Advantages Plastic Bottles Over Glass Bottles For Drug packaging

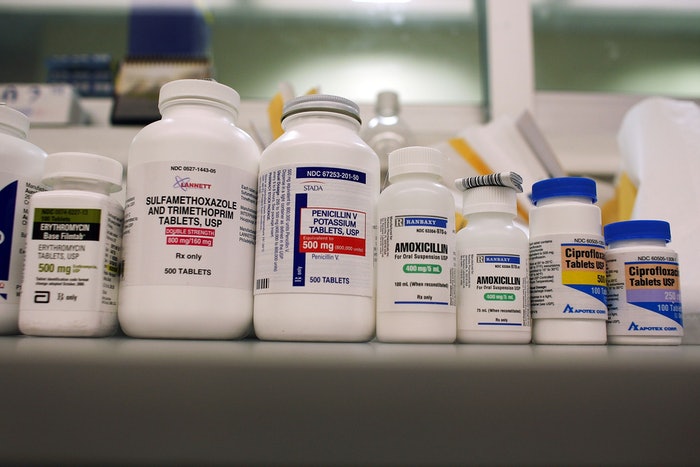

The two most common materials used for drug product packaging are glass and plastic,both of which offer their unique share of advantages.

Plastic isn’t always the first material that you think about when discussing recyclability, especially when compared to glass. But after some research, we believe plastic should be chosen over glass, especially for the food and beverage ,pharmaceutical markets.

There are three key areas where plastic excels in cost savings compared to glass:

. Weight and Durability

. Health and Safety

. Recyclability

We think it’s important that you know how utilizing plastic can help improve your bottom line. That’s why we want you to have all the information you need to make an informed decision about your product packaging.

Weight and Durability

Glass is heavier and more fragile than plastic. This makes transportation more expensive due to increased weight and the need for packaging materials to cushion the product during transportation.

Additional materials makes for a greater environmental impact. Because glass is more fragile than plastic, statistically, there will be more loss during transport (and in general) leading to decreased profits.

Plastic is much lighter and more durable than glass. This makes it cheaper to transport. Because there are fewer trips and less packaging material needed it also leaves a smaller carbon footprint. Additionally, plastic is more flexible than glass, making it easier to be molded which enables brands to build identity.

The Washington Post published an article discussing the disadvantages of glass peanut butter jars. It concluded that plastic was, for the most part, better for the environment and cut costs.

They reported, “The problem, as Vermont Peanut Butter points out, is weight. Glass is far heavier than plastic. Two years ago, peanut giant Planters cut packaging weight by 84 percent when they switched from glass to plastic jars.”

Health and Safety

Because glass is fragile, it has a tendency to shatter and can create a potentially dangerous and messy situation. The shards left behind create a safety hazard.

This affects those that work in factories, transportation, retail, and finally the consumer. While glass will break, plastic has the ability to deform and bounce back into shape if dropped, thus it is less of a safety hazard.

There have been many concerns about chemicals in plastics getting into the contents of the container and becoming harmful. Polyethylene terephthalate (PET) plastic is the greenest, cleanest type of plastic. It does not contain bisphenol-A (BPA), a chemical that has the potential to seep into foods and beverages and possibly cause health concerns. The PET Resin Association (PETRA) states that, “PET is the world’s packaging choice for many foods ,beverages and pharmacy because it is hygienic, strong, lightweight, shatterproof, and retains freshness.”

Recyclability

An article from Packaging of the World (POTW) said that while the recycling of glass peaked in the nineties, recycling of plastic is still growing. They reported, “Over forty percent of the plastic made is recycled, as compared to only twenty percent of glass containers.”

In conclusion,compared with glass bottles, plastic bottles will have three outstanding advantages for you to choose as your premier pharmaceutical drug packaging.

Plastic Reduces Production Costs

Right from the start, glass has a cost disadvantage compared to plastic: glass is more expensive to produce.

The manufacturing processes for both plastic and glass packaging are overall quite similar, as both involve heating the material and then using molds to give it its desired shape and thickness.

Where glass production differs from plastic, however, is in the amount of energy required to manufacture each bottle.

Depending on its specifications, glass melts at between 1400°C to 1600°C. Meanwhile, plastic melts at a much lower temperature, at around only 170°C. This means plastic requires significantly less energy to shape and manufacture.

Further, advancements in molding technologies continue to lower plastics production costs, as bottles can be shaped using less heat and more quickly, requiring even less energy. Taken as a whole, plastic production is a more efficient process than that of glass.

Working with a reputable plastic manufacturer ensures products are efficiently produced and costs will be reduced. This makes plastic an optimal packaging solution for you and the consumer.

Plastic Reduces Shipping and Handling Loss

Shipping is a complex, time consuming, and often expensive process. There is a lot that occurs throughout the shipping process:

.The empty bottles are shipped to the filling location

.Then the bottles are filled

.After filling they must then be distributed to consumer locations

This multi-stage process leaves a lot of room for potential issues, including product loss. The more often glass bottles must be handled, whether during the shipping or filling process, the higher the potential for damage to occur. Glass can easily shatter.

This poses a safety concern, but it also means a cut into your bottom line.

Shaking and bumping are common during the shipping process. This leaves glass vulnerable to chipping, cracking, and shattering. On the other hand, plastic is more durable and resists cracking and breakage.

Plastic Offers Lower Transportation Costs

Glass is comparatively heavier than plastic. Consider the following measurements: glass has a density of approximately 2.6 g/cm3 compared to HDPE plastic, which is around 0.9 g/cm3.

This makes glass almost three times heavier than plastic of the same size. In addition, plastic containers can be made thinner than glass bottles, further reducing their weight.

Let’s compare a 2 oz. glass jar and a 2 oz. HDPE plastic jar as an example. We’ll assume that both jars have the same dimensions and a 53mm neck opening. A 2 oz. glass jar with a 53mm neck opening will weigh around 82.2 grams. In comparison, the 2 oz. plastic jar weighs only around 13.0 grams. This means it would take 6.3 plastic jars to equal the weight of a single glass jar. This difference is substantial – especially when ordering pallets of bottles in bulk.

Conclusion

The right material will depend on the needs of your organization. Factors often include packaging safety, cost considerations, and the product itself. If managing costs is at the top of your list, then plastics make a compelling case.

Bottle Unscrambler Related Products

Bottle Unscrambler Related Posts

Bottle Unscrambler Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine