AIPAK Automatic Labeling Machine Videos

AIPAK automatic labeling machines can be used in all industry’s labeling,as it include round bottle /cans/jars/tubes,side face,flat plane,uneven surface types automatic labeling machines.All AIPAK automatic labeling machines adopt mature PLC control+touch screen control system technology,that is easy to operate and maintain.The labeling position and the stop bar can be adjusted according to the size of the object to be affixed.The machine and spare parts all use material S304 stainless steel and anodized senior aluminum alloy,with high corrosion resistance and never rust.

AIPAK Videos

How mineral water bottle labeled by the automatic labeling machine?

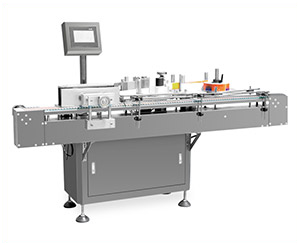

AIPAK full automatic bottle labeling machine fits for a wide range of products. One machine can basically achieve all the required of product labeling, especially for low-volume, variety and changeable specifications labeling which can largely improve the labeling production efficiency and reduce equipment investment costs; it widely used in cosmetics, food, toys, daily chemical, electronics, pharmaceutical, plastics, printing and other industries, such as flat shampoo bottles, packing boxes, cosmetic flat bottles, bottle caps, plastic shell, SD cards, batteries, flat, arc, circle face, concave, convex or other attached label.

Want More Demo Videos

How shrink sleeve label applicator works on mineral water bottle?

Shrink sleeve label applicator uses innovative technology to apply sleeves and labels to containers including jars, bottles, & more.The machine adopts PLC Control and color touchscreen, servo driven label feed, stepper driven cutting mechanism, quick change knife plates and mandrel style sleeve handling.It is mainly is suitable for all kinds of containers, shrink film packaging of various shapes and materials (such as: food and beverage, cleaning supplies, cosmetic and so on all kinds of plastic bottles,glass bottles, PVC, PET, PS, tin and other containers), can be fully wired with production line operation and single operation, empty bottles or can packaging use after filling, automatic fast packaging, save a lot of artificial cost, at the same time greatly improve product packaging effect.

Want More Demo Videos

How double side corner automatic labeling machine for carton box

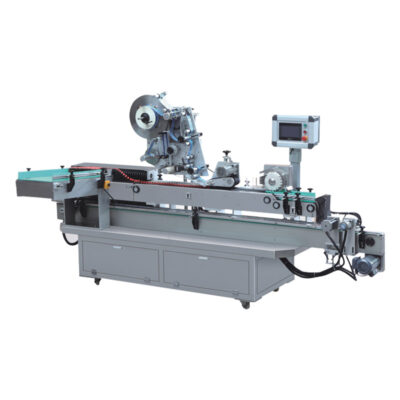

AIPAK double side automatic labeling machine can be applied for carton box,bottles,cans,premade bags sticker labeling.It can be connected with automatic filling machine,can sealing machine,capping machine,ink-jet printing machine,carton packaging machine etc. to make a fully automatic packaging line.The machine is suitable for round shaped containers such as sprayer bottles,PET bottles,glass bottles, tin can etc.

Want More Demo Videos

Automatic Flat surface labeling machine make labels

AIPAK flat plane automatic labeling machine speed is at least equal to 10 worker speeds.It has good labeling effect that the labels are neat,beautiful and not easy to waste.With AIPAK automatic labeler machine,you will save your labor costs,that it is your short term investment with long-term return choice.This kind of flat surface automatic labeling machine can only be appled for adhesive labels/stickers on any flat surface products.

Want More Demo Videos

How fully automatic high speed wrap-around labeling machine works

AIPAK wrpa-around labeling machine is designed for non-standing cylindrical containers (round bottom or head-heavy) or products that can not standing stable, such as ampoule, vial, crayon, tube, lip balm containers, small batteries, etc.The whole equipment is qualified with GMP requirements and made of SUS304 stainless steel and high-class aluminium alloy. The machine has many functions such as guiding, separating , labeling, attaching, counting. Adopt PLC control system combined with LCD touch screen , setting and operation is easy and clear. The labeling position of height can be adjusted as requirement, and the machine can be incorporated with a packing line or operated individually.

Want More Demo Videos

How automatic labeling machine labels round cans

AIPAK round cans automatic labeling machine is made of stainless steel, which is wear-resistant and corrosion-resistant, and will not rust when working in any harsh environment.Adopt advanced electric eye objects and label's detection sensitivity is high. The labeling efficiency is greatly improved.Imported light sensor can be used to adjust the sensing position by screwdriver, and the positioning is more accurate.

Want More Demo Videos

How freezer bags labels by automatic labeling machine

AIPAK this machine can be used for separating paper and labeling on it.The machine is in small size and can work automatically,saving working space and improving efficiency.It can be widely used in pharmaceutical, cosmetic,food industries.With PLC control panel,it is easy to set parameters like labeling speed and labeling time.It is easy to operate,the language of the panel can be customized as needed.

Want More Demo Videos

Automatic cartoning machine and labeling machine working process

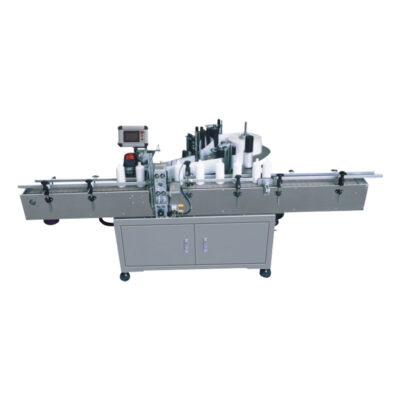

AIPAK automatic labeling machine is suit for different kinds products need labeling on on front and back sides at the same time, also suit for round bottle labeling warp around.The machine uses the servo send label system to send label on product surface,its spare parts all use material S304 stainless steel and anodized senior aluminum alloy,with high corrosion resistance and never rust.Low voltage circuit all use the German Schneider brand.

Want More Demo Videos

Automaic lableing machine labels pharmaceutical vial bottle round bottle

AIPAK automatic labeling machine id widely suitable for foodstuff, cosmetic, pharmaceutical, pesticide and other industries. It is single and double side labeling for flat, square and round bottle . Automatic controlled by computer (PLC)easy operating.No bottle no labeling. It can change specifications easily. It adopts servo motor, achieved closed loop control low malfunction rate. High efficiency. Fast speed.

Want More Demo Videos

High speed round bottle labeler automatic labeling machine

AIPAK round bottle labeling machine suit for differnet size round products labeling in food, medicine, daily chemical and other light industries.All the labeling machine adopts Electrical cabinet,Conveying mechanism,Roll label device,Brush label device,1# labeling engine,Operation system and control system.The accuracy of our sticker labeling equipment makes them best suited for delicate pharmaceutical bottles, and it can get a speed up to a minimum of 200 bottles per minute.

Want More Demo Videos

How automatic labeling machine make irregular labeling

AIPAK this automatic labeling machine adopts advanced technology,that will cover the circle lable on the PET bottle.The machine’s structure is compact,and suitable for the producton line of different direction and different height.With tools,the driven machinery can be adjusted to meet different bottle size,adopting advanced man-mchine automatic controlling technology,main component adopst famous brand.

Want More Demo Videos

Square carton box flat surface automatic labeling process

AIPAK flat surface automatic labeling machine can be used for flat bottles, round bottles, square bottles of single and double side labeling, such as shampoo flat bottles, oil flat bottles, hand sanitizer double side labeling round bottles, two with stickers, double standard to improve production efficiency, widely used in daily chemical, cosmetics, petrochemical, pharmaceutical and other industries.It is widely used in cosmetics, daily chemical, electronics, pharmaceutical, metal, plastics and other industries.Such as the shampoo flat bottle labeling, flat bottle labeling oil, shampoo bottle labeling, etc.

Want More Demo Videos

Whole Medicine Production Line with Labeling,Printing,Cartoning,3D Package and Boxing

AIPAK this labeling machine is made of SS 304 and high-class alloy, the controlling system adopts advanced PLC with touch screen, easy to operate and calibrate, with high speed, high labeling precision. This machine can be used independently, and can also be installed on any product lines. This machine can stick labels on various round or cylindrical objects, bottles, jars, tins, cans, etc.

Want More Demo Videos

Automatic Side Labeler Machine Labeling Process

AIPAK labeling machine is for the round bottle labeling in the industry like food,oil,pharma,wine,cosmetics and so on.The machine with elegant design can be easily operated and maintained by the common worker, who requires no special training in operation this machine.Just give a simple adjustment to produce another product when you want to swap the different kinds bottle labeling.

Want More Demo Videos

High Efficient Round Bottle Labeling Machine

AIPAK round bottle labeling machine is suitable for any shape product two sides labeling, such as bottle, can,carton, food container, medicine, daily chemical industry and so on.With PLC and touch screen control panel,it is easy operation, many units parameter setting and save.Automatic stop when label breaks down or runs out, Malfunction self-testing and display with alarm.High labeling accuracy, long-time using.All components are precisely processed by CNC to ensure high quality.

Want More Demo Videos

See How The Labels Are Sticked To Round Box By Flate Plane Labeling Machine?

AIPAK automatic plane labeling machine is suitable for the flat plane labeling machine, especially for the side, top and bottom of paper stickers. The machine body is small, and can be used in narrow places or wiring. It can be equipped with a bar code printer to integrate with the supervision system.The plane labeling machine is mainly composed of SUS304 chassis; Conveyor belt; Labeling head; Head adjustment, etc. Siemens PLC and touch screen are adopted; As the main component, the servo motor controls the high-speed operation of the equipment. The equipment is safe, efficient and stable; Comply with GMP and CE specifications.

Want More Demo Videos

Have you Ever Noticed How the Groove Lid Box Labeled By Flate Plane Labeling Machine?

AIPAK automatic plane labeling machine is suitable for the flat plane labeling machine, especially for the side, top and bottom of paper stickers. The machine body is small, and can be used in narrow places or wiring. It can be equipped with a bar code printer to integrate with the supervision system.The plane labeling machine is mainly composed of SUS304 chassis; Conveyor belt; Labeling head; Head adjustment, etc. Siemens PLC and touch screen are adopted; As the main component, the servo motor controls the high-speed operation of the equipment. The equipment is safe, efficient and stable; Comply with GMP and CE specifications.

Want More Demo Videos

See How the White Oil Bottle Labeled by AIPAK Double-side Automatic Labeling Machine?

AIPAK double-side automatic labeling machine Suit for differnet size shape products, such as round square jars, flat bottle,oval bottle, round cans.Electrical cabinet, Conveying mechanism, Separate bottle device, Roll label device, Brush label device, 1# labeling engine, Operation system and control system.Machine and spare parts all use material S304 stainless steel and anodized senior aluminum alloy, with high corrosion resistance and never rust.

Want More Demo Videos

Good Quality Round Bottle Automatic Labeling Machine For Beer Cans

AIPAK round bottle automatic labeling machine designed for round bottles or other common cylindrical products. Such as cylindrical plastic bottles ,glass bottles,metal bottles. It is mainly used for labeling of round or round containers in food and beverage, medicine, and daily chemical industries.The bottle separator can control the bottle conveying speed by adjusting the separator speed, and the operation is simple and convenient.

Want More Demo Videos

Have you ever seen how square bottle labeled by the automatic labeling machine

AIPAK offers various multifunctional automatic labeling machines, suitable for labeling all kinds of bottles such as PET bottles, plastic bottles, glass bottles and metal bottles. All automatic labeling machines are widely used in pharmaceutical, electronic, metal, cosmetic, beverages, food, plastics,daily chemical and other industries, greatly improving productivity and labeling quality.

Want More Demo Videos

See How the alcohol bottle labeled by AIPAK Round Bottle Automatic Labeling Machine

AIPAK round bottle automatic labeling machine adopts self-adhesive film roll labeling paper. The labeling adopts a roll-on method to prepare automatic bottle feeding and closing devices. It can complete the bottle placing, labeling and closing procedures at one time. It is also optional The ribbon coding machine synchronously completes the label production date printing. This machine adopts Mitsubishi PLC control and synchronous tracking. The label output is controlled by a stepping motor to ensure that the label output speed is synchronized with the reel speed. It is a modern mechatronics product with excellent and reliable working performance.