About The Wet Granulator Machine- 4 Things You Must Remember

The concept of granulation technology

Granulation technology: It is used to process powder, molten liquid, aqueous solution and other materials into a certain shape and size granules.

The purpose of granulation

First, improve the liquidity, facilitate packaging, tablet pressing.

Second, prevent the segregation phenomenon of each component due to the difference in particle size density.

Third, it prevents dust from flying and adhesion to the wall.

Fourth, adjust the bulk density to improve the dissolution performance.

Fifth, improve the uniformity of pressure transfer in tablet production.

Sixth, easy to take, easy to carry, improve the value of goods.

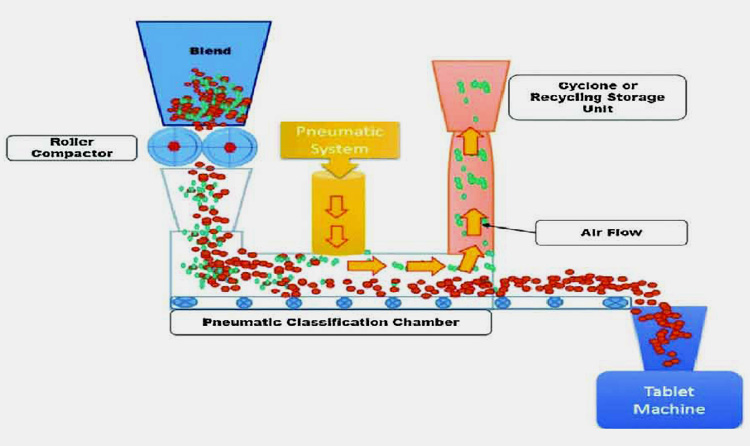

Granulation methods: wet granulation, dry granulation, one-step granulation, spray granulation, wet granulation are the most used.

Application of granulation technology: It is widely used in solid preparations, especially in granules and tablets.

Wet Granulation

You need to add adhesive and or wetting agent first to make soft material, sieve and made of wet particles, wet particles after drying and then through the whole grain. Wet particles have the advantages of better surface modification, beautiful appearance, strong wear resistance, good compression formability and so on, which are widely used in the pharmaceutical industry.

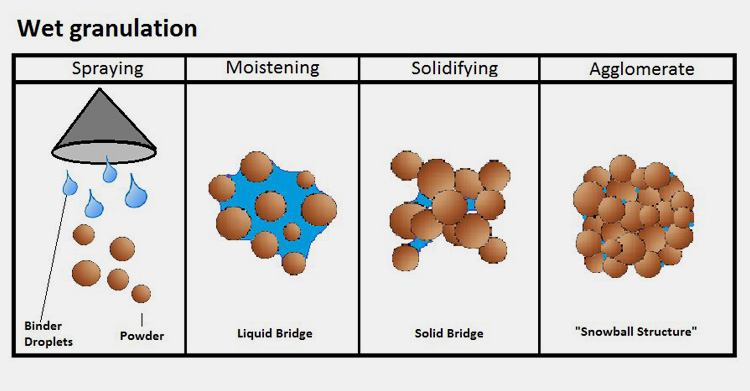

The mechanism of wet granulation: First of all, the liquid in the adhesive will be wet the surface of the drug powder, so that the adhesive force between the powder particles, and then in the liquid bridging and external mechanical force under the action of a certain shape and size of particles, after drying and finally in the form of solid bridge consolidation.

Wet granulation mainly includes the process of soft material, wet granule, wet granule drying and whole granulation.

Soft material: mix the raw and auxiliary materials fine powder, which is weighed according to the prescription, and add an appropriate amount of wetting agent or adhesive to mix it into soft material.

Soft materials should pay attention to these problems:

First, the type and amount of adhesive should be based on the nature of the material.

Second, the concentration of adhesive added and mixing time, according to different varieties of flexible control.

Third, soft wood quality. Due to the differences in raw materials, it is difficult to establish a unified standard, generally mastered by experience, with the hand pinch can form a block, finger light pressure and can be split open.

Fourth, the length of wet stirring time has a great relationship with the soft material of the particles. The longer the wet mixing time, the greater the viscosity and the harder the particles are made.

System of wet particles

It can pass the soft material through the screen into pellets. When the particles fall from the sieve hole like long strips, it indicates that the soft material is too wet, wet mixture or wetting agent is too much.

On the contrary, if the soft material through the sieve hole is powder, indicating that the soft material is too dry, it should be adjusted appropriately. Commonly used equipment: swing granulator, high speed mixing granulator screen: nylon wire, galvanized iron wire, stainless steel, plate four kinds of screen.

Wet particle drying

The wet particles made by screening should be dried immediately, so as not to agglomerate or compression deformation (stainless steel plate can be used to make good wet particles spread out and placed from time to time to solve the problem of wet particles storage agglomerate and deformation).

Drying temperature: It is determined by the nature of the raw material, generally 50-60℃. For some drugs that are stable to humidity and heat, the drying temperature can be appropriately increased to 80-100℃.

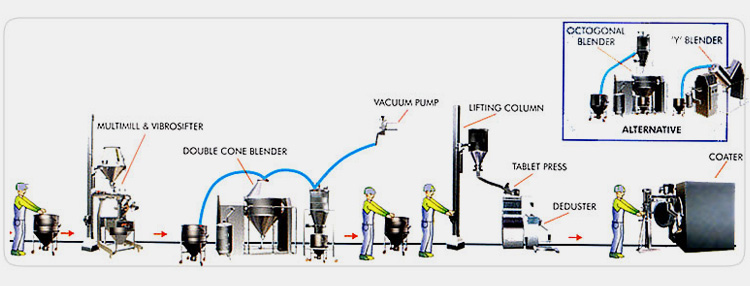

Drying equipment: The commonly used are box-type (such as oven) drying, boiling, drying, microwave drying or far-infrared drying heating drying equipment.

The whole granules

Wet granules should be screened after drying to break the granule to meet the granule size requirements or tablet pressing requirements.

Granules: It can be used that the wet particles used in the screen mesh number is small and within 10 mesh (1 screen), the part can not pass the sieve hole for appropriate crushing, and then in accordance with the particle size requirements, according to the lower limit of particle size specifications, over 60 mesh or 80 mesh (5 screen), classification, take 10-80 mesh particles.

Tablets: Particles can be used rather than the mesh number of wet particles screen mesh.

Factors Affecting Wet Granulation

Natures of the raw and auxiliary material

First, fine powder, loose texture, dry and poor viscosity, small solubility in water. Choose adhesive with strong viscosity, and the amount of adhesive should be more.

Second, the solubility in water is high, and the viscosity of raw material is strong. Choose wetting agent or adhesive with small viscosity, and the amount of adhesive is relatively less.

Third, sensitive to moisture and easy to hydrolyze. You can not choose water as the solvent of the adhesive, but you should choose absolute ethanol or other organic solvent as the solvent of the adhesive.

Fourth, it is sensitive to heat and easy to decompose. Try not to choose water as the solvent of adhesive, choose a certain solubility of ethanol as the solvent of adhesive, in order to reduce the particle drying time and reduce the drying temperature.

Fifth, it is stable to humidity and heat. Choose the lower cost of water as the solvent of the adhesive.

Moistening agents and adhesives

Moistening agent: A liquid that can be moistened by moistening material to produce a moisture that is strong enough to be moistened easily to make granules. The wetting agent itself is not viscous or viscous, but can wet the material and induce the viscosity of the material itself, so that it can be aggregated into soft material and made into particles

Adhesive: a cohesive solid powder or viscous liquid that causes non-viscous or less viscous materials to aggregate and bond into particles or compression shaped. Such as povidone (PVP),hydroxypropyl methyl cellulose (HPMC), sodium carboxymethyl cellulose (CMC-NA), syrup, etc.

Granulating and cutting time

When making soft material, stir cutting time should be properly mastered, generally mastered by experience, with the hand pinch can form a block and not stick to the hand, finger light pressure and can be split open. Long cutting time, too strong viscosity, difficult granulation. Cutting time is short, the viscosity is not strong, the granulation is not good.

Applications of Wet Granulation technology in pharmaceutical production

Application of granulation technology in granules

Granules (granules) refer to dry granular preparations made of drugs and suitable excipients. There are relevant regulations that clearly point out that the weight of particles and powders that cannot pass through No. 1 sieve and No. 5 sieve must not exceed 15% of the total weight (the general internal control standard is 10%).

All granules must be granulated, and various factors should be considered comprehensively, and the granulation prescription should be determined through experiments. Common granules: azithromycin granules, amoxicillin granules, etc.

Application of granulation technology in tablets

Generally, the preparation of tablets includes two methods: direct tablet pressing and granulation tablet pressing, wet granulation tablet pressing is the most widely used. Wet granulation tablet, suitable for damp - heat - stable drugs.

The wet Granulator machine, as the most widely used pharmaceutical machine improves production and facilitates people’s lives. In terms of the wet granulator machine itself, it has many aspects needed to innovate and upgrade so that it can continuously meet the demand for high-quality pharmaceuticals.

As for customers, you need to know more information and details about the wet granulator machine, which makes you effectively solve the problems during production and maximize the production of medicines.

Don't forget to share this post!

Granulator Machine Related Posts

Granulator Machine Related Products

Granulator Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide, tips and trends sent straightly to your box? Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine