Cartoning Machine For Blister: The Complete Buying Guide In 2025

Why is carton packaging an essential packaging method in the pharmaceutical industry? Because it is safe, reliable, environmentally friendly and convenient. Whether in various food, medicine, daily necessities and other industries, cartoning machine can bring you a lot of surprises. Not only blister packs, but also cotton swabs, ointment tubes, syringes, gloves or other medicines.

Whether you choose horizontal or vertical type, the use process, types and advantages of cartoning machine are similar. If you are very interested in this charming equipment, you can read this article carefully. It can bring you endless inspiration. Start your exploration!

1.What Is Cartoning Machine For Blister?

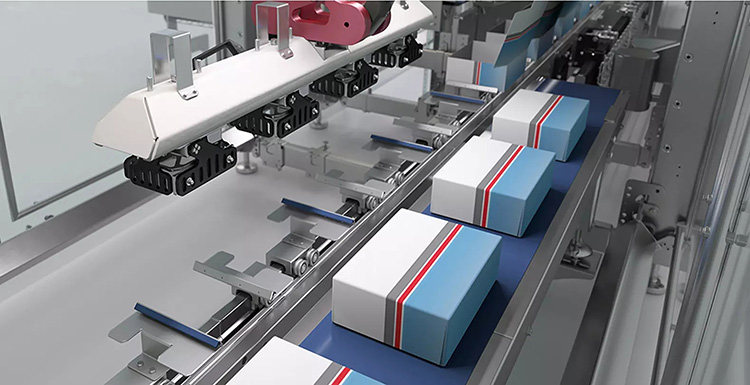

AIPAK cartoning Machine For Blister

Cartoning machine for blister is a highly efficient and multifunctional packaging equipment widely used in various industries such as food, medicine, daily necessities, cosmetics, and electronic components. It can load various products into cartons, and then print batch numbers, seal, label, etc.

In addition to blister, it is also suitable for packaging various pills, cotton swabs, hoses, syringes, gloves or other medical supplies. By packaging these products in cartons, it not only improves the shelf life of the products, but also facilitates subsequent transportation and storage.

2.Except For Blisters, What Else May Cartoning Machine For Blister Pack?

Cartoning machine for blister is powerful and flexible. Except for blisters, it can also pack:

Tubes

Tubes-sourced: behance

Whether it is a variety of hoses or hard tubes, cartoning machine can be flexibly applied and packaged. Including various creams, ointments, gels, lotions and other products. It can provide you with suitable, economical and practical carton packaging, so that the products are not contaminated and have a longer shelf life.

Vials

Vials-sourced: adelphi

Vials are specially used to hold various liquids, latex textures, creams and semi-solid products. Among them, it is most widely used in the pharmaceutical industry. Cartoning machine for blister is suitable for carton packaging of vials.

Ampoules

Ampoules-sourced: igboxes

Various types of pharmaceutical ampoules products can be protected by carton packaging, which is not easy to volatilize and pollute, and is convenient for subsequent transportation and storage.

Bags, sachets, pouches

Bags, sachets, pouches-sourced: yellowimages

Through the secondary carton packaging of various bags, sachets, pouches packaging products, it can further help beautify and protect the appearance of the products.

Bottles, trays

Bottles, trays-sourced: dairyfoods

Nowadays, more and more bottles and trays are packed with cartons for better display and performance. Except that, the packaging of cartons is used for storage and transportation.

Insulin needles

Insulin needles-sourced: saveritemedical

Insulin needles are specially used for diabetic patients to inject insulin. Most insulin needles on the market are packaged by cartoning machines. Through carton packaging, insulin syringes and needles can be packaged safely and conveniently for storage and transportation.

3.What Are The Types Of Cartons For Blister Packaging?

There are two main types of cartons for blister packaging. One is paperboard folding cartons, and the other is corrugated folding cartons.

Paperboard folding cartons

Paperboard folding cartons-sourced: zeepackaging

Paperboard folding cartons are usually made of a single layer of paperboard. It can be used for paper box packaging of most products in life. Because it is easy to cut and shape, and light in weight, it is widely used in various industries.

Corrugated folding cartons

Corrugated folding cartons-sourced: cactuscontainers

Corrugated folding cartons are made of two layers of paperboard. Compared with paperboard folding cartons, it is thicker and stronger. Because of the inter-layer in the middle, it has excellent strength and is very suitable for packaging various heavyweight products.

4.What Are The Carton Styles For Blister Packaging?

Carton styles for blister have various folding methods, and all of them can be automatically and efficiently packaged by cartoning machines. Among them, they are classified as follows:

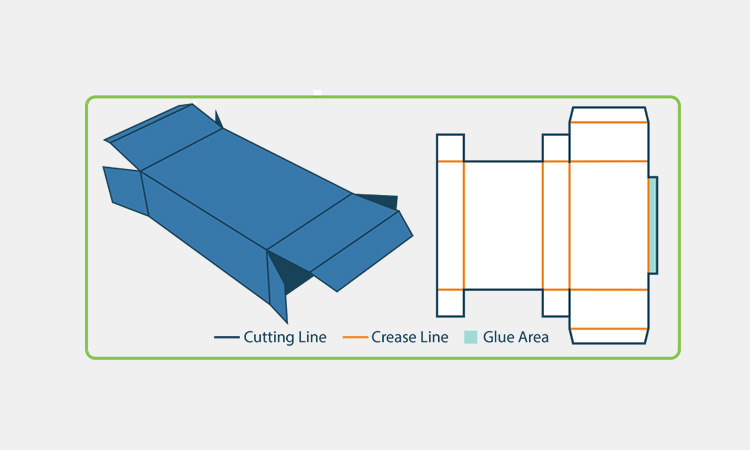

Straight tuck box

Straight tuck box-sourced: conquestgraphics

Straight tuck box is the most common carton style in the market. It is widely used in various industries. Through the top and bottom closing plates, it can directly insert the product into box from front to back, and fix it by sealing. It is simple and efficient, and is the most commonly used carton packaging method.

Reverse tuck box

Reverse tuck box-sourced: conquestgraphics

It is slightly different from the straight tuck box. It can also insert the product into the box from front to back. But the difference is that its front and back seals are in opposite directions.

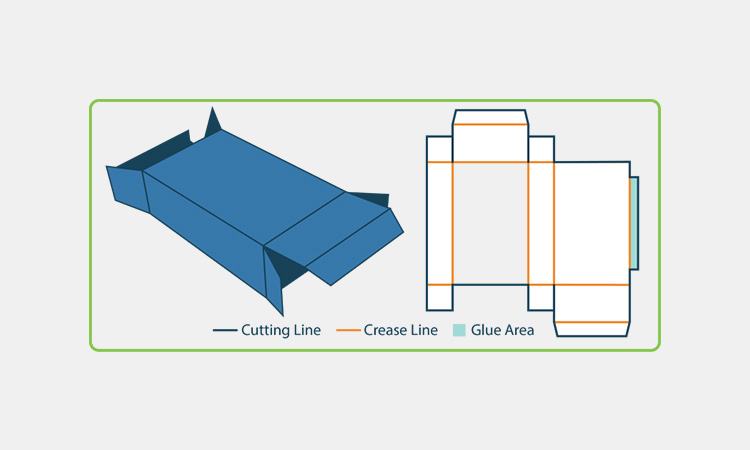

Lock bottom box

Lock bottom box-sourced: conquestgraphics

Lock bottom box is specially designed for packaging expensive and high-priced products. It mainly pushes the bottom cover plates into each other to form a solid base, thereby wrapping the product so that the product will not be easily torn or leaked due to being too heavy.

Crash bottom box

Crash bottom box-sourced: fineprintltd

Crash bottom box can provide a solid anti-collision base for your product. It can not only facilitate the standing of the product, but also store and support heavier products.

5.What Are The Applications Of Cartoning Machine For Blister?

Cartoning machines for blister are suitable for almost all industries on the market. These include

Pharmaceutical industry

Pharmaceutical industry-sourced: oliverinc

The most widely used cartoning machine is for packaging such as blisters, injections, and ampoules. It is also suitable for accurate and efficient packaging of medical products of other specifications and sizes, such as disinfectants, gloves, protective clothing, medical consumables, etc.

Food industry

Food industry-sourced: modpac

Snacks, seasonings, beverages, health products, etc. in bags, bottles, cans, and pouches can be quickly and efficiently packaged in cartons by cartoning machines. Through the secondary packaging of cartons, the appearance of the product can be improved. Customers can be attracted, and it is convenient for subsequent sorting and storage.

Cosmetics industry

Cosmetics industry-sourced: ctfassets

Whether it is the frequently used toiletries in life, or the cosmetics that most women often use, as well as personal care products, the cartoning machine can provide accurate insertion and boxing. It can handle all kinds of bottles, tubes, cans or bagged products you need at the same time.

Household industry

Household industry-sourced: oliverinc

Whether it is frequently used detergents, soaps, cleaning products, or cleaning tools, the cartoning machine can be used to effectively package and provide you with accurate printing and labeling.

Electronics industry

Electronics industry-sourced: ibexpackaging

Various circuit boards, connectors, cable parts, screws, etc. can be quickly packaged in cartons by cartoning machines to ensure product integrity and avoid damage to electronic products during transportation and storage.

6.What Can Cartoning Machine For Blister Bring You?

The cartoning machine for blister can bring you:

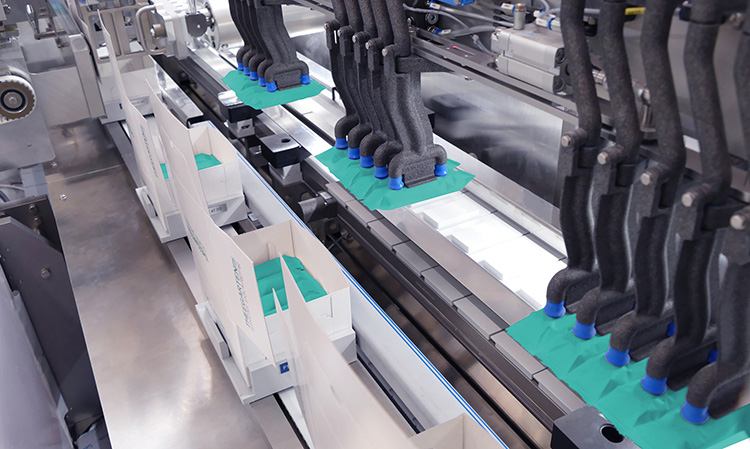

Automatic cartoning

Automatic cartoning-sourced: koerber-pharma

Without manual intervention, the cartoning machine for blister can realize the steps of efficient product sorting, cartoning, sealing, printing and labeling. It can save you costs and energy.

Strong adaptability

Strong adaptability-sourced: theegarten-pactec

Whether it is the pharmaceutical industry, food industry, cosmetics industry, or electronics industry, it can be applied to the carton packaging of almost most products on the market, and can be applied to products of different weights to meet all your packaging needs.

Precise control

Precise control-sourced: rotzingergroup

Cartoning machine for blister can provide independent precise control according to the different products you need to package, and provide complete and fast carton packaging for all your products.

Improve efficiency

Improve efficiency-sourced: dms

Compared with others who are still using manual or semi-automatic cartoning equipment, the fully automatic cartoning machine can simplify the packaging process of your items, improving overall efficiency, and thus shorten the packaging time.

Versatility

It can not only handle blister carton packaging of various shapes and sizes, but also flexibly adjust various configurations and parameters, and customize according to different products, with high flexibility.

7.What Are The Types Of Cartoning Machine For Blister?

According to the overall design structure of cartoning machine for blister, it can be divided into two types: vertical cartoning machine and horizontal cartoning machine:

Vertical cartoning machine

Vertical cartoning machine-sourced: paxiom

Vertical cartoning machine refers to a model in which the packaging carton of the item enters the carton in a vertical direction. It is also generally called a rotary cartoning machine. When the carton is placed vertically in the cartoning machine, it will be folded into a fixed shape, and then the item is inserted into the carton, and finally packaged, labeled and printed.

Horizontal cartoning machine

Horizontal cartoning machine-sourced: googleusercontent

Horizontal cartoning machine refers to a model in which the packaging box of the item is fed into the cartoning machine in a horizontal manner, and the product is also directly inserted into the packaging box in a horizontal manner. It is more widely used and convenient. However, this type of packaging machine will also occupy a large area and have higher cost requirements.

8.How Does Cartoning Machine For Blister Work?

The working method of the cartoning machine mainly includes the following steps:

Working principle of AIPAK cartoning machine for blister

Carton feeding

The number of product boxes is calculated in advance and placed on the storage rod of the box. When the device detects the box, the push rod will push the box into the track for product packaging.

Product feeding

The product you need to package is laid on the track manually or automatically. After the device detects the product, it will move it to the pushing area.

Carton fixing

The guide rails and clamps of the device will fix the carton and fold and seal the bottom.

Product box loading

When the bottom of the carton is sealed and fixed, the product will be pushed into the carton by the guide rails and push rods.

Carton sealing

When the product is pushed into the carton, the top of the carton will be automatically folded and sealed by the guide rails until the product is completely wrapped in the carton and sealed.

Number printing

The packaged product carton will be printed with the product batch number, production date and other relevant important information.

Unloading

The packaged and labeled products move along the conveyor belt to the next stage.

9.What Are The Main Parts Of Cartoning Machine For Blister?

The cartoning machine is stable and durable, and each of its components is carefully designed, produced, tested and installed. Its main components include:

Main parts of AIPAK cartoning machine for blister |

|

| Control panel | The control panel can provide you with fully automatic product carton packaging program settings and adjustments. Whether your equipment is starting to work or in operation, it can adjust various parameters for you anytime and anywhere. |

| Electric motors | Electric motors can provide continuous and stable power for your equipment during work, improve the speed and efficiency of your product packaging, etc. |

| Carton tooling system | It can help you fix and fold cartons of various shapes and sizes, and perform various cutting, folding and forming according to your packaging requirements. |

| Safety system | Equipped with advanced safety systems and sensors, the safety system can not only improve the safety of your operation process, but also improve the efficiency of the equipment. |

| Transport system | This part is mainly composed of a conveyor system, guide rails and rollers. It can move and transport the products you need to package and the cartons you need to move according to the trajectory you need. |

| Chute | Chute helps you eject and unload packed cartons. |

10.How Does Cartoning Machine For Blister Performs Accurate Filling And Blister Placement?

The secret of cartoning machine for blister performs accurate filling and blister placement is:

Equipped with professional sensors

Equipped with professional sensors-sourced: cloudbf

Cartoning machine for blister is equipped with professional sensors that can help you accurately detect and locate the number and position of cartons and products, helping you to accurately place and insert products and cartons. The whole process maintains the integrity of products and packaging materials.

11.What Are The Closing Techniques In Cartoning Machine For Blister?

The closing technique standards of cartoning machines vary, but the most common closing procedures include:

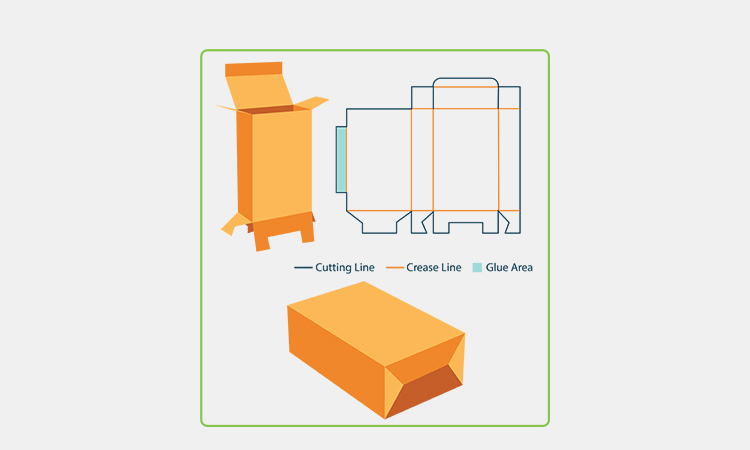

Folding

Folding-sourced: jochamp

When you feed the carton to be packaged into the machine, the guide rails and push-pull rods of the machine will fold and cut your carton according to the parameters you set. This allows the carton to fit your product perfectly, thus completing the perfect packaging.

Hot glue sealing

After completing the carton packaging, if you want to strengthen the seal of the carton, the machine can use a smearing hot glue to form a permanent seal. This design is more suitable for expensive and heavy products. It can provide a durable and strong seal for your product.

12.Can The Cartoning Machine For Blister Integrate With Other Packaging Line Equipment?

The cartoning machine for blister is suitable for any product line that needs carton packaging. For blister packaging, the products it can connect include:

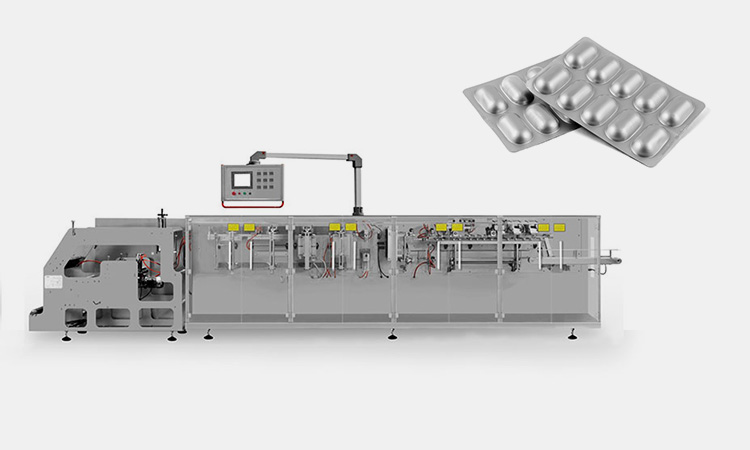

Blister packaging machine

AIPAK blister packaging machine

The blister packaging machine is a device specially used for blister packaging in various industries. Its main application industry is the packaging of various pills and capsules for pharmaceuticals. The main working principle of this equipment is to make a cavity aluminum foil plate by thermoforming or cold compressing the thermoformed plastic or cold-formed aluminum film. Then the various pills and capsules that need to be filled are filled and sealed.

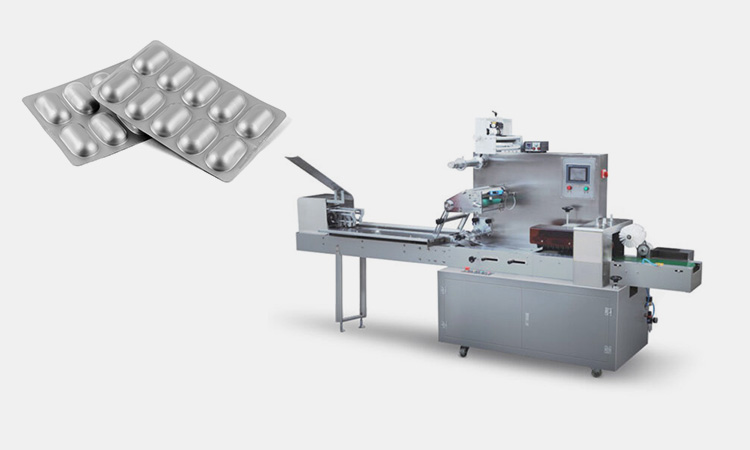

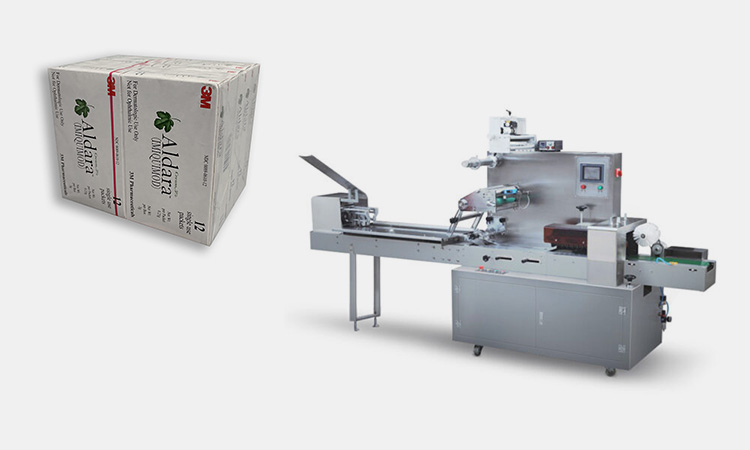

Flow wrapping machine

AIPAK flow wrapping machine

Flow wrapping machine, also called as horizontal flow wrapping machine, is a continuous packaging machine specially used for products in various industries, and is mainly suitable for solid products. It mainly uses plastic film to horizontally seal the product with a horizontal back seal. Flow wrapping machine can wrap the blister in plastic to facilitate the subsequent carton packaging.

Premade pouch filling machine

AIPAK premade pouch filling machine

Premade pouch filling machine is a popular solution for pouch packaging in the pharmaceutical and food industries. It is flexible, adaptable, and compatible with various products. This machine is also used for blister packs. Although it is not common in the pharmaceutical industry, it is also a viable pouch packaging solution for blister packs.

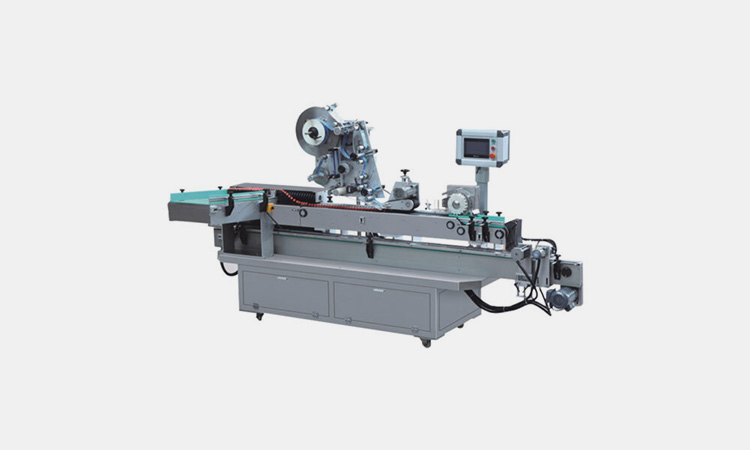

Automatic labeling machine

AIPAK automatic labeling machine

Automatic labeling machine can fully or semi-automatically label various products that need to be labeled. Whether it is a carton, bottle, can or packaging bag, it can provide a stable, accurate, efficient and unique labeling process and can directly print labels. Make the label stable, durable, clear, intuitive, etc.

Cellophane overwrapping machine

AIPAK cellophane overwrapping machine

Cellophane overwrapping machine, also called as three-dimensional transparent film packaging machine, specializes in packaging various carton or box products using BOPP film or PVC plastic film. It is widely used in various cosmetics, pharmaceuticals, food, health products, chemicals, agricultural products and other industries. Cigarettes are one of the most commonly packaged products.

Carton packing machine

ALLPACK carton packing machine

Carton packing machine, also called as carton sealing machine or carton sealer, can pack various products in cartons efficiently and with high quality. In addition, it can improve the accuracy of packing and save enterprise costs. This equipment can provide customized packing solutions and services according to customers' products.

13.Does Cartoning Machine For Blister Offer Special Packaging Requirements?

Cartoning Machine For Blister Offer Special Packaging Requirements-sourced: epackprinting

Sure, cartoning machine for blister offers special packaging requirements. Most fully automatic cartoning machines are able to meet customers' various customized carton packaging requirements. It can adjust the carton size and pack according to the blister size you provide.

14.What Are The Maintenance Process For Cartoning Machine For Blister?

Maintenance Process For Cartoning Machine For Blister-sourced: safetyculture

Cartoning machine for blister is very important for any industry. It not only brings protective and high-quality carton packaging to products, but also improves efficiency and reduces costs for your packaging industry. Its maintenance process are:

Daily cleaning

After using the equipment, clean the residue, dirt, dust and debris inside and outside on a daily basis;

Use a specific disinfectant to wipe the surface of the equipment and disinfect it regularly;

Specially check the material inlet and outlet;

Natural air drying;

Regular lubrication

Regular lubrication-sourced: santiemidwest

In order to reduce the wear between the equipment parts, regularly check, repair and lubricate the key parts of the equipment;

Use a specific lubricant to deeply lubricate the key parts according to the manufacturer's requirements;

Key lubrication points include bearings, chains, gears and slide rails;

Electrical check

Electrical check-sourced: echomachinery

Regularly complete the electrical inspection of the cartoning machine to ensure the smooth operation of the equipment;

Focus on checking the electrical connection wires and connection points of the equipment to check whether there are any broken or corroded wires;

Use tools to detect whether the voltage is stable;

Mechanical inspection

Mechanical inspection-sourced: competenz

Check and record whether the equipment is running smoothly and whether there is any noise or vibration during each operation of the equipment;

Debug the equipment before use and conduct a trial run;

15.How To Troubleshoot The Cartoning Machine For Blister?

Whether in daily use or later maintenance, cartoning machine for blister will also encounter problems. Let's briefly discuss their solutions.

Troubleshoot of Cartoning Machine For Blister-sourced: knowmax

| Problems | Reasons | Solutions |

| Packing carton jam | The main reason for this problem is the material problem of the carton. | Choose carton raw materials that are compatible with the equipment;

Choose the corresponding cartoning machine according to the thickness of the carton; When the equipment is worn, especially the push rod and conveyor belt, regular maintenance, debugging and replacement are required. |

| Glue leakage | Glue leakage will cause the product to be poorly sealed at the end, causing a series of quality problems. The cause of this problem is that the glue spray series is blocked or malfunctioning. | Adjust the temperature of the glue spray equipment;

Clean or debug the glue spray system; If the equipment fails, repair and replace the glue spray system in time. |

| Failure to insert brochure | The reason for this problem is that the thickness of the paper box is too thick or too thin, resulting in the guide rail or push rod detection error, so the brochure is not inserted completely; | Check and calibrate the placement position of the brochure in advance;

Choose the paper box material with appropriate thickness; Test run in advance to check the smoothness of brochure insertion. |

Conclusion:

Blister carton packaging technology is constantly improving, and the scope of use is constantly improving. More customized services are also updating and improving. Through this complete buying guide of cartoning machine for blister, you may get all the professional knowledge of equipment operation, maintenance, cleaning and purchase. If there are more you want to know, please come to AIPAK now!

Don't forget to share this post!

Cartoner Related Posts

Cartoner Related Products

Cartoner Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine