V Type Mixer: The Complete Buying Guide In 2025

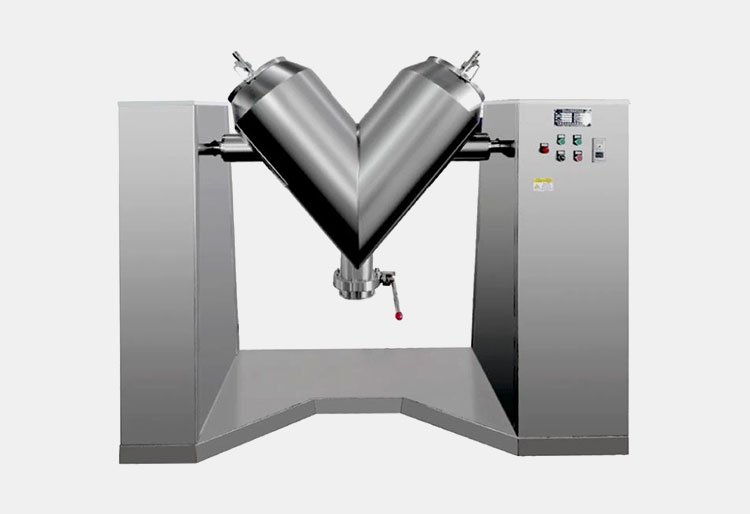

Does your production unit look like alphabet V? Yes, this is a V type mixer! Why did scientists pick ‘V’ to design a mixer? Isn’t that interesting? V type mixer is one of the most popular mixers that provides you with flexible mixing of your ingredients. You can use it for small, moderate, and bulk quantities mixing, and it is a choice for working in various health, nutritional, and other fields.

This blog gives amazing information related V type mixer. We have discussed the primary details of the machine with so many relevant points that you must be able to understand and implement in your manufacturing operations. Don’t go anywhere and have a look at useful information.

1.What do you know about V type mixer?

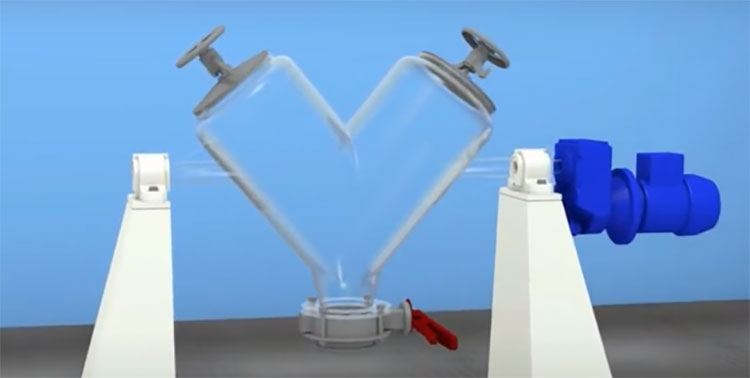

A V type mixer is used to blend the different materials where a machine is subjected to merge properly and reinforce them. This is a very simple structured mixer that is composed of a twin shell design unit with cylindrical shells that are connected at a proper angle to look like a V-shaped instrument. Certainly, when you are designing the machine, you have to keep selected parameters in your mind that help in the mixing of components.

For example, the shells join one another by following a certain angle such as 75° and 90° angle. In some cases, it also has an angle range of 70° to 90°. However, the machine surface must be smooth to provide you with a uniform mixing without the risk of segregation of granules or the mixing particles, etc. So, a V-type mixer gives you a promising mixing keeping with a moderate revolution per minute that ultimately gives an ideal momentum.

2.Why do you need a V type mixer?

This is a unique machine in the world of manufacturing that is capable of treating several compounds altogether to give you a homogeneous mixture in each cycle. That is why different industries prefer to install V type mixer in their production line to obtain a significant amount of benefits. If you are interested to know why this type of mixer is so popular, then look at the below discussion where we have highlighted the important advantages of V type mixer.

Easy & Uniform Mixing

Easy & Uniform Mixing

The purpose of designing twin shells are the V type cylinders is to yield flexible and uniform mixing of raw ingredients. The twin shell when allows the movement of substances with different characteristics by using diffusive mixing properties.

