Cream Tube Filling Machine: The Complete Buying Guide In 2025

Ever wonder why your favorite cream product lasts for so long? Well, it is because of its sturdy packaging. You would have seen creams in numerous packaging styles but the most favorite is tube packaging.

But how they are perfectly filling without any mess or spill? Here comes a game-changing machine- a cream tube filling machine. Yes, with this piece of equipment, industries have a harmonious combination of precision and productivity. This powerhouse is a central fixture in every manufacturing sector and ensures every tube is packed and sealed with 100% flawlessness.

How does it work? What are its components? Thinking about these questions? Then, get comfortable because you’re about to uncover astonishing secrets to the world of a cream tube filling machine.

1.What is meant by a cream tube filling machine?

AIPAK Cream Tube Filling Machine

Cream products are often thick and viscous and, hence, are difficult to dispense in packaging. A specialized machine- a cream tube filling machine- is found in the manufacturing units to pack the creams in durable packaging. This equipment has a compact construction and is composed of two fundamental processing stations (filling and sealing areas) that perform the loading and closing of squeezable tubes.

The cream tube filling machine is built to handle creams with a diverse range of viscosities and thicknesses. Besides this, this equipment holds a major advantage of precision and cleanliness in filling. In this way, you can’t have any inconsistency and contamination in product filling.

This ultimately makes this machine vital in industries, which hold ultimate standards of sanitation and quality control.

2.How cream tube filling machine is advantageous to industrial sectors?

A cream tube filling machine is a great addition to the manufacturing industries and provides manufacturers with a significant edge in cutthroat business. It is all because of its fast filling and 100% fill reliability. For those readers, who are wondering about the advantages of cream filling machine, you’ll discover its top best benefits below:

More Speed Means More Filled Orders

More Speed Means More Filling

Are you looking for ways to maximize your product loading speed? Then you can easily achieve this goal through the integration of a cream tube filling machine. You will find fast-filling systems in this unit that guarantee a higher rate of cream loading in a significantly short time.

These components work as well-oiled machinery in order to ready more product batches for distribution in the market.

Loading Precision Each Time

Loading Precision Each Time

What is your first priority as a business owner? Surely, it is filling precision. You would be interested in accurately loading your cream products to the target volume.

Overfilling certainly wastes your expensive product while underfilling is a sure way to lose your customer trust and reputation in the market. To eliminate this problem, a cream tube filling machine can be your perfect solution and delivers extremely reliable filling with clockwork precision.

Sanitary and Clean Dispensing

Sanitary and Clean Dispensing

Hand filling usually adds a fair share of contaminants or foreign objects to the cream tubes. And fails to meet hygienic standards in consumer-based industries. But now you have got a cream tube filling machine for clean and hygienic dispensing of creams. This equipment is fabricated with GMP-compliant materials, such as stainless steel.

They are easy to clean and corrosion-resistant. Hence, using this machine, you can dose your products with peace of mind.

Outputs Alluring Tubes

Outputs Alluring Tubes

This machine typically comes with advanced sealing and coding stations. They are essential in presenting an appealing look to the final tubes. Isn’t it great! With sealing units, the bottom ends are delicately pressed and embossed with stylish patterns. Also, with these components, you can efficiently distribute your packed tubes without undesired corners. This trimming of edges is generally carried out by cutting knives.

Handles a Multitude of Tube Formats

Multitude of Tube Formats

You certainly asked yourself the question does a cream tube filling machine handle different tube formats? If yes, then you would be pleased to know that owing to its fast-changing parts, you can easily process multiple tube formats and designs. Consequently, this machine is considered a worthy investment for not only processing your present tube styles but also for your future tube innovations.

3.What industries incorporate a cream tube filling machine in their productions?

A cream tube filling machine is the heart of all those industries that routinely process cream products. No matter which industry you belong to, you can regularly use this machine to improve your overall production rate and minimize your operational expenses.

