Intermittent Cartoning Machine: A Complete Guideline In 2025

"Are You Being Held Back by Your Packaging Process? “This Is How to Fix It."

Have you ever thought that how the industries packed such a huge amount of products in less time with high precision? It’s only possible by an amazing machine which is intermittent cartooning machine. In 2025, industries are exploring for more efficient ways to package products in quicker and less wasteful way with improved quality. Intermittent cartoning machines can help with that! These machines are very helpful in providing accuracy, high productivity and flexibility, preventing misalignment and error free products, which are revolutionary factor for changing the fate of industry.

In this complete buying guide, you’ll know about all the important features of machine and professional advice on selecting of this machine. To find out how an intermittent cartoning machine might improve your packaging, keep reading!

1.What is an intermittent cartoning machine?

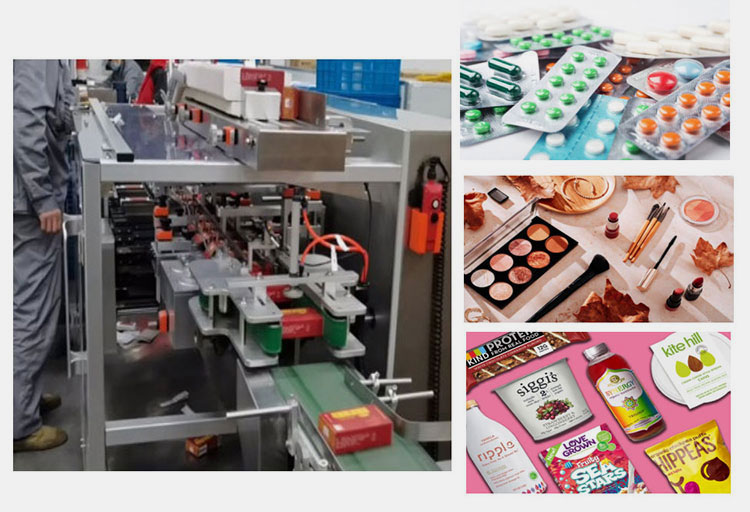

Intermittent cartoning machine-Picture Courtesy: utmostusa

An intermittent cartoning machine is a high technology packaging machine works in a sequential manner. It works in step by step, which range from creating plain carton sheets, to forming carton boxes, and then loading them with various products, securely seals them with high power glue and in last, carton discharging. This machine work best in various industries like medical industry, food industry, cosmetics and skin care industry and pharmaceutical industry. It work best for all sizes cartons.

2.What is the main difference between an intermittent cartoning machine and a continuous cartoning machine?

It is important to understand the key differences between intermittent and continuous cartoning machine while buying. Here are some of the differences. Have a look!

| Feature | Intermittent Cartoning Machine | Continuous Cartoning Machine |

| Operation | Stop-go motion | Continuous, smooth motion |

| Speed | Low to moderate speed | Higher to very higher, suitable for large-scale production |

| Precision | Higher accuracy in product placement | Focuses on speed over precision |

| Product handling | Suitable for Irregularly shaped, or varying sizes | Best for uniform, rigid products |

| Production output | Low to medium | High-speed, large-scale |

| Complexity | Smoothly operate and maintain | More complicated, requires skilled operators |

| Customization | Use for various carton sizes and shapes | Limited customization due to high-speed constraints |

| Cost and Maintenance | Lower cost and Simpler Maintenance | Higher cost but more cost-effective for mass production |

| Footprints | It requires less space | It requires more space |

3.What industries employ machines for intermittent cartoning?

Intermittent cartoning machine is used across various industries. This machine is the best option for various product packaging because it handle various size of cartons and have high accuracy. Here are a few usage particular to the industry:

Pharmaceutical Industry:

Pharmaceutical Industry- Picture Courtesy: Gil Pack

You often visit pharmacy and see a pack of delicately packages of medicinal products, this is all possible due to intermittent cartoner machine. The uniqueness in maintenance friendly and high precision make this machine a perfect choice for packaging of pharmaceutical bottles and prepare various cartons. This machine ensures the germfree packaging and proper batch number labelling. The beautiful packaging of various pharmaceutical products makes them a high demand in the market.

Cosmetics & Personal Care:

Cosmetics & Personal Care- Picture Courtesy: Popsugar.com

You see an aesthetic fragrances bottles and skincare boxes on store shelves; thanks to intermittent cartoner application. It helps in packaging of lipsticks, lotions, eye shadows and skincare in a very delicate way, by ensuring the maintenance of texture and appearance of the product. This ensures that products reach markets in secure way and meets the high requirement of the consumers.

Medical & Healthcare:

Medical & Healthcare-Picture Courtesy: LABTAG.com

Intermittent cartoner machine is suitable for all shaped products especially suited for irregular shaped products. So, in the packaging of various medical products i.e; syringes, diagnostic kits, and supplements, intermittent cartoning machine do its wonderful job by ensuring no contamination during storage.

Food Industry:

Food Industry - Picture Courtesy: Sealstrip

The intermittent machine is stop-and-go machine so it works in efficiently and satisfactorily manner. It fills various beverages and pack various foods in food industry. This makes them fresh and free of germs. In this way, it is suitable choice for food businesses because it manage different product forms and carton sizes.

Oral and Safety Products Industry:

Oral and Safety Goods-Picture Courtesy: Green People

Intermittent cartoning is a versatile and safe process, it ensures that everyday necessities like razors, detergents and toothpastes etc. should packed in a risk-free and in desirable manner. As it automatically place and seals the items so in a very short period of time, it can pack thousands of cartons which is good for various businesses and for consumers.

Electronics Industry:

Electronics industry-Picture courtesy: Maripak

For electronic appliances, its safety is very important. To reduce the possibility of damage and ensure its safety, intermittent technology performs it job in an amazing way. It pack charges, batteries and headphones in a strong and durable boxes and improving the overall quality of the products.

4.What are the main types of intermittent cartoning machine?

You might be wondered why some intermittent cartoning machines works best and runs smoothly while others face severe breakdown? This secret lies within choosing the correct machine for unique packaging of products and for your business.

So, for selecting the right intermittent machine for your business, different types of cartoning machine as discussed as below:

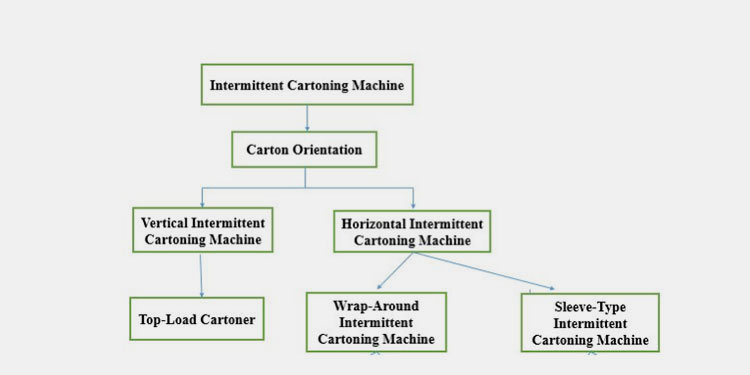

Flowchart of types of intermittent cartoning machine

Based on Carton Orientation

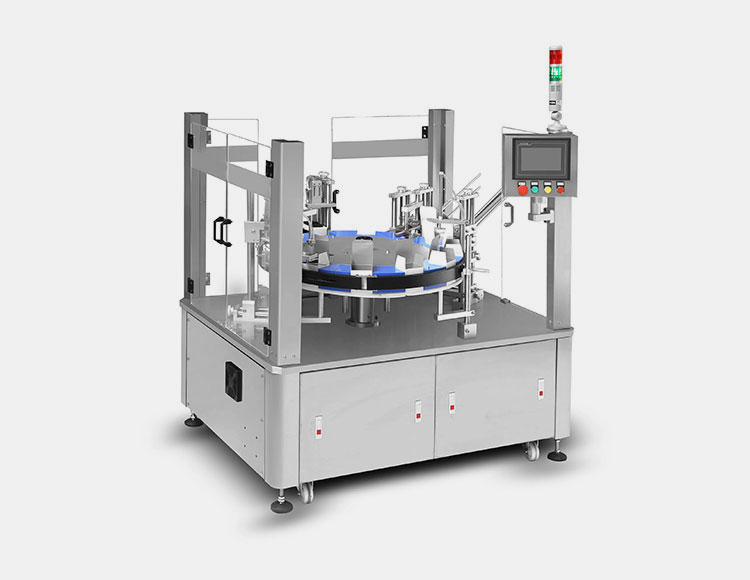

Vertical Intermittent Cartoning Machine

Vertical intermittent Cartoning Machine

The vertical intermittent cartoner work in stop-and-go sequence where the cartons remain stationary and the products are placed vertically into the cartons. The cartons are then sealed by hot-melt application. You can use it for the packaging of tea bags, vials, shampoos and electronic devices.

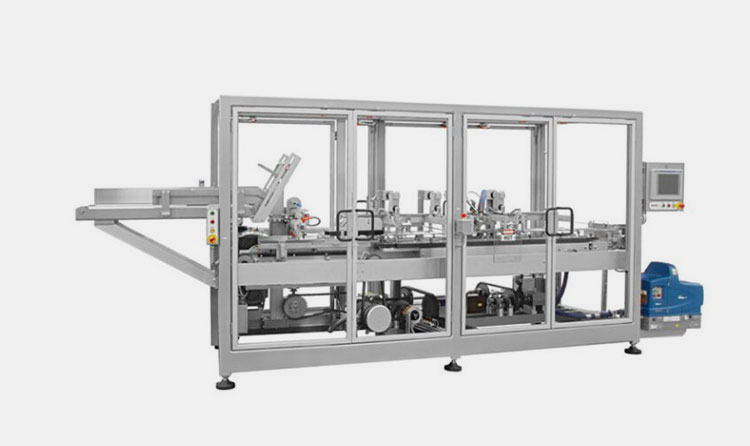

Horizontal Intermittent Cartoning Machine

Horizontal intermittent Cartoning Machine-Picture courtesy: AIPAK Pharma

You see the blister packs and tablets packaging in a captivating way, which ensures the safety of these products. Thanks to horizontal intermittent cartoning machine which perform its function. In this machine, cartons are transported horizontally and product are placed from side in these cartons. Then, the machine folds the top and bottom flaps and then by using high quality glue, seal the carton. The sealed carton is then placed in conveyor for further printing of expiry date and barcode etc.

Based on Product Insertion, Carton style and Enclosure type:

Top-Load Cartoner ( Vertical intermittent Cartoning Machine)

Top- load intermittent Cartoning Machine-Picture courtesy: DirectIndustry

This is the type of vertical intermittent machine in which the products are placed in the cartons in vertical position before going into the next station. This machine is suitable option for irregular shaped products like snacks and frozen foods and fruits.

Wrap-Around Intermittent Cartoning Machine

Wrap-Around Intermittent Cartoning Machine-Picture courtesy: Atlanta Packaging

This is the type of horizontal cartoner technology. This machine operates in different steps, ensuring safe and compact packaging. It picks flat sheet of cartons and wrap around the products ensuring secure fit. Then, it sealed it by using mechanical locking systems like slots. It provide glueless sealing which reduce the cost and also creates strong and compact cartons.

Sleeve-Type Intermittent Cartoning Machine

Sleeve-Type Intermittent Cartoning Machine-Picture courtesy: Serpa Packaging Solutions

This is also the type of horizontal intermittent cartoning machine which operates in steps. This type of machine picks flat sheet of cartons and fold around the products in U-shaped or you can say, it is partially packaging of products procedure, which ensure the visibility of products in cartons. This machine is best option for the packaging of beverage bottles and medicinal bottles.

5.How intermittent cartoning machine works?

Working steps of intermittent cartoning machine

Have you ever wondered how millions of product, we use in our daily life, are package in different cartons with high precision? Do you want to know about this?

It is crucial to know the working principle of intermittent cartoner machine. Let’s know that how intermittent cartoning machine works. Keep reading!

| Flat cartons loading | In the first stage, you have to supply cartons on the transport system. Here, it is important to load proper flat sheets in order to prevent misalignment. |

| Carton erection | At this stage, sheets are lifted by grippers through suction cups. With the help of mechanical arms, cartons are opened into 3-D shape, and then you’ll find fully erected cartons placed on carton transport lugs. |

| Product insertion | The desired packaging products, by pusher mechanism, are pushed into the open cartons. The insertion method of products depends upon the products to be pack. E.g. if you want to pack blister packs, then it’ll be done by gravity-feeding method. At this step, leaflets of products are also inserted which have compulsory information related to products. |

| Cartons closing | The cartons closing stage involves the precise flap folding and sealing. The sealing method involves glue, friction locking mechanism and tape sealing. It ensures consumer safety and ensuring cartons intact during storage and transportation. |

| Cartons discharge and collection | In the final stage, you’ll collect your desired products and this task is done by this machine which reduce labor costs and meets the high demand of your business. |

6.What are the parts of intermittent cartoning machine?

Intermittent cartoning machine perform its wonderful job by integrating electronic, mechanical and pneumatic components. These components work in synchronized way to ensure products safety, packaging quality, error free packing and producing high quantity in less time with high accuracy.

For your convenience, let’s enlist some of the basic parts of this equipment, given in the table below:

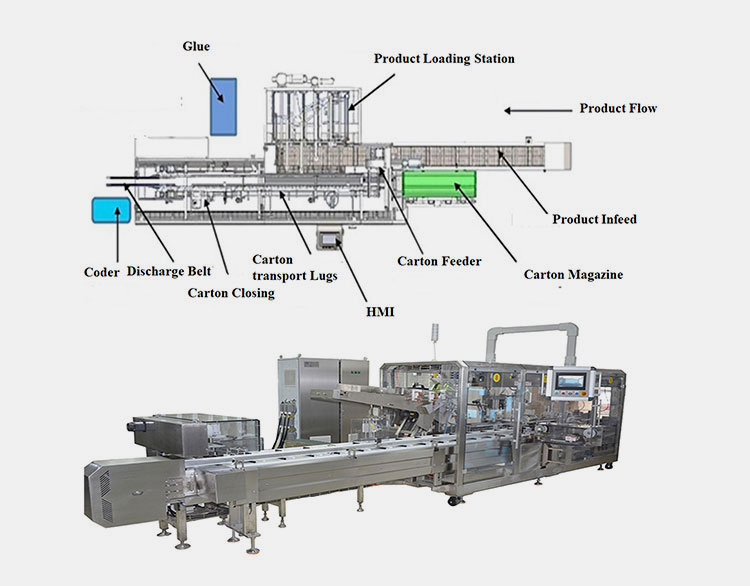

Parts of intermittent cartooning machine

| Product loading station (Conveyor) | The product loading station is a section of this machine where you can introduce products into the cartons either manually (used for small bottles) or automatically by the machine. The conveyor portion is responsible for your products for moving through different stations and prevent jamming by using adjustable tracks. |

| Product infeed Station | The product infeed station is responsible for proper positioning of products before placing in cartons. It has sensors which prevent misfeeding of products into the cartons. |

| Carton Magazine | It is the section where storage of different sized cartons are present and they eliminate pre-cut and flat cartons before used for the packaging. In this portion, risk of misfeeding is very low because it automatically slide down to the feeder. |

| Carton feeder | Carton feeder is the portion where it picks up carton one by one, open them by gripper and transfer for further processing. It is very important step because any failure in carton opening can cause system stoppage. |

| HMI touch Screen | It is the display screen of intermittent cartoning machine which controls the whole processes taking place in machine. It can track size and sealing pressure of carton. You can start and stop this machine by HMI screen. |

| Carton Transport Lugs | It is the portion where proper position of carton is ensured by ensuring correctly closed the carton. This will stabilize your cartons and preventing from falling and any damage. |

| Leaflet Insertion | Some products documentation is essential so, this section folds and inserts the leaflet of the product before sealing. |

| Carton sealing Unit | After completing the process, carton is sealed either by using glue, hot-melt mechanism or by mechanical pressure. Hence, compression rollers are pressed over the closing end of the cartons until glue settled. |

| Discharge and collection Belt | This area discharge sealed cartons out of cartoning machine and further proceed the cartons into the collection area. In collection area, you’ll find your grouped cartons according to their batch number. |

| Coder | This station ensures the printing of important information’s like product expiry date, batch number and QR codes on the products and cartons. |

| Glue station | Hot-melt or cold-glue used for the compact and durable packaging. |

7.What are the major benefits of incorporating an intermittent cartoning machine?

With the increasing number of population and their needs, businesses are looking for adopting a smarter solution for their products packaging with high precision and accuracy. And how is it possible? This job is only possible by using intermittent cartoning machine.

You’ll know about the major benefits of this machine in this article. Don’t stop, keep exploring!

Product protection

Product Production

For the development of businesses and for the satisfaction of customers, products protection is the crucial factor. This cartoner, which performs in stop-and-go motion, works with high accuracy and ensures the proper positioning of products before placing in cartons. The sensors in this machine help detect the damage products before loading. This is the perfect solution for delicate bottles like vials and medical ampoules.

Smooth operation

Smooth operation- picture courtesy: Syntegon.com

Unlike other cartoning machine, intermittent cartoner works in stop-start manner which ensures the securely insertion of products, insertion of leaflets which is very important for pharmaceutical products and placement of product accurately. So, in this manner, this machine operates smoothly. This ensures the placement of all types of products whether it is irregular in shape or delicate products.

Versatility in Carton Handling

Versatility in carton handling

Intermittent cartoner handle all types and sizes of cartons so it is suitable option for all type of your business. It is suitable for packaging of pharmaceutical, food, electronic and cosmetic products. It can also seal cartons by various methods like glue-sealed and lock-up method.

Improved Quality Control

Improved quality control

Have you ever wondered why the exact product sealed in proper carton? This is due to intermittent cartoner because it has sensors which detect misalignment and reducing the risk of faulty packaging. It also detect and inspect the product presence in proper cartons.

Reduce Product wastes

Reduce product wastes

This machine can handle your cartons efficiently. It can eliminate damaged cartons and ensuring only correctly loaded cartons proceed for sealing. It can also reduce labor costs and energy.

8.What kind of maintenance does an intermittent cartoning machine need?

Think of machines which is game changer for industries, need just few minutes for its smooth functioning. For its efficient working and longevity of machine, you must have keep an eye on machine for its amazing job. For your convenience, we’re discussing some basic maintenance steps:

Maintenance of intermittent cartoning machine

| Cleaning | You have to remove dust, wipe down pushers, lenses and conveyor belt on daily basis to ensure smooth functioning of this machine. On weekly basis, clean dirt buildup in chains and rollers to prevent clogging. Once in a month, if you are handling the sensitive products like food, pharmaceutical products, sanitize the machine thoroughly. |

| Lubrication | You must be aware that it has movable components like grippers, suction cups and chains, so, add lubricants (oil, grease)in order to maintain smooth functioning. It must be remember that before applying new grease, remove old lubricant residue to prevent clogging. You have to inspect the leaks as well. |

| Electrical inspection | Regular check the control panel. Inspect all wiring in the system. In a month, you have to completely inspect electrical cabinet to check connectors as well as circuit breakers for any sign of corrosion and overheating. |

| Mechanical inspection | While operating, if you observe irregular vibrations or sounds, it could indicate misalignment so, inspect bolts, pushers, rotatory arms and conveyors. Replace any component like rollers etc. if noticed any wear. |

| Operator training | Operatormust have complete knowledge of stop, start and pausing of machine. Provide training to recognize and resolve any fault in the machine. |

| Preventive maintenance | You should must update and adjust machine system to maintain constant operation to ensure longevity of machine and operate efficiently. |

| Record keeping | You have to assign responsible team members to investigate machine performance and oversee records. Identify recurring issues and think for the implementation of long term solutions. |

9.What problems do intermittent cartoning machines typically have?

Before starting a machine, are you sure intermittent cartoning machine is ready to package millions of your products? Let’s explore the most common issues, their causes and possible solutions, you might face!

Problems in carton feeding, carton jamming and Inconsistent Carton Sealing

Carton Feeding Issues

| Problem and Causes | Solutions |

| One of the mainproblem is cartons not entering station. If you encounter this problem, then your productions becomes inactive.

The cause may be cartons misalignment in magazine. |

To handle this problem, clean the suction cups and adjust the magazine for smooth cartons flow. Use correct size and high quality of cartons. |

Cartons Jamming

| Problem and Causes | Solutions |

| You may encounter carton jamming in machine because it is one of the frequent headache while operating the machine. The packaging boxes get stuck in the conveyor. To know about this problem, you have to know about the cause.

Causes of this problem may worn out pushers, too weak or too rigid cartons and incorrect carton sizes. Defective equipment can also be the cause. |

Carton jamming is blocking the flow of cartons and everything seems to stop. To ensure the flow again, you have to check the conveyor first, you have to check the quality of cartons then, and inspect the guide rails to slide the cartons smoothly. Furthermore, replace the loose parts of machine to do their job perfectly. |

Inconsistent Carton Sealing

| Problem and Causes | Solutions |

| Isn’t it frustrating that someone is buying your product and it’s not properly sealed? The glue is not properly bonded and leads to open package.

The possible causes are clogging in glue nozzle, incorrect temperature and weak mechanical pressure on flaps. |

To overcome with this problem, you should to review the system and adjust them for sealing. Clean the glue nozzle and set the temperature of glue. You should keep the temperature of glue moderate i.e. if too cold then it wouldn’t make a bond and if too hot, then will dry before sealing. If the sealing is by mechanical method, then you have to increase the pressure by adjusting the machine setting. |

Conclusion:

To wrap the detailed guide about the intermittent cartoning machine, it can be concluded that it is highly efficient packaging solution to package wide variety of products that meets the need of industries like pharmaceutical, food, consumers and cosmetics. It is easy to handle and suitable for all style and sizes of cartons. So, it is preferred machine for businesses for packaging products and gain the trust of their customers.

Don't forget to share this post!

Cartoner Related Posts

Cartoner Related Products

Cartoner Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours