What Are Medicine Capsules Made Of?

Isn’t surprising how a small shell with powerful ingredients for your body’s physiology? In the pharmaceutical world, the capsule shows wonders by enclosing potent medication. Once you take them, it starts producing its action slowly and gradually. The ultimate aim is to provide therapeutic effects. Now come to the topic, do you know what are medicine capsules made of? Be with us! In this article, you’re going to read about authentic and easy-to-understand information related to capsules and their manufacturing.

Read on to learn more about it!

1.What is a medicine capsule?

Medicine Capsule

A medicine capsule is a small cylindrical or oval-shaped casing that encloses the medicine inside. This can be made up of either a hard shell or soft shell, animal-based, or plant-based to encapsulate the materials. Upon oral administration, it dissolves inside the body and tries specifically to reach the target site and produces a therapeutic response.

Indeed, the medication is most often bitter with an intolerable smell. Therefore, medicine capsules have emerged to solve the issue and improve patient compliance. This can hold powder, granules, and various other states of medicine effectively, so not only adults but young children can also take and swallow them to get beneficial health effects.

2.What are the types of medicine capsules?

When you see the medicine capsules then it might look the same but exactly things are different. Different types of capsules may look the same but in actuality, they’re formed by certain variations in ingredients. We have talked about each type of medicine capsule briefly.

Gelatin Medicine Capsule

Gelatin Capsule

The gelatin capsules are mainly derived from animal sources and are commonly used for centuries in the production of capsules. Along with being therapeutic, the medicine gelatin capsule itself offers you health benefits such as protection for joints, joint-related aches, gastric system, improved sleep cycle, and sharpening memory.

The commonly used animals are cow, chicken, and pork. The extraction of gelatin is involved with pre-treatment, extraction, and refining. Thus, after passing through a series of steps it can be useful for manufacturing of gelatin medicine capsule.

| Hard Gelatin Medicine Capsule | Soft Gelatin Medicine Capsule |

| This is the most traditional and commonly available type of medicine capsule in the pharmaceutical manufacturing industry. A two-piece shell that is composed of a head and a body.

The primary medicinal substances are filled in the body, and it is then secured by the head. This is an ideal and economical type that is mainly used for dry and powder substances such as pellets, granules, and prescription and non-prescription medicines. |

The texture of soft gelatine medicine capsules is flexible and stretchy. This type of capsule is sealed hermetically. Substances like oils, serums, liquid supplements, or semi-solid medicines are mainly encapsulated in soft gelatin capsules.

Additionally, many substances that are best known to possess hygroscopic properties are also dispensed in soft gelatin medicine capsules. This is because these capsules ensure high protection against external environmental conditions and prevent oxidation or material degradation. |

Plant Based Medicine Capsules

Plant-Based Medicine Capsules- Picture courtesy: SMP Nutra

These medicine capsules are also termed vegetable or vegan capsules. As compared to animal-based medicine capsules or gelatin, they’re derived as an alternative option. This means those people who are not willing to use gelatin-based medicine capsules opt for plant-based medicine capsules. They’re safe, and a good option for those who’re allergic to animal-related formulations.

| Hydroxypropyl Methylcellulose or HPMC Medicine Capsules | This is the most commonly employed material for manufacturing plant-based medicine capsules. It is actually a polymer that is taken from a plant’s cellulose. This is mainly available in the cell walls of plants and is the best-known material that is excellent in the formation of medicine capsules. Therefore, HPMC medicine capsules are free from animal-based constituents and offer a strong capsule stability property. |

| Pullulan Medicine Capsules | These medicine capsules are made from pullulan, a natural polysaccharide derived from fungi. These capsules offer an eco-friendly alternative to gelatin and vegetarian capsules. Pullulan capsules are known for their excellent stability, particularly under humid or high-temperature conditions, and are increasingly popular in the nutraceutical industry. |

| Starch-Based Medicine Capsules | This carbohydrate is also extracted from plant sources and is known as a complex carbohydrate with a long chain of glucose moiety. The texture of starch upon reaction is stretchy and elastic, that’s why it is used in the making of medicine capsules. They’re available in many vegetables like corn, cane, tapioca, etc. |

| Agar-Agar Medicine Capsules | This is the jelly-like substance that you take from seaweeds or algae. Agar agar helps in the promotion of the jelling consistency of medicine capsules and provides many benefits related to our health such as GIT, joints, blood sugar level, cholesterol, etc. Moreover, the agar agar medicine capsules are considered as a stable material that can withstand high temperatures for example: above 85°C (185°F). |

| Pectin Medicine Capsules | This is a polysaccharide extracted from fruits especially apple, or citrus fruits. Due to its thickening properties, pectin is used in the formation of medicine capsules. It offers greater consistency and excellent formation of capsules and helps in maintaining your health. A good vegan capsule option with ideal gelling properties with smooth texture. |

3.What are medicine capsules made of?

A thin layer of capsule shell is composed of several essential ingredients to make an effective medicine capsule. For example:

Jelling Ingredient

Jelling agent- Picture courtesy: NutraViva

The jelling ingredient is the foremost element that acts as a base of a medicine capsule. We have already described several types of jelling agents suggesting gelatin which is derived from animal sources, and plant-based sources such as HPMC, pullulan, etc. Therefore, this ingredient helps to provide a jelly-like consistency to the medicine capsule.

Water

Water- Picture courtesy: Croix

Distilled water or purified water acts as a main vehicle in the making of medicine capsules. It is primarily used to dissolve the various solid or powdery ingredients, and by the incorporation of water content, the jelling agent itself acquires the settling and enhances the viscosity of the formulation. Remember the water must be treated or without contaminants and unwanted particles; otherwise the medicine capsules quality would be affected.

Glycerine

Glycerine- Picture courtesy: Anveya

This is also an important component that is used in many formulations of pharmaceutical products. The purpose of using glycerine in medicine capsules is to approach the vehicle properties as well as the humectant agent. This element is used for retaining the moisture content of the medicine capsules, if you ignore this ingredient, the capsule formation could be so harder and it won't attain flexible or elastic properties. Also, glycerine has beneficial effects on your body ‘s physiology and ease of swallowing.

Sorbitol

Sorbitol- Picture courtesy: StyleCraze

This is also a humectant that keeps the moisture content of the capsule shell well-maintained and elastic.

Colorants

Colorant- Picture courtesy: Cooking with ELO

You have seen multiple types of capsules composed of vibrant colors. For example, the body and the head with of two different colors, and some of them are transparent, etc. So, choosing the color is dependent on the type of medication and the decision of the manufacturer.

The purpose of using color is to enhance beauty, increase patient compliance, and distinguish your brand. Therefore, synthetic or natural coloring pigments are used i.e. titanium dioxide, food colorants that do not impose any unwanted effects.

Preservatives

Preservative- Picture courtesy: Fortcap

Sometimes your capsule's shell degrades or loses integrity. However, they are still safe and do not progress to the challenge of contamination. This is all because of preservatives with minor or negligible amounts; offering high protection against the progression of microbes. For example sodium benzoate, potassium sorbate, etc.

Flavoring Agents

Flavoring agent- Picture courtesy: CapsCanada

Many nutraceutical or pharmaceutical medicine capsules are added with a flavoring agent to increase patient compliance especially when they are designing medicine capsules for children's formulation. When you open the capsule packaging, it gives a positive effect. Also, the patient can take them and don’t feel stressed when it is inside their mouth. The commonly used flavor in medicine capsules is citrus fruit, menthol flavor, strawberry, etc.

4.Why is a medicine capsule made?

Medicine capsule- Picture courtesy: Capsuline

There are certain important reasons for which medicine capsules are made. For example:

A suitable alternative to other dosage formulation

Some people find it difficult when taking tablets or liquid formulations. If you observe the shape of the capsule, it is cylindrical and is mainly created for easy swallowing without any trouble. Therefore, this is a good option due to its flexible swallowing properties.

Encapsulated medication without taste

Bitter powder or medicine is hard to consume, the capsule medicines are embedded in a shell therefore you don’t feel any taste during oral intake. So you can take medicine timely without fear of bitter taste.

Target site release

Many capsules are specially designed to disintegrate and release active pharmaceutical ingredients in their specific site. For example: controlled released capsule medicine, sustained release, etc. are created in a way that follows the time-based releasing action to offer a subtle therapeutic response.

Specific & accurate dose encapsulation

The capsule medicine is composed of accurate doses you need every time. In this case, you can rely on manufacturer and pharmacist dose assessment. Therefore, you can just pick the capsule and consume it without worrying about dose making. Moreover, the filling of medicine takes place in top-notch machines that promise whatever you receive is ideal for your therapy.

Safety of medicinal substance

The capsule medicine shell is made up of a combination of various ingredients such as gelatin, plasticizers, etc in order to form a stable covering around the medication encapsulated. Thus, it is safe from physical factors and acts as a barrier to protect against oxidation, the entrance of air, gases, etc that affect the potency of the medication ultimately your medicine is safe inside the shell for long periods.

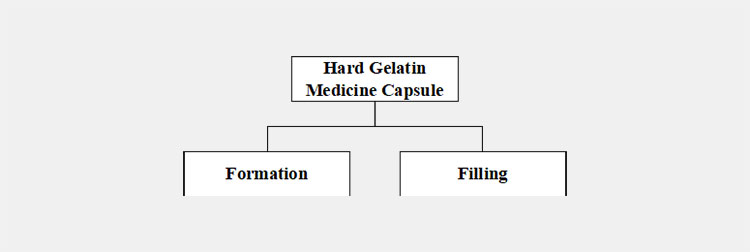

5.How hard gelatin medicine capsule made of?

To explain the answer, we will divide the description into two basic sections:

Formation of Hardgel Medicine Capsules

The formation of hard gel medicine capsule is based on the following:

Solution preparation & Cooking

| In this section, the gelatin slurry is prepared by mixing the gelatin of optimized concentration with purified water. Along with this process, the other ingredients are added and cooked till a homogenized slurry formed. The entire process is taken place in a melting and cooking tank. |  |

Medicine Capsule Molding & Cutting

| There are molding dies for acquiring the shapes of medicine capsules. The slurry is incorporated into molds and left for a certain time to get drying time. After acquiring shapes, they are separated automatically and trimmed finely into the body and cap of the capsule. The empty medicine is ready. |

US Validation Service |

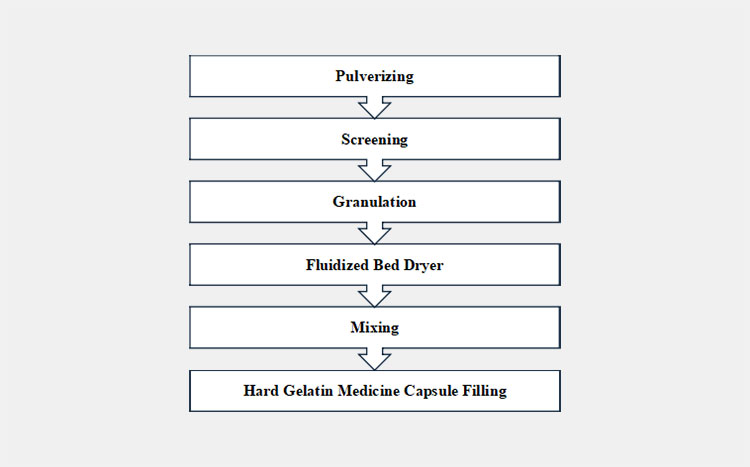

Filling of Medicine Capsule

Before going to filling the medicine capsule, you are going to move ingredients across the following steps:

Steps of Medicine Capsule Making

| Pulverizing

AIPAK Pulverizing Machine |

Inside the capsules, you will need materials in a fine and minute texture. Therefore, to make them the finest consistency pulverizing steps are carried out which is also known as a crushing grinding.

The pulverizing machine works by grinding using centrifugal force that in turn reduces the material size. The machine itself is comprised of static and movable blades, that work opposite to one another in a fast velocity to compress and break out the particles. |

| Screening

AIPAK Screening machine |

Screening is mainly done by a sifting machine which is also known as a vibratory sifter. With the help of continuous vibration, the sorting and screening of the granules and powders take place. Ultimately you get a powder bed of uniform sizes which is absolutely ideal for in encapsulation of hard gelatin medicine capsules. |

| Granulation

AIPAK High Shear Granulator |

To get the ideal flow property of the powder and granules, the granulation is done. There are two types, dry granulation and wet granulation.

Dry Granulation This type of granulation does not require any moisture or water content. A machine which is known as a roller compactor helps in the compaction of powder to form a thin ribbon or a slug as powder passes from two hard rollers that moves opposite to one and another. Later, it has broken down into the finest particles. Wet Granulation To get the particle with a smooth texture and subtle uniformity of dusty powders, wet granulation is preferred as it is involved with liquid binders with powder. Therefore, you get the particles with improved density. A high-shear mixture granulator is mainly used for achieving the wet granulation process which is composed of multiple impellers with a vacuum-based design tank. The powder and solvent are added to the machine. The required material density is formed by the action of agitators and impellers that help in producing uniform granulation. |

| Fluidized Bed Dryer

AIPAK Fluidized Bed Dryer |

This is the next after wet granulation; a fluidized bed dryer helps in the elimination of excessive moisture content present inside the treated powders. The machine is capable of fluidizing the static powder bed with the help of induction of hot air. The particle remains in the fluidized state to eliminate the excessive moisture and offer ideal filling ingredients. |

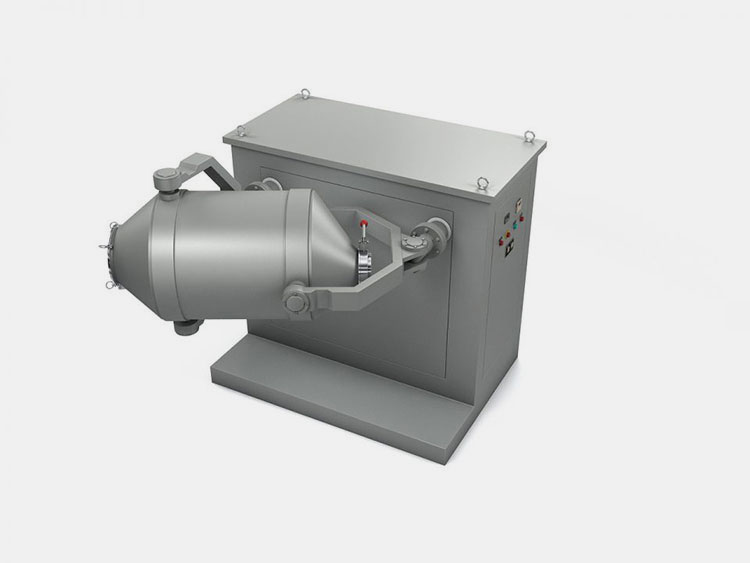

| Mixing

AIPAK Mixing Machine |

There are several mixing machines, for example, V- mixer, ribbon mixer, planetary mixer, etc. that help in the mixing of active pharmaceutical ingredients with fillers or excipients. The mixing is always required prior to subjecting your formulation to a capsule-filling machine. |

| Hard Gelatin Medicine Capsule Filling Machine

AIPAK Medicine Capsule Filling Machine |

There are three types of hard gelatin medicine capsule machines available that are mainly designed to fill an accurate dose inside the capsules and lock properly.

Manual Medicine Capsule Filling Machine you can manually adjust the number of empty capsule shells; the machine can unlock them and with the help spatula, you can fill the empty capsules. Repeat the procedure to the capsule body and the caps can be locked. Semi-Automatic Medicine Capsule Filling Machine In a semi-automatic capsule machine, you just need to load and unload the empty and filled capsule tray. The remaining entire task is performed by the machine automatically. Automatic Medicine Capsule Filling Machine In the automatic capsule filling machine, the unit itself is capable of directing the capsule bed for separation, filling, and joining automatically. The machine is featured to identify the presence of capsules and is capable of managing powder filling with accurate concentration with the help of digital smart PLC systems. |

6.How softgel medicine capsule made of?

The making of medicine softgel capsules where a machine is capable of running so many things as a standalone solution.

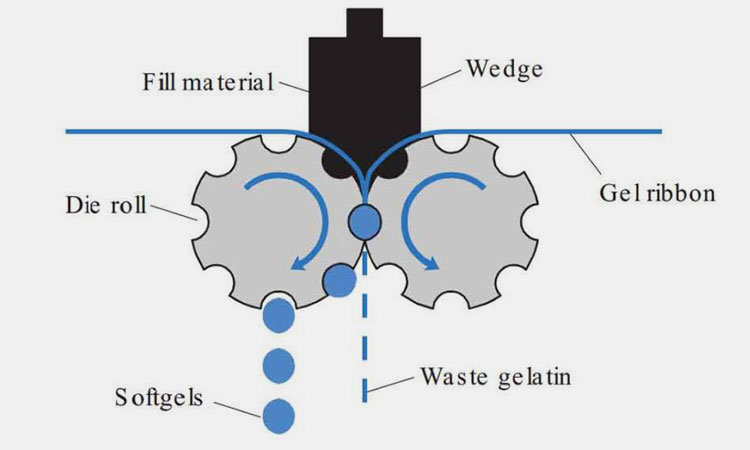

The Process Structure of Softgel Medicine Capsule

Formation Of Softgel Medicine Capsule

| The softgel medicine capsule where a gelatine ribbon is created when it is passed through the rollers that produce a thin layer. The machine is subjected with medicine to filled. The rotary die of the machine helps in the shaping of the capsule where the material is dropped followed by the hermetic sealing of softgels. The produced capsules are smooth-surfaced and ready to move for drying. |

AIPAK Softgel Encapsulation Machine |

| Drying

By using the tumbling drying unit, the unwanted moisture is eliminated making your capsule soft and flexible which is easy to consume and store for a long time. |

Tumble dryer |

Conclusion

After reading the blog on ‘What are medicine capsules made of’, we assume that you have found this article worth reading. Apart from major ingredients in medicine capsules, there are a lot of important roles of types of machinery that help in the formation of standard and customized products. If you are interested in knowing about a one-stop solution then contact AIPAK. We have been involved in medicine capsule machines for pharmaceuticals, nutraceuticals, R&D, and so much more industries for more than a decade. To know about a broad range of machineries at affordable prices. Contact us now.

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine