Best Auger Filling Machine

- Automatic Weight Feedback Scale

- Dust Remove Device Ensure Cleaning

- Side Open Hopper Easy to Clean

- Fully Welded and Polished Screw

AIPAK Auger Filling Machine

AIPAK automatic auger filling machine has mixing and filling function,which is specially and professionally designed to do dosing and filling work.All AIPAK auger filling machines are suitable to fill the powders into bottles,cans,and bags,that can fill the materials like coffee powder, wheat flour, condiment, solid drink, veterinary drugs, dextrose, pharmaceuticals,powder additive, talcum powder, agriculture pesticide, dyestuff, and so on.The filling mouth is adjustable according to different containers.All AIPAK auger filling machine has high precision, error≤±1%, with high speed,with digital tube display, simple and convenient to operate.The filling and weighing range is: 1-20/50-500/100-5000 g,workbin is made of stainless steel or organic glass, quite easy to unpick and wash without tools.

AIPAK Auger Filling Machines

Semi-Automatic Spice Powder / Baby Powder /Food Powder Auger Filling Machine with Weigher

AIPAK semi-automatic spice powder/bady powder/food powder auger filling machine can do measuring and filling work. Due to the special design, so it fits more to the fluidic or low-fluidity materials, like milk powder, gourmet powder, solid drink, white sugar, dextrose, coffee, fodder, solid medicine, agriculture pesticide, granularity additive, dyestuff, and so on. LCD or touch screen control( in Chinese or English), Servo-motor driving screw. The surface of whole machine is made by stainless steel material except of motor. Knockdown Transparent hopper, which could be washed without tooling.

Dexterous and flexible

Easy removal

Invariable materials and package-weight specifications

Get A Free Quote Now

Semi Automatic Dry Powder Auger Filling Machine with Screw Feeder

AIPAK semi automatic dry powder auger filling machine with screw feeder is applicable to all kinds of powder and mixed powder-like material weighing filling, such as: fertilizers, additives, flour, milk powder, coffee powder, washing powder, solid drink, sugar, monosodium glutamate, condiments (such as spicy fresh), natural flavoring , enzymes, feed powder (powder, superfine powder), mixing quantitative powder-like material filling.

Suitable for all kinds of bottles, cans, bags

Adjustable feedback value

Stainless steel

Get A Free Quote Now

Tin Aluminum Can Auger Cup Automatic Coffer Dry Milk Powder Small Bottle for Food Auger Filling Machine

The head of auger filling machine is mainly composed of filling assembly, stainless steel plexiglass bucket and other institutions. The machine surface material adopts 304 stainless steel, corrosion resistance; In line with national GMP design requirements; Filling and mixing are imported motor, stable performance, high filling accuracy; Not leaky; Easy to disassemble, wash and replace the screw; With the automatic production line connection stability, high filling efficiency! By changing the screw attachment, it can adapt to the packaging of various bottle specifications, powder and fine granule materials.

Safe and reliable, wide adaptability

Humanized design

Beautiful appearance

Get A Free Quote Now

Automatic Bottle /Can/ Jar Dry Auger Filling Machine

AIPAK automatic bottle/can jar dry powder auger filling machine is a new designed that we make it according to the old turnplate feeding one one side . This machine ould be used in filling mold powder ,albumne powder, condiment,dextrose,rice flour,cocoa powder,solid drink and so on. This auger filling machine is suitable for dry syrup, talcum, Pharmaceutical Powers, Food & Beverages, Cosmetics powder, Pesticides Powder,Cocoa Powder packing, Protein powder packing etc.

PLC and contact screen control

Servo motor filling control

Filling weight adjustable

Get A Free Quote Now

Auger Filling Machine Filling Powders

Auger Filling Machine Finished Products

The Buyer's Guide

Auger Filling Machine: The Ultimate Buying Guidelines in 2025

Lots of people are confused when it comes to filling and portioning an accurate volume of powder.

For this purpose, the majority of manufacturers prefer auger filling machines for handling powdery products, especially for the grinding of extremely fine particles.

It’s so obvious that due to growing competition in the marketplace every manufacturing company needs to assess a way to facilitate their powder substance down the distributing chain with safety. Furthermore, they aim to supply powder products to end-consumer with excellent quality, hygiene, and originality.

From spices, flour, beverages to personal care goods such as talcum, baby powders, tooth powders; from therapeutic medicines, nutraceuticals, sweeteners to chemicals like pesticides, powder coatings, and so on. We consume an infinite list of powders in our routine life.

So, many brands offer a more appealing and attractive way to dispense powdery products using modern filling equipment. This growing trend gradually obsoleting the usage of manual filling equipment and adopting an innovative way to filling powdery products.

Hence, the auger filling machine is a distinctive tool that gives the powder manufacturing business a lot of benefits of world-class technology.

Read on to know more!

1.What is an auger filling machine?

Auger filling machine meant to fill a right and accurate concentration of product into its confined container. A product in the machine is stored in a chamber called ‘hopper’, each cycle of filling process accompanied with a predetermined concentration of product in the package.

While the package is a bottle that can be fixed for manual filling or can be queued up for filling automatically with the help of using a conveyor system.

Furthermore, an auger is a drill that is made in the shape of a screw used to drill the accurate holes in raw material. This machine can be used to fill, powdery, liquid, semi-solid, and granular materials.

Auger Filling Machine

Many sugars, salt, spices, cosmetics, and liquid selling manufacturer use this machine for easily filling procedures. Using the right configuration, this machine is perfect for handling many types of products such as free-flowing and non-free-flowing products.We’ll discuss free-flowing and non-free-flowing products later in this blog.

But, certain types of material are not supported by auger filling machines, such as tobacco as it tangled all over the auger, filling of fruits, cornflakes and raw fruits can be compromised by the auger filling machine as it can be crushed during the filling procedure.

2.What are the pharmaceutical powders and their classifications?

Powders are the oldest and conventional form of dosage formulation. It has the most multi-connotation in pharmacy. It is also a physical form of substance that is dry with finely divided particles used as the fundamental base for many solid dosage formulations such as tablets, capsules.

Not just this, you can also use powders in the pharmaceutical manufacturing of ointments, suspensions, and syrups. Additionally, their topical preparations are meant for medicated applications for skin, burn, and related issues.

So, it won’t be wrong to say that powder is a magical ingredient at the ‘HEART’ of all pharmaceutical preparations.

Thus, to improve the quality, and preserve efficacy it is necessary to understand the behaviour of powders. No- doubt this is a challenging task that entirely exerts positive effects on many variables.

Naturally, they’re derived from hard vegetable sources such as bark, roots, and wood such as rhubarb, cinchona, and charcoal. All synthetically available drugs are introduced with natural powders that are incorporated with insoluble drugs such as bismuth salt, calomel.

Classification of Pharmaceutical Powders Based on Dispensing

Powders can be generally categorized by the way they’re dispensed to the consumer into bulk powders and divided powders.

Other classes of powders are based on particle size and usage.

Bulk powders

Bulk powders are free-flowing dried powders that are available in one or a mixture of finely divided powdery substances. They are basically intended for internal and external applications supplied in large quantities and mostly applied for less potent preparations. They are measured in acceptable accuracy and safety with the help of measuring devices such as a teaspoon or measuring cups. This practically limits the application of oral dispensed bulk powder to dietary supplements, with analgesics and laxatives. They are mainly used for topical purposes.

Bulk Powders

Divided powders

Divided powders also termed chartulae that are dosed individually in a distinguished pack. Traditionally, they are packed in wrapping paper while volatile and hygroscopic drugs wrapping are done using aluminum foil and plastic bags.

Divided powders treated for potent drugs that are effective and potent in a very low concentration. They are significantly intended for internal applications only.

Divided Powders

Sorting of Pharmaceutical Powders Based on Applications

Considering the application of pharmaceutical powders for internal and external uses are briefly discussed below.

Pharmaceutical Powders for Internal Applications

Pharmaceutical powders used internally are most often solid, loose, and dry particles presented in variable sizes and one or more active components with and without excipients. They are taken orally such as antibiotics or administered via intranasal way or administered as an insufflation into body cavities.

Pharmaceutical powders for internal use

Pharmaceutical Powders for External Applications

External or topical powders are also termed as ‘cutaneous powders. They are presented in solid, loose, and dry particles with variable degrees of fineness.

Pharmaceutical powders for external use

They are also available with and without excipients in different coloring matters. A cutaneous powder is externally applied to the compromised wounded area. They are also be used as Over the Counter (OTC) or prescribed to deal with different injuries. While they are mostly not recommended to apply directly to oozing wounds due to the formation of hard crust.

3.What are free-flowing and non-free-flowing powders?

Whether it can be protein milk or herbal spices, or pharmaceutical products, their mixing always requires a proper blend and a well-specialized technique of handling. For this, you need to understand the flow properties of powdery substances because every substance has its own extrinsic property.

For auger filling machine we need to understand about free-flowing and non-free-flowing substances.

Free-Flowing Powders

As its name shows free-flowing powders are non-cohesive substances and are easy to flow. For instance, salt, granulated sugars are free-flowing powders when dispensed. They generally do not form any shape when applying pressure, furthermore, these types of substances cannot be compact even applying extra pressure.

Non-Free Flowing Powders

Non-free-flowing powders, are cohesive in nature and form a compact structure by applying extra pressure. Non scientifically, you can test non-free-flowing powder with a finger test. For instance, you can press the finger into a container of a powdery substance, if you feel the compression of the product after removing your finger, then it is described as non-free-flowing powders.

Determining whether the powder is free-flowing or non-free-flowing is of prime importance for a successful powder packing project.

Furthermore, free-flowing powders utilize volumetric or free-flowing auger filler for packaging, whereas non-free-flowing necessitates a specialized auger filler to dispense cohesive materials.

4.How does the auger filling machine work?

The working criteria of the auger filling machine are based on the following steps as followed:

AIPAK Automatic Auger Filling Machine

#1- Feeding of Filling Parameters

This step is accompanied by filling parameters involved during the filling process on the auger filling control system.

#2- Feeding/Filling of Empty Containers

For the filling of containers using a manual auger filling machine, operators feed the assigned containers one by one to their respective place on the machine and initiate the filling of the container via foot or finger switch. For automatic auger filling machines, a power conveyor system is used to queue up the containers to be filled.

#3- The Filling Process

The feeding of filling products is continuously provided to auger screw via hopper that eventually provides an accurate fill.

Since an auger filling machine is a volumetric filling machine, therefore, this machine won’t the products before each cycle of filling.

Auger drive helps in rotating the auger screw under a constant acceleration as it sustains the powder into the hopper’s tube.

An agitator blade rotates in the opposite direction of the auger screw and a separately controlled unit. This helps in homogenization and de-aeration of the product also helps to break the inconsistencies of non-free-flowing powdery products. Moreover, the agitator blade widens down the tube’s throat to avoid the formation of cavity and rat-holing. This ensures a consistent filling on the machine’s auger flights.

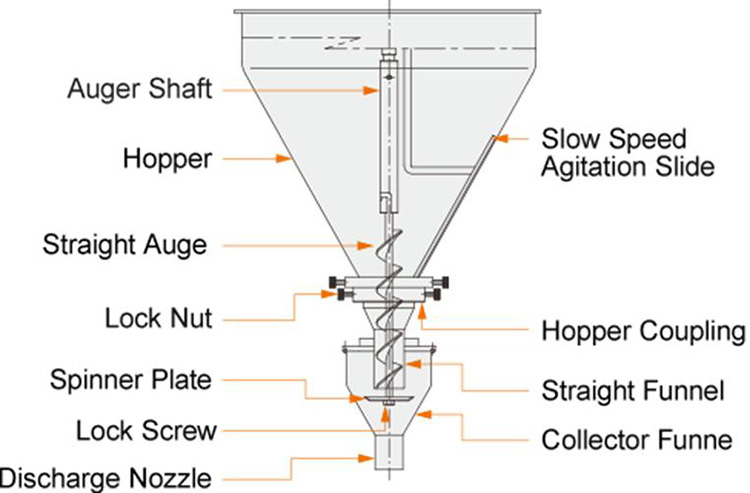

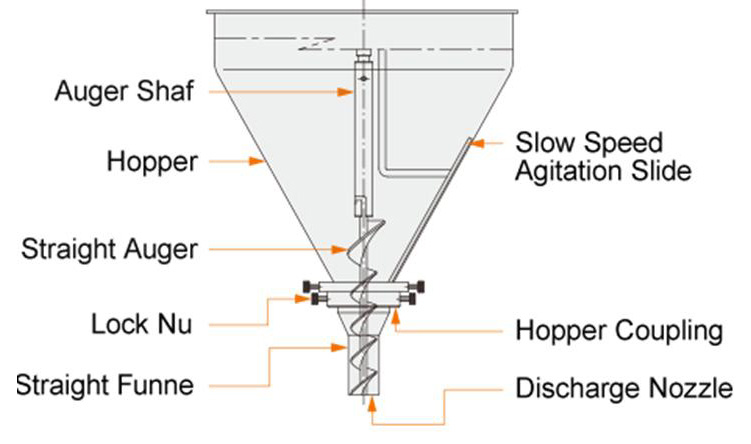

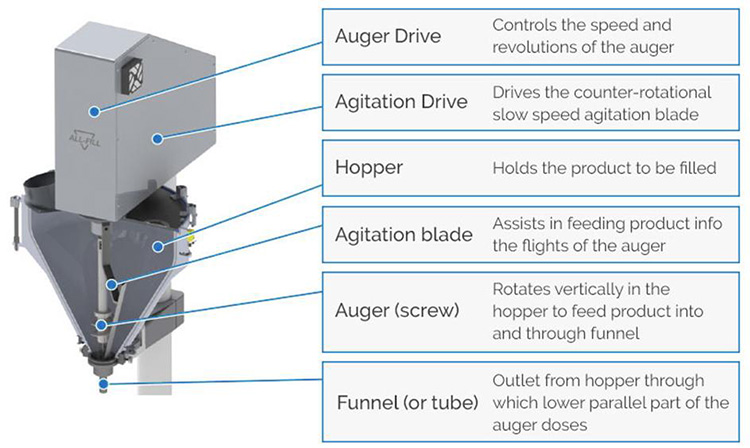

5.What are the key components of an auger filling machine?

An auger filling machine comprises the following basic components to help the filling processes.

Agitation

An auger filling machine is provided with ‘agitator blades’ that help to transfer the products towards the flight of the auger. This includes high speed and slow speed agitation.

A high-speed agitator blade is positioned on the auger shaft that works with the same speed as the auger.

A slow-speed agitator blade is basically driven by a separate motor, a gearbox, and a chain drive of the machine.

The slow-speed agitator blades move in the opposite direction of the auger, while both agitators’ blades installation take place before using the machine.

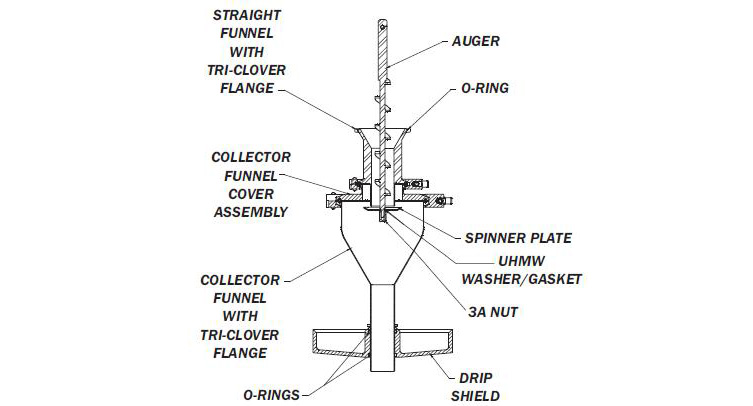

Auger

Auger is the main component that helps in the product dispensing directly into a container. The auger is installed into the auger shaft over Fill Head and easily be removed from the auger shaft during maintenance and service procedures.

There are several types of auger are available that are selected relevant to the amount of product to be dispensed, applications, and types of products.

Similar to agitator blades, the auger is also installed by the operator before using the machine.

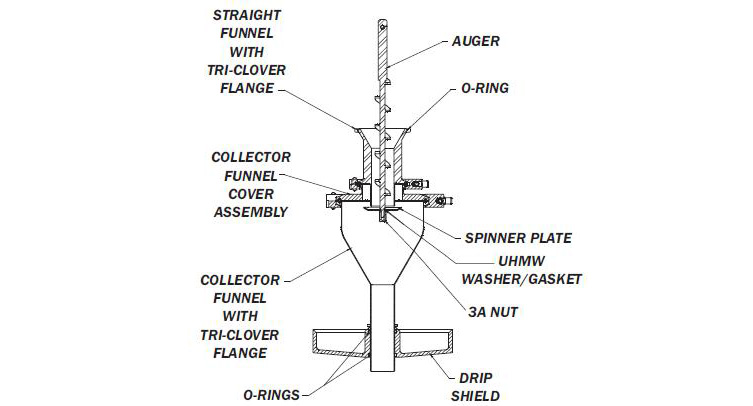

An auger may include the following accessories:

A drip washer

Spinner plate

Adapter shaft/ auger locking collar

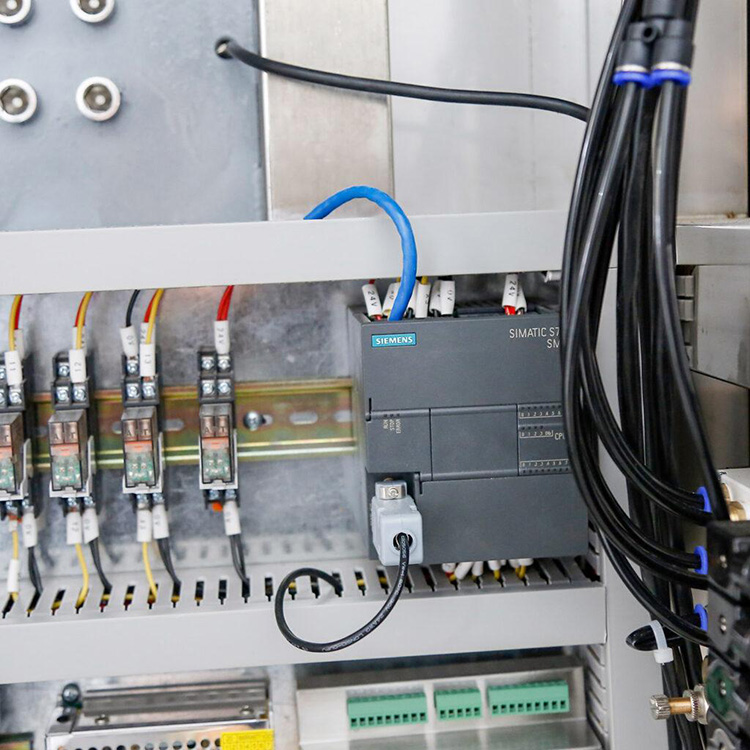

Auger Machine Controller

The filling process of the auger machine is mainly controlled by a separate unit known as Auger filling machine controller mounted on a nearby machine. This includes a regulated Programmable Logic Controlled or PLC with a Touchscreen Human Interface/HMI.

The user manual helps to operate each protocol and system feeding process.

Fill Motor

The auger machine operation is basically attained with the help of a high-performance Fill motor that is installed within the Fill Head.

This motor and corresponding motion control electronic pack system facilitates a precise, well-controlled movement of the auger in order to dispense a well-defined concentration of filling products. It generates sufficient power to distribute every component of the filler machine without any interruption. This component is of prime importance as it converts electrical energy into mechanical energy effectively.

Foot Switch

An external switch that is typically foot-operated helps the user to initiate the operation. With the help of footswitch signals, a supplied information on filling machine control system filling procedures gets started.

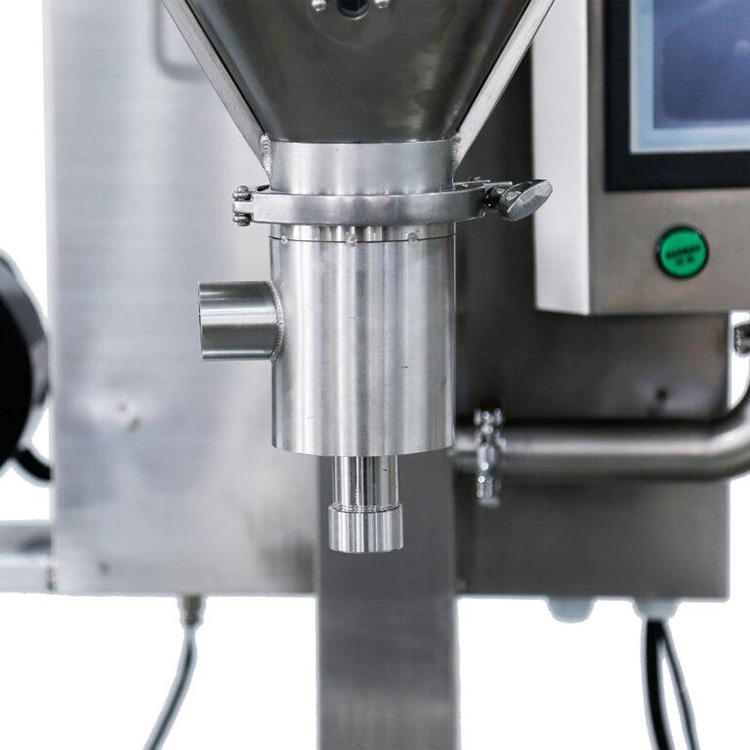

Hopper

A hopper is a prime component surrounded by the Fill Head. This hopper also includes a smart-disconnect coupling that allows easy removal and fitting of the hopper for cleaning and maintenance purposes.

To install a hopper or re-adjustment requires a proper alignment corresponding to other components of the auger filling machine. A proper alignment of the hopper will help you to get a precise, accurate, and controlled dose delivery.

Level Controller

The hopper of the auger filling machine may associate with the ON/OFF level controller. The level controller helps to determine the remaining amount of powder/product in the hopper. The level control is installed on the top of the hopper and utilized to actuate the equipment for re-supply the additional material into the hopper. Additionally, this part of the auger filling machine ensures an accurate filling as the timer helps in tracking the filling process.

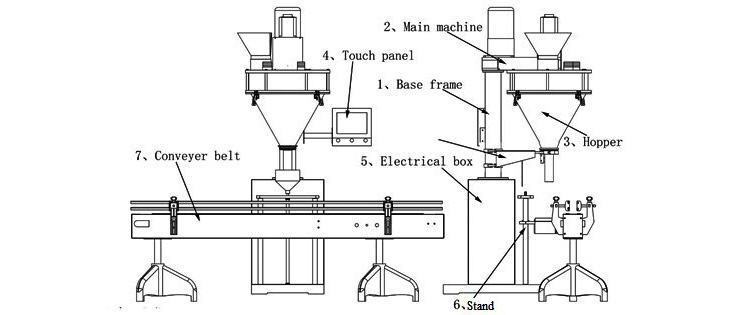

Conveyor System

A conveyor system of auger filling machine is used to carry a continuous movement of products containers. The belt is extended between two endless loops for feasible activities from one part to another part of the machine.

A conveyor system of auger filling machine

Dusting Unit

Working with powder is a sensitive procedure, as it can hold dust during the mixing procedure. Therefore, the auger filling machine has a dust removing device that specifically works to collect the dust particle when it enters the machine.

A dusting Unit of Auger filling Machine

Discharging Unit

When the process of filling is achieved then a filled container is removed from machine with the help of discharging unit. A discharging unit helps to move the filled product container for final packing.

Discharging Unit of auger filling machine

Support Structure

The whole system of the auger filling machine is mounted compactly on supplied stands known as a support structure.

6.What are the industrial applications of auger filling machines?

There is a broad range of applications for auger filling machines. It has the ability to deal with various kinds of powders such as free-flowing and cohesive or non-free-flowing powders. The procedure of filling powders into their confined containers becomes very simplified by using an auger filling machine.

Industrial application of auger filling machine can boost your brand and business in many ways.

Improving Brand Value: By flexible and accurate powder packaging can improve your brand value as the consumer gets attracts via observing presentation and correctness.

Extended Shelf Life: An excellent powder packaging may improve and protect the flavor, freshness, and potency of the product which ultimately increases product shelf life.

More Reliability and Functionality: Using auger filling machines for automatic packaging processes with greater speed and accuracy ensures reliability and uniformity of the packaging process.

Since powder is one of the fundamental substances used in a broad spectrum of manufacturing units. Therefore, you can find several applications of auger filling machines on a large scale of the industrial platform as discussed below.

Pharmaceutical Industry

When you get a pharmaceutical dosage formulation, you will notice an accurate concentration of dispensed material that is actually safe and effective for oral administration. Similarly, when you consider a topical application of powders, you’ll get the exact same result.

Indeed, there might be some extensive tool that helps to dispense an accurate dose during the filling process.

The standard practice for pharmaceutical preparations is evolving with modern techniques day by day.

Auger filling machines avoid chances of error and eliminating the need for manual handling for measuring powders. Thus, an accurate and high precision is achieved when encountering an auger filling machine for pharmaceutical dosage packaging of powders.

Pharmaceutical Powders

Heavy Metal Industry

To run a successful business in the market you will always be required with specialized equipment to run a smooth system. A powder filling solution by using an auger filling machine for the heavy metal industry must meet customer expectations and financial goals.

Sulfur Powder

Auger filling machine is a versatile machine that works independently for filling heavy metals with a high level of automation. They can easily handle fine and large particles of substance such as aluminium powder, copper, and iron powder during the powder filling packaging process.

Iron Powder

Food and Beverage Industry

Auger filling machine has several applications in the food and beverage industry for product filling purposes. These machines meet GMP standards suitable for milk powder, coffee powder, wheat flour, etc. The high-speed auger machine enhances business productivity, easy to operate which protects your product from an entry of foreign particles.

Auger filling machine for Food and beverage industry

Veterinary Industry

Some veterinary medicine is based on powder formulation. Thus, an auger filling machine is useful in the veterinary industry that animals can easily take while such powder can easily be solubilized in water.

Plastic Industry

In the plastic industry, polypropylene powder is generally used during the manufacturing process of plastic materials such as plastic containers, pills containers, dishes, etc. Therefore, an auger filling machine can be used for filling such types of powders.

Plastic Material

Chemical Industry

In the chemical industry, reactive and non-reactive powders are being packed using an auger filling machine. The filling of powder can be done in respective bottles and sachets. An auger filling machine is generally used to deal with the filling of pesticides, herbicides, and other laboratory material.

Agriculture Industry

The industry consumes auger filling machines to pack organic and inorganic products, like fertilizer. Auger filling machine facilitates safe handling and packaging that you can easily transport the filled material to any part of the world.

Cosmetics Industry

Auger filling machine is extensively used for powder filling purposes in the cosmetic industry. You can use an auger filling machine for packaging baby powder, loose powder, cosmetic detergents, etc.

Auger filling machines provide a high-quality cosmetic filling into respective containers, jars, makeup kits, etc. As the cosmetic industry rapidly evolving day by day thereby, innovative technology of auger filling machine also try to accommodate filling properties feasible for various shapes and sizes of containers. Furthermore, auger filling machines also deliver product filling varying from various levels of viscosity.

Cosmetic powder containers

7.What are the classifications of auger filling machines?

Manual Auger filling machine

At the beginning of any business, a small-scale industry or individual will prefer an extremely cost-effective way of spending money on equipment costs.

A manual auger filling machine is used to fill powdery material suitable for small-scale production. It is a very fast and efficient way of filling process ideal for both free-flowing and non-free-flowing products.

A Manual Auger Filling Machine

The manual auger filling machine is perfect for dealing with powdery particles possessing good fluidity and is also used for filling thick powder that has poor fluidity like corn starch. This machine is not suitable for dealing with fragile flake material or material with high specific gravity.

The accuracy of manual auger filling machine is based on manufacturing precision, co-operation gap between auger and catheter and rotation of auger speed, etc.

Manual Auger Filling Machine

Semi-Automatic Auger Filling Machine

Semi-automatic auger filling machines working is generally controlled by a PLC controller while all parameters can be easily stored using a touch-screen control panel. Thus, semi-automatic auger filling machines are convenient for operators to use. Furthermore, you can easily fill the desirable weights within certain limits without altering or transferring them into another machine.

AIPAK Semi-automatic Auger Filling Machine

A semi-automatic auger filling machine has an auger screw, electronic weighing measuring mode which is associated with a micro-controller. This machine is accompanied by an automatic error correcting option.

This machine is appropriate for filling condiments, flour, milk product, protein, veterinary, and other powders.

Automatic Auger Filling Machine

A fully automatic auger filling machine is based on modern technology that controls the entire working process automatically. Thus, you do not require extra manpower to run the operating system as it itself utilizes up-to-date technology for efficient outcomes. The entire operation of filling powder, measuring, and weighing of filling material is accurately regulated with high automation. This machine is not only limited to deal powdery materials, but you can also fill granules of smaller sizes packed in various shapes of packets and pouches.

Automatic Auger Filling Machine

There are few advantages of using a fully automatic auger machine.

It is a cost-effective machine as there is no labour work required during the powder filling procedure.

It provides maximum accuracy and precision during the filling procedure.

An automatic auger filling machine is robust that is capable to yield error-free work on a larger scale of the manufacturing process.

8.What are the benefits of an auger filling machine?

The major benefits of auger filling machine are as following:

Fast Working and Easy mobility

Due to its compact and closed structure, it can move easily and has the fastest working acceleration.

Stable and Gentle Working Processes

Auger filling machine has little friction and facilitates stable working.

Touch Screen Display

You can find a working menu using the TOUCH SCREEN display available in English and other convenient languages to make easy understanding during operating it.

User Friendly

A significant alarming system warns the users in case of unpredictable matters or warnings. Also, it is safe for humans and user-friendly.

High-Quality Equipment with Easy Maintenance

Auger filling machine is made up of stainless steel making them user and environment friendly. Additionally, this structure is easy to clean and maintain the machine.

Flexible Adjustment

You can fill multi-containers by using an auger filling machine, thus it is not hard to adjust this machine corresponding to your product type.

Easy Handling of Equipment

Auger filling machine is flexible to handle for perfect filling of an accurate and precise amount of product in no time. Therefore, the value of this machine on large-scale production cannot be overlooked.

Highest Process Reliability

Auger filling machine is an innovative and cost-effective means of volumetric filling. Because it facilitates comprehensive outcomes with less expenditure of raw materials during the filling process. Thus, you’ll get improved production by expending no time.

9.What are the disadvantages of auger filling machine?

Auger filling machine is a well-acknowledged and innovative means of filling products. As you already know nothing is perfect surround you, everything has pros and cons.

Discussed below are some disadvantages of auger filling machines.

Powders with Irregular densities

Auger filling machine is not suitable to deal powders with irregular shapes as well as densities. You possibly notice inaccurate behaviour while dealing with such substances.

An Expensive Technique of Filling Products

Auger filling machine is an expensive way of filling products especially when you are encountering a larger scale production unit.

Determining Nature of Filling Products

Powders are generally available in a free-flowing and non-free-flowing form. While every manufacturing unit maybe deals with free-flowing or non-free-flowing substances. Therefore, the principle of working of auger filling machine is not the same for both types of powders.

Auger Filler for Free-Flowing Powder

Auger Filler for non-free-flowing powders

Therefore, it is necessary to understand the nature of substances and the principle of handling such substances. Side by side, you will require a slow agitator while working with non-free flowing substances and vice versa for free-flowing substances.

10.What are the installation requirements of the auger filling machine?

For the installation procedure, you will use the following tools and materials prior to initiating the work. For instance, screwdriver, adjustable wrenches, hopper alignment tool, a sealer, and gear lube. For electrical and pneumatic connections, you may require some additional equipment. The procedure and recommendation related to installation auger filling machines are as followed.

Inspection and Unpacking

Upon receiving the auger filling machine from the manufacturer, you should inspect for any wear and tear of the machine. If it does not appear broken or damaged, then you may continue the further procedure.

Site Requirement

Auger filling machine is designated to work in a variety of industrial platforms without the need for special equipment. The general operating conditions of auger filling machine are:

Temperature: 0 t 0° to 50° C

Relative Humidity: 5 to 100%

Electrical Requirement

For installation, all electrical systems should be lockable safety disconnected switches. The auger filling machine is connected from power capacity input mains at the site. Furthermore, electrical requirements such as voltage, frequency are listed on the machine’s tag and a provided wiring flow diagram.

Product Site Requirement

Before initiating an installation, the site should be assessed in terms of product availability and their resupply to a hopper. Furthermore, the product level should be fixed within 2”-3” top of the hopper for the proper filling operation.

11.What safety measures are needed during the installation and working of the auger filling machine?

By following certain guidelines of installation of auger filling machine will reduce the chances of an accident, operator’s injury, or damage to the machine/equipment.

Let’s get into it!

Use an appropriate lifting tool to place a machine in its assigned position. For this, you need to refer to the shipment record and choose the lifting equipment.

For the positioning of the machine, you will require a stable, sound surface that not only supports the total weight of the machine but also additional equipment and operators.

The installation area should relatively be cleaned and dry with proper air-circulation and lighting.

As you know during the filling of certain powders, a dust explosion hazard can occur. Therefore, to be cautious for ignition and combustion issues for which you should be prepared accordingly.

All electrical connections should abide by industrial practices, following local regulations for the establishment of electrical codes.

The entire installation procedure should be accomplished while DISCONNECTING from the auger filling machine at Safety Disconnect Switch. All power should be reconnected after completion of work.

After installation of auger filling machine, check if it is working properly or not. Thus, to operate the auger filling machine you’ll necessitate the following consideration points. Additionally, never ignore the use of Personnel Protective Equipment (PPEs) to operate the machine.

All safety guards should be well-placed during operation.

Never attempt for adjustment when electrical power is connected.

All parts of the machine such as the auger, agitator should be presented with snagging hazards when in use.

Never put the hand or any foreign object into the hopper during processing.

After supervising the working mode, switch OFF the electrical power. Never over-lubricate the auger filling machine with oil and grease as it will catch the dust that will compromise the moving parts.

12.What are the important maintenance factors of the auger filling machine?

Scientific maintenance and management of auger filling machine are very important for improving your profit and reduce the cost. By following routine patterns on a daily, and monthly basis will ensure a continued, reliable operation of the auger filling machine. It will not be only ascertaining a suitable work condition but also help you to identify a potential problem that could lead to machine breakdown.

Daily Maintenance

Daily basis maintenance points include:

Check all electrical connections for loose and frayed wires that could lead to cause a short circuit.

Inspect if the filling controller is operating properly.

Swipe any left-over particles, accumulated products, dust, or moisture on the external surface by using a clean and dry cloth.So, clean the machine and remove debris on the machine in time.

Remove or tighten any loose tool around the machine to avoid injury.

A routine inspection of each component of a machine, electrical appliances, and abnormal noises should be performed. Furthermore, a timely entry/listing of each action, accident, and maintenance should be recorded.

Monthly Maintenance

The following points should be considered every month.

Inspect the agitator gearbox for purpose of lubrication and oil break. In case, oil leakage is present contact the service provider and recheck on a daily basis until the unit is removed or replaced.

Check for any worn-out missing teeth of gears and sprockets.

Inspect the sealing of oil and grease.

Properly lubricate the idler sprockets with a suitable shot of multi-purpose greasing coat on equipment tools such as conveyors, agitator, etc.

Check the alignment of Hopper.

Clean out foreign particles that may have collected around and inside the Fill Head.

Note: auger filling may be working in a dust filling condition due to the nature of products. Therefore, over-lubrication may result in the stickiness of particles on oil and greasy surface. Ultimately it will affect the moving parts of a machine and their function may be compromised.

13.What are the technical problems of auger filling machines and how to troubleshoot them?

Auger filling machine is an automatic technical tool that is the best choice to deal with dry, non-sticky powdery materials. The production capacity of auger filling machine is based on the need of users, cost, and production size. However, practically during the filling operation, there may be some failure in the proper functioning of auger filling machines. This is necessary to understand the perspectives of machine technical issues and mastering how to tackle auger filling problems is worthy.

No-Electrical Power and Motor Tripping

Sometimes machine does not start which is possibly caused by no electrical supply or motor tripping. If the operator cannot start the auger filling machine, it is necessary to check whether a filling sensor identifies or detects the signals within a reasonable limit. Furthermore, the air compressor should be in proper functioning mode. For this, you need to check a circuit breaker and reset the overloads of the auger filling machine.

HMI Problem:

Auger filling machines are confined with an LCD touch screen system. Most often a touch screen system enters the intelligent power saving mode when it is not operated for a longer time. Thus, the user can bring it back by tapping any part on the touch screen to regain its activity.

Equipment Starts but Does not Dispense

There might be some symptoms when the machine starts but it doesn’t dispense the material. The probable cause might be the initiation switch or accessories. For this, you need to energize the circuit initiation and inspect the direction of motor rotation.

Furthermore, when machines do not support agitation services, you need to inspect the functioning of the controller, motor starter, and drive train. Reset the agitation settings, reset the overloads and agitation gearbox and sprockets.

Accuracy Problem

Almost every customer pays complete attention to get 99.9% precise and accurate filling outcomes while using auger filling machines. If the user finds inaccurate and unstable behaviour during the process of auger filling machine, then,

It should be checked whether agglomeration occurs or not. This problem can be encountered by turning ON the blender motor for evenly mixing of material in the hopper.

Product dripping, for this you need to inspect the setting of accessories.

Weight variation can also occur when a machine has Hopper head pressure, thus it must be maintained at 2” to 3” of variation. Furthermore, maintain the hopper at a high level.

The revolution of auger should not be less than 3 while the acceleration speed should be high for more consistent products.

Correct the hopper and equipment alignment.

Improper Functioning of Clamp and Hold Device

Whether a Clamp and Hold device of auger filling machine fails to work. Then, you check the electric switching valve and air supply pressure.

If all electrical switches are functioning well then focus on a voltage of reversing valve coil. Because if all electrical switching is perfect then you’ll find fault in reversing valve, and it should be replaced.

The mentioned above problems are commonly encountered with auger filling machines. The user should ensure the working of equipment which is based on the overall structure and correct installation procedure so it will be easier to detect the problems and their solutions.

14.How do you select filling accessories for the auger filling machine?

The selection of filling accessories depends upon the flow characteristic of powdery material. The guidelines for choosing filling accessories will facilitate a smooth, rapid working process.

Firstly, you need to identify the product types to be filled using an auger filling machine. As we already discussed above auger filling machine basically deals with two types of powdery products such as non-free-flowing and free-flowing powders.

Before, selecting the final accessory for the filling procedure, you should test the product and container to ensure the auger filling machine fulfils your requirements.

Recommended auger filling accessories and setup configuration is discussed below.

Non-Free Flowing Powder

Examples: bakery, talcum powder, etc.

Product Setup

Non-free-flowing products are cut off cleanly after the end of each fill cycle includes a self-feeding auger, slow speed agitator blade, and lip funnel.

The lip funnel is protected via entry of any foreign particle that causes contamination by an O-Ring.

A ‘drip shield allows dripped material to accumulate before the cleaning procedure.

The mechanical configuration of non-free-flowing powder accessories

Free-Flowing Powders

Example: Granulated sugar, breadcrumbs, etc.

Product Setup: A free-flowing powder works on a straight auger, with a high-speed (A-3), and low-speed agitator or you can consider a flake blade.

Furthermore, a straight funnel, collector funnel cover, a spinner plate, Lip funnel, and comprising a clamp.

The mechanical configuration of free-flowing powder accessories

15.Does the auger filling machine comply with international quality standards?

The international quality standards entail all relevant requirements, specifications, products services, and their characteristic of auger filling machines. Auger filling machines significantly meet all basic parameters regulated by international bodies assigned for food types of equipment. The international quality standards are necessary when it comes to an encounter with those machines that deal with the production of foods, medicines, nutraceuticals, or herbal supplements.

Given below are the following product certification that auger filling machines comply with.

CE Mark of Quality Standards

CE mark is mandatory to ensure the manufacturing machine meets all the essential parameters of health and safety. A CE mark also indicates all the parts of the auger filling machine are well-documented.

GMP Standards

cGMP is the main regulatory standard necessitate for every pharmaceutical and food industry. This ensuring a safe quality mechanical approach of Current Good Manufacturing practices for human consumption.

ISO Certifications

An ISO accreditation validates the following managing and manufacturing system as significantly complies with assigned quality assurance and standardization. Each certification has its independent standards that are categorized numerically.

FDA Compliance

FDA standards ensure this machine is fully complied with their assigned standards to deal with pharmaceuticals, food, and beverages.

16.What are the important consideration factors that you should follow before purchasing an auger filling machine?

Mentioned above details about auger filling machine, it is also critically important to know about following factors while buying this machine.

Machine to Best Fit Your Budget

In the realm of packaging machinery, you must consider those equipment that easily fits with your budget and provides high performance, versatility, and perfect efficiency. So always opt for such machine that help you to execute and implement the workflow less downtime, no wastage of products and suitable for your packaging container types such as sachet, bags, or containers.

Machine to Best Fit with Production Demands

The manufacturing capacity of every equipment is different from other equipment. Similarly, if you consider automaticity of auger filling machine, then a fully automated machines are generally preferred by many manufacturer companies than manual or semi-automatic.

Thus, if you have high production demand then always opt for fully automatic auger filling machine that will not only save your time, but also manpower, technical error, and excessive cost.

Machine Best Fit for your Product Type

Always keep in mind the type of product you are dealing with before buying an auger filling machine. Because most often some machine can only deal with specific product type such as, free flowing or non-free flowing powders.

So, it is of prime importance to know best machine for your manufacturing products.

Conclusion

In a nutshell, auger filling machine is the best fit machine to run a successful business in the evolving industrial world. Therefore, selecting a perfect packaging instrument such as auger filling machine is a tool to get versatile, error-free, fast, and reliable processing for dispensing different types of powders smoothly. We hope this blog has helped you to learn about all basic and advance knowledge of auger filling machine that you must know before investment.

GET A FREE QUOTE