How Does Pressure Drop Affect Tablet Pressing Machine Efficiency?

Have you ever wondered the forming of your tablet while you take it? You may have known the tablet pressing machine which makes the efficient and reliable work for tablet pressing. In the tablet pressing work, there may be some problem or affecting factors. How does pressure drop affect tablet pressing machine efficiency.

How much you know about tablet pressing machine? What are the benefits of tablet pressing machine? What are the main type pf tablet pressing machine? How does tablet pressing machine work? What affect the efficiency of tablet pressing machine? You can be the professor after you reading this post. Come on and have a reading.

1.What Is Tablet Pressing Machine?

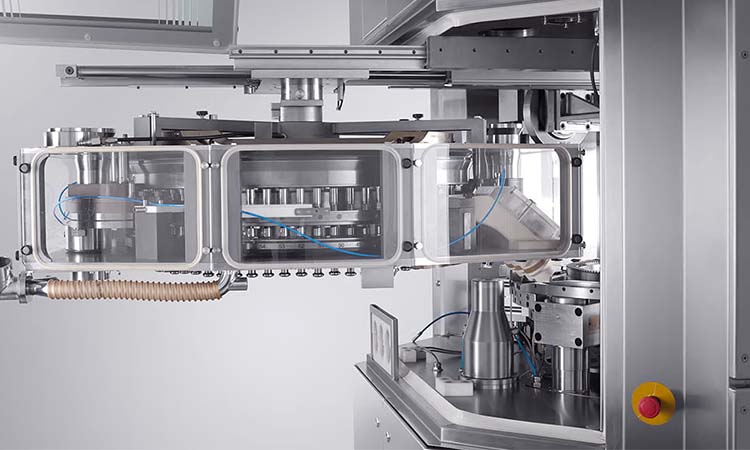

AIPAK Tablet Pressing Machine

In many industries, you cannot avoid the applying of an advanced tablet pressing machine. Tablet pressing machine makes the important job in pressing powder or particles to the even and uniform solid dosage form. The solid and even dosage form can prove the medicine effect, safety and quality.

Tablet pressing machine makes series of work like powder filling, tablet pressing and tablet ejecting. This machine can handle various types of powder or particles. There are tablet pressing machines of different type or structure for your different manufacturing need and material features.

2.What Industry Can Tablet Pressing Machine Be Applied?

Tablet pressing machine can be applied to many industries. And here are the industries which tablet pressing machines are frequently applied.

Pharmaceutical industry

Pharmaceutical Industry-Sourced:pharmaceuticalmanufacturer

Pharmaceutical industry makes the frequent application of tablet pressing machine. Tablets are the common medicine form which is widely applied in various medicine type for its feature like stable, safe and easy to take. Besides the conventional medicine like relievers, antiboitics and so on. You may also find the wide application of tablets in supplementary products.

Cosmetic industry

In cosmetic industry, you can also find the application of tablet pressing machine. For cosmetic products, there are the creative trend for the products manufacturing. Tablets are stable, compressed and safe which are definitely suit the job of various cosmetic products.

Food industry

Food Industry-Sourced:foodinstitute

Tablets can also be the welcomed snack for children and adults. There are various candy or other edible products which can be pressed with tablet pressing machine. Tablet pressing machine can press powder or particles into the even and uniform tablets. In market, there are welcomed pressed tablets which are made with tablet pressing machine.

3.How Does Pressure Drop Affect Tablet Pressing Machine Efficiency?

Pressure dorp makes the significant affect for tablet pressing work. How does pressure drop affect tablet pressing machine efficiency.

Reduced production speed

Reduced Production Speed-Sourced:alpsleak

Increased tablet pressing cycle

Pressure loss means that additional time is needed to compensate for the lost pressure to achieve the same tablet pressing effect. For example, a compaction process that could originally be completed with one pressing may require two or more pressings due to pressure loss, tablet pressing cycle increase and tablets pressing time reduce.

Limiting equipment operating speed

To ensure tablet quality, operators may reduce the running speed of high-speed tablet presses when pressure loss occurs. It allows the material more time to be subjected to pressure to compensate for the effects of pressure loss. This directly results in the equipment being unable to operate at its designed high speed and reduces production efficiency.

Impact on tablet quality leading to rework

Impact On Tablet Quality Leading To Rework-Sourced:acg-world

Cracked or loose tablets

Pressure loss can result in insufficient compaction of the material inside the mold, leading to insufficient binding force within the tablet. It makes cracked or loose tablets. Statistics show that when pressure loss is between 10% - 20%, the incidence of cracked or loose tablets may increase by 20% - 50%. These defective tablets need to be reworked or scrapped, thereby reducing overall operational efficiency.

Weight variation exceeds standards

Pressure loss may cause uneven filling of material in the mold, resulting in tablet weight variations that exceed the specified range. For tablets with strict weight precision requirements, exceeding the weight variation standard will cause the entire batch to fail quality checks, necessitating re-production, which severely impacts production efficiency.

Increased equipment wear and failure

Increased Equipment Wear And Failure-Sourced:atten2

Increased component wear

In the presence of pressure loss, to achieve the required pressure, the pressure-applying components of the equipment have to bear a heavier load. For example, uneven pressure between the punches and the molds will lead to increased wear on the punches and molds. Taking the mold as an example, under normal conditions, the mold might last for 100,000 tablets, but due to uneven wear caused by pressure loss, its lifespan might shorten to 50,000 - 80,000 tablets which increases downtime and reduces operational efficiency.

Cause of equipment failure

Pressure loss can cause the equipment's drive system, hydraulic system, and other components to experience abnormal pressure and stress which can lead to failures in these systems over time. For example, unstable pressure in the hydraulic system may damage components like the oil pump and oil pipes. Equipment failure leads to production halts, and maintenance and troubleshooting take considerable time which may severely affect the operational efficiency of high-speed tablet presses.

Increased energy consumption

Increased Energy Consumption-Sourced:energymagazine

Additional energy consumption

To compensate for pressure loss, equipment needs to consume more energy to maintain pressure. For example, the motor must output greater power to drive the pressure-applying mechanism, resulting in higher energy consumption. It is estimated that with every 10% increase in pressure loss, energy consumption may increase by 15% - 20%. This not only raises production costs but also reflect a decrease in equipment operational efficiency.

Reduced Energy Utilization Efficiency

Pressure loss leads to energy waste in the process of pressure transmission, as energy cannot be effectively converted into the mechanical energy required for tablet pressing. This reduces the overall energy efficiency and operational efficiency of the high-speed tablet press.

4.What Are The Benefits Of Tablet Pressing Machine?

Tablet pressing machine can make great help for tablet pressing work of many manufacturers. What are the benefits of tablet pressing machine?

High efficiency

High Efficiency-Sourced:jethrojeff

Tablet pressing machine is high efficient. The machine with different automation level and manufacturing scale has different efficiency. In all, tablet pressing machine is high efficient and can deal with tablets of various size and shape and medical powder of different type.

High precise

High Precise-Sourced:verywellmind

Tablet pressing machine is high precise in pressing tablets. You may have the bad condition like tablet breaking, tablet loosing and so on avoided here. The high precise of tablet pressing machine makes the outstanding job in making the high qualified and great tablets products.

Flexible machine

Tablet pressing machine is high flexible in dealing with various kinds of tablets products. You can adjust the tablet pressing machine to make the tablets with various size and type. The tablet pressing machine is so flexible that you may apply it for various tablets type and size.

Easy to operate

Easy To Operate-Sourced:gea

Tablet pressing machine is easy to operate. It avoids the complex process of making panel or other parameter. You can operate with little training. The easy operating machine takes so much benefit for your manufacturing business.

Low waste

For some material with high price, you should have little waste for them. Tablet pressing machine makes the best use of powder and particle material. It reduces the waste and makes the best use of the various raw material.

5.What Are The Main Type Of Tablet Pressing Machine?

There are various type of tablet pressing machine. And here are the main type of tablet pressing machines.

Single-punch tablet pressing machine

AIPAK Single-punch Tablet Pressing Machine

Single-punch tablet pressing machine can be operated manually or automatically. This type pf tablet pressing machine is suitable for the small scale production. Each rotary makes the single pieces of tablet pills. The easy changing of mold or relative parts promote the making of the great pills.

Rotary tablet pressing machine

AIPAK Rotary Tablet Pressing Machine

Rotary tablet pressing machine is more efficient and can handle the large scale tablets pressing work compared with the above mentioned tablet pressing machine. The multiple sets of punches of rotary tablet pressing machine can handle the large scale production easily.

Flower-basket tablet pressing machine

AIPAK Flower-basket Tablet Pressing Machine

Flower-basket tablet pressing machine is the pressing machine which can handle the large scale production of various industries. This type of machine is stable in structure, high degree in automation level. It is highly flexible and can make the outstanding pressing for tablets of various type and size.

High speed tablet pressing machine

AIPAK High Speed Rotary Tablet Pressing Machine

High speed rotary tablet pressing machine can handle the large scale manufacturing with high speed. The high automation level and precise manufacturing work makes it outstanding in the various tablet pressing machine types. It can make the various tablets with different shapes and structure. The great pressing ability makes the high qualified tablets for your manufacturing.

Effervescent tablet pressing machine

AIPAK Effervescent Tablet Pressing Machine

Effervescent tablet pressing machine is the machine specially designed for effervescent tablets pressing. This equipment is good at pressing the active ingredients, binder and other material for the effervescent tablets of different size and type. It can make great deal for the tablets of the special features.

6.How Does Tablet Pressing Machine Work?

Tablet pressing machine can always make the pressing work with high efficiency and quality. How does tablet pressing machine work?

The Manufacturing Process Of Tablet Pressing Machine

Filling

Tablet pressing machine makes the accurate and precise filling for its tablet products. It distribute precise amount of powder to each mold hole. The distributed powder has the close relationship with tablet size and weight. You may adjust the powder weight for the tablets products size and type.

Compressing

After the filling of material in each pole, it is time for tablet compressing. This process decides the appearance of your products. You can change the type or size of your mold for the tablet appearance adjusting. The tablet forming of tablet pressing machine comes from the pressing of two punches and the mould. The strength, move and many points decides the features of the tables.

Ejecting

Ejecting refers to the removing of your tablets from tablet pressing machines. The rejected tablets will be collected for the next step inspecting or packaging. The tablets will be rejected with full completeness from this machine. You can have your tablets compressed well from this process.

7.What Affect The Efficiency Of Tablet Pressing Machine?

Tablet pressing machine cannot always be so efficient. And here are the factors which may affect the efficiency of tablet pressing machine.

Material problem

Material Problem-Sourced:askthescientists

Your powder material makes a lot affect for your tablet pressing manufacturing. For the sticky powder, there will be problem in tablet pressing. You should adjust material feature for the smooth and suitable tablet pressing process. The unsuitable material can also lead the break of tablets.

Improper compression force

Improper Compression Force-Sourced:pharmaceuticalmanufacturer

Compression force should also be adjusted for your qualified tablets. The unsuitable tablets force may lead the tablets feature change. The tablets which are too hard or too short are both unqualified in market. You may adjust the compression force according to your medicine formulation.

Lack calibration

The improper or wrong calibration may make the breakage or wrong feature of your tablets. You should thus make the regular check of your machine and make the proper calibration for your tablet pressing machine. The regular and right calibration can also make the nice maintaining for your products.

Worn parts

Worn punches, blocked feeder and many other worn parts can all make the trouble for tablet pressing manufacturing work. For the prevention of worn parts, you should make the regular check, maintaining and caring for your tablet pressing machines. The emergent replacing of your worn parts is essential for your tablet pressing work.

8.What Are The Common Tablets Problems?

In tablet pressing work, you may find some problem. And here are the common tablets problems and its relative solutions.

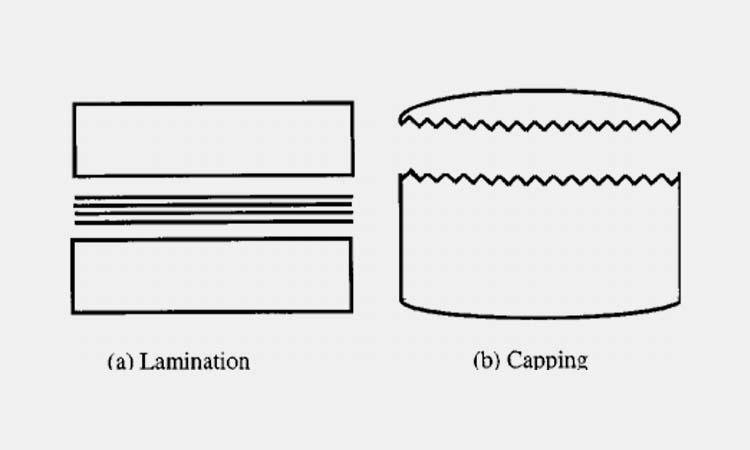

Tablet lamination and capping

Tablet Lamination And Capping-Sourced:researchgate

Tablet lamination and capping refers to the top or bottom split or fracture. It damages the inner structure of tablets and affects the effect of your tablets. For the solution, you should adjust the compression force, apply right punch and make the sticky formulation. This can help avoid the lamination and capping of your tablets.

Tablet sticking

In the last step of your tablet pressing work, tablet sticking happens and makes the ejecting hard. It may lead the tablets break or incomplete. This happens for the raw material feature and compression force problem. You should also care your punches condition for your tablet sticking solution.

Tablet breaking

Tablet Breaking-Sourced:consumerlab

The broken tablets won’t make great sale in market. Tablet breaking comes from raw material problem mainly. For powder with high moisture or large particle size, it is easy to make tablet break. And besides, you should also pay attention to compression force. The adjusting of punch and mold can help you make the great tablets.

Tablet mottling

Tablet Mottling-Sourced:ipharmachine

There are various tablets with bright color in market. Tablet mottling makes the bad first impression for customers. And this phenomenon comes mainly from the uneven mixing of medicine powder. You should also maintain the suitable moisture or heat for powder in storing and manufacturing process as the two factors can also lead tablet mottling.

9.How About The Future Trend Of Tablet Pressing Machine?

Tablet pressing machine is inevitable in so many industries. Do you know the future trend of tablet pressing machine?

High automation

High Automation-Sourced:commtel-networks

In future, the tablet pressing machine will be highly automatic. The high automation level can make the more intelligent and digital tablet pressing work. It can save your energy in tablet pressing process and make the more qualified, efficient and accurate tablets products.

Energy consumption

Energy Consumption-Sourced:siobhanmchugh

The strict regulation on world protection and more awareness promote the work of energy saving and environmental protective tablet pressing machines. This future trend can help protect the world and reduce the pollution on environment.

Customized tablet pressing work

Customized Tablet Pressing Work-Sourced:foodinstitute

The personalized medicine work promotes the customized tablet pressing machine. For the fulfilling of precise and personalized work, there is the trend of customized tablet pressing machine which is made for the small scale production and personalized work.

Conclusion

How does pressure drop affect tablet pressing machine efficiency? Do you know the way to make the best efficiency of your tablet pressing machine? Tablet pressing machine is so efficient and beneficial. And for other problem or question, you may have no hesitate to contact us now.

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine