Automatic Vial Filling and Stoppering Machine: The Complete Buying Guide In 2025

Thinking of filling aqueous solution, suspension, viscous liquids or even biologic in a vial? can any machine handle all that?! Yes!! If you want aqueous solution, suspension, viscous liquids, biologic products or freeze-dried powder formulations to fill in the vials, this automatic vial filling and stoppering machine would be a good to go, made in a way that your end product would be safer, higher in quality and free from any contamination.

In this automatic vial filling and stoppering machine complete guide I’ll provide its function, advantages and how it can help you to achieve a significant stage in development of your desired vial filling products.

Let’s get started!

1.What is automatic vial filling and stoppering machine?

Automatic vial filling and stoppering machine - Picture courtesy: AIPAK

It is a machine which requires automatic filling of the vial with liquids, suspension, vaccines or freeze-dried product with rubber stopper capping on it immediately right after filling so that no contamination can take place. This automatic vial filling and stoppering machine have peristaltic pump which is used to fill the vials with utmost accuracy.

2.Through automatic vial filling and stoppering machine which type of products can be filled?

By this automatic vial filling and stoppering machine, you can fill the vials for different perspectives.

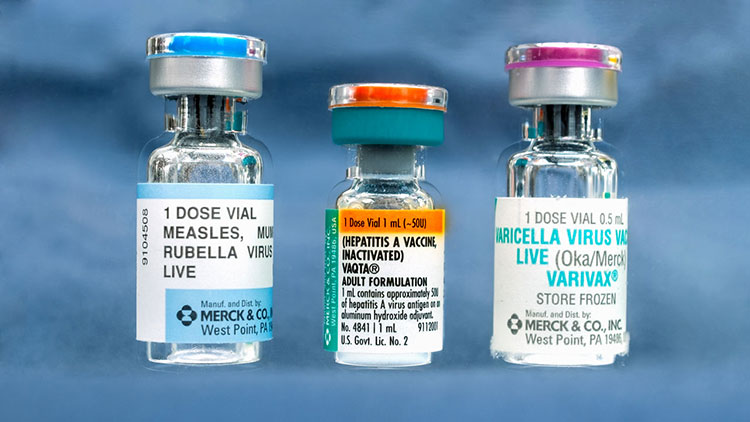

Pharmaceuticals

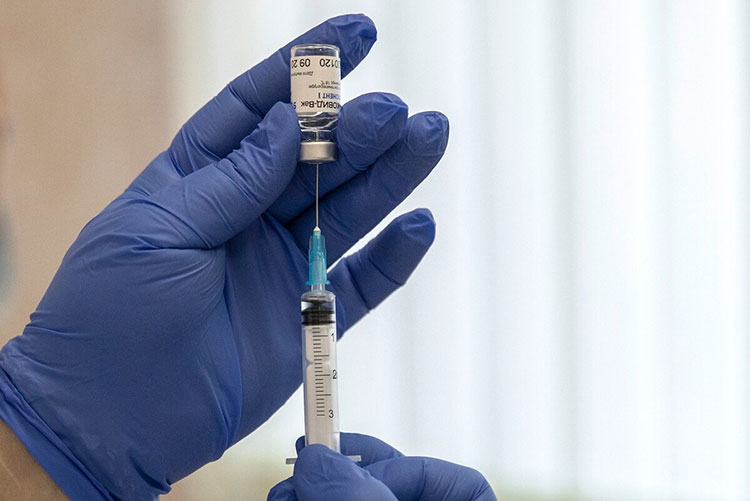

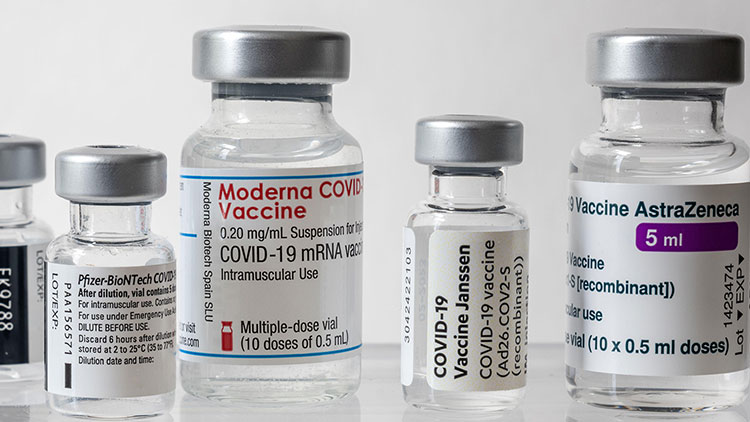

Pharmaceuticals - Picture courtesy: Syntegon

Pharmaceutical companies use this automatic vial filling and stoppering machine for various purposes, automatic vial filling and stoppering machine fill the vials with vaccines, injectables and suspension, this automatic vial filling and stoppering machine produces high grade purity products because it practices the GMP. There is a lot of injectables easily fill in dry vial properly pack, seal and ready to dispatch through this automatic vial filling and stoppering machine.

Nutraceuticals

Nutraceuticals - Picture courtesy: Stoelzle

For preserving different natural products, herbal extracts, essential oils, probiotic suspension and vitamins you can opt for this automatic vial filling and stoppering machine, which not only store the desired volume but make it possible to free from microbial contamination. Many plant extracts also preserve through this automatic vial filling and stoppering machine which can later be used for research purposes.

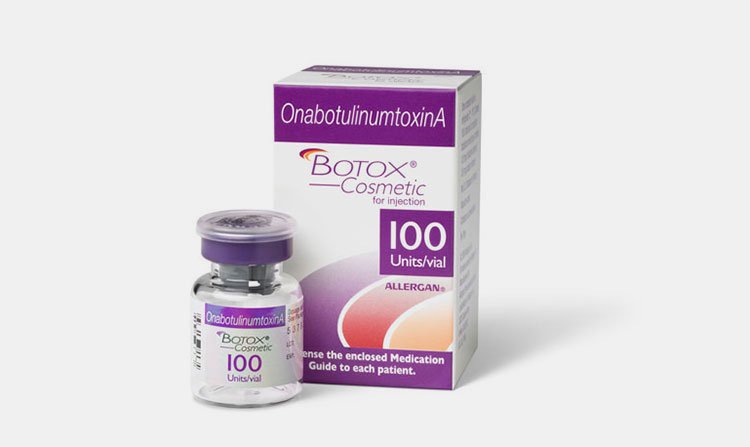

Cosmeceuticals

Cosmeceuticals - Picture courtesy: ReAesthetic

There is plenty of cosmetic application in which automatic vial filling and stoppering machine is use, for scalp treatment, anti-aging treatments, facial serums, perfumes sample and skin tightening solution, all needs a good vial filling and stoppering machine with precision to fill the desire amount.

In cosmetic preparations a lot of different chemicals are used which are easily transfer through automatic vial filling and stoppering machine to a dry vial in a speedy way with no errors, also through this way on a larger scale a filling takes place with higher accuracy which also ensures the GMP standard compliance.

Customization options and automation level is adjusted to get the desired results.

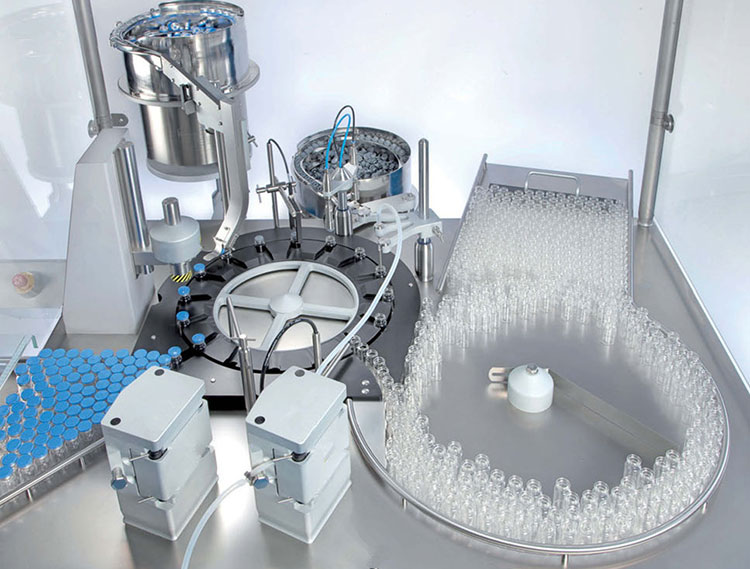

3.What is the working principle of automatic vial filling and stoppering machine?

Automatic vial filling and stoppering machine - Picture courtesy: Groninger

Step:1 Vial feeding:

Dry vials are moving on the stainless-steel conveyor belt with a steady state to the filling unit.

Step:2 Vial filling:

It is the process where desire amount of dose/liquid fills the vials with the help of nozzles.

Step:3 Vial stoppering:

After filling these vials deliver to stoppering unit which are located on the same platform. Stoppering unit consists of bowl and chute designate for desired stopper size. Stoppers are store in vibratory bowl and delivered to vial through chute.

Step 4 Vial exit:

Stoppered vials collected for cap sealing operations. Automatic vial filling and stoppering machine makes sure no vial left empty.

In-feed and Out feed: It moves the vial when they are fed and then removed from the automatic vial filling and stoppering machine carefully.

4.What are the main components of an automatic vial filling and stoppering machine?

This automatic vial filling and stoppering machine typically consists of 3 system;

a) Filling system

b) Stoppering system

c) Conveyor belt system

a) Filling system:

Vial filling- Picture courtesy- aquatec

In this system automatic vial filling and stoppering machine makes sure all the liquid or material can be transferred from storage tank to filling heads then it can be filled in the vial properly without any wastage by the filling heads, which consists of nozzles and syringes.

b) Stoppering system:

Vials stoppering - Picture courtesy: Dara Pharma

In this system a feeding bowl and chute is present who’s function is to make sure that all the stoppers deliver to stoppering unit from where it inserts into vial. The whole process requires pneumatic system which provides power to the automatic vial filling and stoppering machine so the process ensures smooth supply of stoppers to vials!

c) Conveyor belt system:

Vial feeding- Picture courtesy: Harikrushna

It makes the vial in a way that it should be aligned properly before filling & then exit after placing stopper on each vial.

5.What are advantages of using automatic vial filling and stoppering machine?

Vial filling machine - Picture courtesy: AIPAK

Below are the advantages of using automatic vial filling and stoppering machine;

To increase the production capacity with full accuracy:

These automatic vial filling and stoppering machines usually have high speed operation so it can fill and stopper thousands of vials per hour. Due to presence of conveyor the workflow is continuous ultimately it increases productivity.

Nothing can beat the automatic vial filling and stoppering machine which save operational and labor cost as well. This machine follows the GMP standard which allows environment free from any kind dust or germs, the end product which is pack and fill in a vial is of higher quality.

Sterility Assurance:

Vaccination filling and stoppering in sterile area - Picture courtesy: Rieckermann

This automatic vial filling and stoppering machine provides injectables and biologic filling, so it needs to fulfill GMP compliance, it works in a sterile environment that no microbial contamination can take place because any impurity in a vial could affect human health.

Free from contamination- Picture courtesy:Washington post

Scalability:

This automatic vial filling and stoppering machine have parameters which can adjust the speed, type etc. It contains pumps, filling heads which can be upgraded by the passage of time. If need more designs, you can add more filling nozzle.

Monitoring of pressure and temperature:

The machine monitors the pressure and temperature through the process so that no over and under filling can be taken place, it helps to prevent leakage, breakage of vials.

6.What are the safety features built into the automatic vial filling and stoppering machine for operators and product integrity?

For operators the safety features come in a way that it can;

Stop the mechanisms upon emergency

Emergency button- Picture courtesy:iStock

In case of emergency, injury or damage the automatic vial filling and stoppering machine have mechanism that it halts the machine operation.

Maintenance Reminders and Diagnostics

It is installed in the machine it prevents any kind of breakdown, if maintenance required it reminds operator. It has Installation of Warning Signals and alarms.

Monitored fluid handling and vial detection

Vial detection- Picture courtesy : Freepik

This automatic vial filling and stoppering machine has specialized features which can observe the flow, volume and pressure of liquid being processed.

Automatic calibration:

Automatic vial filling and stoppering machine made in a way that it calibrated automatically according to the conditions.

Ability of contamination control:

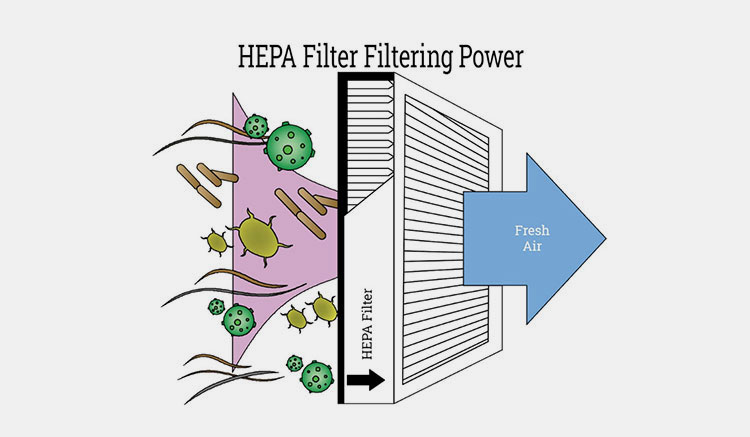

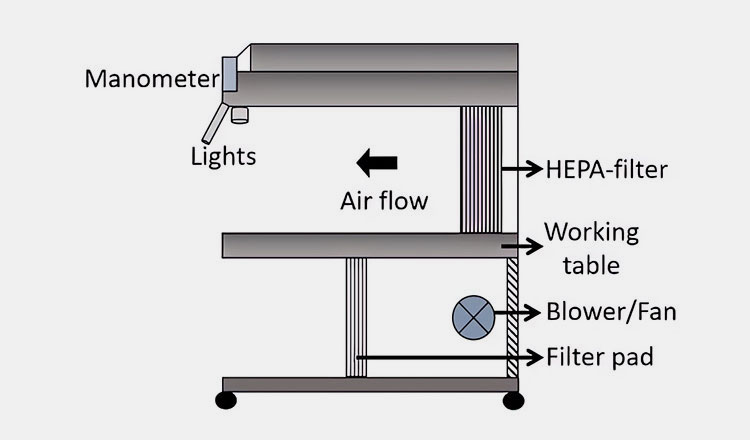

The automatic vial filling and stoppering machine has laminar flow along with HEPA filters which has a function that it protects the environment, provides aseptic area for filling and sealing the vials.

7.How automatic vial filling and stoppering machine different from simple vial filling machine?

Simple vial filling - Picture courtesy - Syntegon

Automatic vial filling and stoppering machine -Picture courtesy: AIPAK

| Feature | Simple vial filling machine | Automatic vial filling and stoppering machine |

| Definition | It focuses on vial filling process | It’s a fully automated process that provides accurate vial filling |

| Stoppering functionality | Done by manually or a by a separate operation | It places a rubber stopper on vials immediately after filling to maintain sterility |

| Speed | Do it for small batch production, slower process | Made for large scale production with high speed |

| Precision | May have variation in fill volume due to manual adjustments | It has various pumps for accurate vial filling |

| Sterile environment | Often used in less regulated environment | Used in sterile clean rooms or in aseptic production environment |

| Safety features | It has basic controls with limited monitoring | Include sensors for vial filling precision, fill volume and stopper placement |

8.Which aspects should be considered while purchasing the automatic vial filling and stoppering machine?

The use of pharmaceutical - grade contact materials:

Whenever manufacturer uses automatic vial filling and stoppering machine it should be in their mind that their product will not deteriorate, for this purpose manufacturer always chooses the automatic vial filling and stoppering machine because their materials are of inert, high purity and certified one that it will not affect the drug also ensures the stability and high purity.

Without pharmaceutical grade material the drug will be degraded, become toxic and contamination will also take place in it.

Laminar airflow with HEPA filtered air:

Laminar airflow - Picture courtesy: Industrial quick research

Laminar flow-Picture courtesy: Biology reader

Laminar airflow is unconditional smooth flow of air could be horizontal or vertical in a way that it expelled out the contaminants and clean the area. HEPA filters are the one who remove the dust, microbes, aerosols or spores and free the area from any kind of contamination so the filling of vials and sealing will be done in sterile area.

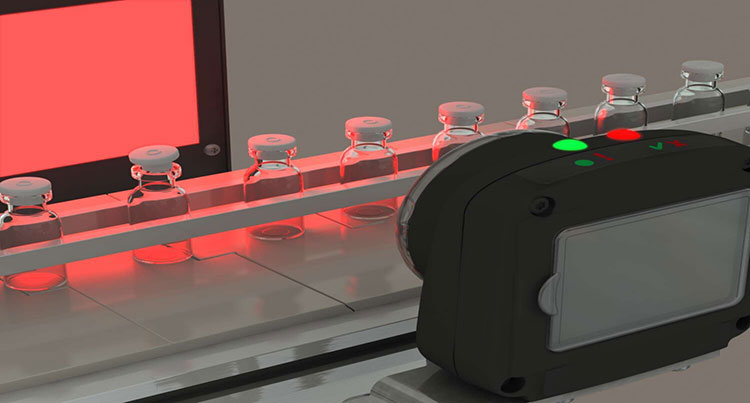

Stopper sensors which detect vial filling:

Sensors-Picture courtesy:Banner

In automatic vial filling and stoppering machine stopper sensors are installed in a way that it will verify whether vials have been filled by drug or not, also check the stopper has been inserted. Sensors have advanced technology that it has optical, laser and force sensors.

If the vial is under-filled the sensor detect it and remove the vial from line. If any stopper doesn’t insert correctly the sensor detects it, vial will be rejected and sent for reprocessing.

Sterility and Contamination Control:

Steam-sterilizes the machine -Picture courtesy: Epidor

Always select the automatic vial filling and stoppering machine which have aseptic environment so that no microbial contamination can take place, automatic vial filling and stoppering machine should have RABS restricted access barrier system between the operator and sterile zone, it will protect operator from environment and product from contamination. Automatic vial filling and stoppering machine should also have isolator which is a sterile area consists of HEPA filters. CIP or SIP can also consider when looking for automatic vial filling and stoppering machine.

CIP--------Automatically washes internal lines (no disassembly)

SIP--------Steam-sterilizes the machine after CIP, ensuring aseptic condition

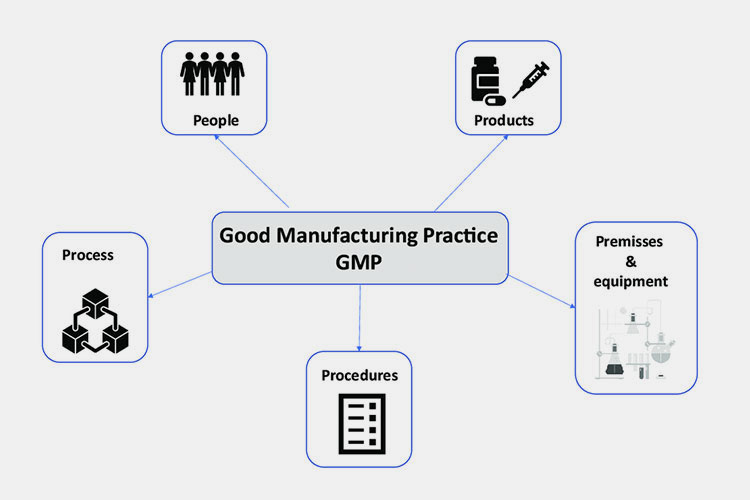

Compliance and Validation:

GMP-Picture courtesy: ResearchGate

When you are planning to buy an automatic vial filling and stoppering machine you just need to confirm that automatic vial filling and stoppering machine follows the guidelines of cGMP, FDA, EMA and WHO.

CGMP make sure that drug meets the good manufacturing practices, FDA ensures drug and equipment approval, EMA stands for European agency that have a check and balance on medicines and biotech products, WHO is world health organization it has a guideline for vaccines and public health relate stuff.

Automation and Integration:

When you are going to buying an automatic vial filling and stoppering machine just make sure it has integration system in a way that every other part interlinked with next part for example washing unit first wash the vials before filling then capping unit comes which sealed the filled vials with stoppers/caps then comes labelling system which automatically label the vials.

These all will work in a connection which ultimately save the time, labor and reduce the contamination, Automatic vial filling and stoppering machine should have advance control software system so you can check automated traceable production line.

Flexibility:

Before buying to automatic vial filling and stoppering unit check whether your equipment is flexible or not like it should be in a way that it can handle multiple type of products it could be biologic or suspension or viscous solutions.

It can also handle various vial size; in this way you can formulate new products in future from the same automatic vial filling and stoppering machine. System should have ability to handle different viscosity, automatic vial filling and stoppering machine can fill the vials with aqueous solutions to oily solutions to suspension for example automatic vial filling and stoppering machine should fill vaccines in a vial also vitamin D oil can be fill in a vial from same automatic vial filling and stoppering machine.

Protein based injectable should also be filled in a vial in this way it supports wide product range. You can also upgrade the automatic vial filling and stoppering machine to higher speed module as well these all features make your machine budget proof and future friendly.

Build Quality and Materials:

Upon selecting an automatic vial filling and stoppering machine, you should check which materials are used in the automatic vial filling and stoppering machine to ensure they do not affect your product, automatic vial filling and stoppering machine parts should be of stainless steel having high corrosion resistance it will ultimately protect our pharmaceuticals.

Supplier Reputation and Support:

When you are going to buy automatic vial filling and stoppering machine always check the reputation of suppliers, they should be trustworthy and often provide technical support, they tend to provide installation and training to your staff, when automatic vial filling and stoppering machine purchased, they should offer maintenance services as well.

User Interface and Operation:

while purchasing the automatic vial filling and stoppering machine check whether it has Intuitive HMI touchscreen controls or not this makes the operator to easily control and monitor the system. The interface should be in different languages so that it can be helpful to use internationally. System should have alarms and alert to check the problem and fix it.

Cost Considerations:

Before buying the automatic vial filling and stoppering machine just look beyond the price of automatic vial filling and stoppering machine which is the total cost of installation, training, spare parts replacement in future and maintenance.

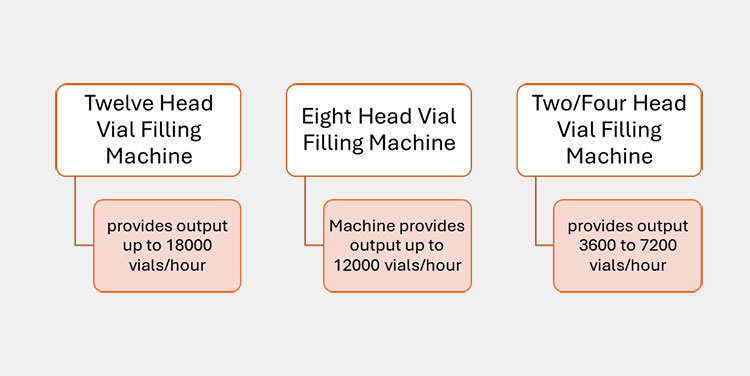

Production Capacity:

While purchasing the automatic vial filling and stoppering machine you need to consider your production capacity in terms of vials per hour, if your volume increase can this automatic vial filling and stoppering machine handle the production capacity. Always choose machine that align with your current needs and future perspective.

Vial Compatibility:

Vial size- Picture courtesy -Aptar

When you go for getting this automatic vial filling and stoppering machine you need to see your vial type and size that matters a lot and it depends upon the product you are going to fill in it.

Dosing Accuracy:

Dosing accuracy- Picture courtesy- DiabetesWise

Dosing accuracy in pharmaceuticals is highly critical as overfilling or under filling can compromise patients’ health and safety. You need to check how precisely automatic vial filling and stoppering machine can fill the vials. Pumps is the most important factor that affect the precision of filling. There is different type of pumps used to fill the vials with precision,

| Peristaltic pump | Sterile, sensitive liquids |

| Piston pump | Viscous or oily solutions |

| Vacuum filling | Foamy or light liquids |

9.What volumes you need to fill through automatic vial filling and stoppering machine?

You can fill volume up to your desired limit ranging between 0.1ml-100ml depending upon your vial size. The automatic vial filling and stoppering machine uses peristaltic pumps and piston pumps through these pumps volume adjust in vials ranging from injectables to sterile formulations.

Vial size:

Vial size - Picture courtesy: Indiamart

Vial filling always depends on the vial size you are using, suppose if you are using 2ml vial size the filling would be between 0.2 ml – 2 ml and so on.

Product type:

For different drug type you have to use different vial, there is a aqueous solution, viscous, suspensions and powders that have to b filled in the vial and for this different pump are also used to fill the desired amount.

10. Does your end product from automatic vial filling and stoppering machine is contaminated free?

An end product would be the one who went with all the processes from a vial from filling, stoppering till sealing. Yes, our end product is free of contamination because it is taken care of following steps;

Aseptic Environment:

It is the area where HEPA filters are fitted along with Laminar flow so that no chances of contamination will take place.

Sterile Contact Parts:

Automatic vial filling and stoppering machine should have such parts that its not effecting the drug because those parts are of pharmaceutical grade stainless steel.

Stoppering Under Sterile Conditions:

Stoppering should be in sterile area with no human contact so reducing contamination risk.

In-line Sensors:

Sensors has been installed in the system so automatic inspection would be done, any vials when is under-filled or without stopper will be taken out from line.

Environmental Monitoring:

Any kind of dust particle, microbes, temperature and humidity constantly monitored so the whole processing environment will be in such way to make a high-grade product.

Compliance with Regulatory Standards:

Sterile product - Picture courtesy: globalEDGE

Automatic vial filling and stoppering machines complies with all the regulatory standards CGMP, FDA, WHO so the end product which we will get is of pure, high-grade quality which will not affect the patient’s safety and health.

Conclusion:

After reading the blog on automatic vial filling and stoppering machine, you will be confident about the series of important step involved in it, how to use this machine and what steps you need to consider while purchasing this automatic vial filling and stoppering machine. Always approach the best machinery for your production, machinery with good manufacturing practices will automatically bring quality in your product and for this no one can beat AIPAK, which offers you the best quality budge friendly machines. Don’t hesitate to reach out us for any quires and information related to machines.

Don't forget to share this post!

Vial Filling Machine Related Posts

Vial Filling Machine Related Products

Vial Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine