PROJECT STORY

1

Mr.Jonalyn is the project manager of a pharma group in Bangladesh,that has been focusing on development,production and distribution of pharmaceuticals for over 30 years and specialising in the contract manufacturing of parenteral medicines predominately used in local hospitals and intensive care.The old ampoule filling line still in use in his factory was purchased from Germany in 1998.

In 2010,Mr.Jonalyn’s company decided to build a new sterile facility factory to increase its production capacity.So they are looking for a reliable supplier of ampoule filling lines who offered the benefit of a short delivery time,and other critical process parameters in choosing the lines that include the compact design,energy efficiency and less trainning time for the operators.After several times’ comparsions,Mr.Jonalyn decided on us.

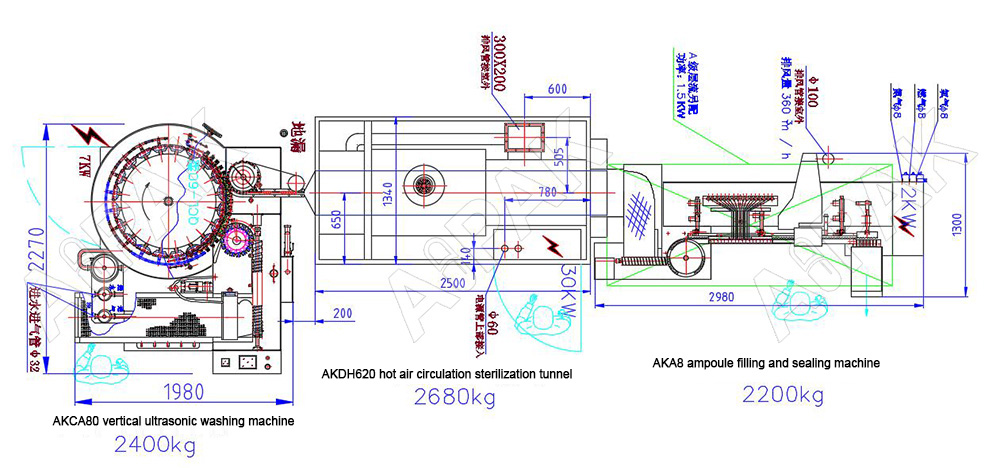

PROJECT LAYOUT

1

Project Details

1

In September 2010,Mr.Jonalyn odered an AKBL-8 ampoule filling line with an AKCA80 ultrasonic washing machine,an AKDH620 hot air circulation sterilization tunnel,AKA8 ampoule filling and sealing machine,and capping machine ,and we delivered within 10 months.During the same in 2021,the ampoule filling line has been put into production.

Now Mr Jonalyn has used the AKBL-8 ampoule filling line to fill and seal a variety of ampoule shapes and sizes, at speeds of 200 ampoules per minute with a fill accuracy of +/- .5%.

The most important feature of this linkage production line is the cleaning method and the filing and sealing rate that the most popular way in the world,and and the inclusion of Restricted Access Barrier Systems (RABS) and Cleaning-In-Place and Sterilizing-In-Place (CIP/SIP).

Mr.Johnlyn was quite satisfied with our fast delivery and high efficient filling and sealing that not only help them expand their production capacity while also meet the cleanroom standards.

VIEW MORE PROJECTS

Related Products

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586