Now in this section, you’ll discover what industries are currently benefiting from a cream tube filling machine:

Cosmetic Industry

Cosmetic Industry- Picture courtesy: RMS beauty

Whether creams, lotions, foundations, lip gloss, sunscreen, moisturizers, or hair gel, you can buy all these cosmetic products and more in squeezable tubes. Hence, here you can see the utility of the cream tube filling machine. With this machine, cosmetic brands can boost the general appearance of their products.

Food Industry

Food industry- Picture courtesy: Gastronomixs

Numerous food industries are using tubes for packing their mayonnaise, condiments, ketchup, honey, and chocolate spread. For this packaging, they certainly make use of a cream tube filling machine, as it offers mess-free and spill-free packaging without even the tinniest of filling errors.

Pharmaceutical Industry

Pharmaceutical industry

In the pharmaceutical industry, a variety of creams, gels, pastes, salves, ointments, or lotions are packed in the tube packaging. Therefore, a cream tube filling machine is best for sanitary pharmaceutical applications because it includes safety doors and a hygienic design. These features are renowned for acting as a barrier for microbial pathogens and dusty objects.

Personal-care Industry

Personal-care Industry

No personal care industry is complete without a cream tube filling machine. Do you know why? It has a key function of filling toothpaste, hand sanitizers, shampoos, and soaps in easy-to-use tubes. No fill variation and zero product wastage are a few of the biggest reasons behind the popularity of this equipment in the personal care industry.

Chemical Industry

Chemical industry- Picture courtesy: Anzo Australia

One of the major users of a cream tube filling machine is the chemical industry. You may find it mindboggling that a wide array of chemical products, for instance, adhesives, lubricants, glues, grease, sealants, and varnishes are distributed in the tube packaging. This instrument is the means to introduce lightweight and portable chemical packaging in the market.

4.What are the stages in working of a cream tube filling machine?

One may think of a cream tube filling machine like a puzzle. Only by learning its working mechanism can you achieve complete control over its operation. Its working has a few steps that occur in a sequential manner to have a seamless workflow. Now, let’s look at the steps involved in its working:

Loading of Starting Materials

Material loading

Before beginning the operation, your first step will be loading cream products in the hopper. After that, you will turn on your equipment, which powers up the whole filling setup. Then the cream-based product will flow from the hopper to the filling unit. A sensor is integrated into the hopper that automatically detects the level of product and notifies you once the cream goes down a certain threshold.

Placement of Tube Containers

Tube Feeding

In the second step, you will put the empty tubes inside the tube magazine- found at the top of the machine. From there, tubes are picked by a vacuum swing gripper and placed into proper orientation in the tube holder. They are oriented in such a way that the opening of the tube is facing upside down for filling.

Product Loading

Cream dispensing

Now the tubes are ready for actual filling. The filling systems, especially filling nozzles are the main components that supply the tubes with precise doses of creams. This filling step is performed with the help of pistons or pumps. Creams flow to the filling nozzles and tubes with up and down movement or rotation of filling devices.

Tube Sealing

Tube Sealing

Next up: it’s time for the tube sealing process. At this stage, you’ll ensure product protection and freshness. The sealing station takes advantage of heat or ultrasonic waves to secure the mouth of the tube and impart a smooth tube finish. Sealing jaws exert high pressure to tightly press and seal tubes.

Coding and Trimming

Coding & trimming

After sealing, the sealed tube is moved to the coding unit, where the coding apparatus imprints useful product notes (name, formula, ingredients, manufacturing and expiry dates, and batch number) on tubes. Finally, the trimming scissors carry out cutting or trimming of sealed edges of tubes. In this way, you’ll have a finished tube with a neat and clean design.

Tube Offloading

Offloading- Picture courtesy: Three Bamboos

In the end, you’ll observe packed tubes being discharged from the machine and collected on the conveyor belt or discharge chute for the next packaging steps.

5.Explain some fundamental parts of the cream tube filling machine.

Various manufacturers regard the cream tube filling machine as a simple design. But that isn’t the case. Because reality is far from the truth. Normally, the cream tube filling machine has a complicated invention with numerous parts- each with its specialized role in smooth working.

Hence, we’re mentioning some vital parts for your learning:

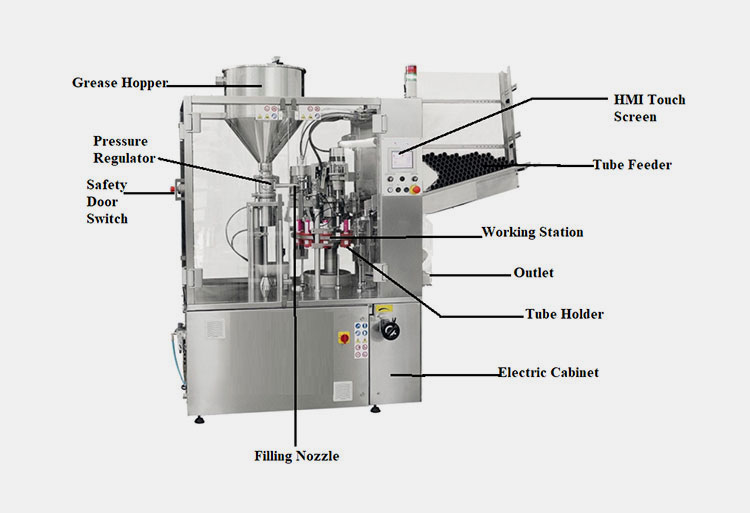

Parts of Cream Tube Filling Machine

| Grease Hopper | You certainly have spotted a hopper at the top of the equipment. It resembles a funnel-like structure and stores cream-based products in bulk for non-stop work. |

| Pressure Regulator | You will see a knob-like button at the bottom of the machine which is a pressure regulator. By rotating it, you can modify the pressure for product dispensing. It is essential for keeping pressure steady for filling. |

| Safety Door Switch | It is a vital safety and security feature of a cream tube filling machine. It is a glass protective barrier between you and the main machine construction. Through this part, you can view equipment operation from a distance without touching its working parts. |

| Filling Nozzle | Ever wondered which component is responsible for filling? Filling system but more precisely, filling nozzles are a central fixture with which you have an efficient and spill-free cream loading. Sometimes, these elongated parts extend to the base of the tube for drip-free dispensing. |

| Electric Cabinet | The electric cabinet is a driver of the cream tube filling machine because it powers motors and working stations. It provides electrical energy to the machine for working. Simply put, you could say it along with its wires, switches, and breaker allows you to switch on and turn off the device. |

| Tube Holder | Tubes don’t trip and fall from the working station due to the tube holder. It is a circular cavity that firmly holds tubes during machine operation. |

| Discharge Outlet | It is a tray-like structure. You can collect fully packed tubes from this part. The packed tubes are ejected to the discharge outlet after the completion of their packaging stages. |

| Working Station | It acts like a working table of the machine. You may see various components- for instance, filling nozzles, tube holders, sealing jaws, and, trimming knives- attached to the working station. Tubes undergo sequential steps with rotation of the working station. |

| Tube Feeder | This unit is located on top of the instrument. It is used for storing bulk quantities of tubes. It feeds tubes one by one to the vacuum prism swing. |

| HMI Touch Screen | It is a main interactive component through which you will control the equipment and fine-tune it according to your preference. You’ll find small icons or buttons on this touch screen to input instructions with a simple swap of your finger. This screen also allows operators to view the progress of the operation. |

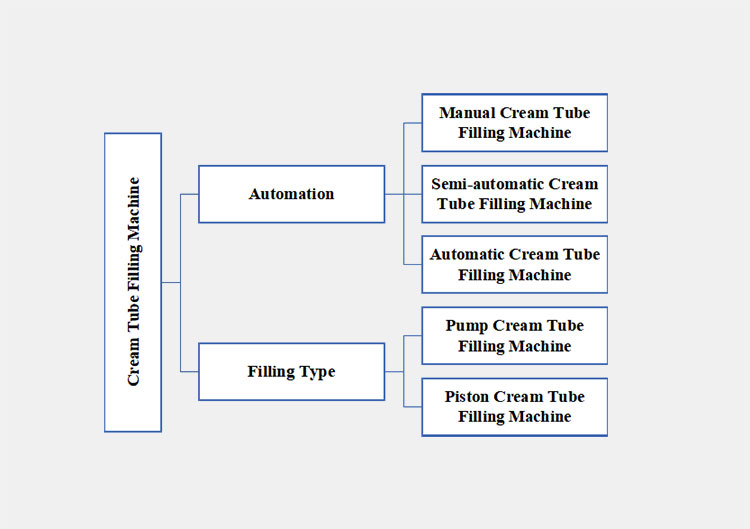

6.How can you classify a cream tube filling machine?

Now, when you go to buy a cream tube filling machine, you’ll certainly discover that this equipment is available in numerous designs, models, sizes, and automation. This wide assortment could be confusing. But don’t get overwhelmed, as we’re here detailing various classifications of this instrument for your convenience:

Classification According to Automation

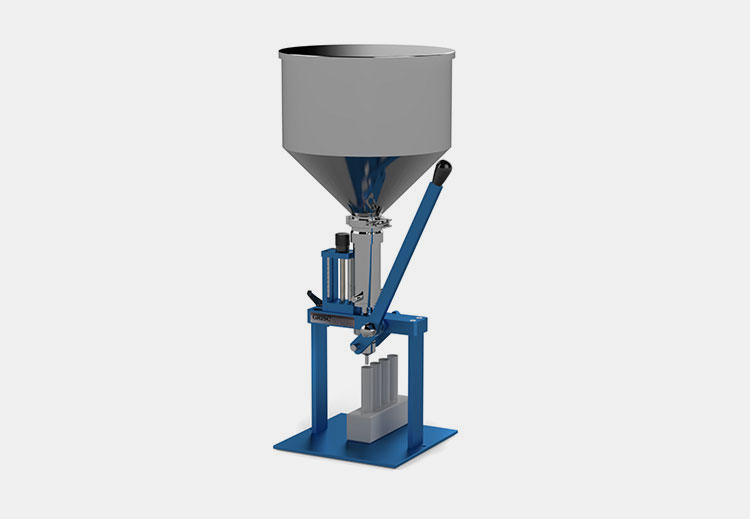

Manual Cream Tube Filling Machine

Manual Cream Tube Filling Machine- Picture courtesy: CroPharm

Here is exciting news for you if you’re a small newbie in the cream-based filling business. A cream tube filling machine is also offered in small, portable, and benchtop designs to improve the efficiency of small businesses. This machine is characterized by hand-held levers or knobs for product loading by hand.

Although it is a major improvement from hand filling, still you’ve to perform the loading and removing of tubes manually.

Semi-automatic Cream Tube Filling Machine

AIPAK Semi Automatic Cream Tube Filling Machine

Semi automatic cream tube filling machine is a mid-sized equipment and is present in the middle of an automatic cream tube and manual tube filling machine because of its both automatic and manual mode of operations. You can get automatic filling operations by adjusting some control options. It is a perfect option for medium-sized businesses that want to increase their production speed.

But managing this machine is still hectic as you’ve to place and remove tubes by hand from the device.

Automatic Cream Tube Filling Machine

AIPAK Automatic Cream Tube Filling Machine

It is the latest addition to the series of cream tube filling machines. As every step in this equipment is automatic, hence; it is less labor intensive. However, compared to its other counterparts, it is significantly heavier and has more footprint. On the other hand, it is capable of dispensing massive quantities of creams in a small-time window.

Perhaps it is pleasing for you to learn that you can have absolute precision with this unit since it is equipped with top-notch sensors and weight-checking systems.

7.What tube materials are packed by the cream tube filling machine?

Today, you’ll find tube packaging of diverse materials in the market. These varieties serve functions like high visual appeal, increased product protection, and improved customer convenience. Some of these materials processed by cream tube filling machine are discussed below for your information:

Plastic Cream Tubes

Plastic Cream Tube- Picture courtesy: Jars King

Now, plastic tubes are everywhere from cosmetics to pharmaceuticals, from chemicals to food. Ever thought about why? Well, plastic has murmurous plus points, for instance, easily purchased in bulk, less expensive, lightweight, more pliable, and easier to squeeze. Besides this, it is highly rust-resistant and doesn’t react with chemicals.

Laminated Cream Tubes

Laminated Cream Tubes

They are a hybrid option that boosts the benefits of plastics but presents barrier protection against air, light, and, water content similar to that of metals. Laminate tubes are typically manufactured from ABL or PBL. They have a premium look with luxurious appeal. In addition, they maintain product integrity throughout their lifetime. Due to their metallic finish, you can make them your first choice for packaging high-end cosmetics.

Aluminum Cream Tubes

Aluminum Cream Tubes

They hold the second-most top place in the market because of their anti-rust features, enhanced ductility, and airtight structure Moreover, they can be crimped to provide a tamper-evident seal. They are most common in pharmaceutical industries, as they are more suitable for medicated creams and ointments. They have a lower environmental impact because of their higher recycling rate.

Metal Cream Tubes

Metal Cream Tube- Picture courtesy: BEAUTYSOURCING

Although they are not widely common still some manufacturing sectors- for instance, automotive and paint- utilize them. Metal tubes are normally created from tin or lead and have excellent rust tolerance. Furthermore, they are relatively more durable than other tubes, thus highly preferred for specialized applications, like packaging lubricants, adhesives, and sealants.

8.What sizes and shapes of tubes are processed by a cream tube filling machine?

Different industries have their specialized needs for tube packaging. To fulfill these diverse needs, a cream tube filling machine is designed to process tubes of varying shapes and sizes. Hence, you can easily change its parts to process a particular size and shape tube.

Tube Size

Sizes Of Cream Tubes

If you’re working with miniature tubes, a cream filling machine can easily accommodate the smallest sizes ranging from 65-85 mm in length, with a 3-10 ml fill volume. For those manufacturers dealing with the largest-sized tubes, this equipment can manage tubes 180-215 mm long, which is about 200-400 ml.

Tube Shapes

Brand differentiate their products with innovative tube shapes. Especially, those running cosmetic businesses use stylish tubes to create a premium look. Here are a few common shapes of tubes:

Cream Tube Shapes

Round Tube

It is one of the most prevalently seen tube shapes on retail shelves. It has a straightforward manufacturing process and is relatively easy to load.

Oval or Flat Tube

It is a squeezable tube, which offers ease of product dispensing while minimizing its wastage. It is fairly easy to display on selves and serves as a perfect tool for brands. It has a luxurious appeal.

Square Tube

It is gaining traction owing to its unique geometry. This shape is effective in capturing customer attention. You can use this tube shape to save space in packaging. This is because it stacks better. Moreover, there is no risk of rolling or falling with it.

Custom-Shape Tube

This type of tube features an innovative design and is quite popular for packing specialty items and luxurious beauty products. Custom-shaped tubes come in ingenious formats, for instance, tapered tubes, dual-chamber tubes, and ergonomic grip tubes.

9.What are the major problems of a cream tube filling machine? How can you resolve them?

Let’s be real, no machine is perfect, and you’ll definitely have some occasional hiccups when operating a cream tube filling machine. But with operational knowledge and skills, you’ll easily overcome these problems. So, let’s have a read about some frequent issues with a cream tube filling machine and their remedies.

Stoppage in Cream Flow From Nozzles

Stoppage in Cream Flow From Nozzles- Picture courtesy: Globalsource

Sometimes, it seems that cream is refusing to come out of filling nozzles. This will lead to a roadblock in production. Usually, you’ll encounter this problem due to failure to adhere to a proper cleaning schedule. Which creates product deposition in filling nozzles and hoses. Moreover, this issue could be due to incompatibility between product viscosity and machine pumping capacity.

Solution

You can rectify this issue by following these instructions. First and foremost, implement a routine cleaning schedule of machines. Thoroughly wash out the interior of filling nozzles and hoses. For more extensive cleaning, you can integrate CIP (Clean-in-Place) systems with your instruments. Lastly, make sure that you’re filling appropriate products as per machine pumping capability.

Misplacement of Cream Tubes

Misplacement of Cream Tubes- Picture courtesy: Norden

During the tube feeding process, you could have a high chance of misplacement and improper orientation of tubes. It will block the working station and cause the halting of filling and sealing down the line.

Solution

You should pay attention to the alignment of tube holders and guide rails and properly align them if necessary. The tube feeding system must be cleaned routinely to put a stop to debris accumulation. It is recommended to integrate sensors with the machine. They will automatically detect the orientation of tubes and notify you in case of an error.

Presence of Bubbles in the Cream Tube

Presence of Bubbles in the Cream- Picture Courtesy: Resource Boy

Have you ever observed air bubbles in your cream-based products? This problem is more prevalent than you might have anticipated. You may have variations in filling from tube to tube due to entrapment of air in cream.

Solution

To solve this problem, opt for vacuum-based filling components, as they are very effective in de-airing products. Before filling always stir the product thoroughly to prevent air ingress in it. Last but not least, you can prevent abrupt pressure drop by modifying your fill speed range.

Leaky or Weak Tube Sealing

Leaky or Weak Tube Sealing

The top reason behind the contamination and leakage of creams is improper sealing. With weak seals, you’ll have more issues of product quality.

Solution

Rest assured, you can sort out this problem in no time by simply altering the inputs of sealing temperature and pressure. To get the desired sealing, you must correctly align tubes. Before starting operation, you’re required to clean the sealing area of moisture or product buildup to have adequate sealing.

10.How to choose a well-matched cream tube filling machine for your setups?

Setting Up Right Cream Tube Filling Machine

You surely desire your cream tube filling machine to run smoothly for many years. Carefully plan every big and little detail of your buying process because it is a significant investment. Consequently, here are some top tips for you to guide your selection process.

| Calculation of Processing Capacity

|

The output capacity varies from one cream tube filling machine to the next. And this makes the selection process quite challenging. To overcome this taxing problem, you should have a rough idea about your required number of orders per day. To maximize your end-of-day inventory, consider equipment with higher working capacity. |

| Test Your Product Viscosity

|

Are you filling thicker and creamier products? Or are you loading fluffy or thinner viscosity liquids? Decide on a cream tube filling machine with suitable filling systems. This is because piston-based filling devices are more capable of dispensing high-viscosity products. On the other hand, you’ll find peristaltic pumps more suitable for mild-viscosity liquids. |

| Machine Integration

|

Would you prefer a standalone machine or one engineered for seamless integration? Test machine integration capabilities or standalone performance before buying. If you’re planning to complete your packaging products, then your cream tube filling machine must be compatible with your current or future batch coding, labeling, and capping machines. |

| After-Sale Service

|

It is a universal fact that every industrial machine is prone to fail in some capacity or another after a certain operational period. To fix these failures, you will require some serious repair expenses. In this case, partner with a manufacturer who offers long-term after-sale assistance in the form of technical support, repair services, or training programs. |

Conclusion

In this blog post “Cream Tube Filling Machine: The Complete Buying Guide In 2025” several key advantages, uses, working steps, and classes are highlighted to equip you with vital information about the cream tube filling machine. Let this knowledge be a stepping stone for your buying process. Yes, the choice of the right equipment is the best means to boost your standing in competitive business. Now ready for purchasing? We suggest contacting AIPAK’s customer support. Why us? Simply because we are experts in manufacturing top-notch industrial machines that serve businesses for many years to come.

Don't forget to share this post!

Tube Filling Machine Related Posts

Tube Filling Machine Related Products

Tube Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine