All Sizes of Capsule Available

High Productivity & Fully Automatic

High Efficient & GMP Standard

Want A Free Consultation

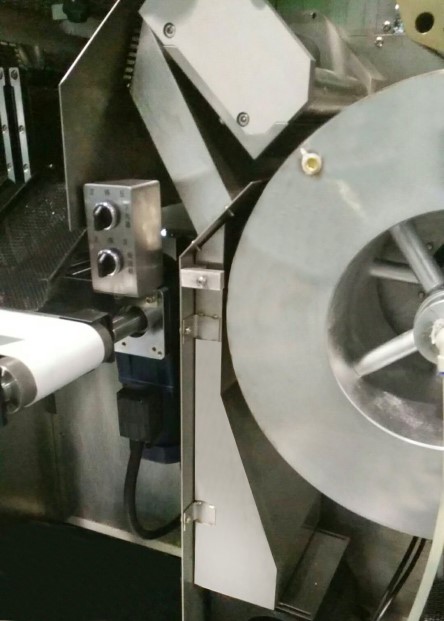

SEM-250 Series Soft Capsule Produce Equipment

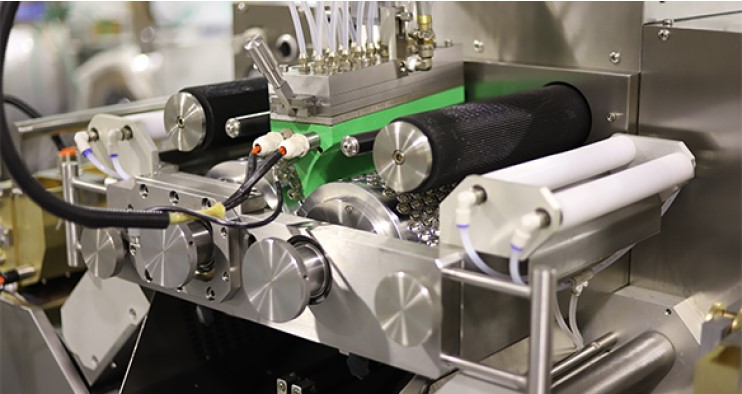

This machine is the absorption of advanced technologies at home and abroad, based on a combination of soft capsule production process and the characteristics of the use advanced technology and high quality materials.Meet the GMP requirements of well-designed. This machine consist of soft capsule machine, sol pot, mould (roller die), capsule conveyor, tumbler dryer, cooling air machine, vacuum pump, drying tray, vacuum mixing barrel and electrical control system and other ancillary equipment. This machine cans all kinds of drugs, food, cosmetics, oils and hydrophobic substances in the quantitative suspension or paste injection pressure and encapsulated in gelatin membrane, the formation of various sizes in sealing the soft capsules. This machine is widely used in small scale production.

FEATURE

- Employ horizontally glue pumping mode and components of each system can be independently controlled, which creates great convenience for adjustment.

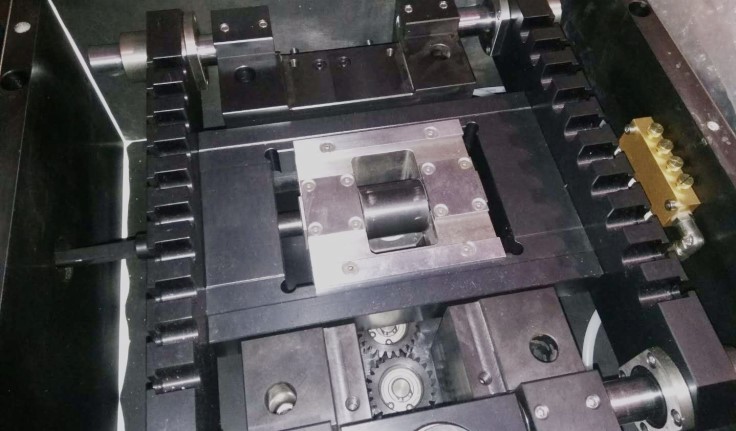

- Take pneumatic pressurizing as the rotary molding pressing way, visible figures, easy, fast and able to lengthen die life.

- Controllable oil capacity for glue film lubrication realizes minimal quantities of lubricant; with cleaning free of ethyl alcohol or petroleum ether, avoid danger during washing and reduce production costs.

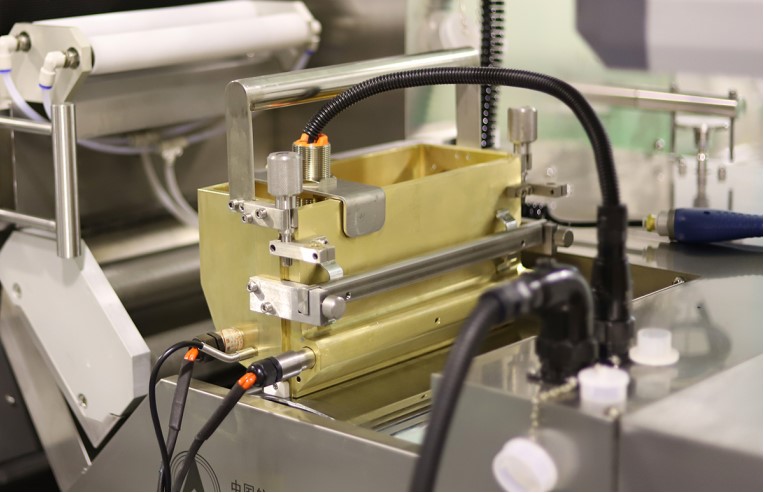

- Accurate adjustment on gum thickness, independent control of distribution.

- The parts joining contents, gelatin liquid and gelatin film should have bright and clean surface for convenience of cleanness and disinfection.

- The horizontal principal axes on the head of soft capsule machine has no more than ± 0.03 mm of jumping degree and there is no clamping stagnation for the pressurization and relocation of soft capsule machine head’s left principal axis. In case of the pressurizing contents belong to oils, within 1 – 4 r/min rotation speed of principal axis, the head die of soft capsule machine can manufacture soft capsules with complete appearances and neatly cut pills. The joints of soft capsules are beautiful and firm without leakage; If the compressed contents are Chinese medicine suspension liquid, within 1- 3.5 r/min rotation speed of principal axis, the head die of soft capsule machine can manufacture soft capsules with complete appearances and neatly cut pills. The joints of soft capsules are beautiful and firm without leakage.

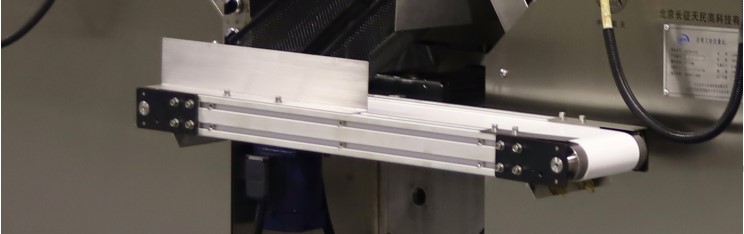

- When the soft capsule machine pressing pills, the pill dropping machine can neatly and fast drop pills. The rubber brush on the bottom of dies can clean up gelatin pills without causing damage to dies.

- During the compressing and production process of soft capsules, the gelatin box of soft capsule machine can adjust the gelatin tape's thickness by the front and back hand wheels of gelatin box. In case of any inconsistency between the thicknesses of gelatin tape on left and right, it can adjust the front and back hand wheels of the horizontal gelatin box to make the thickness uniform. During the compressing and production process of soft capsules, the gelatin liquid inside the gelatin box of soft capsule machine can automatically supply glue by cover valve and glue liquid level sensor. When the liquid level declining, the sensor will send signals to control and open the cover valve to supply glue; when the glue liquid reaches the required level, the sensor will send signals to close the cover valve to stop supplying glue.

- The left and right capsule shell rollers of soft capsule machine should have smooth surfaces without distinct scratches, and its jumping degree is less than 0.08 mm. The linear velocity of left and right capsule shell rollers can be adjusted as per demands through touch screen. The gelatin tapes generated during producing have even thicknesses and smooth outer and inner surfaces.

- The soft capsule cooling system is used for cooling the shell rollers on both sides of capsule, and the rollers' temperature can be automatically regulated through touch screen within 10°C-20°C to satisfy the demands for the production of different capsule shells and soft capsule products ; the soft capsule cooling system consists of outdoor cooling unit and inner condenser of soft capsule machine where the cooling system is transferred to liquid refrigerant which will send the cooling capacity of cooling system to the capsule shell rollers of both sides through pump. The sensor in the system is used to automatically control condensation temperature and further regulate the capsule shell rollers' temperature.

- The load precision of feed pump is ±1.5%; upon the test on feed pump of matching operation by 0-5 r/min in die's principal axis, no abnormal vibration happens. It is not required to adjust the injection time if adopting the design concept of automatic pump.

- The capsule product's percent of pass should be no less than 97%.

- The soft capsule should not be scratched, extruded or spilled out of the rotor while being shaped and dried in drying system.

DATA SHEET

|

Model |

RJN-250 |

RJN-200 |

RJN-15 |

|

Roll mode speed |

0-6rmp |

0-5rmp |

0-5rmp |

|

Roll mode size |

£150x250mm |

£103x200mm |

103x100mm |

|

Capsule production |

100000/h,8#olive,500mg/pill |

62400/h,8#olive,5mg/pill |

30000/hour(8#olive) |

|

Material feeding quantity |

0-3 ml |

0-2 ml |

2.5l |

|

Load difference |

<= ±2% |

<= ±2% |

<= ±2% |

|

Load precision |

<= ±1% |

<= ±1% |

<= ±1% |

|

Power supply |

380v 50HZ |

380v 50HZ |

380v 50HZ |

|

Motor power |

1.1kw |

300 ml/h(5rpm) |

0.75kw |

|

Total power |

9Kw |

9Kw |

5Kw |

|

Dimensions |

2110 x 1000 x 2000mm |

2050 x 890 x 2000mm |

1680 x 600 x 1550mm |

|

Weight |

1400KG |

1200KG |

550KG |

VIDEO

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586