Lightly Stirring of Materials

Lightly Stirring of Materials

In pharma industries, nutraceuticals, or health products, the fragile medication of raw materials is those that are delicate in nature and more prone to get affected by the physical environment. That’s why the mixing of such substances takes place in specialized equipment like V type mixer. The delicate handling of the unit ensures the low impact forces in the tumbling of the materials. It directly leads to excellent mixing with low particle sizes. The machine promises to not disturb the structural integrity and functional properties.

Consistent in Throughput

Consistent in Throughput- picture courtesy: Viking masek

The V type mixer is popular for producing accurate and uniform mixing of up to 98%. This is the significant property of this unit leaving lesser probability for non-mixing compounds or segregation. Also, this is ideal for free-flowing substances associated with different densities. For instance, powders, granular substances, pellets, etc.

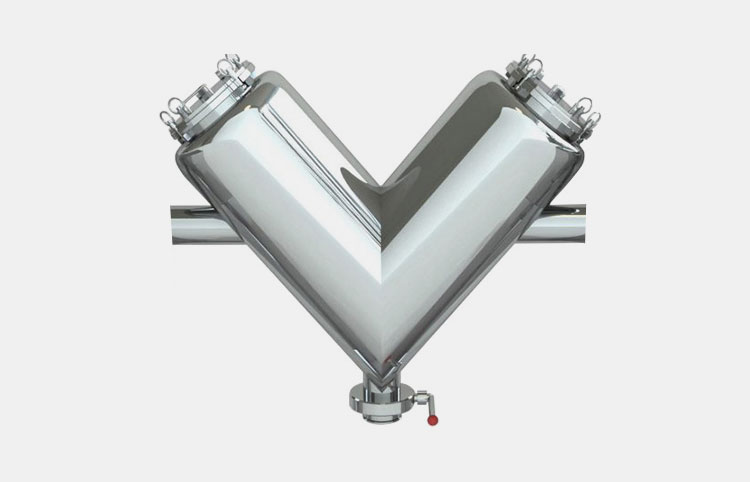

The Finest Construction and Material

The Finest Construction and Material- Picture courtesy: Lactalis Ingredients

The shape, design, and material used in construction, ultimately allow a flexible way of cleaning the machine. The food-grade stainless steel with smooth and sleek ensuring no stickiness of the treated substances. Moreover, it is very easy to clean the edges and corners of the unit. You can also utilize the vents that are presented for loading and unloading to clean the machine. Thus, it directly reduces the risk of cross-contamination and offers a high level of hygiene.

An Enclosed Medium for Mixing

V type mixer- Picture courtesy: Wanda

The V type mixer is made up of an enclosed and strong shell. You can load the mixing ingredients and close the valves. Thus, the material is mixed in an enclosed tank without the involvement of the external environment. so the dust can't spread in the working area, nor unwanted particles can enter the unit. This is entirely the safest option for mixing ingredients and for users.

3.Where is V type mixer needed the most?

A V type mixer is an entrusted tool for mixing various formulations. This is because it subtly performs tasks with powerful uniformity. The unit has broad applicability in the production world. By offering fast and efficient output with affordable production costs, it is mostly preferred by manufacturers to opt for working setups. We have talked about different industries where applications are significant that are carried out for the manufacturing of products.

Pharmaceutical Industry

Pharmaceutical Industry- Picture courtesy: Omya

In pharmaceutical formulations, if the mixing is insufficient, the formulation can’t be formed. If it is formed, then the potency would be affected by uneven mixing. Therefore, the V type of mixer is used for the effective mixing of free-flowing and delicate substances. For example, the formation of solid dosage formulation, liquid, topical, vaccinations, dusting powders, etc.

Nutraceutical Industry

Nutraceutical Industry- Picture courtesy: CSIRO

It is an important sector of manufacturing formulation where mainly substances are extracted from natural sources to benefit well-being. The nutraceutical ingredients required blending for the formation of tablets, softgel, capsules, syrups, sprays, etc. It is involved with several substances such as actives, fillers, various binders, flavoring, etc. For that, you need strict hygiene and compact units; a V-type mixer is ideal in this way it offers a one-stop solution in providing mixing and cleaning parameters.

Food Industry

Food products- Picture courtesy: Home Cooked Roots

Whether it is small industry or large, home-based food preparation or commercial. It is not possible to get uniformity and correct proportions without mixing. A V type mixer is a good tumbling solution for food products like spices, sugars, flour, seasonings, etc. Whether it is packaging and production of dried products or preparation; this reliable machine is a must-have unit in every food sector.

Chemical Industry

Chemical Industry- Picture courtesy: Kymera International

For a safe and homogenous mixing of chemicals, a V type mixer is primarily installed in every chemical industry. The machine’s enclosed structure is considered as a protective feature for managing and handling chemicals of various natures, for example: mild to corrosive, etc. Therefore, for proper distribution, all exhibited chemicals inside each product are possible in V type of mixer. For example, acidic salts, basic, neutrals, organic, inorganic substances, etc.

Agriculture Industry

Agriculture Industry- Picture Courtesy: Angie’s List

An agricultural field mainly relies on the involvement of various agricultural substances that can promote crops and improve the health of plants. Side by side, how to prevent the invasion of pests, insects, etc, different chemicals are used. For that V type mixer is ideal to provide an ideal product which is critical for agricultural practices. For example: pesticides, growth promoters, fungicides, insecticides, phosphate rocks, fertilizers urea, lime, and so much more.

Cosmetic Industry

Cosmetic industry- Picture Courtesy: The list

Cosmetic formulations mainly evolved from mixing. The cosmetic products are all way come from compact to puff, which is now improved with unlimited products such as face tint, blushes, lash thickeners, lip gloss, translucent powders, setting powders, finishing powders, loose powders, pressed powders, and so much. The V type mixer is majorly used in the cosmetic sector for dealing with delicate cosmetic products without damaging their structural integrity.

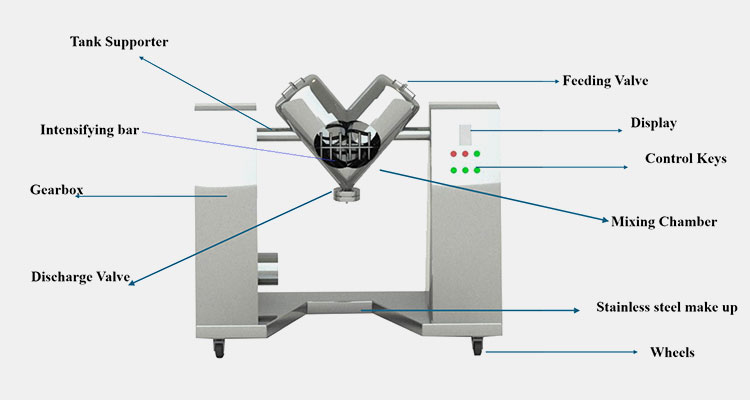

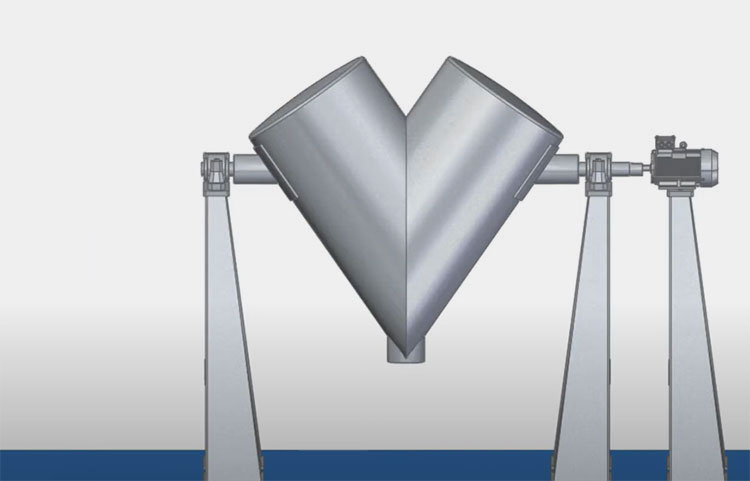

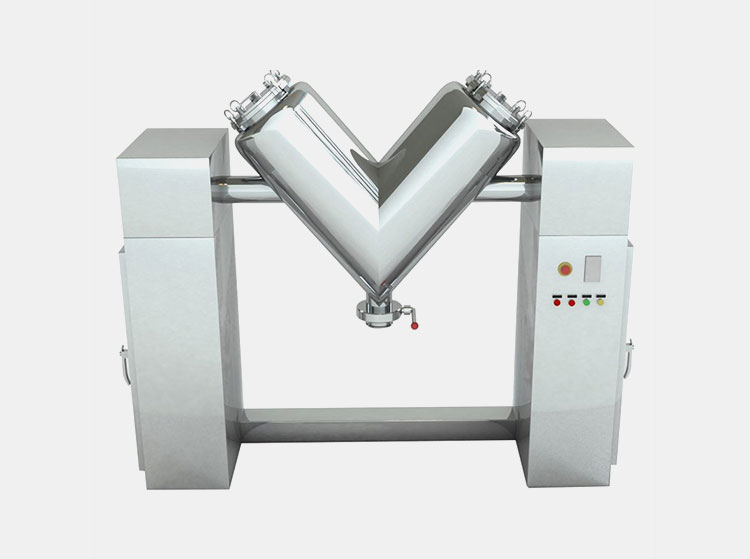

4.What is the construction of V type mixer?

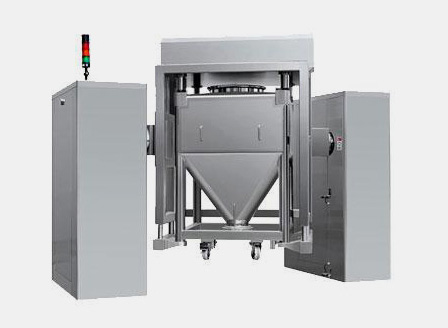

AIPAK V type mixer

V type mixer is a simple structure machine where every component is meant for a specific task. The ultimate objective behind the parts of the machine is to provide a description for easier operating modes.

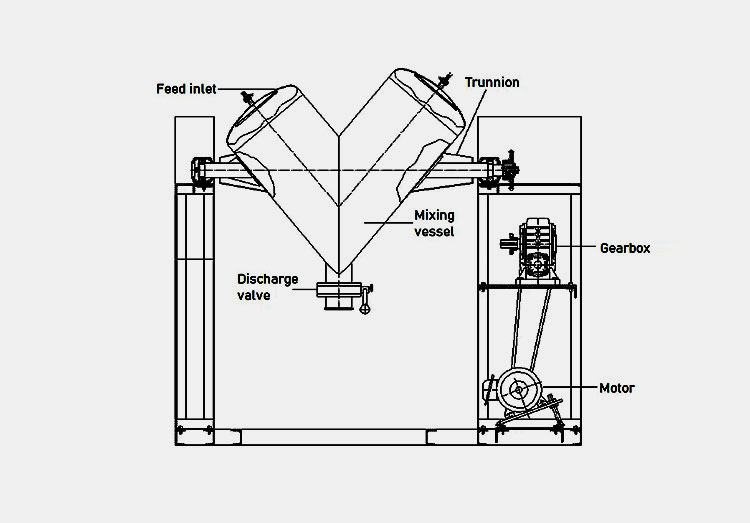

Tank supporter/Shaft

V Type Mixer Tank Supporter/Shaft- Picture Courtesy:Lleal

The V type mixer is composed of a major in a heavy tank for the mixing ingredients. The main function of the unit is to move them gently and produce the mixing force. That is why you need structural support. The primary function of the tank supporter is to provide stability to the tank against shakiness or vibration when the tank or the mixing vessel is in movement.

Feeding valve

Imaginary Structure For Feeding Valve

This is a kind of introductory opening which is also known as an inlet. It allows you to establish the various ingredients meant for the mix-up. The design of this part is specially made with an enclosure. Once you pour different substances inside the tank; you can just close the closure and lock it to secure the raw ingredients. Therefore, along with the gateway for material, this section also provides anti-leaking properties to substances during the mixing procedure.

Display

Display- Picture courtesy: Maxiblend

In conventional practices, the mixing unit entirely relies on manual handling. But today in the world of modern technology, you can see the status of the process just by watching or visualizing the display of the machine. It is included with the speed of the unit and, the types of ingredients incorporated inside the machine. Moreover, you can also modulate the different settings of the process simply by using this touchscreen and can also troubleshoot the major problems, feed the new protocols, recall the memory, etc.

Control Keys

Control keys- Picture courtesy: Inoxpa

The machine is provided with control keys mainly used to regulate the major functions of the unit. For example, switching ON and switching OFF the machine, an emergency STOP. Furthermore, you can also manually regulate other parameters of the system by using control keys.

Mixing Chamber

Mixing Chamber- Picture courtesy: Inoxpa

This is the major portion that is known to be a Game Changer. In this section, you introduce the material to be blended. The various mixing forces inside this vessel are created and maintained for this certain period till it is ensured that the mixing has occurred. The tank provides inlets and discharging outlets where you can easily incorporate the material into the tank and unload the materials after the procedure.

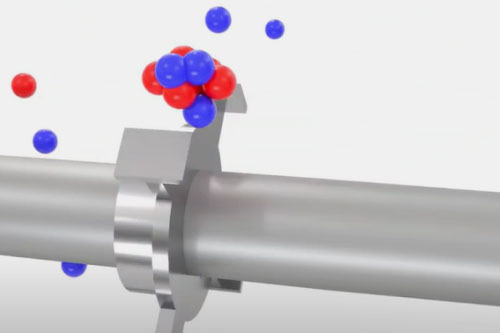

Intensifying Bar

Intensifying bar

In every mixing machine, there is a kind of agitator facilitated to catalyze the combining ingredients process. Also, to eliminate the presence of unwanted clogging powder or lumpiness, the intensifying bar is used to break them and produce a smooth and uniform powdery texture of the mixing substances. Therefore the chances of agglomeration become minimised with the help of an intensifying bar.

Gearbox

Inside structural presentation of V type mixer

This is the major chamber that improves the transmission of electrical energy into mechanical energy. Hence offering the momentum to the V type mixer. So, whether light particles or the mixing of heavy particles, the subtle rotational velocity of the machine is mainly accelerated with the gearbox. It ensures that mixing is carried out without any interruption or obstruction in the practice.

Discharge Valve

Discharge Valve

When the subjected materials are mixed properly under the required time. You can discharge the loaded material with the help of an outlet without any chance of spillage.

This part of the machine is mainly designed at the bottom of the tank. Consequently, the delivery of subjected substances takes place with the help of manual operation. You can untwist the lever presented with a discharge valve to loosen the bolts and allow easy opening. Additionally, whenever you have to clean the machine, you can also use this portion.

Stainless Steel Body

Stainless steel body- Picture courtesy: SeFluid

V type mixer body is mainly made up of food-grade stainless steel. It ensures that the subjective material inside the machine is secure and safe. The machine is coated with materia

ls based on anti-corrosive properties and it is quite easy to clean. Moreover, if you slide your hand on the unit, you can feel how smooth its outer and inner surface is. Therefore, it assures your machine is constructed with highly astringent regulatory standards.

Wheels

AIPAK V Type Mixer

Today, every machine design is based on user requirements and how it can help to ease your burden. In this case, the wheels are provided for the machine to smoothen the movement for installation and allocate the equipment. It is a critical part of the machine that ensures mobility as well as supports the system in case of integration.

5.How V type mixer work?

If you’re wondering the challenges for working with V type mixer then we have found the solution. Just see the discussed below easy steps and illustration of processing so you will realize the simplicity of the unit. For simplification, we have divided the steps into some major headings. The V type mixer working is just right here:

STEP 1: Loading of Material

| Description | Picture

|

| Just start the machine and put the data using control key and display presented on the machine’s front. This is suggested to load the mixing ingredients up to 50 to 70% of concentration. If you load more than that, the tumbling forces would be disturbed, and the sufficient mixing won’t be occurred. The loading of the materials is taken place by using the infeed or inlet of the machine. |

Loading of materials |

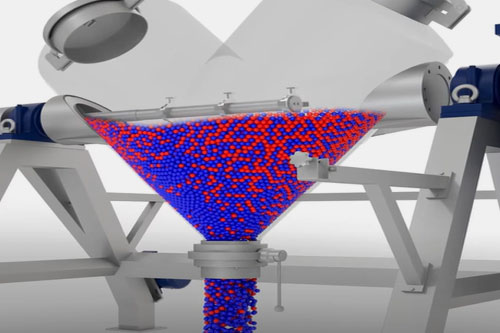

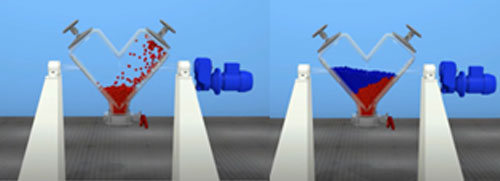

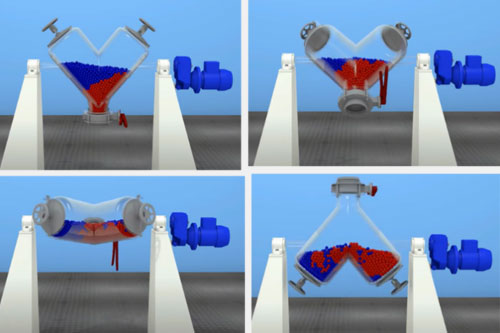

STEP 2: Circulation of the Tank

| Description | Pictures |

| After adding the material, closed the main inlet valves and start the process. The machine is capable of revolve around the fixed shaft by following ten to thirty revolutions in a minute.

These steps ensure that a thorough mixing is achieved by as the entire vessel revolves around the support so there won’t be any chance where any particle escapes from mixing pattern. |

Rotation Of Mixing Tank |

STEP 3: Allow mixing for certain time & Discharge

| Description | Pictures |

| Indeed, the greater force is required to lift the mixing tank but the falling down is taken place by force of gravity. Therefore, the merging action is allowing the material blending from various directions. The process time is varying, and it is depending upon material to material and its flowability ratios.

The powders with less flowability requires excessive time than light or fine particles. Also, the action of intensifying bar is facilitating more subtle mixing where lumps or agglomerated particles are broken down into smaller sizes particles. |

Lumps Breakage with Intensifying Bars Discharging |

6.How to classify the V type mixer?

A V type mixer is a standard type and its classification is only available related to available different sizes. For instance,

Mini V Type Mixer

Mini V Type Mixer

There’s good news for newbie or people with small businesses. A V type mixer is also presented with small and benchtop sizes to bring mixing task for sensitive material in a subtle and smooth working pattern. This is an ideal option for research studies or production with small batch sizes. The machine is capable to run material of 2 to 8L.

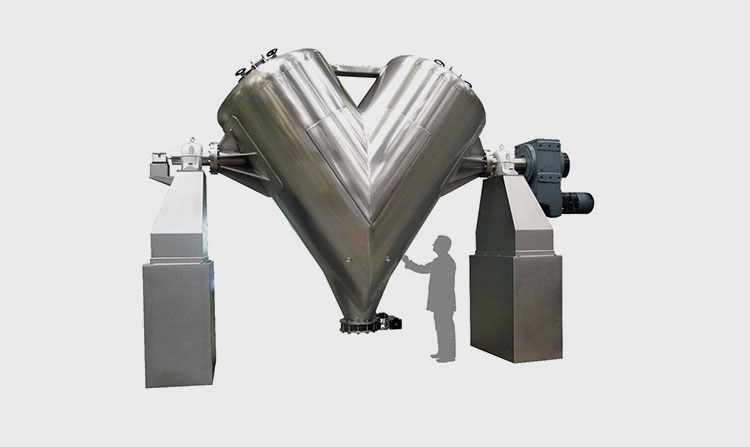

Industrial V Type Mixer

Large V type Mixer- Picture Courtesy: Freund Global

As compared to mini-V type mixer, this unit is heavy and capable of running powders with a large accumulating capacity. Here the machine ranges for occupying material ranges from one thousand to several thousand Liters. The machine is mainly used in the production processes of pharmaceuticals, foods, and large industries.

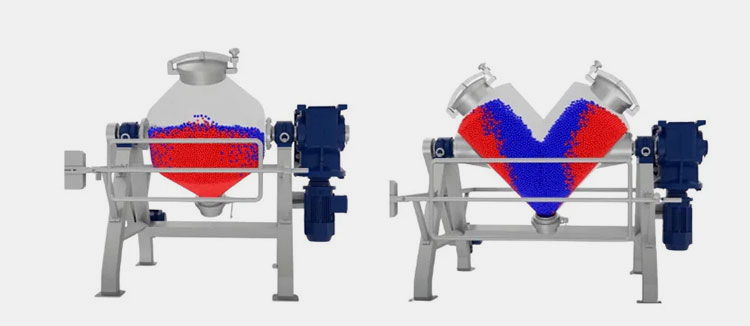

7.Are V type mixer and double cone mixer the same?

Double Cone Mixer and V Type Mixer

No, they are not the same. Indeed, a V type mixer is also known as a V cone blender. However, you cannot make it similar to the double cone mixer. There are certain sharp differential properties of these two machines that make an easy distinguishing point.

Structure

A V type mixer is twin shell cylinders that join together at the point and look like shape V. whereas the double cone mixer is made up of two cones that are designed and joined opposite to one another.

Mixing Speed

A V type mixer offers a fast-mixing velocity by tumbling action of the tank. Whereas the double cone mixer offers a thorough mixing with a gentle and subtle speed. So, when you need an immediate mixing, a V type mixer is ideal.

Application

A V type mixer is suitable for powders belonging to normal to sensitive nature. Whereas a double cone mixer is only referred for powders with delicate, fragile or sensitive nature and necessitates gentle mixing speed.

8.Is V type mixer only suitable for dry mixing?

Dry mixing- Picture courtesy: Evonik

Yes, a V type mixer is only suitable for dry mixing. The wet mixing is the culprit behind the stickiness of the particles and makes the process difficult to manage. The structure of V type mixer is very simple, and it is created by only referring to the dry ingredients.

For wet ingredients or wet mixing, you will be required to add impellers and blades to intensify the mixing speed and induce high shear forces. Moreover, the dry substances if added with wet ingredients will create a strong bond and clogs. It ultimately generates high pressure and force for mixing them which can result in machine damage.

So, the V type mixer is only suitable for free-flowing powders, granules, pellets, etc whereas tumbling forces can produce an even distribution and mixing of the substances.

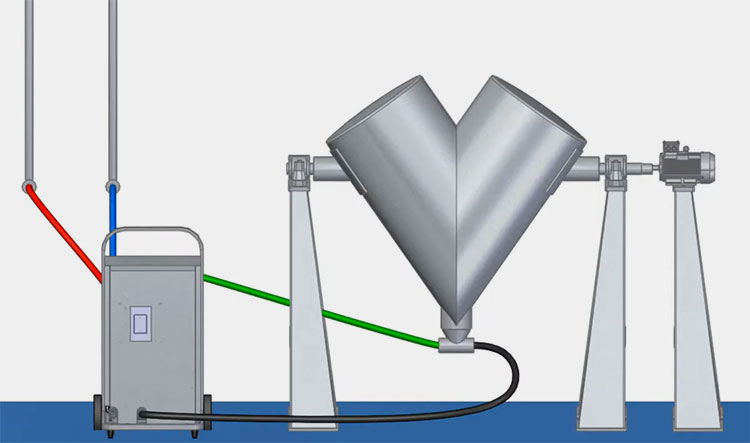

9.How do you clean V type Mixer?

After completing the procedure, you will be required to clean the machine. Although, a V type mixer is not easy to clean when it comes to talk about its internal cleaning. See the below discussion related to cleaning the unit.

External Cleaning

External Cleaning Of V Type Mixer

The external cleaning is pretty easy and it is mainly taken place by manual cleaning. The dry cloth is used to wipe the dust, followed by a damp fabric. The subsequent procedure ensures the elimination of debris and external dust.

Internal Cleaning

Cleaning Of V Type Mixer

Internal cleaning can not be possible by manual procedure, but a vacuum machine is fixed at the opening valve to suck the extra and unwanted leftovers inside the tank. In the case of washing, a motor is connected to two outlets one connection is to provide clean water, and another connection is to remove the water. The pressure nozzle inside the tank ensures intense flushing which results in effective cleanup. A similar unit helps in offering cleansing by vacuum and compressed air.

Conclusion

This blog is mainly a discussion about the design, working, and applicability of the V type mixer. Here, we talked about the main component and related benefits of the machine. We are assuming that after reading the blog, you will be able to learn and explore more about the V type mixer. If you’re planning to start up your business or have any queries. We would suggest you contact AIPAK’s team. Why us? We are experts in pharmaceuticals and related equipment with a top-notch track record of supplying different types of machinery to your doorstep. If you have an astringent budget, then don’t worry! We have the solution for you by providing a series of equipment that best fits your pocket. What are you waiting for? Just message us to start the journey of success.

Don't forget to share this post!

Bin Mixer Related Posts

Bin Mixer Related Products

Bin Mixer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine