An Overview Of The Bin Mixer

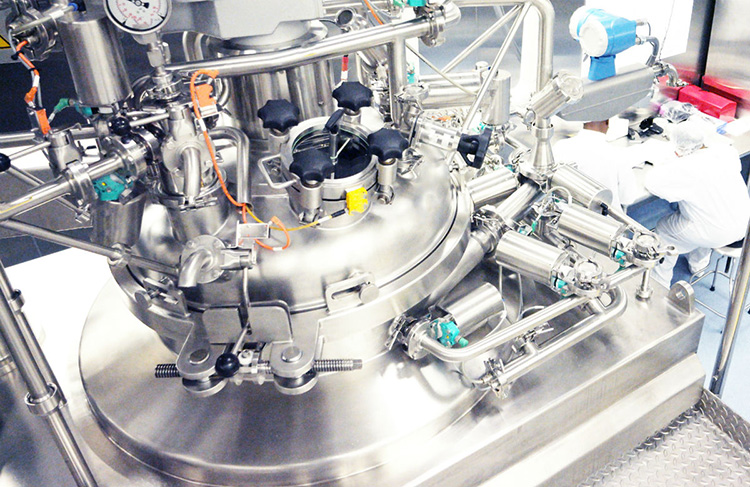

The bin mixer mainly uses machinery and gravity to uniformly mix two or more materials. Mixers are widely used in various industries and daily life. In the pharmaceutical industry, bin mixers can evenly mix raw materials of different components together to form a compound, and can also accelerate physical changes.

For example, the granular solute is added to the solvent, and the dissolution is accelerated and mixed uniformly by the action of the bin mixer. So what are the most common bin mixers in the market, and what characteristics do they have? This is very important to us. Knowing each equipment will help us have a comprehensive understanding of the bin mixer.

Horizontal screw belt bin mixer

A.Main applications:

The horizontal screw belt bin mixer is a new type of high efficiency and high precision particle mixing equipment. It is widely used in chemical engineering, pesticide, dyestuff, pharmacy, food, fodder, petroleum, metallurgy mining and other industries of all kinds of powder particles mixing.

B.Main features

First, advanced structure, convenient operation, safe and reliable operation.

Second, the mixing speed is fast and the quality is uniform. The double helix of this machine is asymmetrically arranged. A large and a small of the double helix widens the range of mixing. Therefore, it is more suitable to mix materials with a large proportion of specific gravity.

Third, the energy saving effect is remarkable, and the energy consumption of this machine is only one tenth of that of the drum mixer.

Fourth, the wear and pressure of granular materials are small, and there is no overheating reaction when mixing heat-sensitive materials.

Fifth, the mixed preparation is stable and does not occur delamination and segregation.

Sixth, the double helix conical mixer is sealed and dust-free, with simple operation, convenient maintenance and long service life. In addition, according to user requirements, the cone can be made into a pressure vessel for pressurization or vacuum operation.

Seventh, the autobiography and revolution of this double helix conical mixer are completed by a set of motor and cycloid needle transmission reducer.

C.The working principle of the horizontal screw belt bin mixer

First, due to the revolution of double helix that makes the powder move around the wall of the cone.

Second, because of the autobiography of spiral blades that make the powder discharge to the central cone for radial movement.

Third, the powder flows upward from the bottom of the cone and is discharged to the surface around the helix for material mixing.

Fourth, the downward flow of powder particles caused by spiral rotation is precisely due to the combination of rotation and rotation of the spiral in the mixer, which forms four kinds of flow forms of powder: the composite movement of convection, shear, diffusion and infiltration. Therefore, the powder can quickly achieve uniform mixing in the mixer.

Horizontal double shaft screw belt bin mixer

Main applications

The horizontal double shaft screw belt bin mixer is widely used in putty paste, stone paint, dry powder, putty, medicine, food, chemicals, feed, ceramics, refractory materials and other solid-solid (powder and powder), solid-slurry (powder and glue slurry) mixing, especially suitable for thick material mixing.

Main features

First, it adopts a U-shaped barrel structure that makes the machine have a characteristics of stable operation, uniform stirring, no dead angle, clean discharge and wide application range.

Second, the inner and outer double-layer ribbons are staggered and mixed back and forth, with a fast mixing speed and high uniformity.

Third, bearings are at both ends of the mixer, the materials are not easy to enter, and the maintenance rate is low.

Fourth, the screw conveyor is convenient for feeding, the feeding port is flush with the ground, and the feeding is labor-saving and convenient.

Working principle of the horizontal double shaft screw belt bin mixer

The machine consists of two parts: feeding and stirring.

First, the feeding part: It enters from the feeding hopper, and the material is lifted into the mixer through the screw blade and enters the mixing drum for stirring and mixing.

Second, the mixing part: When the material enters the mixing drum and performs a back-and-forth staggered movement, the mixing effect is good.

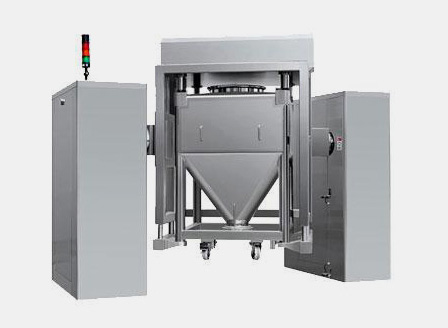

3D oscillating bin mixer

I.Main applications

This machine is used in pharmaceutical, chemical, food, light industry, electronics, machinery, mining and metallurgy, national defense industry and scientific research units of powder, granular material of high uniformity mixing.

II.Main features

First, with multi-directional movement, the material in the cylinder has many mixing points, the mixing effect is remarkable, and the mixing uniformity is higher than that of the general mixer.

First, low vibration, low noise, adjustable station, easy installation and maintenance, long service life.

Second, the container effective loading rate of 80%, short mixing time, high efficiency.

Third, the machine height is low, no special requirements for the plant, reduce capital investment.

Fourth, the mixing bucket and the transmission part of the fuselage can realize the partition

installation, which is convenient to meet the requirements of GMP.

Fifth, it can realize stepless speed regulation, easy to load and discharge.

III.Working principle of the 3D oscillating bin mixer

It performs unique pan, rotation and rock movements in the three-dimensional cube space, and makes the material in a complicated movement state of “rotary flow-pan and reserve fall” in the mixing cylinder, which is the so-called TURBULA state.

It can generate an alteration pulse to continuously push the material, and the turbulence generated by the movement has a changing energy gradient so that each particle in the mixed material has an incapable motion state, and each particles continuously changes its position in the frequent movement and diffusion, which produces a satisfactory mixing effect.

The 3D oscillation mixer consists of a machine base, a driving system, a three-dimensional motion mechanism, a mixing cylinder and an electrical control system. The mixing cylinder that is in direct contact with the material is made of high-quality stainless steel, and the inner wall of the cylinder is precisely polished.

In addition to the above three types of machines, there are many types of mixers. Different types of machines have their own scope of application and their own advantages. How to choose a suitable machine for you requires you to decide according to your own main needs.

Knowing the machine is only one of the steps, and it is also the most basic step. More importantly, it is to solve the problems in the use of the machine in the future, so that the machine can work better.

Don't forget to share this post!

Bin Mixer Related Posts

Bin Mixer Related Products

Bin Mixer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine