Aerosol Filling Machine: The Complete FAQ Guide in 2025

Do you have an aerosol product to produce?

Or have you ever noticed the 2020 novel Covid-19 pandemic has an impact on the automatic aerosol filling machine market?

As during the epidemic,global aerosol spray products such as alcohol, hand sanitizers and disinfectants have increased significantly.

So to have a better understanding of this market and speed up your production to meet the demanding supply,I have done some research and wrote down this guide.

Spend a few minutes reading through,you will get some of the useful information you want.

Let’s begin now.

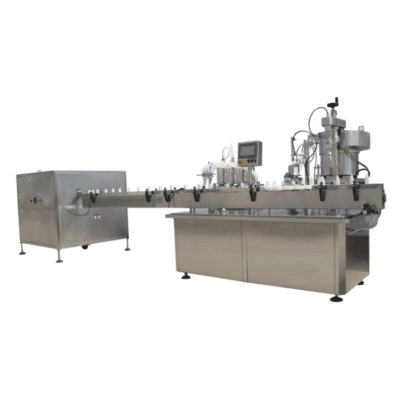

1.What is Aerosol Filling Machine?

Aerosol Filling Machine

The suspension of liquid or gas molecules present in a gas can be described as an aerosol. The aerosols consist of the suspending gas as well as the molecules, which is generally air.

For your particular way of manufacturing, it's really hard to have or even find accurate aerosol filling machines. And as it requires a large amount of pre-investment, you have to keep in mind a lot before making your very last decision.

In the market or industry of aerosol filling machines, whenever you feel overwhelmed, there's a dependence on gaining knowledge of a few important information regarding what elements decide your selections while you decide to go along an aerosol filling gadget.

So, let's check them out gradually

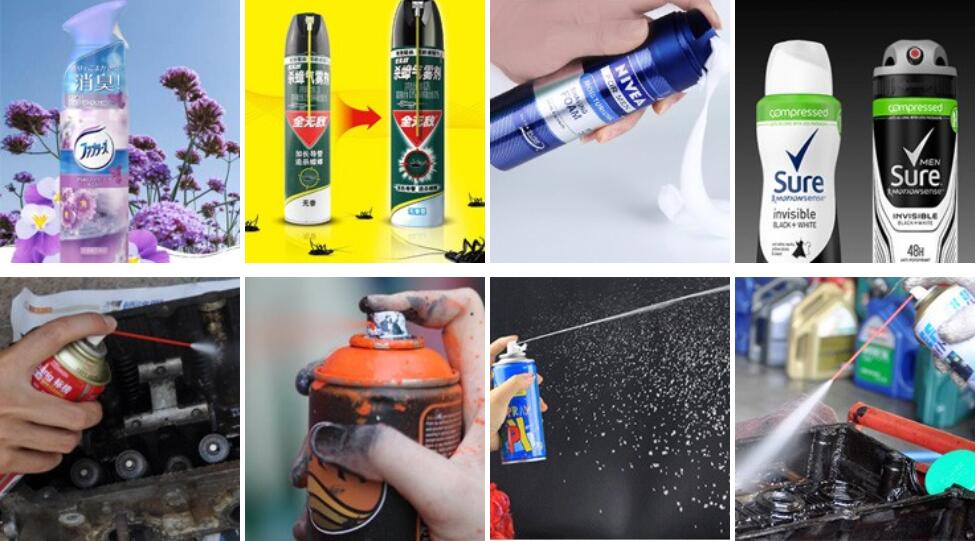

2.Which Industries are Aerosol Filling Machines Used?

Pharmaceutical Aerosols

Aerosol filling machines are being used excessively in different industries. In the commercial market, they are used to fill different sorts of aerosol or product forms. Now to know the industries in which aerosol filling machines are used let’s go:

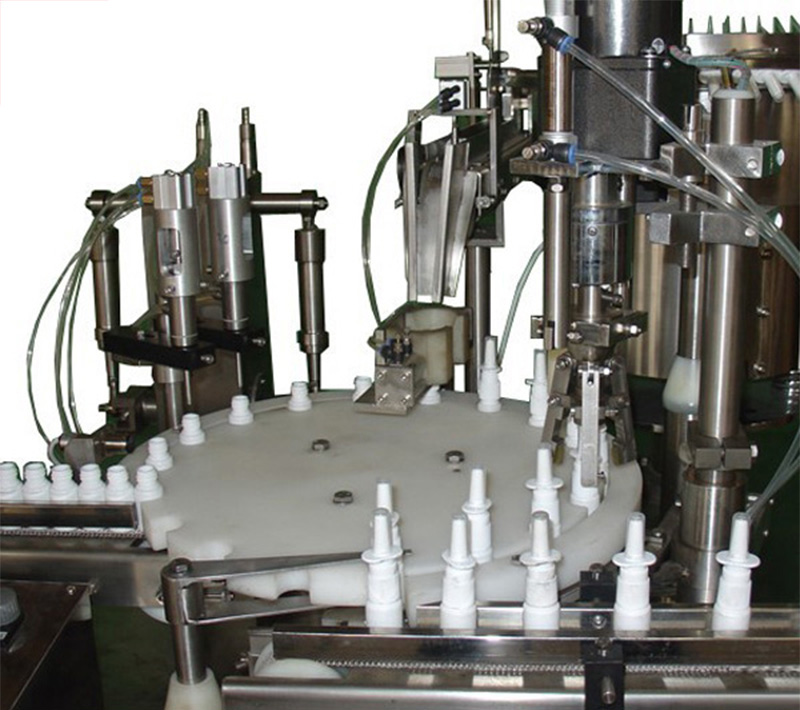

Pharmaceutical

In the pharmaceutical sector, aerosol filling machines are used to fill nasal sprays, MDIs, topical aerosols, and saline solutions.

Perfumery

Perfumery

In perfumery, different kinds of body sprays and perfumes are filled out with the assistance of an aerosol filling machine.

Personal Care & Cosmetics

These days in the cosmetics industries aerosol filling machines are being used to fill out shaving gels/foams, sun-screens, or deodorants.

Technical

Paint Aerosols

In the technical sector or industry, these machines are used such as in car repair products or paints.

Home

In household products like iron starches, insecticides, dust and spot removers, and room fresheners.

3.What Materials Can be Filled by the Aerosol Filling Machine?

What you do is Filling aerosol cans and it is your core product. There are many materials or products we can fill with the help of an aerosol filling machine. In the following we’ll discuss them:

- Aerosol filling machines are used to fill nasal sprays, MDIs, topical aerosols, and saline solutions.

- Different kinds of body sprays and perfumes are filled out with the assistance of an aerosol filling machine.

- Aerosol filling machines are being used to fill out shaving gels/foams, sun-screens, or deodorants.

- These machines are used such as in car repair products or paints.

- For iron starches, insecticides, dust and spot removers, and room fresheners aerosol filling machines are used.

- In Electrical maintenance products, air dusters these machines are used.

4.What will you Benefit from An Aerosol Filling Machine?

The aerosol filling machine is very useful and it helps us in many ways.

Advanced Technology

Aerosol Filling Machine

Aerosol filling machines are capable of meeting the elevated needs in the aerosol industry. The comfort of the usage of those products makes clients want those styles of products over different forms.

There also are different motives at the back of the improved demand. The improved demand additionally stems from the reality that there are available chemical type products. More and extra households use aerosol chemical products.

Benefits for Businesses

These modifications starting from cooking sprays instead of the usage of liquid oils and the elevated use of aerosol cleansing merchandise.

Also, for business purposes, aerosol merchandise is getting used. This exercise is turning into common, and it is predicted to turn out to be more and more common over the years.

In reaction to those modifications, automated aerosol filling machines also are turning into extra advanced. Some of these aerosol filling machines can be running at amazingly speedy rates.

These machines also are quite effortlessly available.

Advantages of Aerosol

Due to the benefits, these Pharmaceutical aerosols are getting the good place in the market. These are described below:

- They are more comfortable or easy to apply.

- Aerosol administration offers fast relief and it is very efficient.

- The balance of the drug is improved through storing it in MDIs and DPIs because the drug isn't always coming in touch with atmospheric oxygen and moisture.

- The drug may be immediately implemented in the damaged areas.

- Administration of drugs through aerosol is a speedy process.

- Aerosols may be used for each local application and systemic applications.

5.Are there any disadvantages of Aerosol Filling Machine ?

There are a few disadvantages of the machines & the aerosols which are described below which you have to keep in mind before buying any aerosol filling machine:

Disadvantages

- Aerosols are highly expensive in cost.

- Discarding empty aerosol boxes is a hard task to do.

- Due to the inconstancy of the propellants, they can worsen the injured skin.

- The aerosol pack has to put far away from the fire and the temperature, due to the fact it can expand excessive pressure in the box which can cause an explosion.

- Sometimes propellants may also reason poisonous reactions, for a protracted duration of time if the remedy is sustained.

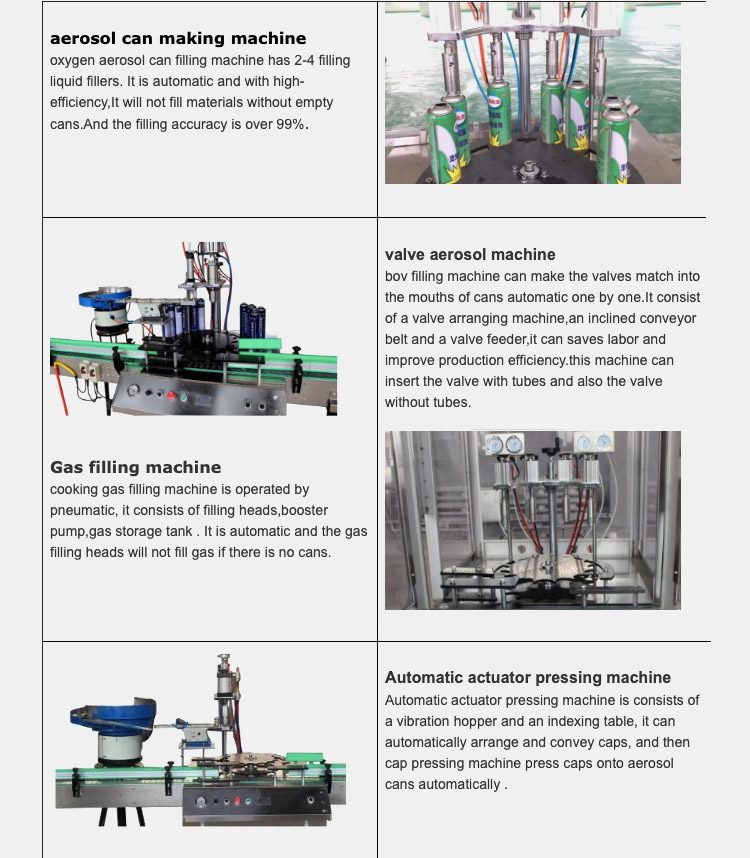

6.How many types of Aerosol Filling Machines are there? What are they?

In order to discover the best kind of aerosol filling machine is specifically supporting you to keep away in following mass production from some possible threat.

In a case, you do not fulfill the need of the production as demanded. You can choose one of the below defined machine to achieve your needs.

In general, you can have three kinds of the aerosol filling machine which are mentioned below:

- Full Automatic Aerosol Filling Machine

- Semi Automatic Aerosol Filling Machine

- Manual Aerosol Filling Machine

So, to find what is the right aerosol filling machine you must choose? Let’s take a look at every kind and discover the best solution to this query.

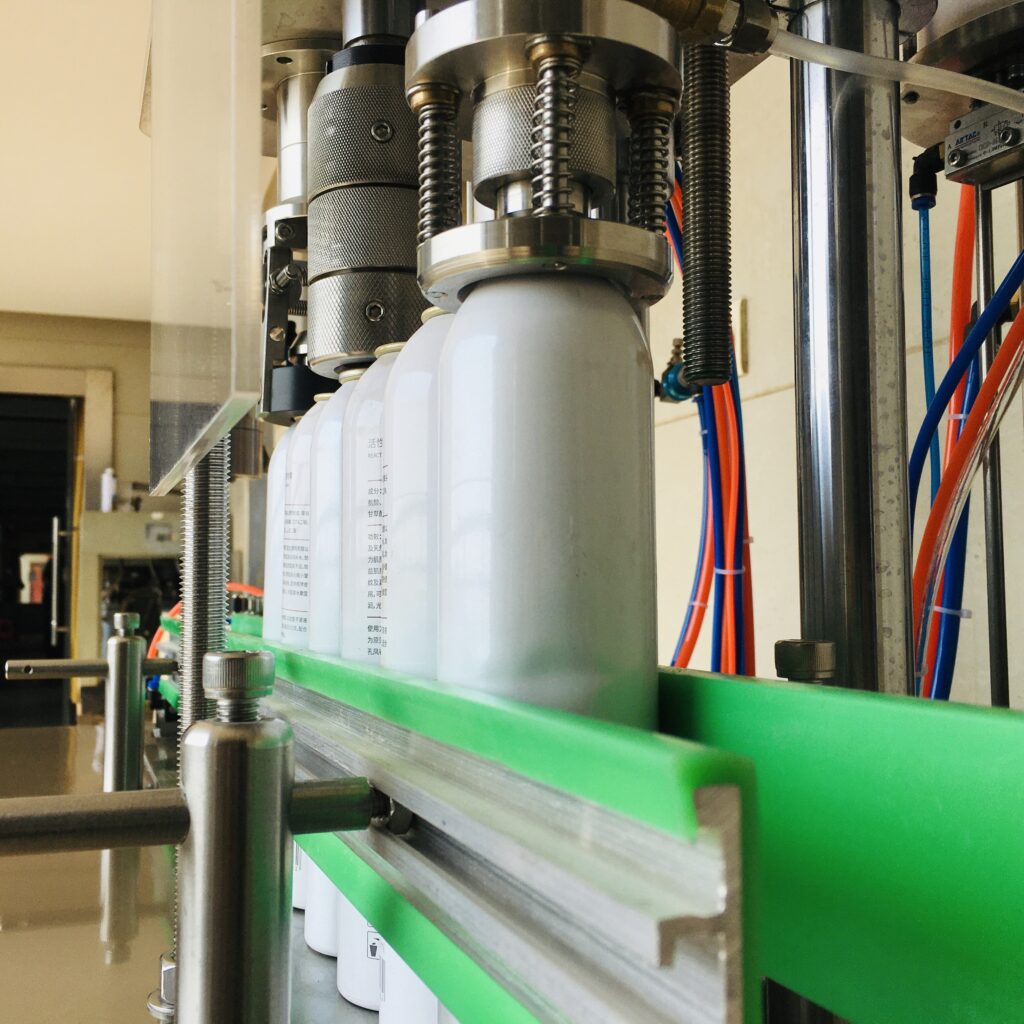

Full Automatic Aerosol Filling Machine

Completely auto frameworks are for high-velocity applications and incorporate transports and electro/pneumatic PLC controls.

They are reasonable for practically any fluid including thick fluids containing particles.

All of the systems are auto and it is used to fill the aerosol.

Semi Automatic Aerosol Filling Machines

These kinds of aerosol filling machines include the features of crimping, gas filling, vacuuming, and gas restoration on a single operating system.

And the filling technique isn't the same as both automatic and manual aerosol filling machines have. It requests vacuuming earlier than some other filling technique, due to the fact the filling process is executed below the cap and maintain the vacuum environmental.

Manual Aerosol Filling Machines

Manual Aerosol Filling Machine

You may listen that it is called the conventional aerosol filling machine because of the pretty long history that belongs to it and its huge variety of applications.

This kind of aerosol filling machine typically follows to filling procedure of crimping, liquid filling, and gas filling. While generating the aerosol products this filling procedure may be very general.

For its application variety, from technical aerosol products to regular customer aerosol products, most of them are accomplished with the help of this general kind of aerosol filling machine.

Hence, in case you are in the application variety and filling procedure, simply go along with this kind of aerosol filling machine.

7.What are the Differences Between Automatic Aerosol Filling Machine, Semi automatic Aerosol Filling Machine and Manual Aerosol Filling Machine?

Aerosol Filling Machine

There are numerous arrangements of the aerosol filling machine. These configurations are described below:

- Full-automatic aerosol filling machines

- Semi-automatic aerosol filling machines

- Manual aerosol filling machines

Before starting anything, you have to determine out what productiveness will you need?

If your demand is high. For instance, you need hundred cans in a single day, which shows you probably looking for a manual aerosol filling machine. But when you need approximately thousands of containers inline within a day, then you definitely have to prioritize semi-automatic aerosol filling machines.

For manufacturing potential that is above thousands of cans inline within a single day, you should go without any doubt with an automatic aerosol filling machine.

Before choosing the right machine, you need to guess that what is the output you want per day, and then keeping this in mind it'll be easier for you to choose which type of configuration will suit you.

Full-automatic Aerosol Filling Machines

In most of the cases, this type of arrangement covered automated gas filling machine, automated cans feeding machine, automated liquid filling machine, automated valve feeding machine, automated crimping machine, automated cap presser machine, automated weighing check machine, automated label machine, automated water-bath checking machine and automatic packaging machine.

Every component is operated exceptionally automated, the exciting aspect is that producer can select a number of those components in keeping with their productiveness requirements and their budgets.

Let's have an example, a client in Europe might include a better labour fee. In this circumstance, we suggest clients go along with the machines which can reduce your labours however it shouldn't affect the manufacturing efficiency.

Such as automated cap presser machine, automated valve feeding machine, automated weighing test machine, automated labour, and packing machine.

Knowing every component operated for what purpose, maintain the important components to maximize the productiveness of your company. But apart from all these factors, it is obvious the better arrangement you want the better price you have to pay.

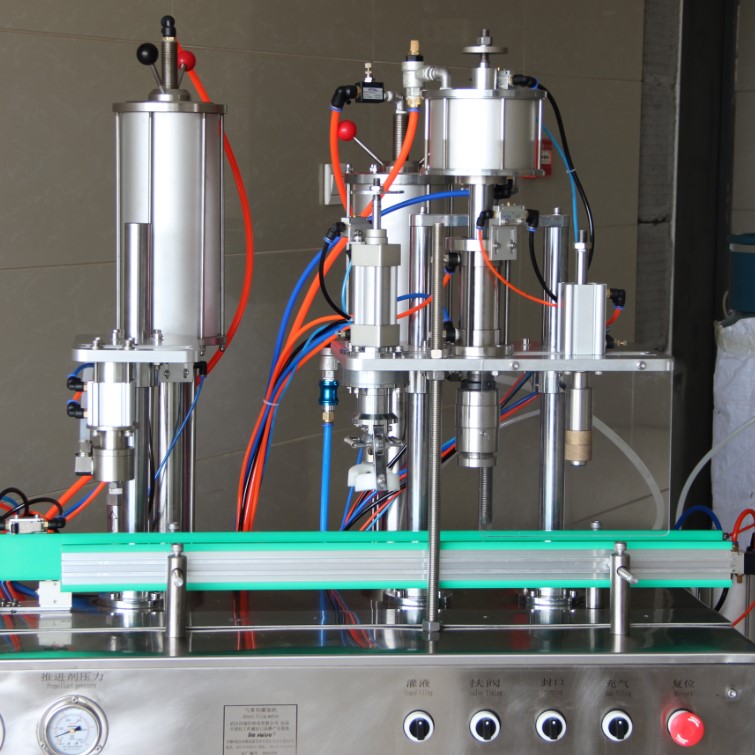

Semi-automatic Aerosol Filling Machines

Semi-automatic Aerosol Filling Machines

These kinds of arrangements generally include an automated gas filling station, automatic bottle-feeding machine, automatic crimping machine, automatic liquid filling station, automatic packaging device.

Each component can operate independently, and you can have some more additional computerized or automatic parts in it. This arrangement is suitable for clients who have a medium range of budget and productiveness requests. The interesting part of these kinds of arrangements is that clients can each extend or lessen the configuration.

When adding an automated valve feeding system, or a few different automated components, expanded the automation immediately. Or to stay the crimping and filling stations only you can take out the automatic cans feeding machine.

Manual Aerosol Filling Machines

Manual Aerosol Filling Machine

You can have an idea of the machine by its name, that is for manually operated arrangement. It comes with crimping, gas filling station, and liquid filling stations.

And every station can have a manual or automated operation. However, this arrangement can’t be fully-automatic operation even in automated mode.

It is the most inexpensive cost amongst all arrangements however it gives you the slowest productivity as well.

According to the type they are also defined as:

Regular Aerosol Filling Machine

This pretty much like the manual aerosol filling machine and also have the normal functionality.

Bag on Valve Aerosol Filling Machine

Bag on valve aerosol filling machine is known for the best working and used widely in the different businesses.

Under Cap Aerosol Filling Machine

These kinds of aerosol filling machines include the features of crimping, gas filling, vacuuming, and gas restoration on a single operating system.

And the filling technique isn't the same as both conventional or bag on valve aerosol filling machines have.

It requests vacuuming earlier than some other filling technique, due to the fact the filling process is executed below the cap and maintain the vacuum environmental.

Under cap aerosol filling machines are applied for air circumstance lubricants, butane gas cartridges, and filling refrigerants, etc.

8.What are the Main Components of Aerosol Filling Machines?

Parts of the aerosol filling machine

However, aerosol filling machine quality really depends on the material of the primary components and design.

what does it mean?

Do you realize that aerosol filling machines are pneumatically driven?

So, in manufacturing with gas and propellant, it is used. For protection purposes, all the parts are fire-proof, even though there are PLC control device aerosol filling machines so all of the electric-powered parts have to be safe.

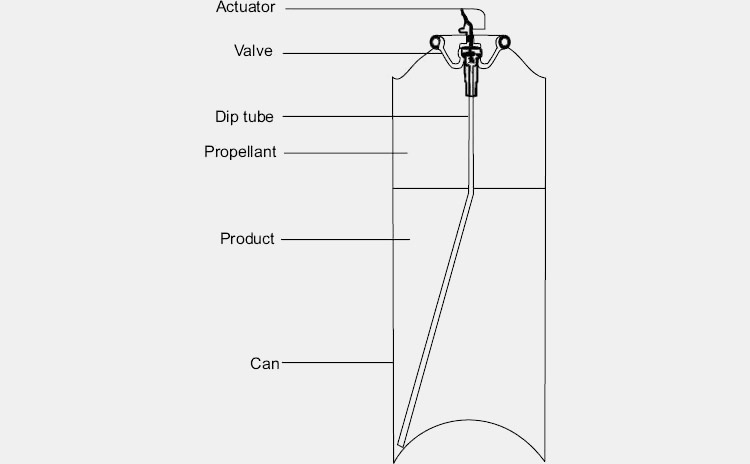

The important and the primary components of the aerosol filling machine are attributed to pneumatic parts, such a

- Propellants

- Containers

- Actuators

- Valves

- Product concentrate

The query is why pneumatic parts are the element that determines the quality or the standard of your aerosol filling machines?

Parts of aerosol filling machine

The reason behind this is that it determines the protection and safety performance of the aerosol filling machine. the maximum vital characteristic in the aerosol filling machine is the protection performance, now no longer the filling capacity, filling speed, filling accuracy, etc.

All the other characteristics depend on the base of protection. Without any protection guarantee, speed, Maximum filling accuracy, the fast filling is worthless.

So, now we’ve to discuss the primary parts of the aerosol filling machine:

Propellants

They are responsible for having the right and accurate pressure inside the container. It’ll provide the finding pressure to expel out the main product from the container. There are a few further types of propellants:

- Liquefied gas propellants

- Compressed gases propellants

Containers

They have to be capable to resist at high temperatures like 130 degrees as well as at high pressures like 140 psig (pounds per sq. inch gauge) to 180 psig (pounds per sq. inch gauge), Let’s have a look at the types of the container as well:

- Metal Containers

- Tinplated Steel Containers

- Aluminum Containers

- Stainless Steel Containers

- Glass Containers

- Uncoated Glass Containers

- Plastic Coated Glass Containers

Actuators

To facilitate you in providing the drug in the preferred shape i.e., spray, foam, wet stream, or solid stream, these actuators are specifically designed buttons. You can have various type of actuators present in the market

- Spray actuators

- Solid steam actuators

- Special actuators

Valves

Valves-Picture Credit Plastic surgery key.com

These valves are very easy to open and close as well. They have the ability to handing over the material in the desired shape or form such as foam, sprays, solid stream, etc. It can supply a good given quantity of the substance used in the therapy.

Now we should check out the types of different valves:

- Continuous spray valve

- Metering valve

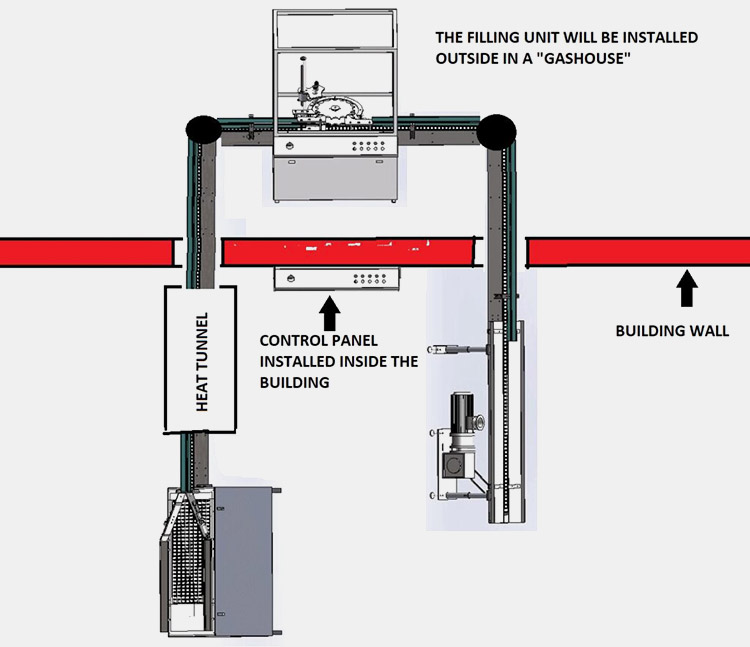

9.What is the Working Principle of Aerosol Filling Machine?

Before going to the working process let’s have a look at the components and know which component is responsible for the specific task:

An aerosol is made up of several basic components:

- An aerosol can

- The propellant

- An actuator

- A dust cap

- The product

- A valve

For traditional aerosols, the important things in the filling system are

- Our system begins with an empty container that is composed of either aluminium or tinplate.

- Along the production line, these empty containers travel and then you deliver the bespoke product in the shape of a liquid to the can. This includes all the working components covered through our Research and Development team, besides the propellant. The quantity of liquid could be very cautiously managed to make certain that it follows Weights & Measures legislation.

3.Your equipment then fits the Aerosol valve to the can. This is a completely vital process and the crimping equipment needs to be cautiously installation through our technical team of workers to make certain that the can/valve seal can not leak.

- After this the container retains along the production line and then under certain pressure equipment injects the propellant, by the valve. The propellant can be in the shape of compressed gas or liquified gas. If a liquified gas is used it'll exist as each a liquid within the liquid section and vapor in the aerosol can headspace.

It's going to generally most effective be within the headspace if compressed gas is used, above the liquid in the container, and there might be very little growth in liquid quantity. Again, the extent of propellant could be very cautiously managed to make certain that it follows to Weights & Measures legislation.

- Once you are done with the filling process, the cans are examined for leaks.

- Once examined for leakage, the load of the can is checked to make certain the ideal fill.

- To make sure complete traceability the actuator is then used to code the date and the batch, earlier than the cap is applied.

- If labelling is needed the cans will go through a labelling system and apply self-adhesive labels or wet glue.

- The product is then being wrapped.

The following video will help you more to have a better understanding of the process,

10.What is the Capacity can Aerosol Filling Machine Fill?

Picture Credit

The filling capacity is critical because it determines what number of completed aerosol products you could produce in an hour.

As you can notice before that the filling speed will be slower if you are going to fill a large amount of volume.

Hence, the final output can be altered according to this.

In general, if you don't change the amount of filling volume there will be no change in the cost and the arrangements of the aerosol filling machine.

But in the case of one aerosol filling machine, you are going to supply numerous kinds and specifications of aerosol merchandise there is a possibility that you may have to compromise on the final aerosol product quality.

In the situation to supply identical aerosol products of numerous specifications, one aerosol filling machine can be sufficient for production. But to shape the accurate length of aerosol cans it has to include a changeable panel.

With these kinds of arrangements, to supply the numerous specifications of the identical aerosol merchandise clients just want one aerosol filling machine.

What if you have to supply numerous distinct aerosol products?

Such as fragrance spray, spray paint, toner sprays?

In these types of situations, just choose a distinctive kind of aerosol filling machine in line with what precisely aerosol product is the proper solution.

11.What Other Equipment are needed form a Complete Aerosol Filling Machine Production Line?

The below listed are some of the equipment that you need to have when running and aerosol filling process.

Bottle UnScrambler

AIPAK bottle unscrambler

Bottle unscrambler for the purpose of aerosol empty systems unscrambles/fast directions is uniquely intended to mass plastic bottle, aerosols and arranged on the belt for the products like that

High-speed bottle unscrambles will be changed in accordance with obliging an assortment of aerosol sizes and shapes.

Auto aerosol unscrambles machine with belt type frameworks with the connected type of the machine, more friendly for the users, and dependable running.

This aerosol unscrambled machine comprises the aerosol revolving plate with a lifter, centralized server, and transports.

Bottle Feeder

AIPAK bottle feeder

Auto feeder for aerosol machine items is offered available for feeding the items into the system. It is quick, better and fast as well. A wide assortment of auto feeding system for the aerosol of machine alternatives is accessible to you.

You can, in the same manner, look for the

Pneumatic

Water-driven

Electric Auto Feeding,

As from food, refreshment, and substance auto bottle feeding of the machine.

Bottle feeder Advantage

Less work and raise creation productivity.

Generally utilized for the aerosol of various sizes and materials.

One handle configuration makes the aerosol feeder simple to activate.

Speed movable to meet creation necessities.

Rotational development makes bottle access successively.

Automatic Capping Machine

AIPAK automatic capping machine

In any type of bundling line that includes fluids, you need to have a solid capping/ covering machine.

The machine will guarantee that subsequent to filling the aerosol, they will get an appropriate seal setting them up for the following stage.

An auto capping/covering machine aids quicker and better position of covers on top of various compartments.

It implies that you can utilize the machine to place, fit and fix covers on various items.

The items can go from refreshment bottles, medication bottles among others.

These are the Other Equipment that is needed to form a Complete Aerosol Filling Machine Production Line.

12.How should you do to Guarantee a Secure and Good Capping during the Cap Aerosol Filling Process?

To ensure good and secure capping during the filling process of aerosols we can use two things:

Caps Sorter

Caps Placer

Now to have a knowledge what type of machines they are, let’s move forward:

CAPS SORTER

The cap sorter is a machine that is used to feed caps to the feeding conveyor in an accurate function and ultimately to the cap placer with the help of an exchangeable sorting disc.

For an easy rotation of the plate the force unit is made from an electrical motor prepared with a gearbox. The sorter operation is managed through an automated system of photoelectric cells (minimal and most queue control) established at the cap feeding conveyor.

This thing ensures the appropriate operation of the complete cap supplying system.

Some of the specifications of these caps sorter are:

| Power Type | Electrical Supply |

| Voltage Requirement | 3x400 Vac, 50 Hz |

| Power Input | 0,92 Kw |

| Capacity | 50 – 60 Cpm, 80 Cpm, 200 Cpm |

CAPS PLACER

It is a device used for the automated putting of plastic caps on the aerosol cans. It is the ultimate device of a manufacturing line. To automatically choose up the cans off the belt cap placers are prepared with an indexing power with an installed can guiding set. Through the conveyor, these caps are fed from a cap sorter.

Some of the specifications of caps placers are:

| Made Of | Stainless Steel |

| Power Supply | Electrical / Pneumatic |

| Power Input | 0,92 Kw |

| Capacity | 50 – 60 Cpm, 80 Cpm, 200 Cpm |

| Height of Supported Containers | 65 Mm – 350 Mm |

| Diameters of Supported Containers | Ø 35 – Ø 66 Mm. |

13.What Quality Standards should Aerosol Filling Machine Meet With?

Quality standards provide requirements and guidelines that ensure the right working of a certain product or a process. The basic requirements an aerosol filling machine is required to fulfill include;

Current Good Manufacturing Practices Quality Standards, cGMP

It ensures continuous production of high-quality products. The word current refers to the most recent standards.

International Standards Organization Quality Standards, ISO

These are international standards for quality control

Food and Drugs Admin Quality Standards, FDA

These standards ensure public health protection

Electronics Quality Standards CE

This guarantees that the product compliance with the EU standards for the protection of health and the environment.

The product should be made up of high-quality stainless steel, it must be safe and easy to operate. In short, the product must be user-friendly.

14.What are the Common Problems of the Aerosol Filling Machine Filling Process? How to Solve?

Like any other machine, an aerosol filling machine can face different problems during its process of filling. The most important requirement of an aerosol filling machine is its smooth and efficient working. Some of the common problems faced by aerosol filling machines are listed below;

Gas leakage issues

Gas leakage could occur from pipes if the pieces of pipes are not joined rightly. The gas leakage issues can affect the performance of an aerosol filling machine. Gas leakage issues can be solved by using a qualified crimping system.

- Solution

A qualified crimping system ensures that there is no gas leakage. Therefore, you should be using a qualified crimping system.

Gas trapping

Gas trapping refers to the retention of gas in the pipes of the aerosol filling machine. Gas trapping also affects the filling speed and thus the efficiency of an aerosol filling machine.

- Solution

This problem can be overcome by using a better pneumatic schematics design that ensures the smooth working of the machine.

Liquid spilling issues

Liquid spilling issues may arise in an aerosol filling machine leading to the loss of liquid, decreasing the efficiency, and ultimately causing financial loss to the factory.

- Solution

Check and balance

Incompatible capping

After filling the bottles, the next problem that may arise is the incompatible capping of the bottles or other types of containers. The capping device should be kept properly and it must be made sure that the device is putting the caps in the right position, sealing the container properly.

- Solution

Incompatible capping may arise sometimes but it can be simply solved by simple inspection of the machine.

15.What should you Consider when Purchasing An Aerosol Filling Machine?

Application of Aerosol Filling Machine

Before purchasing an aerosol machine, you should make sure that it meets the quality standards and has the capability of fulfilling your requirements.

However, the following factors must be taken into consideration:

1.Beware of Scams

It is very important to be super cautious while purchasing an aerosol filling machine. You must be aware of the reputation of the seller and if the seller is suspicious, do not make a deal with that seller. There are high chances that you won't get your product even after paying the whole amount.

2.Quality Certification

Make sure that the seller provides you certain quality certifications like CE, SGS, UL, etc. These certificates hold importance as they verify the quality of the aerosol filling machine. Avoid buying the machine from the seller who fails to provide these certifications.

3.Make Sure the Company has a Legit Website

You should make sure that the company has a legal website other than their profile on an online shopping website like Alibaba or Amazon. Many scam profiles are working on these websites, beware of those frauds. Without doing proper research, you should not order your aerosol filling machine on online shopping websites.

4.Look for Well-reputed Companies

You should make sure that the company you`re willing to do business with has a good record of manufacturing quality products. You should be very vigilant in choosing the company as there are many companies out there making sub-standard aerosol filling machines.

5.Rapid Production

You should make sure that the production speed of the machine meets the desired speed to fulfill the requirements of your business. Different types of aerosol filling machines have different speeds. You should choose the one that meets your business requirements.

6.Stable Performance

You should make sure that the aerosol filling machine you are going to buy has stable performance. Stable performance is very crucial as a relatively slower but stable machine is more productive as compared to an unstable and relatively faster aerosol filling machine.

This can be understood by taking an example. Imagine you have two machines, one fills 80 cans per minute but is unstable and the other one fills 60 cans per minute but is stable, the second machine is more productive as it does its work steadily.

7.Qualified Crimping System

A certified crimping system will be a guarantee that there is no gas leakage in your aerosol filling machine. Therefore you must make sure that the aerosol filling machine you are going to buy has a qualified crimping system.

8.Specialised Aerosol Filling Machines

The selection of the type of an aerosol filling machine depends on the aerosol products. You may need a special type of machine for chemicals like pesticides and spray paint cans etc. An aerosol filling machine is selected on the basis of propellant features.

The propellant features only change the filling accuracy. Size of aerosol cans and aerosol valve types are taken into consideration while selecting an aerosol filling machine. You should make sure that you choose the right type of machine according to your product.

9.Looking for Well-reputed Machines

You should look for an aerosol filling machine that has satisfactory reviews. Give a read to all the reviews on a machine and make sure you choose the machine that has satisfied the previous buyers. Doing this will surely reduce the chances of you getting scammed.

10.Finding the Best Price

You should always be looking for a machine that has a reasonable price. You should compare prices from different sellers and then choose the one that has a reasonable price. This does not mean that you should go for cheaper products with lesser quality, you should always look for a good quality aerosol filling machine at a reasonable price.

11.Shipping Charges

You should also keep a check on the shipping charges as some of the companies may try to overcharge you. You should compare the shipping charges and choose the one that offers the most reasonable charges.

12.Timely Shipping

Timely shipping is very important as you should not be waiting for too long for your aerosol filling machine to arrive. Waiting for too long means loss of time and loss of production which ultimately leads to the financial loss which, being a businessman, you don't want. So make sure that your machine is shipped timely.

16.How to Maintain Aerosol Filling Machine?

Semi-automatic Aerosol Crimping & Gas Filling Machine-Photo credit:dawson.com

Maintenance of every machinery is important and its performance rely on its condition, so it is necessary to maintain your filling machines regularly for better performance.

Cleaning

Aerosol filling machine must be kept clean on regular basis.in order to prevent corrosion liquid or oil debris on the machine is strictly prohibited.

Remove the liquid or oil debris timely. Muffler must be check and cleaned regularly. Before leaving the department clean the surface of the machine once and add the clean lubricant to the activity department. Clean the pipeline and filter it.

Valve must be cleaned regularly and replaced at the time of change. Clean and replace the sound.

Cleaning of valves

Change and replace the pneumatic valve seals, tracheal leaks and replace the pneumatic valve timely. Clean the solenoid valve and replace it if needed.

Check the nozzle if it is properly closed and check the circuit. Replace the pneumatic valve seal ring and air pipe leak timely.

Touch Screen Maintenance Mode

Check the air pressure and check the touch screen maintenance mode screen. Check whether the touch screen and PLC communication lines are loose, if lines are loosed maintenance must require.

Air Pressure

Turn on the air pressure and keep it at around 6 kg. Check the air pressure, check whether the injection cylinder and cylinder are dead, check whether the nozzle is closed under the touch screen maintenance mode screen, and check the circuit. Tighten the lower nozzle and replace the lower nozzle seal if needed.

Power Supply

Turn on the power, turn on the power switch, and check the fuse. Check if the switching power supply has DC24V power output. Release the emergency stop button.

Feeding System

Check your feeding system at regular basis because the main heart of the aerosol filling machine.

Lubrication

Before the piston type filling machine is cleaned, the remaining products should be cleaned, and then filled with soft cleaning liquid.

Cylinder in the factory has been added lubrication, please do not open or add any lubricant to ensure that the surface of the filling machine clean, do not work when the power outage. In addition, adhere to the maintenance and proper use of filling machine at the same time, but also on a regular basis for testing, debugging.

Only in this way can the machine work stably and healthily.

17.What are the Future Prospects of Aerosol Filling Machine?

The pharmaceutical industry is facing plenty of challenges. A lot of research and development is going on for the better future of aerosol filling machines.

Sustainable Products

Consumers are preferring more sustainable products that do not have long-term effects on the environment and easy to recycle.

Customers are changing their preferences towards more environment-friendly packaging products due to various harmful effects of several packaging products.

All-encompassing framework of the dynamics of the market. It mainly comprises critical assessment of consumer’s or customer’s journeys, current and emerging avenues and strategic framework to take enable effective decisions.

Companies are focusing more on consumer-oriented products, and researching on the same to produce cost-effective and harmless packaging products.

Robotized Machines

Aerosol filling machine manufacturers are working and planning for totally robotized machines and equipment’s so that human effort must become minor.

According to research, in upcoming years all machines will be robotized.

More and Effective Production

In future, manufacturers are working on machines performing more efficient and increase the rate of production by making aerosol machines much better.

More Demand for Single Use Component

Aerosol filling machine is increasing demand for greater flexibility and the removal of possible contaminants will find another effective associate in the form of single-use components.

Inspection Quality

facial care by aerosol filling machine

In order to fulfill pharmaceutical quality and standard, manufacturers are working on high end inspection quality so that safety of patients can be more enhanced.

Small Size Batches

Custom-made medicine will continue to demand ever more stretchy and adaptable processing. Smaller batch sizes shift the prominence from speed and mass production of standard dosage products to more personalized products packaged in high-quality materials.

Don't forget to share this post!

Syrup Filling Machine Related Products

Syrup Filling Machine Related Posts

Syrup Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine