15 Most Important Parts of Automatic Capsule Filling Machine You need to know

Facing the large market,you must be very confused how to choose the most suitable automatic capsule filling machine for your mass production.

Or you may spend a lot of time comparing the difference between each type of automatic capsule filling machine.

In fact,for the precise functional process of your capsule filling process,you must get to know what are the most important parts of an automatic capsule filling machine or how are they aligned for the better work with each other.

Now,I have summarized 13 most critical parts of automatic capsule filling machine,spend a few minutes reading through,you will get a brand new understanding of this machinery.

These critical parts/auxiliary devices include:

1.Capsule Hopper

The capsule hopper is the place where all the to be filled empty capsules are stored.

It is made of stainless steel and you will find there may be 3 shapes of capsule hopper ,like cylindrical shapes of capsule hopper,cubic shapes of capsule hopper or conical shapes of capsule hopper.

Besides,the capsule hopper is not sole holding all the empty capsules ,it has sensors to assist to control the supply quantity of the empty capsules .

Normally,one capsule hopper has two sensors ,that is,one is to control when the supply of empty capsules is low,another one is to alert when the supply amount is excess.

When the automatic capsule filling machine is powered on,you will find it will automatically load empty capsules into the capsule hopper.Of course,it will also shut down the capsule filling part when the capsule hopper has no empty capsules.

And for the even and high efficiently filling rhythm,the capsule hopper is also designed with a gate to administer the quantity of empty capsules going into the capsule filling parts.

2.Capsule Feeding Unit

As you can see,generally, the capsule feeding unit of an automatic capsule filling machine stands on the top of the machine,it main function is to control the amount of empty capsules running into the filling parts.

You may adjust this feeding unit according to your actual production requirements.

After from that,any capsules with defects will be not allowed to pass through the capsule feeding unit to the next feeding unit.You will no need to worry about failure filling lead by the original raw capsules .

3.Powder Hopper

The powder hopper is a place that you can put the all kinds of filling materials you want.It is made by stainless steel,that is easy and convenient for your maintain.

Normally,it locates at the same height with the capsule holder.And there is a powder sensor to regulate the amount of powder in this hopper.

Then you may ask how will that powders be driven into the filling part,in fact,there is compact feeding mechanism designed to move the powders into the filling station.

Besides,the powder hopper also performs the function of mixing ,all powders can be evenly mixed before moving into the next filling section.

4.Closed Dosage Device

The Closed dosage device is the place where the precise amount of power dosage goes into the filling hopper to be filled into the empty capsules.

From above,you may have known, here there is the powder sensor to control the flowing of the powder,drive the powder to be filled or cut down the excessive powder amount.

And through the capsule filling process,powders on the dosage dis will be driven into the filling hopper by the compressed air jet.

5.Closed Rotary Turret

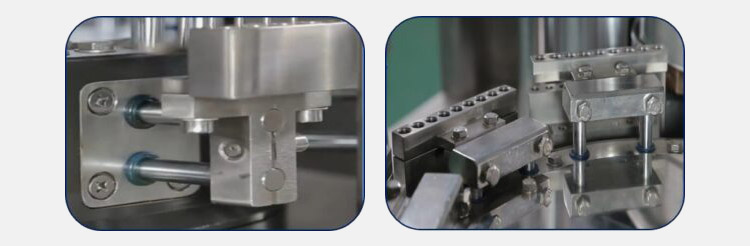

AIPAK new generation of closed rotary turret

From above ,you will see the rotary turret is completely closed design ,that is free from dust ,avoid the shortcomings of old open type who likes to stick powders with oil due to long-time use, and frequent cleaning or cumbersome assembly mold,so as to facilitate the operation of employees.

And the closed rotary turret also meets the requirements of GMP.

To guarantee a continuous filling process,now most automatic capsule filling machine adopt this kind of closed filling system.

And in this part,the upper die adopts two axes to move up and down in a circle, while the lower one uses two axes to move in and out of the circle.All of them are equipped with imported silica gel sealing ring, which reduce the situation of powder belt stretching back and forth due to the moving shaft, it is stable and precise.

During the filling process,the to be filled empty capsules will be delivered to the turret hole holders and the powders to be filled will remain at the filling hopper.

This section,you can adjust the filling specification through the touch screen panel.

6.Mechanical Drive System

The mechanical drive system is the critical part of the automatic capsule filling machine as it starts all the process and determines all the motions that include the main drive,motor ,hopper drive and the vacuum drive of the machine.

It consists of the motor,gear and conveyor which unites to movitates the machine.And also completely closed to get free from dust and avoid other issues led by frequent cleanings.

In fact,there is the PLC control system who displays the technological elements of the automatic capsule filling machine that regulate the mechanical drive system.

7.Lubrication System

You need to know that every type of automatic capsule filling machine must have a lubrication system to lubricate the moving and mechanical parts for long-time use or reduce worn-out.Meanwhile ,guarantee the smooth filling process.

During the empty capsule filling and sealing process,you will need to use the lubrication oil to lubricate the conveyor and the moving parts to reduce the friction between each components.And the lubrication system will work automatically to lubricate the filling and powder dosage discs to make sure sufficient ejection.

8.Vacuum Capsule Separating Mechanism

There are two roles you will find the vacuum capsule separating mechanism play,they are:

1.It connects the powder feeding with the powder hopper,and the capsule loading with the capsule hopper.

2.It is also responsible for separating the caps and body of empty capsules.

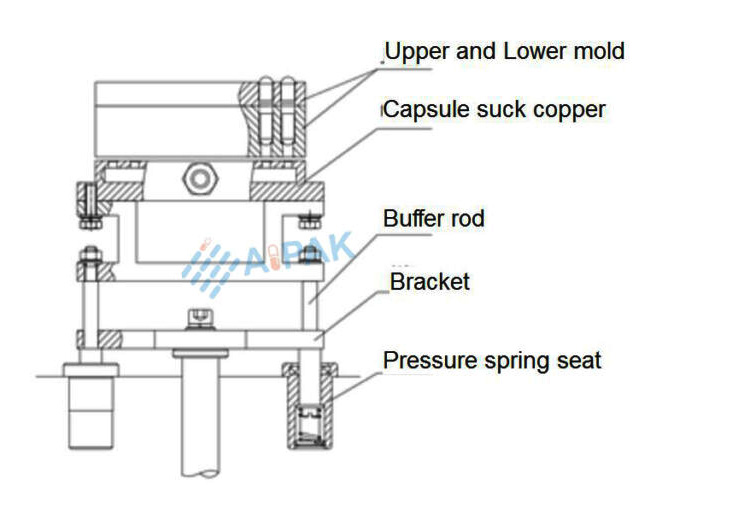

Now,with technological innovation,the vacuum capsule separating mechanism has been upgraded to perform the below advantages:

1.Improve the fit between the suction seat and the capsule mold, improve the vacuum effect, and separate the empty capsule more effectively.

2.Compared with the traditional automatic capsule filling method,the vacuum capsule separating mechanism is more to reduce the impact sound and reduce wear and tear.

9.Safety Door

The safety door is to protect the machine in case any emergency happen,it will automatically shut down the machine when you want to open the door.

In other words,all the functional parts inside this doors are can’t be accessed at will while the machine is working.

10.PLC and Touch Screen Control System

The PLC and touch screen control system have comprised the electric box of the automatic capsule filling machine.

They are the main part where you can key in your capsule filling specifications as per your production requirements.

With the touch screen system,you can regulate all the operations during the filling process.

But in fact,nowadays,as the technology upgrading,the PLC and touch screen system also control other performance of the automatic capsule filling machine,they are:

1.It can control the micro-electric current to protect the machine from overload.

2.It can control the workings status of the machine if there is any emergency.

So,with these automatic system,you will save large sum of labor cost and just need to input all the instructions before initiating the machine.

11.Automatic Feeding Device for Empty Capsule

With the automatic feeding device for empty capsule,you will no need to add the capsules manually.

Nowadays,this automatic feeding device has become a very convenient device in mass production requirements.

It will save your labor and production cost and will be an ideal device for your mass production.

From above,you will see the bottom feeding tube is connected with compressed air, and the empty capsule is transported to the capsule hopper through this automatic feeding device.

It is easy to operate and can automatically start and stop feeding, ensuring the continuity of the machine.

12.Vacuum Feeder

The vacuum feeder in the automatic capsule filling machine is to automatically feed the powder,it is easy to stall and operate ,and its conveying dosage is very good to suit for the filling requirements.

Its has compact structure with no dust pollution, safety and health, low noise,which is very suitable for mass production.

If there is no empty capsule to be filled ,the vacuum feeder will automatically cut off to reduce waste,that perform its high cooperation.

13.Capsule Polishing Machine

For the good appearance of your finished capsules,you will need a special polishing device who is called capsule polishing machine.

There are three types of capsule polishing machine,namely:

.Capsule polishing machine

.Capsule polishing machine with sorter

.Vertical capsule polishing machine

Capsule polishing machine

All of these machines have the same targets that remove the dust and static electricity on the surface of capsule and improve the surface smoothness.

The variation is the capsule polishing machine adopts the stepless speed regulating motor, and the height of hopper is adjustable.

Capsule polishing machine with sorter

While apart from removing dust, polishing and electrostatic elimination, the capsule polsihing machine with sorter can also automatically remove the capsules with light loading, empty shell, debris and separation of body and emission.

The capsule polishing machine with sorter adopts frequent conversion speed regulation, has sensitive and reliable speed, can bear large starting torque, synchronous belt output power to achieve low noise operation.

vertical capsule polishing machine

And the vertical capsule polishing machine has the functions of capsule polishing, sorting and lifting, leaving high space for connecting subsequent equipment.Its inlet and outlet can be adjusted 360 ° circumferentially, which is convenient for production and saves space.And adopts quick installation connection structure that makes the disassembly and installation of the machine more convenient and quick.

Last not the least ,all these capsule polishing machines will not destroy the surface of the capsules.

14.Metal Detector

This metal detector could separate the metals in the raw materials.

It adopts iIntegrated metal foreign matter removal system, even if the metal is sealed in the product ,it can also be detected.

You can choose various calibres and models according to your practical applications.

Besides,this metal detector is compact in structure and easy to install.

15.Industrial Vacuum Cleaner

The vacuum cleaner is used to remove and collect the dust left under the filling station of the automatic capsule filling machine and the scraps in the mould hole.

Conclusion

An automatic capsule filling machine may contain hundreds of thousands of parts,every manufacturer may have littles vartians in its design options or functional performance.But the truth is getting the basic knowledge with these 13 most important parts of automatic capsule filling machine is the essential when you are purchasing .While you can also read the machine instruction manual to get more detailed knowledge about this machine.

Capsule Filling Machine Related Products

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide, tips and trends sent straightly to your box? Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine