Strawberry Popping Boba Manufacturing: The Complete FAQ Guide In 2025

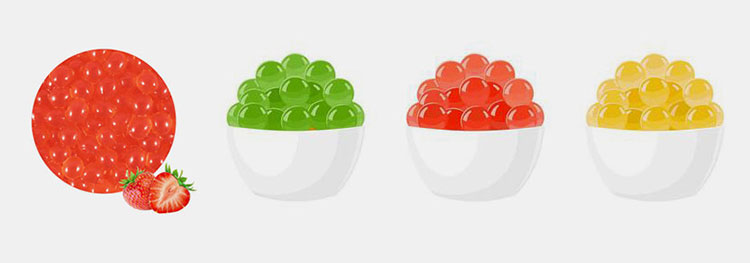

Have you ever tried popping boba and been surprised by its juiciest strawberry-flavored core? Are you curious as to how these beads acquire the yummiest flavor and delicate texture? This softest consistency, mouth-watery flavor, and liquid bursting core of strawberry popping boba are due to an industrial process called strawberry popping boba manufacturing.

Whether you’re a curious food lover, a greenhorn owner looking to invest in a new production line, or an established manufacturing entrepreneur, this FAQ guide “Strawberry Popping Boba Manufacturing: The Complete FAQ Guide In 2025” details and describes everything you need to learn.

From core components and basic equipment to working steps and processing challenges, we’ll cover all your queries- pop by pop. So, let’s begin reading!

1.What is strawberry popping boba manufacturing?

Strawberry popping boba- Picture courtesy: Fun Food Canada

It is an industrial manufacturing process in which world popular strawberry popping boba is produced using different specialized machines. In this manufacturing approach, tiny juice-filled beads are created that explode with sweet and savory strawberry flavor when they are bitten. Popping boba has an exterior delicate gel-like shell encase which is formed by a reaction called spherification. And liquid juicy center is enveloped by this shell.

It is a high-volume processing that involves various working stages, for instance, mixing, specification, cooling, quality control, packaging, and storage. With this manufacturing, manufacturers easily meet high production demands and yield quality products.

2.Why strawberry popping boba manufacturing is advantageous to both manufacturers and customers?

Popping boba is trending all across the world so many manufacturers are investing in popping boba manufacturing lines to generate substantial revenue. Besides generating higher profits for business owners, it also offers various fun benefits to customers. Let’s look into these advantages one at a time.

More Opportunities For Expansion

More Opportunities For Expansion- Picture courtesy: Kerry foodservice

Popping boba, especially fruity types, such as strawberry, has acquired huge traction in every region of the world and people love to spice up their desserts, bubble teas, and smoothies with them. This means there is a huge opportunity for the growth of businesses when they invest in strawberry popping boba manufacturing.

This production not only earns significant profits for businesses but also offers them a commercial edge over their competitors.

Quick Production Times

Quick Production Times- Picture courtesy: Mind Over munch

Yes, this manufacturing process constitutes several high-end machines with which you can easily make your popping boba products on a large scale in short intervals. All this equipment is highly automated allowing you to produce bulk volume batches quickly.

Also, you can achieve reproducible and high-quality outcomes in every product batch due to the accurate and precise control sensors present in these machines.

Room for Innovation

Room for Innovation- Picture courtesy: Pican Delux

If you are one of those manufacturers that enjoy experimenting with new flavors, textures, or nutraceuticals to cater to the ever-evolving choices of your customers, then strawberry popping boba manufacturing offers you room for customization and brand differentiation. You can easily customize your popping boba product by adding complimentary flavor, modifying its texture, and even incorporating vitamin C and prebiotics.

Creates a Unique Sensory Experience

Unique Sensory Experience- Picture courtesy: Bubble tea kit

Why customers from far and wide areas of the world are interested in strawberry popping boba? Because of its unique sensory experience and popping effects of these popping pearls. These only come from specialized equipment and procedures constituted in strawberry popping boba manufacturing. By utilizing manufacturing practices of this processing, brands create fun treats for their patrons, making their beverages and snacks more satisfying and exciting.

Healthy Option

Healthy Option- Picture courtesy: Bubble tea kit

With strawberry popping boba manufacturing, a healthier snack option- popping boba is manufactured for individuals who prefer healthy and clean food products. Popping boba is usually made with natural ingredients, real strawberry extracts, and a minute proportion of preservatives. Moreover, it can be vegan and gluten-free, consequently catering to individuals with diet restrictions.

3.What are various key ingredients utilized in strawberry popping boba manufacturing?

Although strawberry popping boba looks like a tiny bead to you, do you know it is carefully crafted by mixing several ingredients? Yes, different ingredients are utilized in precise ratios in strawberry popping boba manufacturing to bring this flavorful pearl to you.

Here are some main starting materials that are employed in strawberry popping boba manufacturing:

Strawberry Juice

Strawberry Juice- Picture courtesy: Alpha foodie

The tangy and tarty flavor of strawberry popping boba comes from the inner core. This central part is formed from natural strawberry juice, strawberry puree, and natural or artificial flavors. You’ve to incorporate color enhancers if you’re formulating your product from flavoring agents only.

Sodium Alginate

Sodium Alginate

Curious as to how shells of strawberry popping boba are created? Well, a gelling agent or thickening agent- sodium alginate is responsible for providing a characteristic texture of popping pearl.

It is a central chemical involved in spherification. For all those foodies who want naturally sourced products, here is good news for them: sodium alginate is a natural polysaccharide acquired from brown seaweed.

Calcium Lactate or Calcium Chloride

Calcium chloride- Picture courtesy: Food Ingredients Depot

These two are minerals that have a key role in the creation of a gelatin-like shell. They are involved in the reaction with sodium alginate. By this reaction, a thin and flexible encasing is formed around the liquid core. For more flavorful strawberry popping boba, you can use calcium lactate.

However, if you want to create your product with a stronger membrane, then go for calcium chloride.

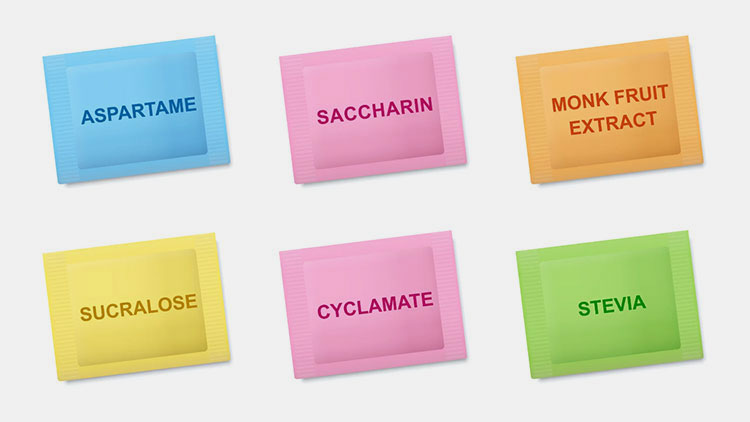

Sweeteners

Sweetners- Picture courtesy: WFLA

Industrial strawberry popping boba manufacturing often utilizes table sugar, glucose syrup, or high-fructose corn syrup as a sweetening agent. Intrigued by the pleasant syrupy consistency inside your popping pearls, it is mainly due to sweeteners. Besides this, they also have a role in improving the sweetness of popping boba. Table sugar is also added during preparation because it behaves as a preservative.

Critic Acid

Citric acid- Picture courtesy: heirloom body care

Do you like a tangy buzz in a strawberry popping boba? This is mainly thanks to the addition of citric aid during manufacturing. It imitates characteristic strawberry essence and also balances sweetness. You also utilize it in the recipes because of its capability to act as a pH modifier, which is vital in accurate spherication reactions and stable shelf life.

Water

Water- Picture courtesy: Stockcake

You incorporate water because it is a base solvent for ingredients used in strawberry popping boba manufacturing. However, you must remember, it should be pure and filtered to maintain product quality and safety.

Stabilizing or Thickening Agents

Stabilizing or Thickening Agents

Their inclusion depends on recipe requirements. To achieve a thicker texture or to avoid particle sedimentation, you can utilize these ingredients. Some of their common examples are xanthan gum or pectin.

Food Dyes

Food dye- Picture courtesy: Asian Inspiration

To create more vibrant-looking popping boba, you can use natural (beetroot red) or synthetic (Red 40) colors. These dyes give a bright red or pink color that customers can immediately identify as strawberry.

4.What are the steps in strawberry popping boba manufacturing on an industrial scale?

Do you think that strawberry popping boba manufacturing on an industrial scale is just like preparing strawberry popping boba at home? However, this is not the case. Industrial scale production is somewhat different from making steps at home as it requires specialized machines and strict manufacturing protocols to have consistent quality products.

But don’t worry because we’re detailing these steps in the following section for your information:

Starting Material Preparation

Strawberry Popping Boba Manufacturing

First, before actual cooking and mixing, different ingredients components, like strawberry juice, flavoring, calcium chloride/calcium lactate, sweeteners, and other optional ingredients are weighed and prepped. Moreover, you also measure the volume of water, as it is used for dissolution. Make sure to use filtered water for product safety and purity.

Cooking and Mixing

Cooking & mixing- Picture courtesy: Kitchen Alchemy

It is one of the pivotal steps in strawberry popping boba manufacturing because error-free mixing has a major impact on the quality of the final product. First, you can mix the desired quantities of sodium alginate with strawberry juice or flavoring using mixers at a controlled speed. Afterward, allow this mixture to rest to defoam or de-air and to fully hydrate.

The juice and sodium alginate mixture resembles a gel-like slurry. Then, you can mix calcium chloride/calcium lactate with the preferred volume of purified water to create a stable calcium bath.

Remember that the mixing or blending of ingredients must be homogenous to ensure the entire set of ingredients is thoroughly distributed in mixtures to offer desirable outcomes.

Deposition and Spherification

Deposition and Spherification

This is the step where beads or boba are crafted. It is the game-changing stage where deposition or droplet-forming machines are used to drop tiny droplets of sodium alginate-juice mixture into a calcium lactate/calcium chloride bath.

You can observe the spherification happening when the droplets encounter with calcium bath. Upon contact, a delicate covering is formed on the exterior of the droplet and encapsulates strawberry juice inside. Yes, it is an ionic popping moment.

Rinsing

Rinsing

After the boba pearls are created, they are moved from the calcium bath into the clean water bath. Here various kinds of impurities or any desired substances, for instance, calcium ions are removed from popping boba shells.

This step is also essential, as it stops the membrane from over-hardening. You have to employ multiple rinsing cycles to keep your boba juicy.

Syrup Addition and Packaging

Syrup Addition and Packaging

After ensuring quality, you’ll place your popping boba in preserved strawberry-flavored syrup to preserve the taste and prevent the sticking of the boba. Lastly, you’ll pack them in retail cups or other packaging containers to ensure their safe delivery to markets.

5.Can you list machines present in strawberry popping boba manufacturing?

Absolutely! Modern food sectors use specific kinds of machines that craft a delightful popping boba that consumers everywhere love to have. Let’s walk through some handy machines that are involved in strawberry popping boba manufacturing:

Colloid Mill

AIPAK colloid mill

This equipment is often used when you want to crush your compounds into the finest ground particles. It grinds sodium alginate into fine powder to uniformly create a slurry mixture. It is designed with fixed and rotary teeth that produce high-shear forces to disperse and emulsify substances.

Cooker

Cooker

For solubilizing sodium alginate in strawberry juice mixture and calcium chloride/calcium lactate in water, a dissolving cooker is typically employed in strawberry popping boba manufacturing. This machine uses constant agitation to smoothly dissolve materials like sugars and sweeteners.

It runs on steam or electric heating to avoid coagulation or sedimentation of substances.

Cooling and Storage Tank

AIPAK cooling and storage tank

You’ll employ this equipment to decrease the temperature of diverse slurry mixtures (for instance, sodium alginate and juice). The cooling and storage tank is equipped with cold circulatory pipes in which cold water is circulated to minimize the temperature of various mixtures.

Moreover, it also stores multiple solutions for some periods to prevent temperature variations.

Popping Boba Machine

AIPAK strawberry popping boba manufacturing line

It is the star of strawberry popping boba manufacturing and in this unit, vibrant-colored popping beads are crafted with the help of deposition nozzles.

Multi-nozzle deposition system is found in this device that drops the required volume of alginate mixture into a calcium bath. The latter component is gently agitated to ensure a smooth gel covering is formed around every droplet. This results in the formation of popping boba balls.

Some kinds of popping boba machines are also equipped with washing systems or bathing trays (multistage water bath or conveyor-based water) in which popping beads are moved for washing surplus materials.

Packaging Equipment

Final product

Depending upon your preferred packaging style, the packaging equipment could be volumetric cup fillers, sealing machines, and labeling devices. They fill containers, seal them with tight seals or caps, and label barcodes, logos, etc.

6.How can you control the size of popping boba in strawberry popping boba manufacturing?

It is vital to control the size of popping boba in strawberry popping boba manufacturing because it impacts the popping sensation and flavor release when the boba ball pops in the mouth. If popping pearls are too small, then it doesn’t offer you satisfying popping, whereas, if they are too large, then you can’t properly chew them.

So, let’s find out some handy factors that are effective in controlling the size of popping boba in strawberry popping boba manufacturing:

Nozzle Size

AIPAK strawberry popping boba manufacturing machine nozzle size

This aspect offers you the most direct control over strawberry popping boba size in manufacturing. The diameter of the nozzle in the dropping or deposition machine is linked with the boba ball size. Smaller nozzles are used for making smaller popping pearls with a diameter of about 3.5 mm.

On the other hand, the manufacturing of large-sized popping boba (up to 10 mm or higher), necessitates the application of larger nozzles.

Deposition Speed and Volume

Deposition Speed and Volume

You’ll be surprised to learn that the drop size or diameter of strawberry popping pearl increases with the volume of sodium alginate per drip. Also, a slower dripping speed also increases the size of the popping pearl and vice versa.

Viscosity of Alginate Mixture

Viscosity of Alginate Mixture

The thickness of the strawberry juice and sodium alginate mixture also significantly affects the droplet size of popping boba. But how is that possible? Well, a gooier mixture might need more pressure to drip and thus form slightly larger popping balls.

Concentration of Calcium Chloride

Concentration of Calcium Chloride- Picture courtesy: My kit TS

It is a less direct control approach for controlling strawberry popping boba size. Although the concentration of calcium chloride mainly influences the thickness of the membrane of popping pearls, nevertheless, its higher concentration might lead to the quick formation of the outer shell. Which, consequently impacts the final size of popping boba.

7.How to differentiate between strawberry popping boba manufacturing and regular boba manufacturing?

Both these forms of manufacturing produce boba but comparing them is like comparing apples and oranges. They are different in ingredients, equipment, preparation techniques, and more. Hence, for your understanding, we are penning a breakdown of the differences between strawberry popping boba manufacturing and regular boba manufacturing below:

Strawberry Popping Boba Manufacturing & Regular Boba Manufacturing

| Aspects | Strawberry Popping Boba Manufacturing | Regular Boba Manufacturing |

| Ingredients | In this manufacturing, you incorporate strawberry juice, sodium alginate, water, and calcium chloride/lactate. | Tapioca starch and water are two primary ingredients in regular boba manufacturing. |

| Consistency of End Product | The final product in strawberry popping boba manufacturing has a soft gelatinous texture and in the center, it is comprised of strawberry juice. And yes, it certainly pops. | The regular boba produced after production has a chewy, gummy-like texture. |

| Manufacturing Approach | This manufacturing primarily involves the technique of molecular gastronomy called spherification. This is a reaction between sodium alginate and calcium ions. | It involves physical techniques, for instance, dough kneading, rolling, slicing, and streaming. |

| Equipment | It utilizes a few machines like deposition tanks, calcium baths, mixers, and washing units. | A large number of devices, such as planetary mixers, extruders, cutting units, heaters, and dryers are utilized in regular boba manufacturing. |

| Temperature | It occurs at room temperature or in a slightly chilled setting. | It uses high temperatures for boiling and steaming. |

| Cooking | Not required. | Yes, regular boba is prepared through cooking techniques. |

| Dietary Restriction | The strawberry popping boba is vegan and gluten-free. | Regular boba is safe for vegan people but it is not gluten-free. |

8.What is the packaging of popping boba in strawberry popping boba manufacturing?

Brands use various packaging styles for their popping boba products to improve brand image and gain more customers. Moreover, safely packing boba is a failsafe way to retain its flavor and texture throughout its shelf-life. Now, let’s have an insight into various packaging styles in strawberry popping boba manufacturing:

Cups or Tubs

Cups

Have you seen strawberry popping boba cups or tubs in grocery stores or dessert shops? These packaging formats are more widely used than you expected. They are made from clear plastic like PET or PP. Their transparent packaging makes an eye-catching shelf display. Tamper-proof lids are often used for sealing these cups or tubs.

Standup Pouches

Stand up pouches

This pouch style is gaining major traction when it comes to packaging strawberry popping boba. You’ll observe that they are engineered from laminated plastic materials with aluminum foil and can display well on the aisles owing to their flat base. Moreover, due to their resealing closures, they’re ultra-convenient to you and others.

Sachets

Sachet

These are tiny snack-sized champions of strawberry popping boba manufacturing. You can carry them anywhere and even pack them in your kids’ lunchboxes because of their small-sized and lightweight. It holds a single serving of strawberry popping boba and gives you precise portion control.

Large Buckets or Tubs

Large Buckets or Tubs

These are industrial-sized and bulk-capacity containers used for food service or B2B supply. They are extremely durable, stackable, and resealed after use. The resealing options, for instance, screw-top lids or clamped seals provide secure closures and maintain freshness when not being used.

9.What is the shelf-life of popping boba after strawberry popping boba manufacturing?

Shelf life- Picture courtesy: O’S bubble

A sealed strawberry popping boba stored at room temperature is good for about 6–12 months. If you put it in the refrigerator (2–8°C), then you might use it within 12-18 months. Its shelf-life is extended approximately up to 24 months if you keep it frozen at -18°C. However, it is best that you use it within 7-10 days, once you open its container.

If you’re a manufacturer and want to prolong the shelf-life of your strawberry popping boba, then you should include preservatives during preparation, maintain a low pH level in mixtures, store your product in syrup, and pasteurize it to kill off microbes. Moreover, using vacuum-sealed containers is a sure way to have a longer product life.

10.What are the technical challenges in strawberry popping boba manufacturing? How to resolve them?

There is a long list of technical problems that may arise during strawberry popping boba manufacturing and these issues may cause some serious nuisance for manufacturers. However, rest assured, here are some useful tips for you to get rid of these issues in no time.

Variability in Boba Size

Variable sizes

Sometimes, you notice during the manufacturing that the end product has differences in the sizes, which impact mouthfeel, product look, and packaging process. Various factors can be the reason for this issue, such as fluctuations in the flow rate of sodium alginate mixture from nozzles, unacceptable consistency of alginate slurry, and damage or material buildup in nozzles.

Solution

To solve this matter, you must employ precision nozzles in your setup. These nozzles have a consistent diameter, therefore, the liquid flow rate from them is constant. You should maintain the desired viscosity of the mixture using temperature and RPM settings. Schedule a daily cleanup and calibration procedure for your droplet system.

Lastly, for uniform boba creation, use PLC systems, as they automate droplet control.

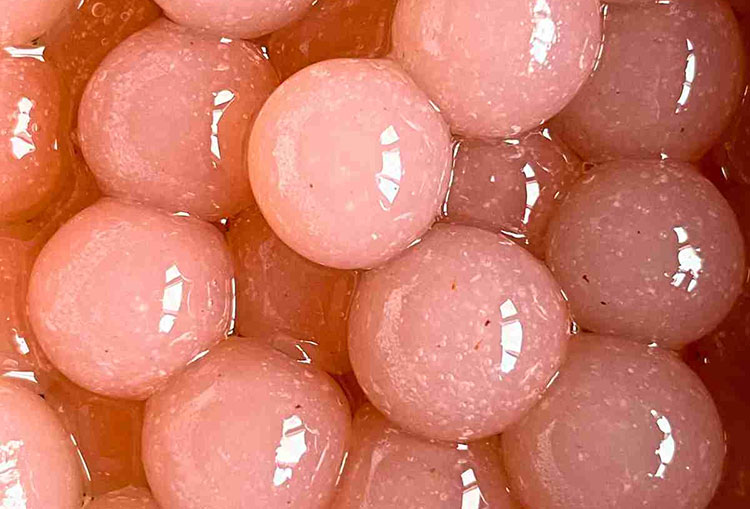

Inaccuracy in Membrane Formation

Membrane of popping boba- Picture courtesy: Hanks tea

It is a most common issue in strawberry popping boba manufacturing. In some events, you’ll get popping boba with shells either too thick or too thin. The thick shells will result in a rubbery texture, whereas, the thin membrane will lead to premature bursting.

More exposure time of droplets to calcium bath, improper quantity of sodium alginate or calcium chloride, or inadequate regulation of pH are the reasons for this problem.

Solution

This issue is easily remedied by following these guidelines, such as using a conveyor-based calcium bath to manage gel formation reaction. Conduct a trial test to identify what concentration of sodium alginate or calcium chloride works best for your strawberry popping boba.

Besides this, your mixture pH should be around 4.5-5.5 for optimal gelation. Also, experts recommend utilizing calcium lactate rather than calcium chloride, as the former facilitates a milder reaction.

Exploding of Popping Boba at Packaging Step

Exploding of Popping Boba at Packaging Step- Picture courtesy: Bubble tea Australia

It can happen when you subject your popping boba to extreme pressure or heat during the packaging process, resulting in its bursting. This issue can stem from unsatisfactory gel texture, mechanical strain on the product during packaging, or high temperature during the pasteurization stage.

Solution

To get this problem sorted, you first adjust the gel texture by controlling sodium alginate concentration. Secondly, you should utilize gentle filling techniques, for instance, gravity or low-pressure pumps for filling popping boba.

Thirdly, change your high-temp pasteurization approach to the cold-fill method. Finally, the best course of action is to perform QC bursting approaches to tweak shell strength.

Separation of Popping Pearl

Separation of Popping Pearl- Picture courtesy: Honest food talk

You might be concerned that your packed popping boba either floats in its syrup or may settle down at the bottom. This problematic issue often reduces product appeal and causes poor syrup absorption.

A number of factors are linked with this matter, for example, a mismatch between syrup and popping boba density, the incorrect proportion of beads-to-syrup, and the presence of air bubbles in popping boba.

Solution

You certainly be thinking about how to solve this separation problem. Well, its solution involves the modification in syrup density using either sugar or thicker so that it will align with the density of the boba.

Another thing is to use a vacuum degassing machine, as it removes trapped air from the popping bubbles. Also, use gentle stirring approaches during the packing step to prevent foaming or the creation of air pockets. It's usually a good idea to stand your popping boba for some time in syrup so that it can properly absorb syrup before going to the packaging stage.

Growth of Microorganisms in Popping Boba

Contamination- Picture courtesy: Pearl Lemon Boba

Gel-like boba with its juicy core is a sure way to foster the growth of microbes if you don’t implement strict hygiene protocols. It can occur because of failure of using CIP systems, weak sealing of containers, and temperature alterations after production.

Solution

The solution to this problem is relatively simple, you just have to install CIP systems for tanks and pipes. Also, make sure to incorporate food-grade preservatives like potassium sorbate in the recipe. Aseptic packaging and tamper-evident seals are quite useful in protecting popping boba from microbes. Always transport and store your popping beads at cold temperatures.

Conclusion

In a nutshell, strawberry popping boba is a trendy concoction for your drinks and desserts that is prepared by following simple approaches at home; however, its industrial manufacturing requires careful control of operational steps and customized packaging. Manufacturers can effortlessly deliver deliciously juicy popping boba to markets by understanding primary ingredients, high-tech equipment, and technical problems involved in strawberry popping boba manufacturing. If you’re an aspiring business owner and are interested in discovering the absolute best popping boba manufacturing machines for your setup, then we invite you to contact AIPAK. Just let us know how can we help and we’re happy to assist.

Don't forget to share this post!

Popping Boba Machine Related Products

Popping Boba Machine Related Posts

Popping Boba Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine