Automatic Capping Machine: The Ultimate Buying Guide in 2025

This is 21st century where every bit of the detail is concerned. Neither you will bear any kind of impurities, nor the buyer of the products.

Now, imagine yourself not capping the products in a proper way and ruining your products. All in the vain, Right?

Solution is doing everything properly after sealing by using latest capping machine.

Now, without any this and that i’ll drive you through all the details of the capping machine.

Every detail will be shared in details here. Let’s dig more!

1.What are the emerging market trends and opportunities for Automatic Capping Machine?

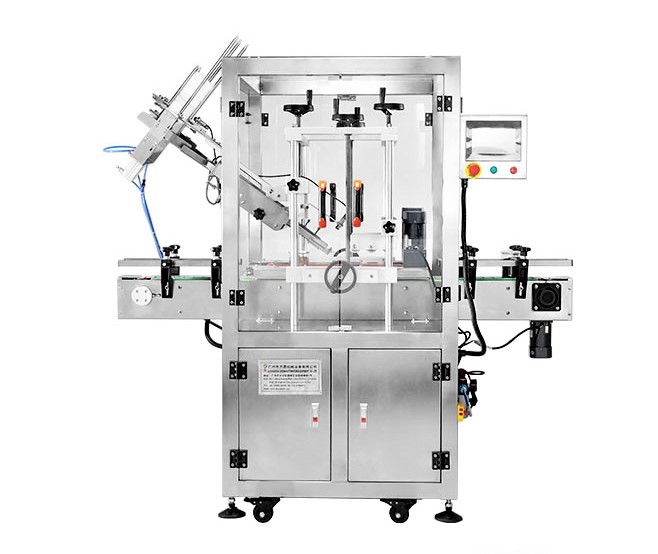

AIPAK Automatic Capping Machine

As you know the market requirements growing very rapidly so you may need quick equipment that can help you for quick production to reach the market trends and values.

With more market requirements, the people are looking for quick production in less time to meet the necessary output.

Market Overview

Automatic Capping Machine is very demanding in the pharmaceutical and some other industries for automatic capping on different bottles and other containers.

It is easy for you to reach the market demands with much durability and dust-free production by using the Automatic Capping Machine.

With more production, you need faster and quicker equipment for perfect packing to reach the market trends so this machine provides you much flexibility in every type of production for packing.

This machine serves dual action for controlling the bottles and then capping them perfectly so the material inside the container does not get wasted.

Opportunities & Future

In the beverage & food industry, the requirement for Automatic Capping Machine is growing rapidly with the rise in these two industries the future of this machine looks bright.

As you can see the packaged food is globally required so the demand for packing machines is also required & the Automatic Capping Machine is very rapid in capping the different sizes of bottles.

Asian region market is expected to grow rapidly within the coming year so this will bring more opportunities for this machine.

Not in the Pacific Ocean all around the world the packing of the product is very important because the product transfer from one place to another and your product must be packed up to a very high level so the product inside the containers/bottles did not lose.

When the bottles are filled with liquid it is difficult for the machine to handle the bottles and capping these bottles because the bottles may have different types and sizes as well so you may require some other equipment for capping.

Automatic Capping Machine is somehow expensive to buy but it provides much flexibility and faster capping for a different type of products & it will also help your production to grow rapidly.

2.What is Automatic Capping Machine Market Custom Research Report With Covid-19 Impact Forecast 2021-2026?

Covid-19 made a huge impact on every field of life rather it is the food industry, medical, clothing, or any other so a custom research report was made for the Automatic Capping Machine industry to show its impact in the upcoming years.

The research report was made on different categories for coming years on the market trends and other areas of this machine.

Here are some following impacts that are forecast for 2021-2026 on the Automatic Capping Machine.

- Production of the Automatic Capping Machine.

- Production by regions.

- Market values & type.

- Applications

- Market Segments.

Scope of the Report

According to the report, the Asian Pacific Ocean is growing very quickly to fulfill the global demands of the world for Automatic Capping Machine.

The demand for this machine is rising widely across the world including Europe, North American, South America, Middle East, Asia Pacific, and the South Africa region.

It also suggests a different type of machines by comparing their production market, applications, and manufactured region.

The report tells some significant points about the Automatic Capping Machine.

- The scope of this machine in the market is very bright as it is used in many industries for capping different types of bottles.

- People finding a lot of production with the help of this machine by scaling their products.

- It shows that the coming years are going to be very bright for the Automatic Capping Machine with the increase of market demands.

- The raw material that is used in the production of this machine is of very high quality so your production remains good in quality.

This report also covers different regions analysis for this machine which includes the following countries from different regions.

In the North American region, the countries that are going to work more by using the Automatic Capping Machine are Canada, United States, & Mexico.

In the European region countries like France, Germany, UK, Russia, and Italy are going to work more on their production with the help of this machine.

AIPAK Automatic Capping Machine

In the Asian region, China is producing most of these machines to fulfill the global requirements on the other hand Japan, Korea, and South Asia region is also working on this machine.

Underdeveloped countries will have great opportunities for leading the market in the coming years and to extend their business with the demand of the machine.

The Middle East and Africa region is also going to benefit from the production of this machine.

Automatic Capping Bottle Types

There are mainly two types of bottles that can be filled by using this machine.

- Plastic Bottles.

- Glass Bottles.

3.What is Automatic Capping Machine?

AIPAK APC-D901 Automatic Capping Machine

As the name of the machine tells you about its functionality so you can say that or elaborate the Automatic Capping Machine is equipment that is used for capping different types of bottles with a different type of caps to make them airtight.

It is very useful in capping different types of items from different types of industries like in the food industry cold drinks and other filler material bottles are capped using the Automatic Capping Machine.

4.What are the Different Available Types of Automatic Capping Machines?

According to different shape and sizes, there are different sorts of Automatic Capping Machines that offers you a different type of functionalities along with the same purpose.

Inline Automatic Capping Machine

One of the most useful machines that is used for capping different types of bottles along with different capsizes. It is one of the most demanding machines in the market.

The production of this machine for capping the bottles is 200 per minute but the difference in capsizing and bottle size may impact the production rate.

It can work automatically for tightening the bottles up to the maximum range and then discharge them without doing any harm that is done with the help of torque control.

Air load and spring system in the Inline Automatic Capping Machine helps it to make your product air tighten and leakage proof.

Snap Automatic Capping Machine

Snap Capping Automatic Machine

Hybrid versions of the snap capping machine are also available in the market but the Snap Capping Machine is specially designed for some specific production like NEPCO.

The working principle of this machine is very similar to the Inline Automatic Capping Machine but to tight the caps up to the maximum level it uses a very minor rate of pressure.

As the expense of this machine is very low as compared to the other machines so it is not that quick in working as fewer components of the machine move when it started the process of capping.

This machine is not that accurate in terms of working via torque and some other forces that need to be done like the gravity force or downward force.

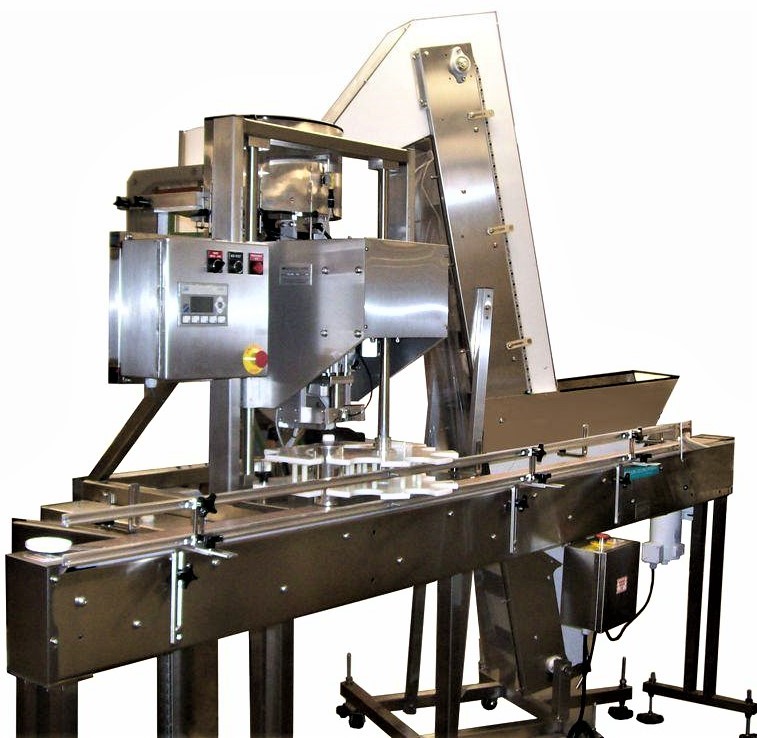

Chuck Automatic Capping Machine

Automatic Chuck Capping Machine

In medical and other industries this machine is used in almost every field for capping the different sizes of bottles. It can be easily customized as you can replace different components of the machine for a different type of production.

It is very reliable and suitable for you to operate the machine for some specific kind of production line because of its customization. Small size bottles can be capped with the help of this machine because it is difficult for a machine to hold the small product and cap it.

By keeping in mind the insane work rate of this machine it is very expensive as well when compared to other machines.

Specially designed for the pharmaceutical industry to tighten the injection bottle caps having liquid and powder inside them.

Cap Placer Automatic Machine

Automatic Cap Placer Machine-Photo Credits: Inline filling systems

Large size containers and bottles having a size of 80 mm or larger can be capped with the help of this machine.

Bottles are placed in a vertical manner so that cross threading will happen to the tightening bolts and the nut threads remain good in shape without getting any damage.

The working principle of this machine depends on the process called conjunction in which the torque is applied up to the required level to place the chuck capper.

Benchtop Automatic Capping Machine

Automatic Capping Machine Bench type

With higher torque functionality this machine is capable of doing the capping with much reliability and very flexible when working with the air pressure for its operations.

When the cap is placed at the top of the bottle the air pressure coming from the cylinder presses the cap for further processing.

This Benchtop Automatic Capping Machine requires less labor for its working as compared to the other machines with more torque operations.

5.How to Choose an Automatic Capping Machine for Your Business?

With the growing market of different packaging products, the value of Automatic Capping Machine is also increased. So, you just need to have some basic and general knowledge about the machine when you are going to choose one for your business.

Here are some following terms that you need to keep in mind while choosing the Automatic Capping Machine.

Purpose of your Business & Production Type

The business purpose for which that you are going to buy the machine must be clear like the medical field, food industry, or some other.

What type of containers and bottles you are going to use for capping like plastic and glass bottles are the two main types of products that are used for capping.

Size & Range of Caps

Different type of caps-Photo Credits: Ampulla Blog

You must consider the cap size that you are going to use for capping the bottles and what type of cap is going to be used for capping.

There are a lot of different caps are available in different sizes as well so, while choosing the machine you need to remember the size and type of the cap-like flat caps are the most useful ones as compared to the other caps.

You need to know the geometric size of the cap that you are going to use in the capping process.

Closure Size & Fitting

Different size of caps-Photo Credits: Freepik

The design of the closure will tell you about the size and its fitting ability. Some closures have a different type of body shape as the plastic cold drinks have closure/cap type with a thread type of line at the bottom before fitting.

All the closure types are referred to as the sorting way of the caps if the sorting is vertically then all the closure types like stoppers and plugs will be fitted on the containers perfectly.

Usually, a machine that can handle different types of closures is not that quick in operating the different types of bottles.

Automation Level

Automation levels-Photo Credits: IntelliFinishing

As you know the labor expense is very high these days due to the impact of Covid-19 so you must need to have a machine that can work automatically and save your labor cost.

Although there are different types of machines are available to buy but some of these have manual working components which will be very risky to operate.

A fully Automatic Capping Machine might be very expensive for you to buy but it will be very useful in terms of production rate and the long run. So, always choose the automatic machinery over the manual one because it will boost your business and give you quality products.

Investment & Environment

Investment & Environment-Photo Credits: Zameen

While choosing the Automatic Capping Machine you must decide how much you are going to spend on it and make your mind accordingly.

Investment is one of the major factors while choosing the machine along with the operating environment. Choose the machine according to your environment in which you are going to operate it.

It will help you to buy the required size machine according to your setup area for the working of the machine.

Other Functions & Factors

There are some other functions that you need to know while choosing the machine-like how much torque accuracy will be done with this machine at what speed.

Always select the machine by keeping in mind the future production of your business. Provide all the necessary information to the supplier so he can provide you the required quality capping machine as per your demands.

6.What are the Different Industrial Applications of Automatic Capping Machines?

In many industries, the Automatic Capping Machine is used for packaging different types of products.

There is a lot of applications in which this machine is used for Automatic Capping.

Applications in Food Industry

Capped cold drinks -Photo Credits: Trademart

Liquid products that we use in daily life often come in bottles as you know that all the cold drinks and liquid food items are filled in cans & bottles. So, this is one of the main applications of this machine in the food industry.

When food is dried and saved for later using the containers that are having the food inside them they are also capped with the help of this machine.

Applications in Agriculture Field

Capping Plastic Agricultural Pesticide Bottle

Fertilizers and other sprays that are used for agriculture purpose they often come in different size of bottles and capping of these bottles are done with the help of Automatic Capping Machine.

These products contain chemicals and losing them during the transfer from one place to another can cause harmful effects so the bottles are made air tighten and leakage proof.

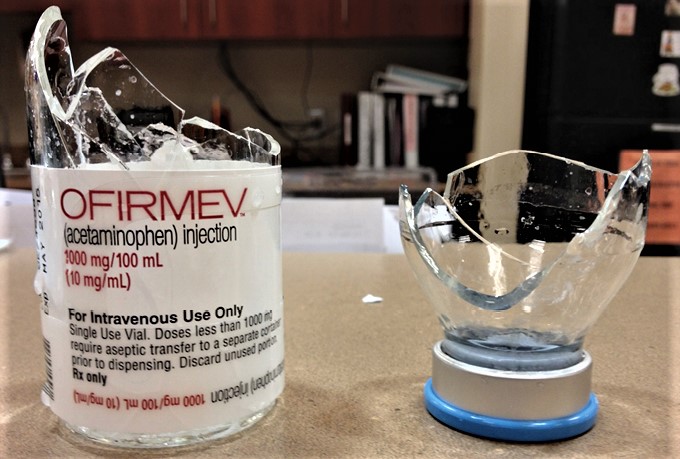

Applications in Medical Industry

Pharmaceutical bottle capping

In the medical industry, many of the vials and bottles contain medicine in liquid as well as in powder form these vials are made air tighten so the dosage remains dust-free.

This is considered as one of the main applications of this machine & it plays a vital role in the production of this field.

To make your product a contamination-free tamper-proof seal is done so that any minor type of foreign particles does not get inside the vials.

Applications in Cosmetics Industry

Cosmetic bottles in different capping & size-Photo Credits: Freepik

In beauty production, some of the products are filled inside the bottles like different body lotions, perfumes, face creams & many more.

7.What are the different Component Parts of the Automatic Capping Machine?

Automatic Capping Machine has some working components that assist the machine for fast and quick production.

These components are as follows:

Belts

The Belt on the rotating wheel -Photo Credits: wikipedia

This component of the machine works along with the station capper system in which they work on the torque for capping on the bottles.

When the bottle is filled or to be filled place it into the capping chamber these belts help to make the grip on the bottles for capping and tightening.

Chucks & Inserters

Chuck & Inserter

Chuck & inserter is a cylindrical shape part of the Automatic Capping Machine with 42mm of diameter. It is used for putting the cap in the desired position before the capping is done.

Different types of chuck inserters are present in the market with different sizes.

Clutches

Different type of clutches-Photo Credits: Mechanical Booster

A spindle is present in the machine that helps to apply the machine to put an accurate amount of torque and clutches help the spindle to do this with more accuracy.

The function of the clutches depends on the type of machine that you are using but basically they do the same work for putting the accurate amount of torque during the capping process.

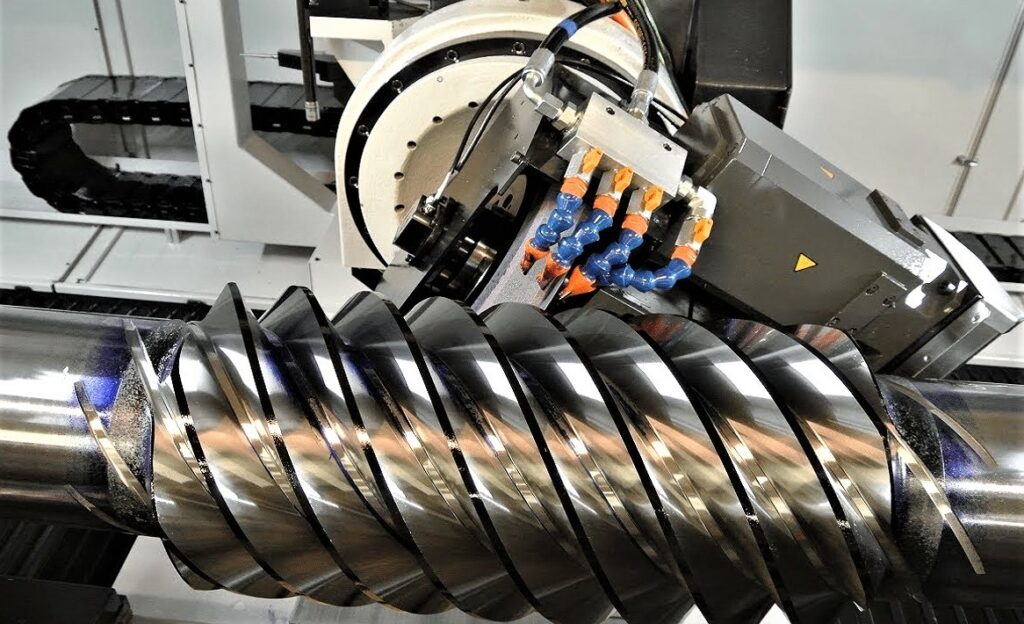

Motors & Gear Boxes

Motor & Gear Box-Photo Credits: Plant Engineering

As you know that every machine has a basic motor which helps to operate all the functions in the machine. In an Automatic Capping Machine these parts are called the heart of the machine.

Every working movement of other parts is controlled with the help of these parts.

Cylinders

Different Cylinders-Photo Credits: Machine Design

It is said that cylinders are very necessary parts of the machine they apply the air pressure on the caps for maximum fitting.

These cylinders also help the machine to rotate the vials for capping.

Gripper Disc

For better gripping on the products with less effort gripper discs in the Automatic Capping Machine provides the required torque to hold the bottles firmly for capping.

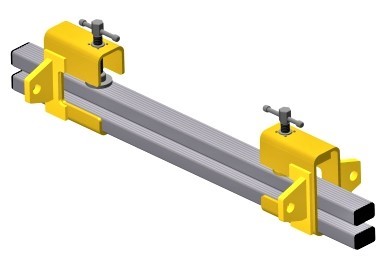

Guarding Clamps & Hardware

Belt clamps-Photo Credits: ASGCO conveyor

As you can see the name of the part tells you the working of it. This part of the machine guards the other working components from getting any kind of damage.

Guarding handle or guarding clamp hardware also provides the assistant in making the connection between different parts of the machine.

Sorters & Feeders

Feeders in the machine provide the caps and sorters do the sorting of the caps whether they are good or not for capping.

Most of the feeders are designed in a straightforward way for feeding the machine by providing caps.

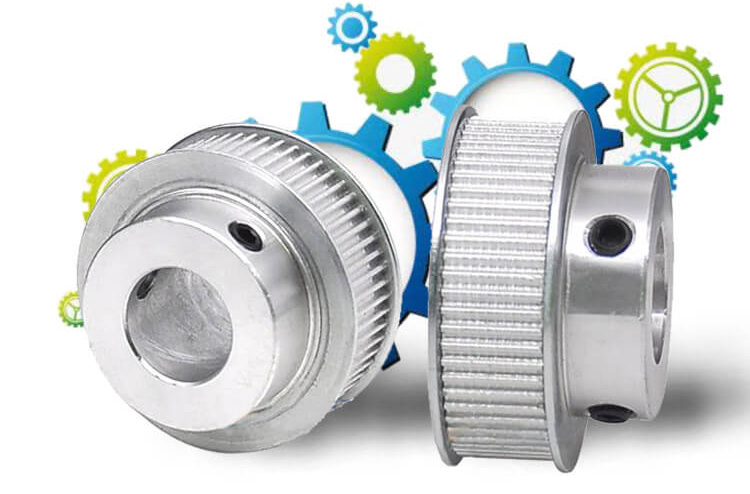

Pulleys

Belt pulleys

Pulleys in the Automatic Capping Machine assist the machine in connecting different parts with each other in the same way as gears and belts do.

This part of the machine depends on the size of the machine.

Shafts & Sprockets

The rotary motion on the cap which is fixed in the shafts is done with the help of shafts & sprockets.

Other parts of the machine make the according to the working of this part & it helps the other parts for better movements.

8.How does an Automatic Capping Machine Work?

AIPAK Automatic Capping Machine Line

An Automatic Capping Machine works on the principle of torque and air pressure. Every machine works in a different way when it comes to size and shape of the machine.

Here is the basic and general working principle of the Automatic Capping Machine.

Step-1

In this step, all type of adjustments is done on the different parts of the machine. First of all the height is set according to the container size so that the product can fit into it.

When the measuring of the right width and size of the containers is done. Belts are set to an accurate angle & with accurate width for gripping the product.

In Automatic Capping Machine caps of the bottles are placed automatically before the capping when everything is adjusted accordingly.

Step-2

When the spindle is adjusted according to the size of the cap it will automatically provide the caps to the machine for fitting on the container.

An elevator or vibrating bowl will provide the caps to the chute part of the machine. Then the machine will tear up the cap for further processing.

Some of the machines work on the rotary motion which is done with the help of chuck cappers & some of them work through the spindle movement which helps to move the container discs for holding the caps.

Step-3

Different types of caps will be managed accordingly by the spindle for stripping them. When the machine works with the chuck header it works on the rotating motion of the caps.

When the caps are stripped and the container is set with perfect height and width then start the working system.

Set the torque value according to the given manual by keeping in mind the container and capsize for the desired capping.

An automatic capping machine has a capacity of capping 200 bottles per minute. Working of the machine will be continuous until your product is finished.

When the capping is done then the containers will be removed from the machine automatically into the discharge plate. So, that’s the basic working of the Automatic Capping Machine.

9.What Automation Level do you Need for Automatic Capping Machine?

When it comes to the automation level different types of machines are present with different automatic working components always prefer the most automated system whenever you are going to buy the machine.

Here is the automation specification that you need in the Automatic Capping Machine.

Use the machine which automatically gets the caps from the vibrating bowl and sets the spindle height and width according to the size of the container.

Spindle cappers are also available in semi-automatic working. By using the semi-automatic spindle you have to set the caps manually on the container for capping. So just buy the machine with an automatic spindle capper so you will need to utilize any effort for putting the caps on the containers.

The automatic spindle will provide you the flexibility to adjust it according to the size of the cap & you can easily set the torque value according to the requirements.

More automation level in the machine will save your time and labor cost as well. You will get more production in very little time.

Use the machine in which you can easily set the angle of the belt & its gripping width according to the bottle size.

10.Will Automatic Capping Machine Work with my Caps and Closures?

Different caps-Photot Credits: Ampulla Blog

If you are looking for a machine that can work on different types of caps and closures then don’t worry you are in the right place.

This Automatic Capping Machine is very capable of doing any kind of capping with different sizes caps.

As it provides you the flexibility for adjusting the spindle according to the size of the cap/closure. So it is very useful for you to do the capping on the choice of your caps and closures.

Machines are present in different types with the same working purpose but some of these machines are not fit when it comes to the different types of caps. But AIPAK Automatic Capping Machine works on different sizes and types of the cap/closures.

Shafts in the machine provide the holding ability up to maximum level and the safety of your product ensures with this machine.

You can easily do the capping on the bottles & vials with the available caps that you are going to use.

11.Can Automatic Capping Machine Handle all of my Bottle Shapes and Sizes?

Plastic & Glass bottle-Photo Credits: Times of India

Different models of the Automatic Capping Machine are capable of capping different types of bottles.

You can easily handle all kinds of bottles by using these Automatic Capping Machines like Vertical Automatic Wheel Plugger, Automatic Chuck Capping Machine, Automatic Snap Capping Machine, and Automatic Spindle Capping Machine.

When it comes to the general sizing of the bottles and types these machines are capable of capping every type of bottle. Adjustable parts in the machine can help you to fix the width and size according to the product requirements.

Plastic and glass bottles can be pack/caps with the help of this Automatic Capping Machine you can easily adjust the spindle and chuck capper according to the size and shapes of the bottle.

So, this machine is very reliable and flexible to use for any kind of production as per your requirements.

The large size of the containers will require the large size of the machine so you can cap the larger containers.

With different features in the machine, it is easy for you to cap any size bottle with the help of this machine.

12.How Fast will the Automatic Capping Machine Run?

Component of the machine that provides speedy production-Photo Credits: LA machines

As the machines often came in different sizes with different production speeds but the average production rate of every Automatic Capping Machine is 200 capping per minute.

This machine can cap 200 bottles in just a minute this might look simple and easy but the work rate of this machine is insane.

With an average speed of 200 cappings in a minute, this machine can cap up to 12,000 bottles in an hour. You can reach the market demands with the help of this fast working of this machine.

The fast working components of the machine provide much flexibility and quick operation in the capping process.

13.What is the Production Capacity of the Automatic Capping Machine?

The production of the machine depends on the working speed of the machine. So we can say that the working speed is directly involved in the production rate of the machine.

Automatic Capping Machine lies in different categories. Some of the machines have some semi-automatic components which make the production slow because you have to do some manual effort while working with the machine.

When it comes to the average production of the Automatic Capping Machine you can say that this machine can do the packaging/capping on 11,500 bottles in an Hour.

It’s a pretty satisfying amount of production with less time consumption. You can easily reach the market values with the help of this production speed.

The machine has an average of 180 to 200 bottles capping in a minute. The machine can also assist you in capping any size of bottles with adjustable parts.

14.How do you Troubleshoot Automatic Capping Machine?

There are some common errors that may occur during working with Automatic Capping Machine and you need to know how to troubleshoot those errors.

Some mechanical errors can also occur because of some damaged components of the machine so always troubleshoot the machine before starting it & check each moving part before operating the Automatic Capping Machine.

Missing Caps

During the capping, some of the bottles may not have caps after the process. So, this is one of the main problems that can make your production slow.

This often happens because of the misplaced caps in the alignment Chutes.

- Solution

To troubleshoot this problem properly align the spindle & chuck holder so that all the caps are set perfectly on to the top of the bottle for fitting.

The troubleshooting of the Automatic Capping Machine can be different because of the specific components like a spindle, chuck cappers, etc.

These machines may require troubleshooting according to their working components.

Bottles Getting Damage

This type of problem occurs when the disc holders are not set according to the size and shape of the bottles, vials. Try to read the geometric measures of the product on which you are going to work.

- Solution

When your product is getting any kind of damage during the capping process. Try to adjust the gripper disc up to the right gap between them to hold the bottle/vial.

Try to have contact with the experienced and related person who knows about the working of the machine so that you can easily troubleshoot any kind of problem.

15.What are the Technical Specifications of the Automatic Capping Machine of AIPAK?

Here are the specifications of the AIPAK Automatic Capping machine with high speed and quick production.

There are some basic and main parameters for the AIPAK Automatic Capping Machine.

| Name | Output | Air consumption | Dimensions | weight | Supply power | pressure |

| High Speed Automatic Capping Machine | 80 to 180 | 0.3 | 2550*1050*1900 | 680 | 220 volts/1.8KW | 0.6 |

Now, move on to the configured specifications.

| NO# | Name of the main parts | Manufacturer Name |

| 1 | Main Motor | TQG ( Taiwan ) |

| 2 | Stepper Motor | Ever Electronica ( Italy ) |

| 3 | Electric Sensor for seeing the bottle | ORMON |

| 4 | Main Control Board | PLC Adopt Delta/ Siemens |

| 5 | Switching Button | Schneider |

| 6 | Main Interface of the machine | Adopt Siemens |

16.What are the different Auxiliary Equipment Used With Automatic Capping Machine?

Assistant gear is otherwise called the hardware for making the total creation line of the cycle.

Bottle Unscramble

Bottle Unscramble is able to feed and manage containers made from different materials such as plastic and metals.

Sealing Machine

AIPAK Sealing Machine

When the containers are filled they are fixed here in this machine. Fixing is being accomplished for dodging any sort of spillage or spilling.

Covering Machine

The following cycle resembles all the more fixing in a superior manner that is concealing the container with the various kinds of the covers.

Printing Machine

Presently, it's an ideal opportunity to make reference to the various subtleties identified with the item you have filled as of now.

You can print bunch subtleties, date of assembling, and expiry date too.

Pressing Machine

The subsequent last advance is pressing every thing into the crate or whatever pressing they go it and that is conceivable with the pressing machine.

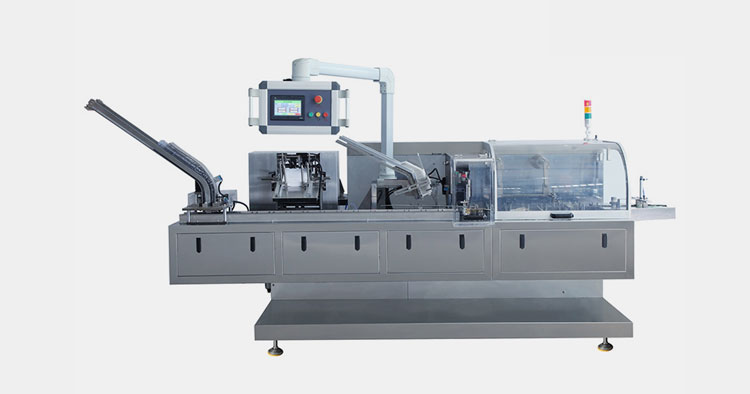

Cartoning Machine

The last advance is making the containers of the relative multitude of items with cartoning machines.

That is the thing that makes the entire creation line for the jug fixing machine.

17.What are the Different Quality Standards for Automatic Capping Machine?

Automatic Capping Machine must be manufactured according to the defined quality standards.

Some European standards are defined for manufacturing the Automatic Capping Machine.

CGMP

CGMP logo -Photo Credits: Standard logos & Co

This standardization tells you about the manufacturing material that is used in making the machine made up of good quality.

Material that is approved by FDA is used in the manufacturing of the machine and this standardization can help you to get the best-manufactured machine.

ISO

All the user requirements must be fulfilled by the manufacturing company and the design of the machine must be according to the buyer’s needs.

CCC

CCC logo-Photo Credits: Standard logs & Co

There are some standards that are also set by the Chinese development market & this standardization tells you about those quality standards that are set by the Chinese for producing the best equipment.

The working efficiency and production rate are checked with the help of this quality standardization.

CE

CE logo-Photo Credits: Standard logos & Co

This unique and safety standardization ensure that you can easily operate the machine in any kind of environment without giving any hazardous damage to the surrounding environment.

ROHS

This quality standard tells you that your Automatic Capping Machine is made up of good material & no reactionary material is used in making the machine.

This standardization put a restriction on different kinds of material that can damage the labor during the working of any kind of electric shock is happened. So, this quality standardization makes sure the equipment is safe and secure to operate.

ASTM

Globally developed standardization that makes sure that Automatic Capping Machine when developed it must go through some necessary practical so that you can get the quality production after the practices being made on it.

18.How do you Maintain an Automatic Capping Machine?

When you buy the machine and started working with it try to do defend the machine from getting any kind of damage and this can only be done with a high maintenance level and accurate settings.

You must need to utilize some energy for maintenance of the machine in this way Automatic Capping Machine will work for long term use.

Maintenance of the machine is as important as the machine itself a well-maintained machine will work at the same level as it is working at the start.

Some points you need to remember for maintaining the Automatic Capping Machine. Here are some of these points.

- Cleaning is one of the main factors for maintaining the machine if you clean the machine according to the given manual time then you will get maximum production rate & cleaning will help your machine parts to work smoothly without any retarding force.

- Lubrication/Oiling all the moving components in the Automatic Capping Machine must be lubricated for getting the best output from them and faster production. Before starting the process all the seat bearings must be greased well for fluid movement.

- Before starting the machine check the spindle & chuck holders and see if they are placed in the required position according to your production line.

- Compressed air which is present in the cap holders must be checked if there is any kind of leakage in the pipeline try to stop the air leakage.

- Vibrating coil is very important in terms of sorting the caps to their preferred positions so always maintain the vibratory coil. If it gets damaged replace the coil.

19.Why Should you Import AIPAK Automatic Capping Machine?

AIPAK Automatic Machine is very helpful many ways for your business. As it is available in different sizes you can import one according to your needs.

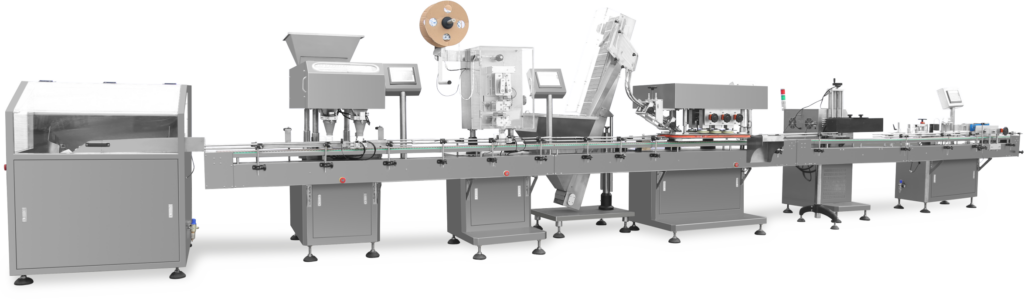

AIPAK Tablet /Capsule/Pill Counting Line

Here are some following important points that AIPAK Automatic Capping Machine will provide you.

- AIPAK is 100 % guaranteed firm that will provide you best certified & genuine product for your business needs.

- You will get more production in less time. So, this machine will help you to grow your business & help you to meet the production rate with quality production.

- If you want the best output from the machine in terms of your production line then importing the AIPAK Automatic Capping Machine will deliver you the required result.

- It is not that difficult when it comes to operating the machine you can easily operate it with some basic knowledge.

- As the machine is fully Automatic you will require less labor in terms of operating the machine.

Conclusion

As you know the machine is very helpful in many ways for your production. So, you need to buy the machine if you want quality production with less time consumption. It will deliver you fast & quick output and very useful on different types of products. You can easily adjust it according to your production need.

Capping Machine Related Products

Capping Machine Related Posts

Capping Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours