know everything about this machine? Now, going over this machine in your mind, is there anything else you still don't understand about it? You can tell your puzzles to us so that you can get the answer as soon as possible.

Don't forget to share this post!

Egg Powder Machine Related Posts

Egg Powder Machine Related Products

Egg Powder Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine