High Accuracy of Filling

Combination structure of triangle knife and dot line knife

Filling parts without sticking material on the pump

Stirring tank speed adjusting system

Fractional cooling system

Want A Free Consultation

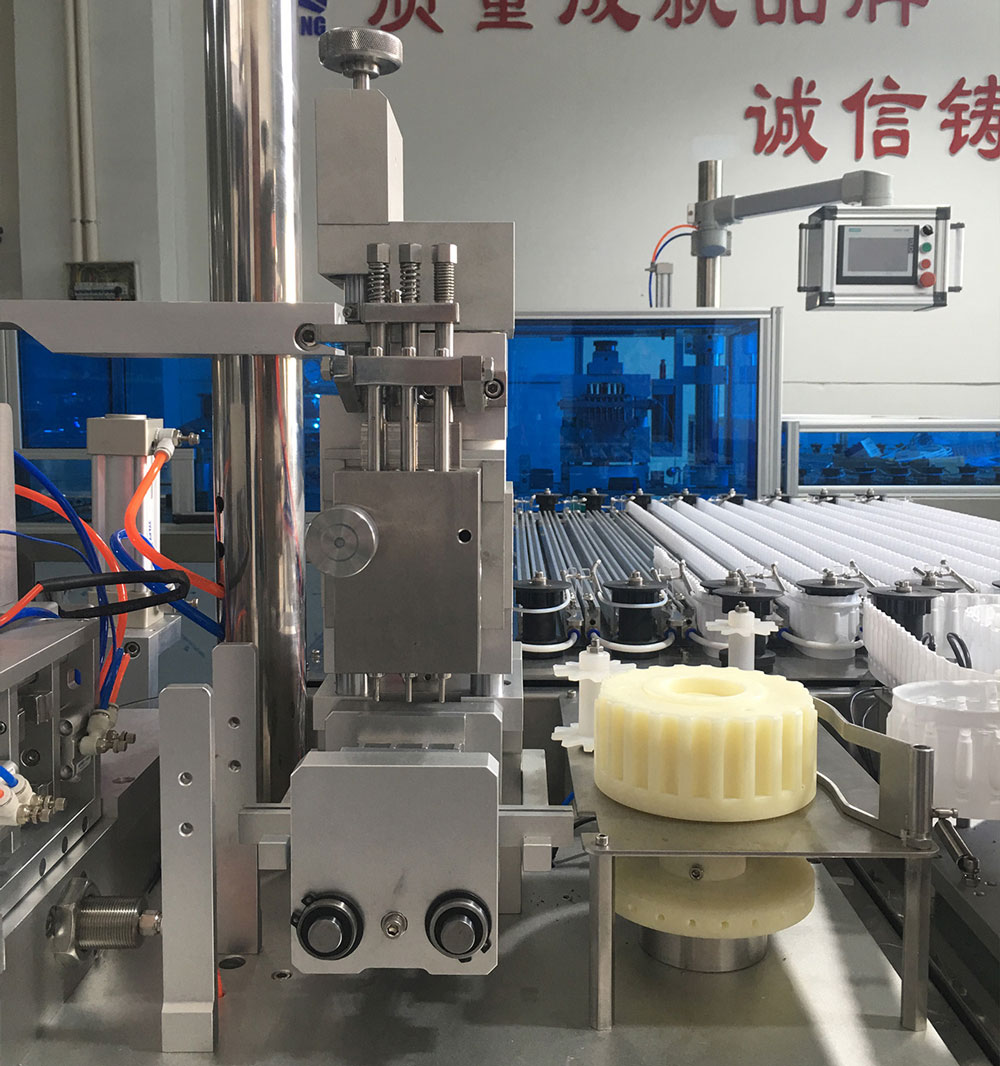

SJ-3L Automatic Suppository Filling Production Line

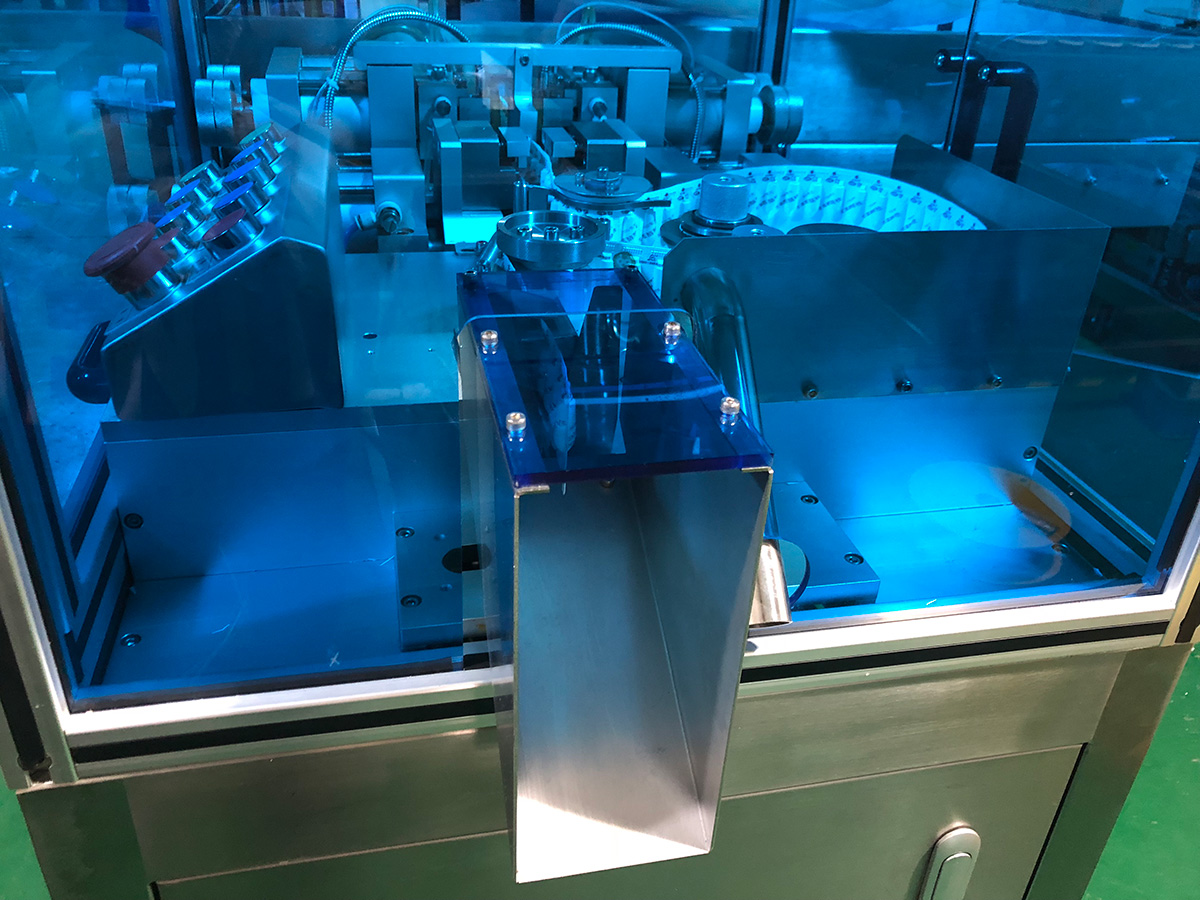

AIPAK SJ-3L automatic suppository filling production line has a stable and efficient manufacturing process, filling, freezing, sealing and other production processes to complete the whole process, and the production capacity is 5,000 grain/hour.

The equipment adopts PLC programmable control and man-machine interface operation, easy operation, convenient adjustment, accurate temperature control and smooth operation.The temperature sensor and microcomputer control system are used to realize high precision thermostatic control.

The liquid storage tank is made of 316L stainless steel, with proper volume, heat preservation and heating function, and accurate temperature control; The tank is equipped with a mixing device to ensure the homogeneity of the liquid in the VAT at any time. The reservoir can be connected with the filling mechanism through the pipe, and the liquid can be kept in circulation to ensure the fluidity of the liquid and satisfy the demand of filling.

The insertion type linear perfusion mechanism can be used to locate accurate, not dropping, and not hanging wall; The single-grain measurement is 0.5-5ml and the filling error is plus or minus 2%.

With continuous cooling design, the post-infusion suppository shell can be fully cooled and the liquid solid transformation is realized.With continuous strip, continuous sealing, sealing process batch number self-printing; The sealing seal should be well sealed, with neat appearance and good value of not less than 98%.It has simple and reasonable design, convenient operation and maintenance.

Working principle of AIPAK suppository filling machine

It will be rolled into the forming area by the clamping mechanism. The mold will be heated by the preheating mold, the mold, the mold, the blow mold and the bubble forming.

Filling

And one-time molding suppository for embedded type filling, filling accuracy + / – 2%, filling material barrel has electric heating insulation system, the top is equipped with a uniform mixing machine in order to make drugs, drug by high precision in VAT filling pump into the filling head, a drug through the other end of the cycle to rest after filling material barrel filling again next time.

Cooling design

The suppository of the whole drainage is entered into the cooling box, and the cooling box is equipped with a cold water unit.

Shearing

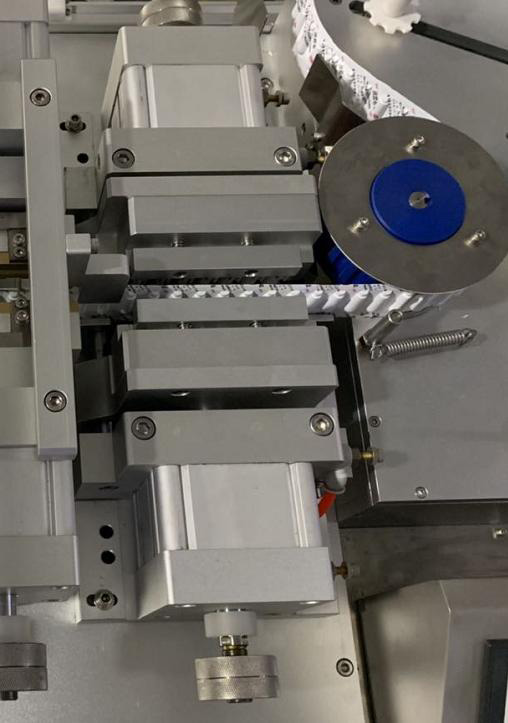

After being cooled, the solid suppository enters the sealing zone: preheating mold (preheating), sealing mould (seal), marking mould (batch number), The triangle knife will be cutting suppository top edge (cutting edge),hob (top), counting shear.

5 Advantages of AIPAK suppository filling machine

1. High Accuracy of Filling

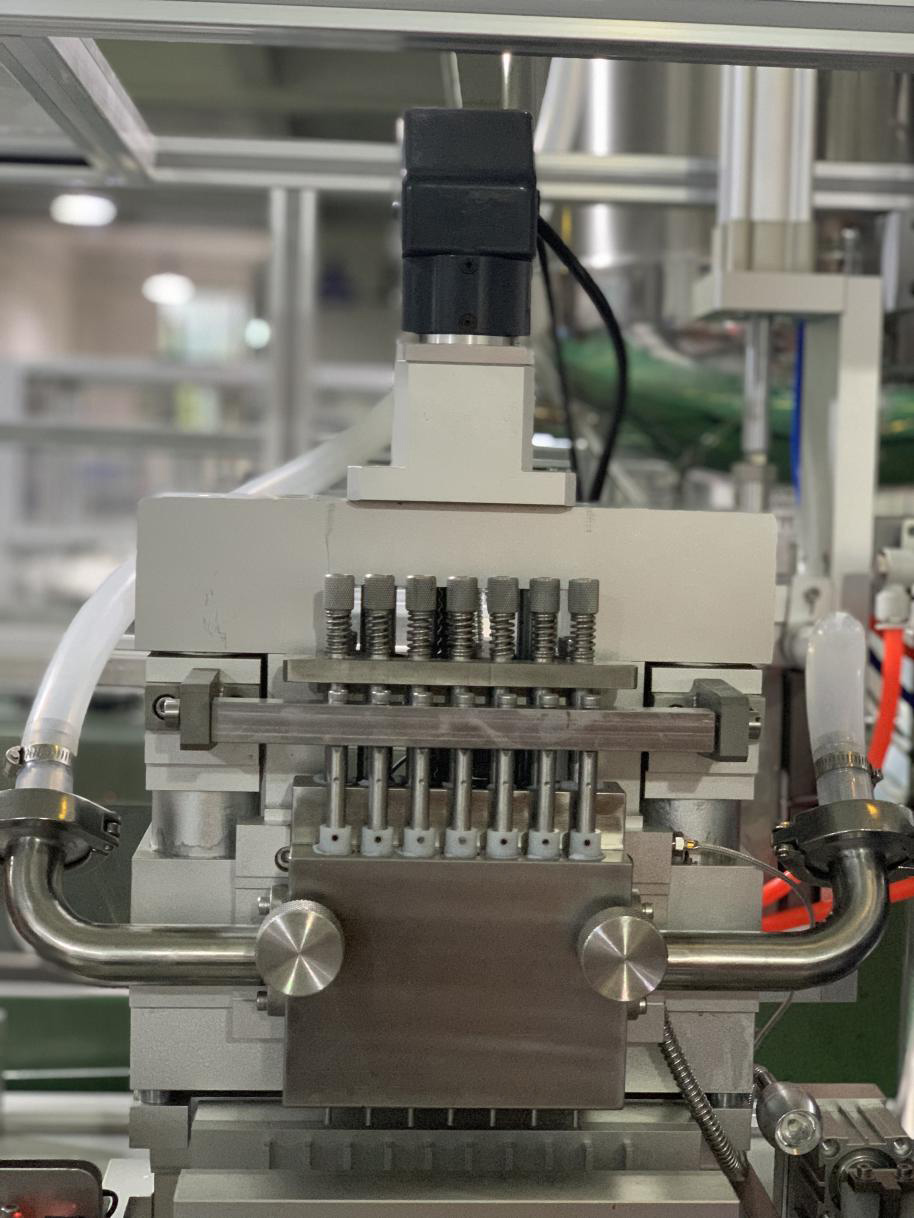

The injection pump body is processed by special process, so that the sealing performance between the piston and the pump body is better, and the infusion volume is more accurate. The dosages can be fine-tuned.

2. Combination structure of triangle knife and dot line knife

Make the both of triangle and the dotted line knives completely coincide, make the bolted shell achieve the easy tear effect.

3. shearing system

Instead of the tedious manual adjustment, the shear number can be completed by adjusting parameters of the touch screen, convenient operation, accurate positioning, stable operation and efficiency.

4.Filling parts without sticking material on the pump

The equipment filling pump has high precision, good sealing effect, smooth inner wall and good stability, so as to achieve the long-term operation without hanging wall phenomenon.

5.Stirring tank speed adjusting system

Because of the different viscosity of the drug matrix, the mixing effect cannot be fixed and the drug can be mixed before the filling, which can affect the drug content of the finished product.

6.Fractional cooling system

The cooling system adopts the latest grading cooling technology, which can be cooled and solved the phenomenon of the edge of cooled material drops and fracture when the medicine is tearing apart.

7.PLC Examine system

The on-line monitoring function of PLC can be used to detect and alarm the fault self-check.

8.Filling parts equipped with anti-static system

Note: by filling parts molding shell before if not including the equipment because of trace drug when filling in the flowing area close to the bolt shell under the action of electrostatic force along the shell wall climbing a short level which could reach the sealing parts of the bolt, thus will affect the back of the sealing quality.

9.Filling parts without sticking material on the pump

The equipment has high precision and good stability, so it can run without wall for a long time.

3.5.10 Sealing and Shearing 3 degrees pre-heating

Be cooled solid suppository into the sealing area: the level of preheating mold (hot) to secondary preheating mold (hot), heat sealing moulds (sealing) – > code (lot number) – hob (clip) above – counting shearing.

3.5.11 Easy operation

Control station height reasonable design, machine operation is simple.

FEATURE

1.The equipment adopts PLC programmable control and man-machine interface operation, easy operation, convenient adjustment, accurate temperature control and smooth operation.

2.The temperature sensor and microcomputer control system are used to realize high precision thermostatic control.

3.The liquid storage tank is made of 316L stainless steel, with proper volume, heat preservation and heating function, and accurate temperature control; The tank is equipped with a mixing device to ensure the homogeneity of the liquid in the VAT at any time. The reservoir can be connected with the filling mechanism through the pipe, and the liquid can be kept in circulation to ensure the fluidity of the liquid and satisfy the demand of filling.

4.The insertion type linear perfusion mechanism can be used to locate accurate, not dropping, and not hanging wall; The single-grain measurement is 0.5-5ml and the filling error is plus or minus 2%.

5.Continuous cooling design, the post-infusion suppository shell can be fully cooled and the liquid solid transformation is realized.

6.Continuous strip, continuous sealing, sealing process batch number self-printing; The sealing seal should be well sealed, with neat appearance and good value of not less than 98%.

7.Simple and reasonable design, convenient operation and maintenance.

DATA SHEET

|

Commodity |

Full automatic suppository production line |

Model |

SJ-3L |

|

Output |

5,000 pcs/h |

single dosage |

0.5—5g |

|

Dosage allowed |

<±2% |

Packaging Film |

PVC\PE (thickness0.15-0.18mm) diameter:270mm |

|

Stirring tank capacity |

30L |

Air pressure |

≥0.7Mpa |

|

Air consumption/min |

1.5m3 |

Water consumption/h |

50kg (recycling) |

|

Working voltage |

3 phase 380V |

total power |

5KW |

|

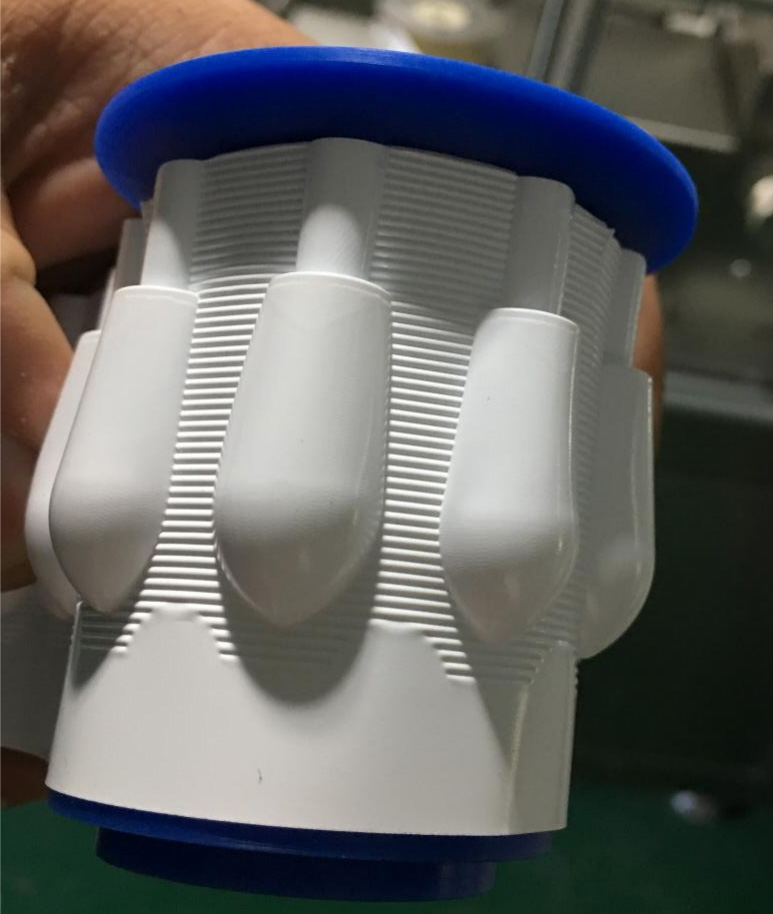

Adopt forming shapes |

Bullet, torpedo and duck shapes and other shapes |

Machine Weight |

1000KG |

|

Adapt Material |

Synthetic fatty acid glycerol, glycerin gelatin, polyethylene glycol etc |

Each distance of suppository |

17.4mm |

|

Overall dimensions |

L3,587mm×W1,388mm×H1,828mm |

||

VIDEO

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586