Aluminium Tube Packaging: The Complete FAQ Guide In 2025

Plastic tube packaging often appears in our daily lives, but upon closer inspection, many of them are made of aluminum. Have you ever used products packaged with aluminum tube? For example, hand cream, ointment, mustard sauce, and so on. Due to its environmental friendliness and durability, aluminum tube packaging have been used in multiple industries.

What do you know about aluminum tube packaging? Do you know what customization options it can offer? Next, I will take you to learn about aluminum tube packaging.

1.What Is the Definition of Aluminium Tube Packaging?

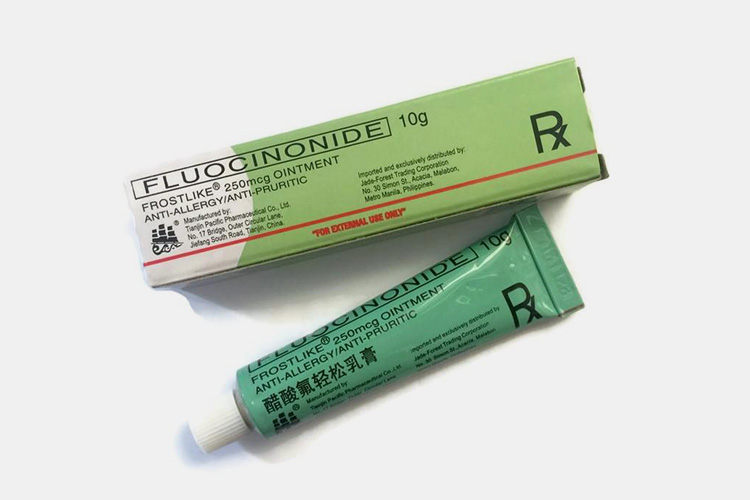

Aluminum Tube Packaging - Sourced: Shopee

Aluminum tube packaging refers to tube packaging made of aluminum material. This packaging form is convenient to carry and suitable for high-strength extrusion, especially for products made of various semi-solid materials.

In addition, aluminum tube packaging can be customized with various patterns, which can attract customers’ attention, so it is widely used in various fields.

2.What Are the Advantages of Aluminium Tube Packaging?

Why is aluminum tube packaging popular among many manufacturers? Do you know what advantages it has?

Good isolation

Aluminium With Good Isolation - Sourced: Furniture Fittings

Aluminum materials have strong barrier property. Some drugs or face cream with poor chemical stability are generally packed with aluminum, which has good characteristics of shading, moisture-proof, airtight, corrosion resistance, non-toxic and tasteless.

Non reactive

The structure of aluminum is very dense, which can protect the inner layer of aluminum from oxidation and prevent chemical reactions between materials such as drugs and packaging materials.

Protecting active ingredients

Protecting Active Ingredients - Sourced: Cosmetics & Toiletries

For products such as drugs and cosmetics, there are many active ingredients. Aluminum tube packaging can protect the active ingredients in the product from chemical reactions.

Sustainability

Sustainability - Sourced: Jersey Girl Organics

With the increasing call for green environmental protection, the recycling and utilization of packaging materials have become increasingly important. As aluminum is a sustainable metal, it can be recycled and reused time and time again, which is beneficial for achieving sustainable development.

3.What Are the Applications of Aluminium Tube Packaging?

Tube packaging is not only lightweight and easy to carry, but also particularly suitable for high-strength extrusion, no wonder it has always been so popular in the packaging industry. Due to its many advantages, aluminum tube packaging can be seen in many fields.

Cosmetics industry

Hand Cream - Sourced: Amazon

Aluminum tube packaging can effectively protect the quality and stability of cosmetics. With the continuous improvement of consumers’ requirements for the quality and packaging of cosmetics, the market demand for cosmetic aluminum tube is also increasing. Common cosmetic products include hand cream, hair dye, sunscreen, and eye cream.

Pharmaceutical industry

Ointment - Sourced: MedsGo

Medicine has higher requirements for aluminum tube packaging. Common medicinal aluminum tube packaging in daily life includes various ointment tube such as eye ointment, skin care cream, dermatitis ointment, salicylic acid ointment, etc.

Chemical industry

Adhesives - Sourced: Fastener + Fixing Magazine

The surface of aluminum is prone to the formation of a dense oxide protective film, which can effectively isolate water vapor, air, etc., and prevent the product from being contaminated during circulation and use. Therefore, aluminum tube packaging can better prevent moisture, seal, and extend the service life of adhesives.

Food industry

Mustard - Sourced: eBay

In order to maintain the freshness of food and extend its shelf life, many paste like products, such as sauce and mustard, are packaged in aluminum tube packaging. In addition, it can isolate water vapor and air from the food.

4.What Are the Differences Between Aluminium Tube Packaging and Plastic Tube Packaging?

As is well known, aluminum and plastic are currently the most common materials for tube packaging. Do you know the differences between these two?

Two Types of Tube Packaging

| Aluminium Tube Packaging | Plastic Tube Packaging | |

| Durability | Due to its high strength and pressure resistance, aluminum material is more durable and sturdy. | It is relatively brittle and easily damaged, so it has lower durability. |

| Barrier property | It has better barrier properties, providing excellent isolation for air, moisture, and light. | It has poor barrier properties, inferior to aluminum materials. |

| Processing performance | It has good processing performance and good ductility. | The processing performance is relatively poor. |

| Corrosion | It is easily oxidized and rusted by impurities in air and moisture, even after surface coating treatment. | It will not corrode and will not undergo oxidation reactions when exposed to water and air. |

| Price | The price is more expensive. | The price is cheaper. |

5.Can Aluminium Tube Packaging Be Recycled?

Recycle Products - Sourced: Iamrenew

As is well known, the material of aluminum tube packaging is aluminum. The recyclability of aluminum products is extremely high, which has important environmental significance. Due to aluminum being a non-toxic substance, the recycling process does not produce pollution and does not pose any harm to the environment.

Therefore, aluminum tube packaging can be recycled and reused multiple times because the physical and chemical properties of aluminum products do not change after multiple cycles of use.

6.Is Aluminium Safe for Pharmaceutical Tube Packaging?

Safe for Pharmaceutical Tube Packaging - Sourced: Environmental Hazmat Services

As a packaging material that comes into direct contact with drugs, the safety of pharmaceutical aluminum tube packaging is crucial. Aluminum materials have strong barrier properties, and some drugs with poor chemical stability are generally packaged in aluminum. Therefore, aluminum is very safe for use as a material in pharmaceutical tube.

However, manufacturers must also strictly comply with relevant pharmaceutical packaging standards to ensure that the material, production process, and quality control of pharmaceutical aluminum tube comply with regulations. In addition, pharmaceutical aluminum tube need to undergo strict testing before use to ensure that they will not contaminate or affect the efficacy of drugs.

7.What Are Types of Aluminum Tube Packaging Finishes?

In order to attract consumers’ attention, many manufacturers use different finishes for aluminum tube packaging. Do you know which finishes are available?

Matte finish

Matte Finish of Aluminium Tube Packaging - Sourced: Bayview Pharmacy

The reflectivity of matte finish of aluminium tube packaging is usually between 10% and 40%, which means they can absorb most of the light shining on them instead of reflecting it directly. This characteristic makes the matte finish appear softer under light exposure. Matte finish has a darker color, but it can create a sense of delicacy that can make your aluminum tube packaging stand out from competitors.

Gloss finish

Gloss Finish of Aluminium Tube Packaging - Sourced: Perfumes e Companhia

The gloss finish of aluminium tube packaging is very smooth, resulting in high reflectivity and reflectivity under illumination. Gloss finish has a more vibrant color than matte finish. After coming into contact with surface dirt, this type of finish can be easily wiped clean.

8.What Are Common Caps for Aluminum Tube Packaging?

According to different styles and product types, aluminum tube packaging can choose different types of caps. Do you know which caps are available? Next, we will introduce the two most common types of caps for you

Screw cap

Screw Cap - Sourced: Amazon

Screw cap, also known as spiral cap, is the most common type of aluminium tube packaging. It adopts a spiral opening and closing method, and the tube packaging can be opened or closed by simply rotating the cap. Commonly used for packaging non perishable items such as food, beverages, and laundry products. The sealing performance of the screw cap is good and easy to use.

Flip cap

Flip Cap - Sourced: Ideon

Flip cap is a type of cap that can be flipped open and closed, typically used for small packages such as toothpaste. Its characteristic is convenient to use, but its sealing is poor, which can easily cause items to deteriorate.

9.What Customized Options for Aluminum Tube Packaging?

When you make aluminum tube packaging, you can customize the design according to your own needs.

Brand and label

Brand and Label - Sourced: L’Occitane

Brand and label stands for the image of your company. You can print the brand logo and other labels you want on the aluminum tube packaging, highlighting the brand's characteristics.

Colour

Colour of Aluminium Tube Packaging - Sourced: Victoria Beckham Beauty

The color of the entire aluminium tube packaging can be chosen, such as white, pink, or blue. You can choose colors according to your own needs.

Size

According to different production needs and materials, you can have different size requirements for aluminium tube packaging, so you can also customize tube packaging.

10.What Are Different Nozzles for Aluminum Tube Packaging?

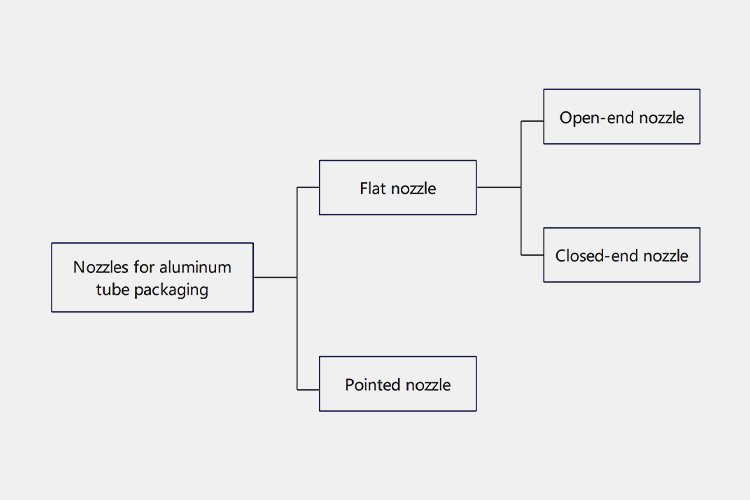

Different Nozzles for Aluminum Tube Packaging

In general, aluminum tube packaging are usually divided into two types: flat nozzle and pointed nozzle.

Flat nozzle

Flat Nozzle - Sourced: Adinath International

The sealing performance of the aluminum tube packaging is good, and the flat nozzle tube with internal spraying and tail glue can better resist corrosion and leakage.

Flat nozzle is divided into open-end nozzle and closed-end nozzle. Open-end nozzle is generally used to fill viscous paste products, such as lubricating grease, soil filling paste, and cream. Adopting an open design, consumers only need to unscrew the lid to use it immediately.

Closed-end nozzle are generally used to fill relatively thin contents, such as glue, hand cream, cosmetics, etc. Adopting a closed design, it can isolate substances such as air, water vapor, moisture, and bacteria from the external environment, reducing the probability of the paste being contaminated and deteriorating.

Pointed nozzle

Pointed Nozzle of Aluminium Tube Packaging - Sourced: expocontabilidate

Pointed nozzle of aluminium tube packaging are usually open, and if paired with a specialized plastic cover, they can achieve a good sealing effect. The opening of the pointed nozzle tubes is usually relatively small, and the amount of paste squeezed out from the tube is relatively small each time. This makes it easy to control the amount of adhesive used in small quantities.

In addition, the pointed part extends outward for a certain distance, which is convenient for extruding the glue and directly applying it to the place where it needs to be used, accurately applying the glue.

11.What Are the Challengesof Aluminum Tube Packaging?

Aluminum tube packaging has many benefits, but there are also some challenges. What do you know?

Complex production

Complex Production - Sourced: Forbes

Due to the need for multiple processes, typically 6-12, the production process of aluminum tube packaging is quite complex. In addition, every step from raw material preparation to final product molding requires precise control to ensure product quality.

High material cost

High Material Cost - Sourced: NightSnipe Lighting

Aluminum is of better quality and more pressure resistant compared to other materials such as plastic, but its cost is also higher, which increases the cost of aluminum tube packaging.

Complicated recycling progress

As mentioned earlier, aluminum can be recycled and has a high recovery rate. However, due to the special nature of materials such as drugs, special lining is also required, which makes recycling more complex.

12.What Technological Innovations in Aluminum Tube Packaging?

With the increasing application and popularity of aluminum tube packaging, this packaging form is constantly undergoing technological innovation.

Aluminum tube with plastic cleaning head

In recent years, the production process of medicinal aluminum tube packaging has been continuously improved. Aluminum tubes with plastic cleaning heads and pointed eye ointment tubes with cleaning heads have been developed, which can avoid the phenomenon of aluminum blackening caused by repeated friction of the pipe thread, further improving the cleanliness of drugs and the safety of medication.

Adopting hot stamping technology

Adopting Hot Stamping Technology - Sourced: Plastic Tube

Using the principle of hot press transfer, the metal printing plate is heated and foil is applied to print golden text or patterns on the aluminum tube packaging. After hot stamping, the product has clear and beautiful patterns, bright and eye-catching colors, and is wear-resistant and weather resistant.

Anti tampering function

Anti Tampering Function - Sourced: abdurachimfs

In order to improve the safety of the product, some aluminum tube packaging has adopted high-quality sealing technologies such as tamper proof sealant to prevent the product from being tampered with.

13.What Should You Consider When Choosing the Aluminum Tube Packaging?

When choosing aluminum tube packaging, remember not to blindly choose one. You should consider many factors that are related to the final product.

Size and capacity

Size and Capacity - Sourced: ETMA

You should specify the size and capacity you want, as different sizes of aluminum tube packaging can accommodate different capacities. Whether choosing small hand cream aluminum tube packaging or large industrial packaging, it is necessary to clarify the size and capacity.

Durability

Although aluminum material can withstand impact and moisture, it is necessary to choose high-quality materials. Different aluminum materials also have different qualities, so choose durable materials for aluminium tube packaging.

Product type

Product Type - Sourced: Making

Different product types may have different material requirements for tube packaging. Some materials have high requirements for aluminum, while others do not require the use of aluminum.

14.What Machine Involved in the Production of Aluminum Tube Packaging Products?

Do you know how the hand cream you use is packaged into aluminum tube packaging? That is the contribution of the tube filling machine.

Aluminium Tube Filling Machine

Aluminum tube filling machine can fill toothpaste, ointment, cream, jelly, chemical adhesives, and various adhesive materials. This machine is made of 304/316 stainless steel for all materials and related parts, and quick change devices are used for cleaning the parts that need to be cleaned, making it easy to disassemble and clean. It is also strictly applicable to GMP standard requirements.

Adopting PLC control, human-machine interface operation or button selection, this machine is easy to operate. Through automatic benchmarking, automatic filling, and automatic tail sealing, the production efficiency is high.

Conclusion

Although aluminum tube packaging is relatively expensive, this packaging form has good light and moisture resistance and is very popular. This article takes you to a comprehensive understanding of aluminum tube packaging. If you have any further knowledge you need to know, feel free to contact AIPAK at any time.

Don't forget to share this post!

Tube Filling Machine Related Posts

Tube Filling Machine Related Products

Tube Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine