Popping Boba Balls: The Complete FAQ Guide In 2025

Popping boba balls or popping boba pearls have gained popularity in culinary art, providing delicious, addictive flavors and fun into various treats like bubble tea, frozen yogurt and drinks. These transparent, juicy and gel-like pearls are filled with tasty flavors that bursts with little pressure into your mouth, providing refreshing sensation.

As we enter into 2025, the popularity of popping boba balls are increasing around the globe. Everyone loves their amazing and juicy taste, their vibrant colors and emerging application in various dishes. If you are a food-lover, small business entrepreneur, or a boba fan, you will must use it at your kitchen or cafes.

This thorough FAQ guide will address all your querries related to popping boba balls like what they are, how to make, which machines are used for manufacturing etc. This guide will also helpful in solving all the doubts about popping boba ball. Let’s explain them. Keep reading!

1.What are popping boba balls?

Popping boba balls

Popping boba balls are small, flavored and juice-filled sphere that burst-out into stream of sweet and tangy juice when bitten. They are generally used as a topping in dessert and drinks. Due to gel-like thin shell of popping boba balls, they are used widely in kitchens and cafes.

Popping boba balls are prepared by spherification process, by using sodium alginate and calcium lactate/acetate.

2.How the popping boba balls are differ from traditional tapioca boba?

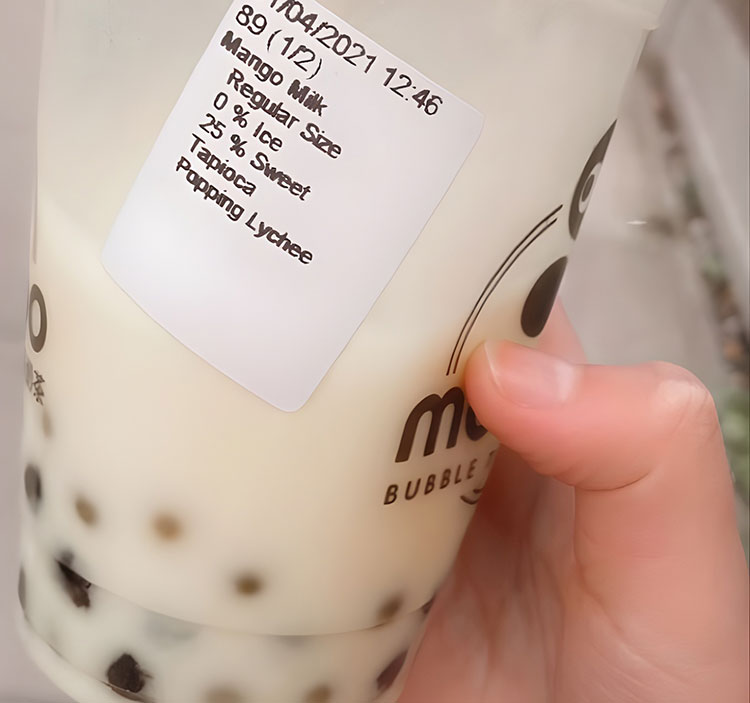

Popping boba ball and tapioca boba

| Properties | Popping boba balls | Tapioca boba |

| Ingredients | The ingredients used in the formation of popping boba balls are fruit juice, sodium alginate, calcium lactate and water. | The ingredients used in the formation of tapioca boba are starch (extract from cassava root, water and brown sugar. |

| Texture | The popping boba balls have soft, think, gel-like texture that bursts into flood of juice when bitten or squeezed. | The tapioca boba has gummy and chewy texture and does not contain any liquid inside. |

| Appearance | Due to flavored inside the boba balls, they exist in variety of flavored and hence, having colorful and vibrant aroma. | Tapioca boba exist in dark brown or black color due to indulging of brown sugar or caramel in making of tapioca boba. But they may also exist in colored versions. |

| Flavor | The flavor of popping boba balls can vary according to the juice flavor. So, diversity of flavors exist. | The tapioca boba has neutral to mildy sweet flavor and this flavor comes from the soaking in sugar syrup. |

| Storage and shelf-life | It can be stored in refrigerator in syrup for later usage. It has long shelf-life. | It is needed to serve quickly because over time, it become hardened it has short shelf-life. |

3.What are the advantages and disadvantages of consuming popping boba balls?

When you visit a café, the mouth-watering popping boba balls on the shelf increase your crave to add it in your dish. You must be thinking about the advantages and disadvantages of it. So, some of them are listed below:

Advantages:

The benefits for consuming popping boba balls are as follows:

Fun and flavorful experience

Fun and flavor-Picture courtesy: Santarrecipes.com

If you are going to café with children and elderly people, then they will must enjoy the burst of fruit flavor. The appealing color and soft sensations in the mouth will provide fun and flavorful experience to your dessert.

Variety of flavor

Variety of flavor

As it is available in various flavors, so you can select any flavor. Then, you can enjoy it with bubble tea, frozen yogurt or your any favorite dessert.

Quick source of energy

Quick source of energy

As popping boba balls have fruit juice, so with each bitten, you will get energy. As the juice may contain carbohydrates, vitamins so, it provides you a quick energy.

Low in fat

Low-fat

You may avoid creamy toppings due to their fat-content but you have a popping boba balls choice. You can easily consume it because it does not have any fat or a very little quantity of fat exist.

Vegan and gluten free

Vegan-friendly and gluten-free

Popping boba balls are entirely made up of plant material so they are vegan-friendly. As it does not contain any grain so it is also gluten-free. So, satisfy your craving with popping boba balls.

Disadvantages:

Everything has advantage as well as disadvantages. Some of the disadvantages of popping boba balls are as follows:

High-sugar content

Sugar-content

If you are taking popping boba balls daily, then you are taking high dose of sugar. This can cause diabetes, overweight and tooth decay.

Low-nutrient content

Nutrient-content of popping boba balls

They are tasty and fun-creating to your dishes but they have low nutrients such as proteins, vitamins are other essential elements. So they are low-nutrient popping bobas.

Artificial additives:

Additives to enhance color and preservative

While for long shelf-life and for adding visual appealing to popping boba balls, some brands add artificial preservatives and color so if you are prefer health over fun, then you must have to check the label on the package of it.

Risk of overconsumption

Risk of overconsumption

As the popping boba balls are tint and add fun to your bubble tea, you may have chances of excessive intake of it. Due to over consumption, you may have chances of excessive intake of sugar s well.

Choking

Choking

If not consumed properly, then your toddlers or elderly people may have chances of choking. So, investigate them for carefully taking it.

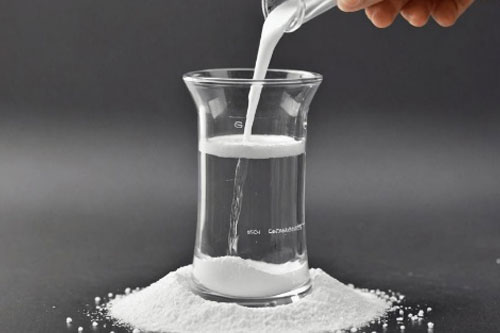

4.What are the ingredients of popping boba balls?

You usually go to café, and see the tiny sunshine, bursting flavored balls. These tiny balls are known as popping boba balls that is ready to add flavored to your drink by slight touch. These balls create a magic to culinary creativity. These tiny balls are made by technique known as reverse spherification.

Ingredients of popping boba balls

The main ingredients used in making popping boba balls are

- Fruit juice or flavored liquid

- Sodium alginate

- Calcium lactate/ calcium chloride

- Water

- Sweetener

- Citric acid

- Preservatives

- Food coloring

| Ingredients | Function |

| Fruit juice or flavored liquid

|

The fruit juice reside inside the heart of the boba balls. You may be thinking are the boba balls exist in various flavored? Yes, definitely the popping boba balls exist in various flavored. The most common popping boba balls flavored include strawberry, lychee, mango, blueberry and green apple. |

| Sodium Alginate

|

Sodium alginate is organic compound derived from seaweed. This compound has unique property in membrane formation. It is mixed with fruit juice to form mixture then it comes in contact with calcium bath. After the contact with calcium bath, it helps in the formation of outer membrane.

|

| Calcium lactate/ calcium chloride

|

Calcium lactate/chloride add to the water and form calcium bath. The mixture-sodium alginate is then add to calcium bath and it forms gel-like boba balls. |

| Water

|

Water is an important ingredient because it add to dilute the fruit juice as well as used for the mixing of calcium chloride/ lactate with water. |

| Sweetener

|

Sweetener such as sugar is added for the addition of sweetening if the juice had bitter taste. Usually corn sugar is used as a sweetening agent. |

| Citric acid

|

Citric acid usually extract from lemon etc. and is used for maintaining the PH of the boba balls. The ideal PH for popping boba balls is 4.0- 4.5. If the PH is too low then the boba formed will be hard and when PH is high then the spherification process may not occur properly. |

| Preservatives

|

The preservatives usually used in popping boba balls are potassium sorbate and sodium benzoate. These compounds are organic in nature and used to extend the shelf life of popping boba balls. |

| Food coloring

|

In order to create attractive visual appealing, some brands add artificial or natural color to popping boba balls. The coloring can brighten and change the color of boba balls. |

5.Are popping boba balls vegan or gluten-free?

If you are following vegan diet then you must be concerned about it. Absolutely! Popping boba balls are vegan-friendly because the components used in the making of it is organic in nature. Some people may allergic to proteins like gluten so for them, yes it is also gluten-free balls. Let’s discuss how they are vegan-friendly and gluten-free.

Vegan-friendly:

Vegan-friendly

The fruit juice used in popping boba balls are extracted from fruits.

The calcium chloride/ calcium lactate used in the formation of boba ball shell is also prepared by chemical reaction of different chemicals and enzymes and that are plant-based.

The sodium alginate is prepared by reaction of alginic acid (obtained from seaweed) and then neutralized it with sodium carbonate and you will get sodium alginate compound.

The water, sweetener (corn sugar), preservative (sodium sorbet) and coloring all added as plant-based.

Gluten-free popping boba balls:

Gluten-free

If you are handling with celiac disease or allergic to wheat etc. then you also don’t worry about the consumption of popping boba balls because it doesn’t contain wheat or barley etc. which has proteins content.

It is concluded that the popping boba balls are vegan-friendly and gluten-free, so you can enjoy your bubble tea with popping boba balls.

6.What are the different flavors of popping boba balls?

Popping boba balls exist in a variety of flavors. The popping boba balls color and flavor vary according to the fruit juice used inside the boba balls. Some of them are listed below:

Strawberry flavor:

Strawberry flavor

It is popping boba balls having red color. The taste of strawberry boba balls are sweet and fresh-strawberries .it is the most commonly used popping boba balls in bubble tea and dessert.

Mango flavor:

Mango flavor

It is also most commonly used popping boba balls. It is orange-yellow in color. The taste is tropical and sweet. Due to incorporation of mango juice, it taste like a mango flavor.

Lychee flavor:

Lychee flavor

These are light and floral popping boba balls. The lychee flavored boba exist in clear white in color and taste is mix of grape and pear.

Blueberry flavor:

Blueberry flavor

It exist in dark purple in color and having sweet and slightly tart like ripe blueberries in taste.

Green apple flavor:

Green apple flavor

Green apple popping boba balls exist in bright green in color. It has crisp and tangy with a sour-sweet apple flavor.

Yogurt flavor:

Yogurt flavor

It exists in milky white or pale pink in color. It taste like tangy and sweet having a creamy twist.

7.How can you use popping boba balls in different creative ways?

Popping boba balls is not just used in bubble tea but also served in different creative ways. Some of the cool ideas are as follows:

In-drinks:

Popping boba in drinks

The popping boba balls are added into iced-tea, milk tea or fruit-tea providing fun and juicy surprise.

In desserts

Sprinkling of popping boba balls

They sprinkle on the top of frozen yogurt and ice cream. They can also be used in the decoration of cakes and pancakes to add extra burst of flavor.

With fruit-dishes

Popping boba balls with fruit chaat

The popping boba balls are mixed with fruit salad for providing extra juiciness and color to it. They can also be layer on jelly or gelatin cups for eye-catchy and aesthetician view.

Fun food ideas

Popping boba balls on pancake

The popping boba balls are also used as a topping along with whipped cream on pancakes or waffles. They can also serve alone with dollop of cream in mini-parties.

8.How popping boba balls can be prepared at home?

Popping boba balls drink

If you are foodie or popping boba balls lover, then you can prepare your favorite boba balls at home as well. For this, you need some basic ingredients for making at home. These ingredients are:

- Water

- Sodium alginate

- Calcium chloride/ calcium lactate

- Your favorite fruit juice

- Coloring and preservatives (optional)

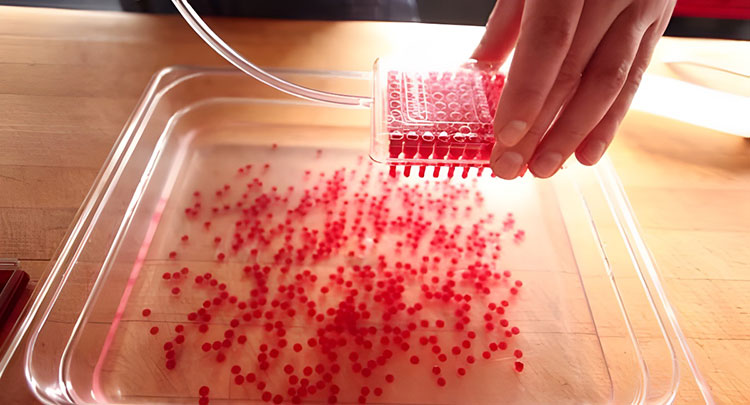

Instruction of preparation of popping boba balls:

Steps of preparation of popping boba balls-Picture courtesy: molecularrecipes.com

Pouring of fruit juice into the bowl:

In the first step, you need your favorite and desired fruit juice.

Mixture formation of fruit juice-sodium alginate

In the second step, add sodium alginate compound into the fruit juice and mix them well until thick mixture form.

Setting of mixture

Allow this mixture for setting in refrigerator for few hours or overnight. The purpose of setting the mixture is to remove bubble. Otherwise, the presence of bubble will disturb the formation of gel-like structure of popping boba balls shell.

Formation of water bath

Then, you need to add calcium lactate or calcium chloride compound into the water. Stir them well and ensure to completely dissolve the calcium salt into te water.

Putting of flavor-sodium alginate mixture into calcium bath

In the last step, you need to add juice-sodium alginate mixture into the calcium bath with the help of syringe or dropper. This mixture must be put drop-wise.

Formation of popping boba balls

This will form round, think gel-like balls in a minute.

Rinsing of popping boba balls

Once, the popping boba balls are formed. You need to rinse them with distilled water to wash excess calcium from the boba. This will prevent boba balls from extra hardening.

Serving of popping boba balls

Your favorite popping boba balls are ready. You can now serve them with dessert, cake, and beverage or used as a topping in beverages etc.

Spherification:

Spherification-Picture courtesy: sciencebuddies.org

The reason behind the formation of popping boba balls is the science. The process known as reverse spherification, is used in the formation of it. The sodium alginate converts into sodium ion and alginate ion. The calcium chloride also ionized into calcium ions (+2) and chloride ions. The calcium has two ions so two alginate molecule form a bond with one calcium ion. In this way, gelatinous structure of popping boba balls are formed.

9.How are artificial and natural flavors incorporated into the filling of popping boba balls?

Incorporation of flavor in popping boba balls

Everyone is a fan of vibrant, juicy popping boba, but have you ever wondered how the flavors incorporated into the popping boba balls? Well, let me tell you the process used is spherification, in which the fruit-flavor and sodium alginate mixture is dropped dropwise into the solution of calcium lactate or calcium chloride.

The calcium chloride/lactate is used as a gelling agent in this process. It combines with alginate and form a layer around the fruit juice or flavored. In this way, you can get juicy-filled vibrant tiny and smooth popping boba balls.

Some brands use artificial flavor to give the boba balls an extra taste which can add fun to your dish while others, use natural flavor. The natural and artificial can also be blended to give the popping boba balls an extended shelf life, better taste and vibrant color.

10.How can the viscosity of the juice or liquid filling affect the popping boba balls?

The viscosity of fruit juice affect the popping boba balls in many ways. They are as follows:

Influence of viscosity on popping boba balls:

| Shell formation

Picture courtesy: Ohsweetcups.com |

If the juice or liquid filling in boba balls are of high viscosity or too thick, then the sodium alginate used may not completely dispersed in juice and leading to thick or may not formed properly. This will result in harder to ‘pop’ popping boba balls formation.

If the juice is of low viscosity or too thin, the shell will formed easily but will be too weak. You may face the sequences like weak and leaky boba balls formation. |

| Popping sensation

|

If the liquid inside the boba balls are too thick then it may create jelly sensation which is less satisfying.

If it is too thin, then you will not enjoy the flavor. If the balance viscosity of juice are inside of boba balls, then it will burst easily in your mouth and will have a wonderful sensation. |

| Flavor release

|

The thin boba balls shell will explore quickly into your mouth.

The thicker gummy flavor may not explode, affecting the flavor experience. |

11.What equipment are used in the manufacturing of popping boba balls on industrial scale?

You encountered popping boba balls in different dishes with fresh, popping and delicious flavor. Have you ever thought what kind of equipment is used in the manufacturing of these tiny, sophisticated balls? How can they be packaged?

Some of the equipments are listed below:

Colloid mill

AIPAK colloid mill

This equipment is used for the shearing and obtaining finest blend of ingredients. It is made up of stainless steel which ensures to provide a hygienic environment to the ingredients. It has adjustable grinding gap for controlled texture.

The ingredients like fruit juice, sodium alginate and stabilizer are blend and homogenized to obtained smooth and fully mixed mixture.

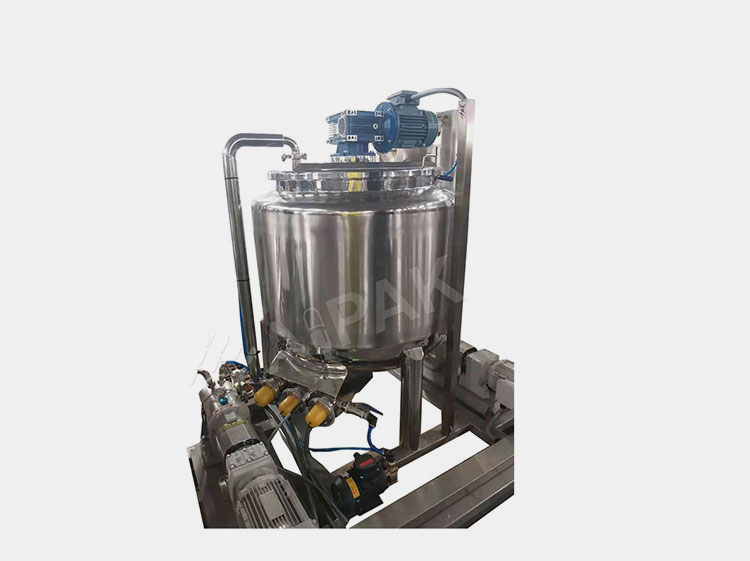

Cooker

AIPAK cooker

For the formation of popping boba balls shell, it is the most important factor to dissolve and fully dispersion of sodium alginate into the fruit juice. Is it possible to obtain the mixture with high precision?

Yes, if you will use cooker for this purpose, you will get a homogenized and fully dispersed mixture of fruit-juice and sodium alginate. The jacketed cooking kettle has temperature-controlled system while agitated-equipped cooker ensures that there will not uneven heating or burning of juice-sodium alginate mixture.

Cooling and storage tank

Cooling and storage tank

Cooling and storage tank is made up of stainless steel to ensure the safety of food ingredients. It has double-layer cooling jackets.

The purpose of this tank is to cool the cooked mixture before proceeding to popping process. It also store sodium alginate mixture in a temperature-controlled environment.

Popping boba balls machine

This is the core-machine used in the synthesis of popping boba balls. In this machine, spherification process takes place. There are two categories of this machine. They are as follows:

Automatic popping boba machine:

AIPAK Automatic popping boba machine

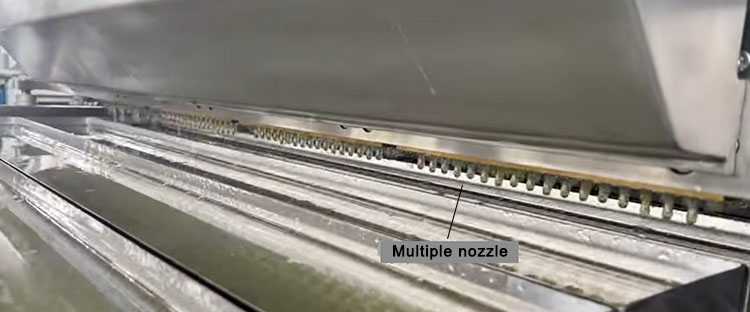

This machine is used for high-speed production of popping boba balls. It has controlled programme. It has multi-nozzle system through which juice-alginate mixture dispensed into the calcium bath. You can adjust the sphere size in this machine as well. Through encountering, it forms sphere and juicy boba balls.

It automatically rinse the formed boba balls with distilled water. It can also collect the finished popping boba balls.

Semi-automatic popping boba machine:

AIPAK Semi- automatic popping boba machine

Semi-automatic popping boba machine is used in medium-scale production. This machine also require operator for its operation. Semi-automated nozzles disperse the sodium alginate mixture into the calcium bath. Operator may control the sphere size and shape.

After the formation of popping boba balls, operator manually or semi-automatically (depends upon the brand) transfer the popping boba balls to the water bath in order to prevent excess water. The rinsing will remove extra calcium from popping boba balls and you’ll get soft and thin popping boba balls.

Packaging machine

Filling machine

The finished popping boba balls need packaging. The filling machine fills the boba balls into jar, cans or cups according to your choice. Then, sealing machine seals the containers in order to preserve the balls.

Labelling

Labelling machine is used to label ingredients and other product information on them.

Thus, by using high technology machines, popping boba balls are finally packaged and stored for later use.

12.How popping boba balls are manufactured on industrial scale?

The increasing demand of popping boba balls in cafes and kitchen globally has increased the number of production of it on large-scale or on industrial scale. You need to follow some of the basic steps involved in the manufacturing of popping boba balls. Let’s explain these steps:

Preparation of ingredients:

Preparation of ingredients (fruit juice, sweetener, sodium alginate, calcium lactate, citric acid)

The very basic step in popping boba balls manufacturing is preparation of base ingredients. All you have to do is arranging the ingredients like fruit juice, sodium alginate, calcium chloride/calcium lactate, stabilizer, sweetener, preservative and water.

Make sure to use distilled water for ensuring impurity.

All the ingredients have to precisely weight by weight balance equipment. By using the correct amount of ingredients, you will get the thin and perfect boba shell.

Mixing and cooking:

Mixing and cooking-Picture courtesy: mxdprocess.com

In this step, you needed to add a known amount of the sodium alginate compound into a quantity of distilled water. This step is very sensitive because the viscosity of fruit flavor matters the most. Make sure to use a moderate viscosity of fruit juice because this will provide a perfect medium for the dispersion of sodium alginate. Proper mix the juice flavor and sodium alginate.

Then, the mixture of juice-sodium alginate should be cooked in a cooker. This will homogenized and properly blend the mixture. This step will make sure that now the sodium alginate is properly dispersed in juice flavor.

Cooling of mixture:

Cooling of mixture

The cooked mixture is now set for cooling. The setting will make your mixture free of air and fully hydrated. If the mixture have bubbles, then the shape and size of popping boba balls have disruption occur. So, in order to create air bubble free, you must have to set the mixture for cooling.

Preparation of calcium bath:

Calcium bath

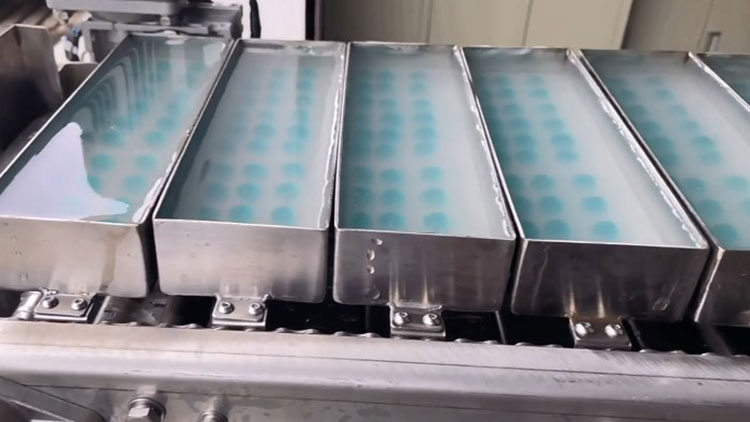

In this step, the known quantity of water is placed in a tank. You have to add a known amount of calcium chloride/ calcium lactate into this water. Make sure to use distilled water. Now, blend and mix the mixture vigorously and homogenously.

You must have to disperse the calcium chloride/lactate smoothly in the water.

Deposition and spherification

Deposition

Now, the pivotal moment has approached where you’ll get the popping boba balls. Through multiple-nozzle in the machine, the sodium alginate mixture will dropped into the calcium bath having controlled size and time.

Spherification

You will noticed, a tiny, sophisticated and juicy balls will formed upon encountering of sodium alginate mixture with calcium bath.

In the spherification process, the sodium alginate is dissociated into sodium ion and alginate ion. The calcium chloride is dissociated into calcium (+2) and chloride ion.

As the calcium ion has tendency to form a bond with two alginate molecule so, two alginate form a bond with one calcium ion. This form a cage like structure and form a gelatinous structure around the flavor.

Rinsing:

Rinsing

The formed popping boba balls are then shifted from the calcium bath into the water bath for rising. The purpose of rinsing is to remove any impurity or cross contamination from the boba balls. It also remove the excess calcium from them because the calcium may cause the boba balls hardened. By removing the calcium from boba balls, you can get juicy popping boba balls.

Storage:

Storage

Now, the finished popping boba balls are ready for storage. They can be stored in protection liquid (fruit juice, water, fructose etc.) to provide them safe and juicy environment.

Then, the boba balls are ready for packaging in cans and cups etc. the cans should be sealed by sealing machine and then labelled them.

In this way, you can prepare the popping boba balls in industries which will satisfy the consumer craving and will help in boosting your business.

13.What are the important components of popping boba balls machine?

You often enjoy tiny, thin and beautiful round shaped popping boba balls that served in different ways. When the juicy flavor dance on your taste bud, then you can’t resist to try it again and again.

The reason behind the fun creating popping boba balls is the science and machinery. But what exactly going on in these hardworking machinery. Let’s look deep into the popping boba balls making machine and see how these balls are made!

Mixing tank

Mixing tank

The mixing tank is like a kitchen where all the ingredients are placed and mixed together. The ingredients are juice, flavor, sweetener as corn sugar or honey, and gelling agents (sodium alginate, calcium chloride).

Droplet forming system

Droplet forming system-Picture courtesy: sinofude

This is like a “chef’s hand” which controls and help in the formation droplet of boba balls. The size, thickness, time and speed is adjustable in this system. It carefully handle and drop the sodium alginate mixture into the calcium bath.

Calcium bath tank

Calcium bath tank

It holds the calcium chloride+ water mixture. In this tank, when the sodium alginate mixture hit into this tank, an iconic beautiful shell is creating around each droplet. This is the ball that “pop” into your mouth.

Conveyor

Conveyor

This is like helper in the kitchen. Some machines have conveyor system that transport the boba along while they are forming. This is like a mini water slider that make sure boba balls don’t stick together.

Water tank

Water tank

The formed boba balls are immediately put into the water tank where washing of the boba balls occur. The reason behind rinsing is to remove chemicals and extra calcium. This makes them soft, beautiful round shaped and taste intact.

Storage tank

AIPAK Storage tank

In storage tank, the finished beautiful and yummy popping boba balls are stored and then packaged in various cans for serving with your favorite frozen tea, drink or whatever way you want to enjoy with.

Control panel

Control panel- Picture courtesy: AIPAK

This is the “brain” of the machine.in order to make sure that each bath is turned out just perfect and right, the operator adjust the popping boba balls size, thickness, mixing speed and time.

14.What are the advantages of using popping boba balls making machine?

Have you ever thought how cafés and bubble tea shops manage to whip up thousands of those tiny, juicy and beautiful round shaped popping boba balls so quickly?

Well, let me reveal you the secret, they have got a secret helper in the form of machine.

This is not just a piece of equipment but it is a game-changer for anyone who wants to make popping boba balls in medium or large batches in continuous way. It not only produce boba balls continuously but also witness for not creating a mess and stress. Here are some basic advantages of this equipment!

| Advantages | Explanation |

| Time and energy saver

|

Less hard work, more fun!

Manually popping boba balls making is taking long time. Thanks to popping boba machine, it speeds up the process. In a minute, it can manufacture hundreds to thousands of popping boba balls with no compromise on the quality of popping boba. |

| Consistent quality

|

This machine creates the perfect boba each time. In a batch, every boba created is of same size, same shape and same flavor. |

| Hygienic production

|

This machine is made up of stainless steel, closed and clean, which provide a perfect and clean environment to the food. Food hygiene is most important in food industry especially if you are serving most of the customers. |

| Customization

|

You want mango flavor today and lychee flavor tomorrow? No worry. This machine can do everything according to your wish. It can switch flavors, size, shape and adding vibrant colors to your dishes. |

| Reduce human error and cost effective

|

If you are running your bubble tea or dessert business, this machine performs an awesome job. No risk of mistakes and spoiled ingredients.

While investment on this machine, it also pays off with no mess and huge production capacity. |

15.How to maintain popping boba balls machine?

Your popping boba machine is doing all hard work, making flavored juicy spheres like a pro! It is just like a best friend, but it also require your attention to keep running smoothly. Here are some of the things that you must be considered to keep your equipment healthy for better boba formation.

Clean your machine daily

Clean your machine daily-Picture courtesy: wfsupportsservices

After a long day of working by machine, you must be clean your equipment with warm water. Otherwise, the sticky stuff build up so fast and result in ruining the machine.

Use food-safe cleaner

Food-safe cleaner-Picture courtesy: unilever-professional.com

The cleaning product must be food-grade because the boba balls are going straight into someone mouth, so the product touch this machine must be safe.

Check for clogs in nozzle

Rinsing of clogs in nozzle-Picture courtesy: systemcleaners.com

Nozzle is used for formation of round shaped beautiful balls. With the usage of mixture, it get clogs. So, you must be gently remove and rinse them after each use.

Keep the control panel dry

Dry control panel-Picture courtesy: dynamicrep.com

You must keep the control panel dry. Don’t splash! Use a dry cloth. If water goes inside the electronics then you will face a heavy bills for repairing.

Deep cleaning

Deep cleaning of machine-Picture courtesy: envirofluid.com

Once a month, disassemble the machine parts. It is like a spa day for a machine. Each part should be deep clean with food-grade cleaner and sanitize them. Let them dry and then reassemble them. Now, your machine is ready for stack of popping boba balls production.

16.What are the challenges when manufacturing of popping boba balls in industrial scale?

While making popping boba balls at home is a fun science. But making them at industrial level, you can face a lot of hurdles. Let’s reveal the scenery behind the curtain of popping boba ball making at large-scale.

| Maintaining consistent quality

Consistent quality |

If you are making a popping boba on large scale, you must be careful about the mixture. Because in large-batch, to keep the size, shape and consistency same is really challenging. If slightly off occur, the boba formed will be too thick or too thin and will not “pop” at all. |

| Ingredient sensitivity

Effect of ingredient on spherification-Picture courtesy:bol.com |

The process called spherification in boba formation, relies on controlled parameters. If slight change in temperature, size or shape occur then the mess in whole batch shell will create. |

| Equipment downtime

Clogging in nozzle-Picture courtesy:airwolf3d.com |

If clogging in nozzle occur, then what would you expect to occur? The stopping of machine will happen. Then you will restart it which is time consuming. |

| Waste management

Waste management-Picture courtesy: Nuwater |

The rinsing and washing of calcium bath and carefully disposing it becomes a really challenging in large-scale. |

| Custom orders and flavor

Custom orders and flavor-Picture courtesy: aheadofthyme.com |

When you have more customs, then demand for different flavor and color is also high. Switching of flavors and cleaning of equipment before switching is really time taking process and will have chances of cross-contamination, so carefully handle it. |

Conclusion:

After reading thoroughly the complete FAQ about the popping boba balls, it is expected that you will have got all the answers to the questions that were puzzling you. You can now ready for exploring different flavors of boba and can also use them in different ways. Now, you can buy and use the popping boba machine for your business. You may face challenging while operating it, but it also needs your love and care. By proper maintenance, it will work in a smooth way and will make millions of popping boba balls in a day. For more information, feel free to contact AIPAK!

Don't forget to share this post!

Popping Boba Machine Related Products

Popping Boba Machine Related Posts

Popping Boba Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine