Automatic Auger Filler

- Intelligent Control Microcomputer Chip

- Simple & Intuitive PLC Control

- Reasonablely & Safely Arranged Structure

- High Speed Servo Motor

AIPAK Auger Filler

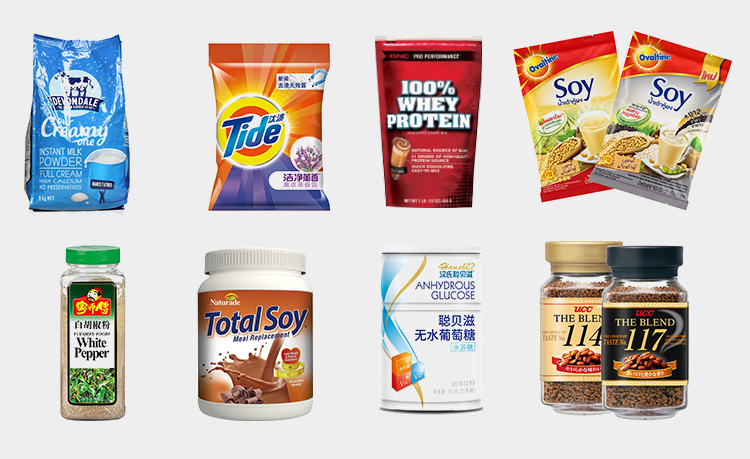

AIPAK auger fillers have besutiful and generous appearance and are all made of stainless steel,that is used for packing all kinds of powder materials in chemical industry, pharmacy and foodstuff industry, such as milk powder, legume powder, tea and medical powder, etc. All AIPAK auger fillers are for 500g 1-5kg powder filling, stainless steel frame, half-open hopper with glass view window, PLC and touch screen control for easy operation and control, which will be flexible for powder weight filling application. All AIPAK auger fillers can be equipped with a loading machine to automatically control the material level,which is more convenient to use and increase production efficiency.The filling motor speed of AIPAK auger filler can be adjustable, to meet the requirements of various materials.

AIPAK Auger Filler

Semi-Auto powder filling machine with weighing, auger filler for spice, milk powder

AIPAK this type of auger filler can calculate and filling work. Due to this special professional design. So it is suitable to the fluidec or low-fluidity materials, like coffee posder, wheat flour, condiment, solid drink, veterinary drugs, dextross, pharmaceuticals, powder additive, talcum powser, agriculture pesticide, dyestuff, and so on.

Accurate and reliable

High degree of automation

No bottles not filling automatic counting

Get A Free Quote Now

Newest Design Milk Auger Filler Powder Filling Machine

AIPAK this serie of auger filler is suit for powder and small granular products filling into pre-made containers,bags ,cans or bottles, widely used in the talc powder ,spice ,coffee powder ,wheat flour , starch powder , Pharmaceuticals ,agriculture pesticide ,dyestuff and so on.This auger filler machine is made of stainless steel 304, meets GMP standard. It is the same material same screw ,once 1 spec parameter item preset , just change the target weight on work page then inner item like the fast filling weight , slow filling weight and mini weight value will be change automatically.

Easy to adjust

Adjust torque is convenient

Meet GMP requirement

Get A Free Quote Now

Tin Aluminum Can Auger Filler Cup Automatic Coffer Dry Milk Powder Small Bottle Filling Machines For Food

AIPAK automatic auger filler is good for filling pepper,ground coffee and milk powder.All AIPAK automatic auger fillers are with mixing function,can work automatically,that improves the working quality.This type of automatic auger filler is widely used to fill powder products like amber powder,diatomite powder,milk powder,matcha powder.It gets a lot of popularity from manufactures come from food,cosmetics,pharmaceutical industries.

Made of stainless steel production

Easy to clean to prevent cross-contamination

Electronic weighing technology

Get A Free Quote Now

Automatic Dry Chemical Powder Filling Mahcine Auger Filler

AIPAK this all-in-one automatic auger filler researched and developed on request of oversea customers integrates powder-filling and cap-putting functions. It can perform filling, cap-putting and cap-pressing (cap - screwing) functions. It has compact structure and is easy to operate.This auger filler is appropriate to fill bottles, tins and boxes with powder and fine granule product, such as milk powder, albumen powder, coffee, glucose, solid medicine, talcum powder, dyestuff, flavours and fragrances.

High capacity automatic

High filling speed and filling accuracy

Full stainless steel structure

Get A Free Quote Now

The Buyer's Guide

Auger Filler:The Complete Buying Guide In 2025

You are well aware of the fact that the first impression is the last impression, if a product looks good it will have better quality. To make your product appealing and attention-seeking you must be packed it in a proper way considering all the required quality standards. In pharmaceutical industries, the packaging and filling of drugs is one crucial process once the drug is being manufactured. The packaging of the drug includes the proper filling, sealing, and labeling.

With the revolution and continuous innovation of different technologies in the industrial sector, the introduction of Auger Filler or Auger Filling Machine is a big blessing to the pharmaceutical industry. Auger filler has given a remarkable shift to the filling of powder, granules, semi-solids, and sticky materials in the bottles.

Auger filler is an ideal replacement for the manual filling process and it has overcome the customers’ complain about the inaccurate and inappropriate product filling in the bottles. With the auger filler the filling of powder and related products in pharmaceutical and other relevant industries like food and beverage industry, the cosmetic industry has achieved maximum accuracy with no waste of the filling substance most cost-effectively and conveniently.

Here I will guide you about the important aspects of an Auger Filler Machine.

1.What is an Auger Filler?

Auger filler is an unique machine that is used for the volumetric filling of free-floating or non-free floating thick paste and powder substances in bottles.

Auger Filler

It is called an Auger Filler because of its property of using a screw-shaped device known as an auger screw for the transport of material in rotatory motion.

2.What are the main components of the Auger Filler?

A fully automatic auger filler has the following components that work in a definite manner for the filling of different powder, granules, and semi-solid substances in the respective bottles.

Screws:

An auger screw is a special component of an auger filling machine that rotates vertically to transport the filling material from the hopper to the funnel. Auger screw is very important as the efficiency of the auger filler depends upon the rotation of auger screws.

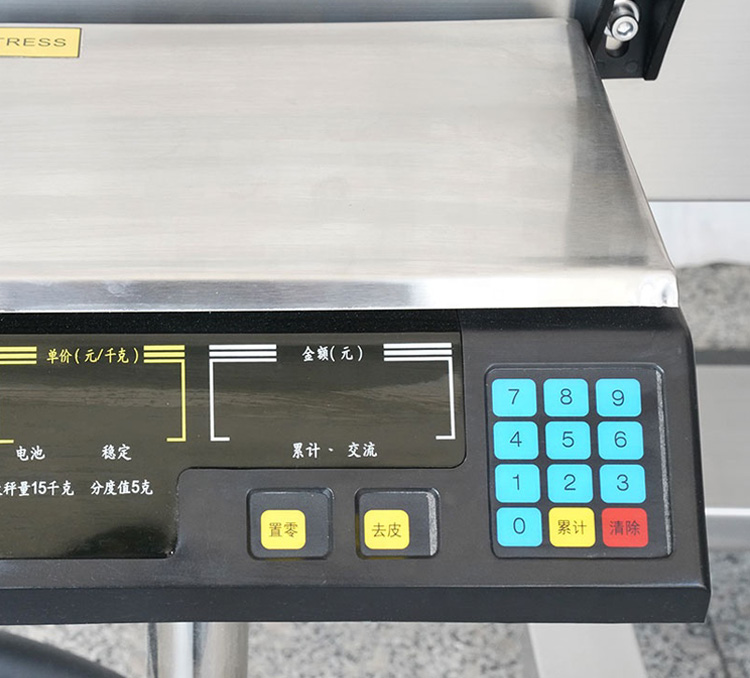

Weighing Balance:

Auger Fillers are equipped with an automatic weighting balance that helps in the accurate volumetric filling of the required substance.

Clamping Leaves;

They are important in supporting the function filling sensors. They facilitate the filling process.

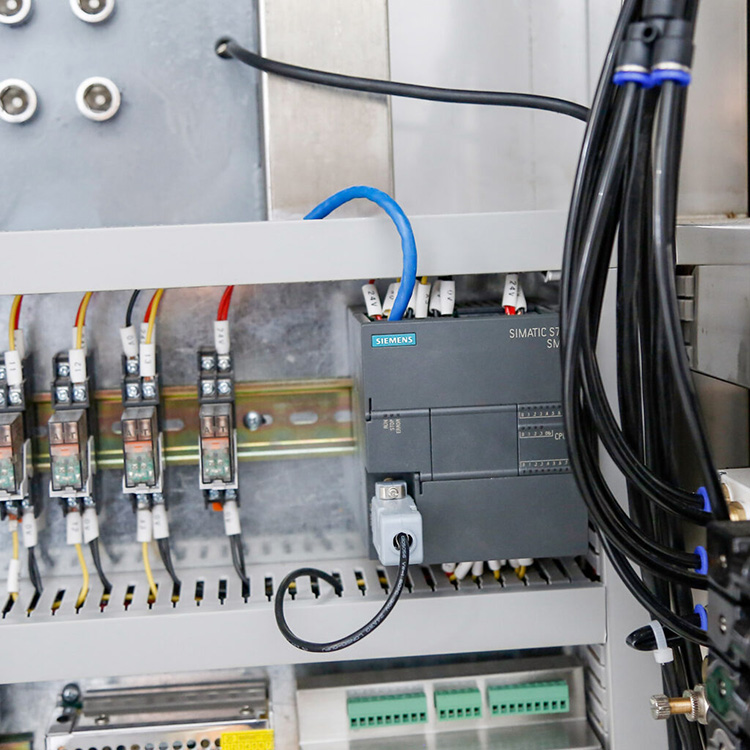

Automatic PLC Control System:

All the programs of the machine are fed into the PLC control system. Different parameters and functions of the auger filler are adjusted using the PLC control system. It has the ON and OFF buttons of the auger filler.

PLC Control System of Auger Filler

Load Shell:

Sometimes the load of the packing material is more than the required normal load, in such conditions load shells work to release the grip from the stress along with supporting the extra weight.

Auger Shaft:

The Auger shaft is important in enhancing the flexibility of the machine and enhancing the function of the auger drive.

Driving Assembly:

This assembly consists of motor and transmitters along with a clutch, brake, or servo system.

Feeder:

All the products that need to be packed are passed through the feeder before they are being filled up in the containers and bottles.

Motor:

It is the main component that provides the necessary power to the auger filler to operate and perform its function. Among motors, there are different types available like an electric motor, stepper motor, servo motor, VFD, and vacuum suction. However, the servo motor is most widely used.

Motor and Power Unit of Auger Filler

Bearing:

The movement of the machine is controlled by the use of bearings. Using a PLC control system the movement of the machine can be adjusted depending upon the pre-defined standards.

Hopper:

It is a container or a vessel that contains and holds the filling product. It transports the filling product to the tooling of the machine.

Cylinder:

The products of filling are compressed and compacted in the cylinder to form the uniform consistency of powder. This action enhances the accuracy of the machine.

Touch Screen Panel:

All the instructions and parameters of the machine are displayed on the touch screen control panel, the operator will set the parameters according to the requirements and then the machine is run to perform functions. As all parameters of the machine are displayed on the screen, thus it guarantees the high accuracy and efficiency of the results.

Touch Screen of Auger Filler

Level Sensor:

Two types of level sensors are present in the auger filler. One is a continuous level sensor and the other one is a point level sensor. Both of these function to check the quantity of the filling product.

Level Sensor of Auger Filler

Speed Controller:

The speed of the auger filler is adjusted using the speed controller, it is present in a box where the speed is controlled and adjusted depending upon the requirements.

Height Adjustment System:

It is the supporting system of the auger filler that is made up of steel. The height of the machine is adjusted using this system.

Inverter:

The direct current is converted into the alternating current using the inverter. This is important for the better functioning of auger filler.

Efficiency Sensor:

The efficiency of the machine is checked by using the sensors. The adjustment of the container, and the amount of filling product are being checked, and in case of any irregularity, the sensors alarm the operator.

Feeding Sensor of Auger Filler

3.What are the different types of an Auger Filler?

To meet with the growing demands of the industry and consumer needs auger filler machine comes in different types, each type having its significant properties and advantages. Here I am going to describe the major types of auger filler to give you a better understanding of the product.

Semi-Automatic Auger Filler:

The products like chemicals, powder, talc, detergent, spices, dried milk, and soil, sugar, and ground coffee can be filled using this type of auger filler. It has a PLC control servo motor that adjusts the auger screws for the movement of substances from hopper to funnel. This machine is easy to operate with a filling range of 0-20ml.

Semi-Automatic Auger Filler

Automatic Auger Filler:

This type of auger filler is the solution to the filling and packaging problem of the industries. It comes with a head and a conveyer along with the PLC control system to set the parameters as per the requirement. It can be a single-headed, doubleheader, multiple-headed automatic auger filler.

Automatic Auger Filler

Galvimetric Auger Filler:

This is a fast and accurate machine that provides a filling capacity of almost 200 liters. This type of machine comes in two models 1200 model filling that fills 0.5 to 20 liters, and 1201 filling model that fills 20 to 200 liters. All the parts of the machine are made up of stainless steel that makes it safe from corrosion and hence no chance of product contamination.

Galvimetric Auger Filler-Image Courtesy: Vtops

Table Top Auger Filler:

This is a very simple and portable type of auger filler. The small size of it makes it an ideal tool for small-scale industries and product runs. It can easily be fitted on the top of the table and assembly of the machine can be done in minimum time. The product is filled in the filling reservoir and the speed of the machine is adjusted using the touch screen control system. The filling is done by using the foot pedal and push-button by placing a container under the filler. This type of machine is most useful in filling pharmaceutical powder and granular products. The speed of the machine can be adjusted for different products.

Table Top Auger Filler-Image Courtesy: medicalexpo

Multiple Auger Filler:

As the name suggests this type of auger filler is suitable for the filling and packaging of multiple products of the food and beverage industry, cosmetic and pharmaceutical industry. This machine comes with many control options that are suitable for different products besides this it also has separate filling controls at each filling position.

Multiple Auger Filler

The machine has high precision and fast working speed with multiple positions of dispensing the products and alternative servo motors placed at each dispensing position.

Fill By Weight Auger Filler:

This is the modern and advanced type of auger filler that has helped a lot in filling a large number of substances with high accuracy along with the customization of the products. Many industries face the challenge of filling products with weight variation and a slight difference in the weight can cause huge loss to the industry. This machine has overpowered this by providing an accuracy of -1% to 0.25%, also it can fill small bags, boxes, containers, and big boxes.

It has also special customized features of dust collector tray and button-up fill container lift. The speed of the production can be increased by using different conveyers. This machine is suitable for the packaging of food, beverage, pharmaceutical, cosmetic, and other high-cost products.

Fill by Weight Auger Filler-Image Courtesy: vtops

Auger Powder Filler:

This type of auger filler helps in the filling of liquids, semi-solids, powder, and granular products with high accuracy and efficiency. It fills the product using the rotatory motion of an auger screw that transports the product to the hopper from where the product is dispensed in the funnel for final filling in the containers, bottles, and sachets at a fast speed.

Powder Auger Filler-Image Courtesy: indiamart

4.How do an Auger Filler works?

The working principle of an Auger Filler is very simple and easy to understanding. Since it is fully automatic the operator doesn’t have to do much work once the parameters are set and the machine is put into operation.

The operator needs to fill the bottles and containers manually into the machine and switch on the machine. The automatic auger filler has a conveyor system that transports the containers and bottles one after the other for the filling of the substances. Once the power has been supplied the hopper of the auger filler will continuously transport the filling product to the auger screw for accurate filling.

Auger fillers are supplied with an automatic weighing scale that measures the volume of each filling substance. Thus, you get the accurate volumetric filling of the substances. The auger screw rotates at a uniform speed through the action of the auger drive and the filling product is feed in the hopper’s funnel or tube.

The homogenization and de-aeration of the filling material are necessary to avoid inconsistency during the filling. This is done by rotation of agitator blade in the opposite direction to that of auger screw. The agitator blade goes down at the bottom of the funnel to prevent cavity formation and guarantees consistency in the filling of the product.

Auger fillers are designed in such a way to achieve the uniform volume of filling substances in each cycle without any inaccuracy or deviation.

5.What benefits you may get using an Auger Filler?

Auger Filler has gained great popularity because of its versatility and wide range of benefits. It has made the packing of different materials very easy for the industries. Some of the major benefits of the Auger Filler are:

- Auger Filler is a fully automatic machine with high efficiency and accuracy.

- Auger filler is a cost-effective machine and is not very expensive.

- Auger Filler can be used for the packaging of both floating and non-floating substances.

- Auger Filler works best when it is completely enclosed thus there is no loss of the powder or any other product.

- Auger filler can be adjusted with different machines used in the packaging of the products like can and form filling machines.

- Auger Filler comes with a touch screen control system that assists the operator to control all the functions according to the requirements.

- The structure of Auger Filler is very versatile and handy that makes it portable and easily movable.

- Auger Filler can fill large volumes of substances, thus you don’t need to change its parts while filling different volumes.

All these benefits make the auger filler ideal equipment of pharmaceutical and many other industries like food, agriculture, chemical, cosmetic, and plastic industry.

6.What are the industrial applications of an Auger Filler?

Auger filler is an invention of modern technology that finds its uses in a lot of industries including pharmaceutical, agriculture, food and beverage, cosmetic, metal, chemical, veterinary, and plastic industries. Auger filler is used in the filling of different powdery and semi-solid substances in all of the above industries in one or another way.

- Pharmaceutical Industry:

In the pharmaceutical industry, auger filler has a major impact on the filling of powder or liquid drugs in different bottles, containers, and sachets. The filling of the drug is done most accurately with minimum wastage and no contamination. Thus, auger filler is an important tool of the drug industry for the filling of different drug quantities in different containers.

- Agriculture Industry:

In the agriculture industry, the major benefit of auger filler is in terms of filling fertilizers.

Different pesticides and insecticides are filled accurately using an auger filler as its ease in the handling, packaging, and transport of the fertilizers across the globe.

- Food and Beverage Industry:

Food and Beverage is one of the biggest industries in the world. All the biscuits, spices, coffee, tea, infant milk formulas, berries, and dairy items are packed with the use of auger filler. The main benefit of using auger filler in the food industry is the accurate packaging of food products with no contamination from human handling.

- Cosmetic Industry:

In the cosmetic industry, auger filler is used for the packing of talcum powder, baby powder, soap, and detergents.

- Metal Industry:

In the metal industry, the main use of auger filler is in the packaging of aluminum, iron, and copper powder.

- Chemical Industry:

In the chemical industry, auger filler is used in the packaging of different harmful chemicals in bottles and sachets.

- Veterinary Industry:

Most of the animal medicines come in powder to ease their administration in animals, all these medicines are packed using an auger filler.

- Plastic Industry:

A plastic powder known as polypropylene powder is used to manufacture different wastebaskets, pails, pharmacy pill dishes, and containers. This powder is packed using the auger filler.

7.What are the limitations of using an Auger Filler?

Some substances pose a hindrance while filling with auger filler these substances include tobacco as the tobacco gets twisted with the screws, and raw fruit and vegetables because of their delicate properties.

Cereals like cornflakes also get crushed while filling with the auger filler as they can’t stand the compression action of the machine.

The working mechanism of the auger filler also affects the filling of the products with irregular shapes and densities.

8.What sort of products can be filled using an Auger Filler?

Different products can be filled using an auger filler. It is used to fill all sorts of liquid, granules, powder, and other semi-solid materials in the containers and respective bottles. Auger filler has a huge advantage in the filling of sugar, powder such as talcum, and other cosmetic powder and flours at relatively high speed than the other equipment.

All sorts of liquids, ready-to-eat foods, processed food items, and cosmetic products can be filled with the auger filler without the emission of dust since the auger filler is equipped with the dust collector of your choice.

9.What types of supporting equipment are used with an Auger Filler?

There are some of the parts that can be replaced in an auger filler for the filling of different substances. These different parts of auger filler are known as tooling systems and they include the following components:

- Double Knife tooling:

All the soft processed food like salads, stews, and cooked rice are being filled up using the double knife tool.

- Self-Feed:

This tool is used in the filling and compression of thick and powder substances like flour, paste, cornstarch, and baking products.

- Straight Feed:

The non-free floating substances are being filled up using a straight feeding tool. These substances include oregano and instant coffee powders.

- Liquid Tooling:

All the liquid consistency substances like oil, honey, lotions, and creams are being filled using the liquid tooling.

- Free Flow:

This type of tool is used in the filling of free-floating substances like the coffee bean, tea, etc.

- Support Structure:

This is the main body or frame of the machine, the whole structure of the machine relay over the frame of the machine and all the parts of the auger filler are confined inside it.

10.What type of problems you may encounter using an Auger Filler?

Using an auger filler you may come across few problems that can affect the accuracy and efficiency of the operation of the auger filler. Here I am describing some of the main problems you may encounter using an auger filler along with the possible solution to these problems.

- The issue with Clamp and Holding Device:

If there is an issue with the working of the clamp and holding device you may need to check the power supply immediately. If the voltage is not proper then you need to change the switch to replace the faulty valve.

- Accuracy Issues:

Sometimes the auger filler doesn’t provide its promised efficiency. It may be because of the change in the consistency of the material. In some cases, lumps may form in the filling material that needs to be checked to maintain the accuracy of the machine.

- Starting Issues:

This may happen that the machine doesn’t start even after the supply of the required power. In such cases, you should check if the sensors detect the signals and whether the air compressor has started working or not.

- Free Flow of Products:

In the case of free-floating materials, there may be accumulation at the closing valve and hopper. The machine will not work properly if this happens, thus you need to check and clean the accumulation of materials.

11.How you can clean and maintain an Auger Filler?

The maintenance and cleaning of auger filler are quite easy. The accumulation of dust on the machine and its different parts needs to be cleaned on regular basis, otherwise, the functioning of the auger filler will be affected.

Clean and Maintain of Auger Filler

The machine is made up of stainless steel thus corrosion of different parts of the machine doesn’t occur making it safe for human use. Thus the body of the machine can easily be cleaned using a stainless steel liquid solution.

With the help of a standard liquid soap or detergent, water, and a soft cloth you can easily clean the different parts of the machine.

The regular cleaning of the auger filler will remove away the remains of different filling products and save the parts of the auger filler from caking and sticking of filling substances.

12.What important points must be considered while buying an Auger Filler?

Before making the final decision of buying an auger Filler you must consider some important features that describe the efficiency and effectiveness of an auger filler. Check for the following points in an auger filler:

- The auger filler must have a filling capacity of 2g to 5kg.

- The machine must come with a fully automatic touch screen control panel.

- The feeding hopper must have a capacity of 50 liters.

- The body and the different parts of the machine must be made up of good quality stainless steel.

- The filling accuracy of auger filler must be ±1%.

- The auger filler must fill up 25-35 containers in one cycle of filling.

- The auger filler must be made up following cGMP quality standards. This ensures the safety of users of the auger filler for both human beings and the environment.

- The size of the auger filler must be standard, i.e. the weight of the auger filler is 200kg, with height and width of 1460mm and 1510mm.

- The electrical consumption of the auger filler must be 220v/380v, 1.4kw, 50-60Hz.

- The CE quality standard must be fulfilled by the auger filler that shows that the electrical requirements of the auger filler are according to the required international standards and it is safe for use.

- It is necessary to check for the FDA and ISO certification for the auger filler which indicates that it is fit for packaging and filling of food and medicinal products.

You can ask the seller for all these standards or simply you can check the guidebook of the auger filler to check the standard features of the auger filler.

13.What are the future aspects of an Auger Filler?

Auger Filler is a product of modern technology that has proved a valuable addition in the packaging of different powders, liquids, granules, and semi-solid substances. The reports have shown a positive increase in the future demand for auger filler in different industrial sectors. Auger filler has generated great revenue for its manufacturers and users. It has reduced the cost of human labor and replaces it with high efficiency and contamination-free filling and packaging of substances. Buying an auger filler will have great impact on your business, also it will increase the market demand of your products in the world of competitors.

Conclusion:

This is the necessary information you need to know about the auger filler machine. In case of any help or query you can contact us anytime for further assistance.

GET A FREE QUOTE