Alu Alu Blister Machine: The Complete Buying Guide in 2025

In today’s revolutionizing world, pharmaceutical industries evolve in packaging process. They come up with new innovation technology to compete in market. Pharmaceutical packaging is not only safe and temper proof but also cost-effective, efficient and easily adaptable with changing production need. Keeping in mind, let introduce you cutting edge technology of packaging is alu alu blister machine.

Alu alu blister machine efficiently packs aluminum foil from both side top and bottom making a secure and temper proof packaging for your tablet, capsule and other solid dosage form. Now the question is what do you know about this machine?

Hang on! In this article about “alu alu blister machine: the complete buying guide 2025” we will discuss in depth about alu alu blister machine, how it works and what factor you need to consider if you are planning to buy this machine. So, read this article to gain in-depth knowledge and got all your question answered.

1.What is the Alu Alu Blister Machine?

Alu Alu Blister Machine

Alu alu blister machine is crucial component of production line in various industries. Alu alu blister machine is a packaging equipment which can efficiently pack product between two layers of aluminum foil. This packaging machine create a barrier against moisture, heat and temperature enhancing shelf life and quality of packed product.

This machine works by cold forming of aluminum to make cavity and after placing product and sealed it from other side by heat and pressure. This machine is easily configured according to new size and format, due to which it can easily adaptable to changing production requirement. This packaging machine is widely used in industries like pharmaceutical, food and herbal industry.

2.Why Do You Need Alu Alu Blister Machine?

Alu alu blister machine is highly efficient equipment which comes with its beneficial feature like high speed production, temper-evident packaging, ease of handling, improve product shelf life and many more. Let’s get into this article, learn some promising outcome of alu alu blister machine.

Tamper evident packaging

Tamper Evident Packaging- Picture Courtesy: CHAL Aluminum Corporation

Alu alu blister machine ensures temper evident packaging which gives assurance to customer that product is free from any contamination and adulteration. This equipment provides sealed and secures packaging that sustains the authenticity and quality of product.

Improving stability of product

Improving Stability of Product- Picture Courtesy: CPHI Online

Alu alu blister machine enhances product stability and prevent degradation of product. This packaging is best fit for product which are moisture sensitive, heat sensitive or light sensitive maintaining product effectiveness.

Reducing labor cost

Reducing Labor Cost

Alu alu blister machine is highly automated equipment, which can easily operate single handedly which means less manual interference. This greatly impact labor cost as minimum number of manual labor required to operate this machine.

Increasing productivity

Increasing Productivity

Alu alu blister machine is high tech automated machine which can efficiently packed large quantities of product in fraction time. It works on high speed which decrease production time and allow manufacturer to meet consumer demand.

Flexibility for various sizes

Flexibility for Various Sizes

Alu alu blister machine can easily configured according to your demand. This versatile feature of this equipment make it standout in all. This equipment can handle various products of different sizes and shapes.

3.How Different Industries Implementing Alu Alu Blister Machine in Their Practices?

Alu alu blister is widely used in various industries. This equipment is used to increase productivity of packaging unit with minimal requirement of labor and reducing cost. In this part, we learn about other industries which are benefitting from alu alu blister machine.

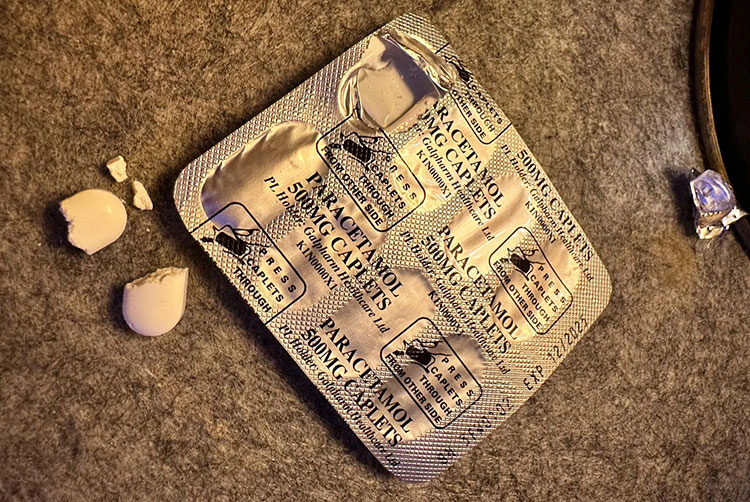

Pharmaceutical industry

Pharmaceutical Industry- Picture Credit: Iflex Indonesia

You have seen your medicine comes in silver packaging. This packaging is done by using alu alu blister machine. This equipment makes sure your medicine reached in your hand with effectiveness and quality. It enhances overall customer experience by providing safe and quality medicine.

Food and Confectioner Industry

Food and Confectionary Industry

Here you will see another application of alu alu blister machine, it is widely used in food industries for packing candies, sweets, gummies and coffee pots. It will maintain flavor and quality of food.

Nutraceutical and herbal industry

Nutraceutical and Herbal Industry- Picture Courtesy: Pharma Trends

Many herbal, vitamin and nutraceutical product are packed by using same alu alu blister machine. It ensures safe delivery and quality of product. This machine improve safety and prevent degradation of sensitive herbal and nutraceutical medicine like omega-3, collagen and antioxidants.

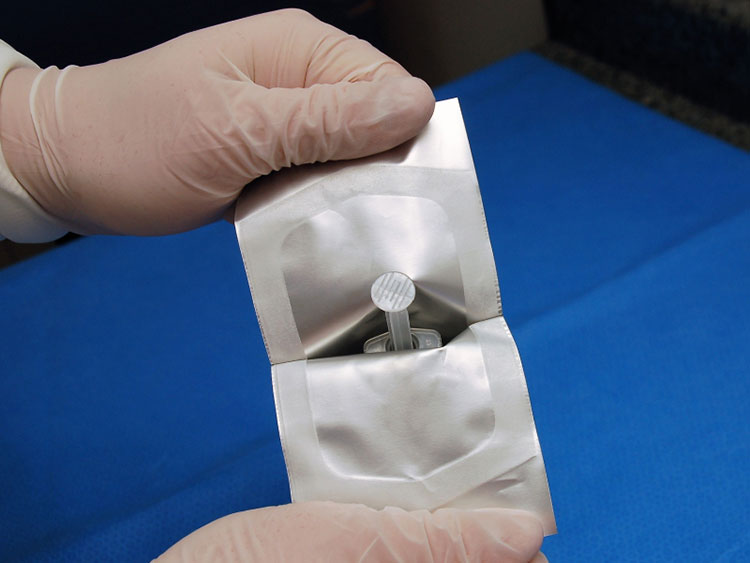

Medical devices industry

Medical Device Industry- Picture Courtesy: Cretex Medical

Medical devices and equipment used in different healthcare sectors are sealed through alu alu blister machine to make them sterile and free from contamination. It is crucial in maintaining integrity of equipment.

Cosmetic and skincare industry

Cosmetic and skincare Industry- Picture Courtesy: Desertcart

If you are skincare lover, you know most skin related product are coming in aluminum packaging. Here you can see another application of alu alu blister machine. Many skin care products like face mask, skincare tablets, serum and many more product ae packed with this equipment enhancing product integrity.

4.What are the Main Components of Alu Alu Blister Machine?

The alu alu blister machine is highly advanced equipment which consists of few important parts assembled together for efficient and smooth working of machine. These are important components which are discussed below for you.

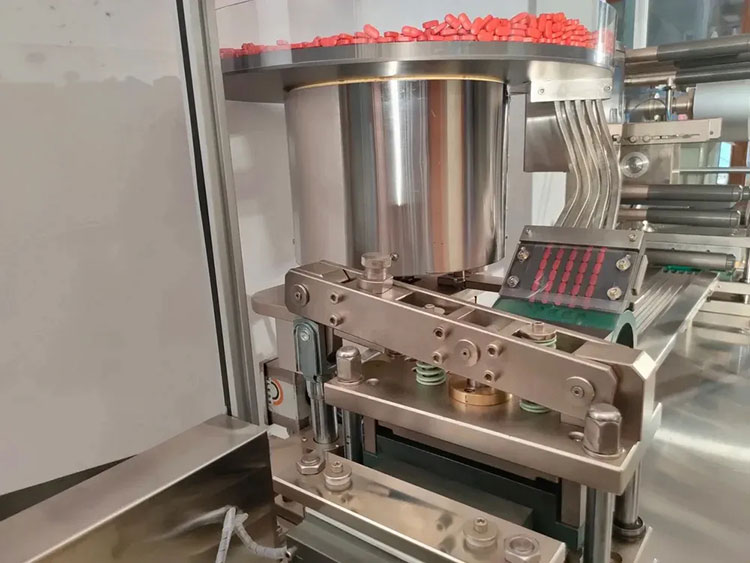

Feeding hopper

Feeding hopper- Picture Courtesy: Jornen Machinery

It is a cone shaped cylinder which placed at the top of machine and dispense accurate amount of product which is pre-set in the alu alu blister machine. It acts as storage for bulk product.

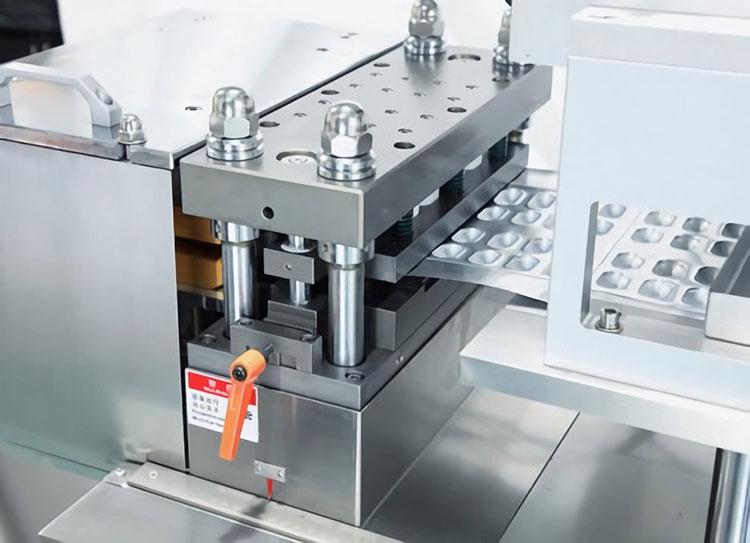

Forming station

Forming station- Picture Courtesy: Pharmaceutical machinery manufacturer

It consists of punches that using pressure create cavity in aluminum foil. This process is called cold forming which does not require heat.

Control panel

Control Panel

It is a small touch screen which is used to control temperature, pressure and speed. This panel is crucial in observing progress in process.

Film delivering roller

Film Delivering Roller

It consists of multistage roller which unwind aluminum foil without creating fold and wrinkles. This aluminum foil is act lidding material to close the alu lau blister packaging.

Sealing station

It is part of machine where all blisters pack is sealed together by using pressure and appropriate temperature.

Cutting station and outlet

Cutting Station and Outlet- Picture Courtesy: CECLE Machine

This the last parts of alu blister machine where cutters are placed and blisters are cut and discharge from outlet and collected.

5.What is the Step by Step Process Involved in Alu Alu Blister Machine?

Preparing Feeding Material

Preparing Feeding Material

First feeding material is prepared. Feeding hopper is filled with product, aluminum foil is unwind and place in roller, temperature, pressure and other parameter are feed through control panel.

Forming blister

Forming Blister- Picture Credit: Pharma Machinery Manufacturer

In the first step, cavities are formed on blister with help of cold forming procedure in which teflon punches are pressed against base plate creating cavity in passing aluminum foil.

Feeding product

Feeding Product- Picture Courtesy: Jornen Machinery

In the next step, feeder hopper dispenses accurate amount of tablet and filled each cavity precisely without any error. The amount product hopper discharge is pre-set by control panel.

Sealing blister

Sealing Blister- Picture Courtesy: Accupak Engneering

After product is placed in each cavity, blisters are moved to next station where they are sealed and closed. The sealing process is done by mild heat and extensive pressure which result in leak and temper proof cell.

Cutting of blister

In this step blister are cut and edges are clean to make similar blister in each batch.

Discharging of blister

After cutting and edges neat aluminum blister leave the alu alu blister machine through discharge outlet.

6.What is the Difference Between Alu Alu Blister Machine and PVC Blister Machine?

Both the equipment is widely used in various industries in packaging process. There are few things which make them different from each other.

Difference Between Alu Alu Blister Machine and PVC Blister Machine

| Features | Alu alu blister machine | PVC blister machine |

| Definition | This machine used to packed product between two layers of aluminum foil with pressure and low temperature. | This machine used to packed product by enclosing product between PVC film( As base layer) and aluminum foil as (lidding layer) creating a leak proof packaging. |

| Forming material | In alu alu blister machine, high quality OPA films are used | In this equipment, PVC film are used to packed product |

| Cost | Cost in alu lau blister machine is much higher than PVC packaging due to foil used as well using of cold forming process. | On the other hand, PVC blister machine is much cheaper but it ability to protect against light and temperature is quite weak. |

| Forming method | It used cold forming method in which foil is pressed under punches to create cavity without involving heat. It is suitable for heat sensitive material. | This is done by

thermoforming process in which PVC film is heated so that it can easily molded under pressure to form cavities. It is suitable for material which are not heat sensitive |

| Visibility | It is opaque packaging and product is not visible from out. This packaging is done for product which are light sensitive. | It is clear packing from one side and product is clearly seem from outside. It is suitable for less sensitive part. |

7.What is an Appropriate Temperature and Pressure Setting in Alu Alu Blister Machine?

In alu alu blister machine, setting appropriate temperature and pressure is crucial factors for an effective sealing of aluminum foil. It is also serve an important aspect by creating a protective layer around product keeping it temper and contamination free.

Temperature

Temperature

In alu lau blister machine, the temperature around 100-140⁰C or lower is set to get proper sealing. This technique is also suitable for heat sensitive material. Temperature is also set according to type and thickness of aluminum foil. Appropriate temperature is important is important form air tight and leak proof seal without damaging blister.

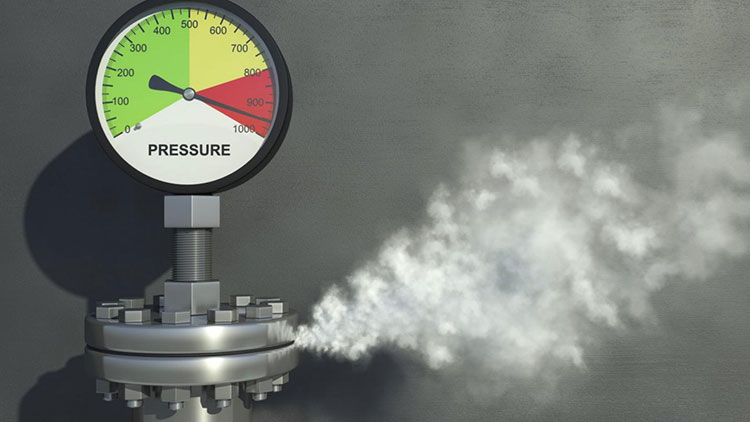

Pressure

Pressure- Picture Courtesy: Alan Stein Jr.

Pressure is critical in both cold forming process which mainly depend on mechanical pressure to giving shape and creating cavities in aluminum foil as well as on heat sealing process in which pressure is combined with low heat to create temper proof and airtight seal. The pressure ranges from 40-80 psi is used depending on thickness and material of foil.

8.How to Maintain Alu Alu Blister Machine?

Maintenance is necessary for efficient or smoothly working of machine. Here are some steps you must follow for maintenance of Alu-Alu blister machine.

Machine cleaning process

Machine Cleaning Process- Picture Courtesy: Cleanroom technology

Machine proper cleaning is important on daily basis after every shift or covering batch in order to avoid contamination because any waste particle left in machine may cause the major issue for the product quality and affect its production. You must ensure that cleaning of machine as per follows the machine maintenance instruction.

Lubricating parts of equipment

Lubricating Parts of Equipment- Picture Courtesy: ISEL, Inc

Proper lubrication of alu –alu blister machine must increase the life of machine and check all the parts that must be lubricate with proper oil in order to continue and smooth working of machine. You must ensure that good quality lubricant use for machine will enhance the machine performance

Inspection

Inspection- Picture Courtesy: Wigmore Trading

Regular timely inspection of machine may not undergo any critical issue which may stop the machine work which lead to wastage of time as well as affect the production therefore in regular inspection cover the issue replace or resolve timely and prevent it from major damage.

Calibration

Calibration- Picture Courtesy: Mesa

Calibration is necessary for consistent performance of machine, calibration include to maintain or checking the temperature, pressure and all the parameters which effect the performance of machine.

9.What Type of Product Can Be Packed Using Alu Alu Blister Machine?

There is wide range of product that can be packed by using alu lau blister machine. Let’s learn about few products.

Capsules

Capsules- Picture Courtesy: Gelita

Capsule are widely manufactured product in various industries like pharmaceutical, herbal and nutraceutical industry. Capsule are packed by using alu alu blister machine to increase stability again moisture, air and contamination.

Tablets

Tablet

Tablets are another widely manufacture dosage form in different industries. Alu alu blister machine is used in its packaging to enhance tablet shelf for moisture and light sensitive product. It also ensures unit dose packaging which enables patient to take correct dose at right time.

Ampules

Ampules- Picture Courtesy: EM PAHRMD

Alu alu blister packaging is not only used for tablets and capsules but it is crucial in ampule packaging. It provides ampule packaging a protective layer which prevent breakage, contamination and tampering.

Surgical equipment

Surgical Equipment

Surgical equipment is also packed by using alu lau blister machine which ensure to protect sensitive, sterile surgical tool and equipment to remain contamination until their usage. It also provides temper evident packaging syringes and needles.

10.What are Common Malfunction Faced in Alu Alu Blister Machine?

As you know equipment comes with their technical problems and malfunctions which can easily handles. In this topic, you will learn some common problem faced in alu alu blister machine and their solution from expert advice.

Blister tearing and breakage

Blister Tearing and Breakage

Generally, alu alu blister machine produce durable and breakage proof blisters. Sometimes, blister damage or wrinkled during sealing which lead to product damage and contamination. It may be due low grade foil material, irregular tension distribution or misalignment of foil feeding roller.

Solution

To overcome this problem, always use high grade foil material never compromised in quality of material. Adjust foil tension or pressure to avoid breakage and always inspect foil feeding roller to avoid misalignment which causes tearing of blister.

Incomplete blister formation

Incomplete Blister Formation- Picture Courtesy: Hunan Grand Packaging Machine

Sometimes it is observed that empty cavity and improper filling of product in blister occur in alu alu blister machine which lead to improper blister formation and can lead to dissatisfaction of consumer. This problem may encounter due to improper working of feeder or due blockage of feeder chute or incorrect feeder speed.

Solution

You can easily avoid this problem by regular calibration of feeding equipment. Proper cleaning and maintenance of feeder can over feeder blockage problem. Make sure to adjust feeder speed according to your requirement so you can get proper filled blister in each batch.

Improper sealing

Improper Sealing

Improper sealing is crucial in alu alu blister machine which can lead to major product damage and contamination. This problem occurs due to incompatible packaging material or inappropriate sealing parameter like temperature and pressure.

Solution

This issue can easily handle by using compatible packaging material in top and bottom layer of alu lau blister machine. Proper cleaning of sealing plates and adjust sealing parameter like temperature and pressure accurately so there no chance of weak seal left.

Incompatibility with packaging material

Incompatibility with Packaging Material

Sometimes, problem arises due incompatibility of packaging material and product may react with packaging material leading to compromise efficacy, color fading of product and contamination.

Solution

It is advisable if you to want avoid this problem, always source material from reliable supplier which provide proper compatibility index of packaging material with different products. Perform pH and compatibility test before initiating alu alu blister packaging of product.

11.What Key Features You Need to Consider Before Buying Alu Alu Blister Machine?

If you are manufacturer and looking for buying alu alu blister machine, then you need to learn about some key feature which you may consider.

Production capacity

Production Capacity

It is advice able to choose alu alu blister machine which can easily upgradeable according to your increasing production capacity. It is an important to consider so you can easily cope with your increasing consumer demand.

Handle different sizes

Handle Different Sizes

Select alu alu blister machine which easily handle variety of product like capsule, tablet and ampules. It can easily upgrade with fast changing tool to adjust with different sizes.

Maintenance and cleaning

Maintenance and Cleaning- Picture Courtesy: SEMEQ

If you are new to alu alu blister machine go for options which have modular design and easily disassemble for cleaning and maintenance. Select stainless steel body for equipment so they are durable and easy to clean.

Ease of integration

Ease of Integration

You should also consider alu lau blister machine which can easily integrate with other equipment in production line so you don’t need to add other machinery and remain cost effective.

Conclusion

Alu alu blister machine is an ultimate packaging solution for manufacture which not only prevent damage but also give temper evident and moisture-barrier packaging. Due to advantage of enable protection, extended shelf life and production efficiency makes it a valuable investment. In this blog, you can get all necessary information regarding alu alu blister machine. If still you are confused or have concern, we really appreciate to connect with our AIPAK service team because we are expert in all packaging equipment.

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine