What Are the Effects of Particle Porosity On Tablet Quality?

Have you noticed that there are always some quality issues in the production of your pills? Tablet press machine, also known as fully automatic tablet press, is crucial for efficient production of tablets in various industries such as pharmaceuticals, nutritional supplements, and others.

Have you heard of particle porosity? Generally speaking, the higher the porosity, the faster the disintegration and dissolution, and the easier it is to absorb.

The quality of tablet pressing is influenced by various factors, and this article mainly discusses the impact of particle porosity on tablet pressing quality.

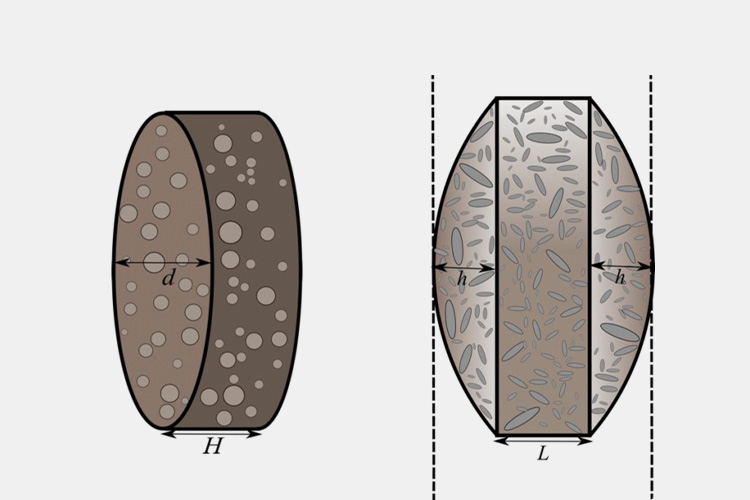

1.What Is the Particle Porosity of the Tablets?

Particle Porosity of the Tablet - Sourced: Link.Springer

Porosity is the ratio of the proportion of heavy voids in the tablet layer, which is the ratio of the volume of voids between particles and the volume of the particles themselves to the volume of the tablet. It is commonly expressed as a percentage.

The porosity of tablets is a comprehensive property related to factors such as particle morphology, surface state, particle size, and particle size distribution. It is a parameter that has a significant impact on the processing properties of tablets and the quality of their formulations. Dispersants, granules, and tablets are all processed from powders, and their porosity directly affects the disintegration and dissolution of drugs.

2.What Is the Production Process of Tablet Pressing?

Production Process of Tablet Pressing - Sourced: Pharmaceutical Process

Tablet pressing is a crucial step in pharmaceutical production, which involves compressing powdered drug materials into tablets for easy administration and dosage control.

Ingredients and granulation

Selecting appropriate ingredients according to the required products. Quality inspectors should inspect them, and attach a qualified inspection certificate. When granulation, the powder must be mixed evenly.

Tablet pressing

The temperature in the tablet pressing operation room is 18-28℃ with a relative temperature of 50% -65%, and maintains a relative negative pressure with the outer chamber. Before and after using the punching die, the smoothness should be checked for grooves, curled edges, missing corners, bursting and wear.

Inspection

To ensure the factory quality of the product, you should inspect the appearance of the tablets, such as the smoothness of the surface. You also need to check the disintegration time limit and dissolution rate.

3.What Are the Effects of Particle Porosity on Tablet Quality?

The influence of particle porosity on tablet quality is mainly reflected in the following aspects:

Weight difference

Weight Difference - Sourced: PharmEducation

When the porosity of particles is too high, the stacking between particles is not tight enough. During the compression process, the flowability of particles may be affected, resulting in unstable filling of particles in the mold pores. This will increase the weight difference of each tablet, making it difficult to ensure the uniformity of tablet weight, and there may be cases where the weight of some tablets exceeds the specified range.

If the porosity of the particles is too small and the particles are too dense, the filling speed may slow down due to the high friction between the particles when filling the mold holes, which will also affect the accuracy and consistency of the sheet weight, resulting in a larger difference in sheet weight.

Hardness

Hardness - Sourced: NPR

A high porosity of particles means that the contact area between particles is relatively small, making it difficult to form sufficient bonding force between particles during compression. Under the same pressure, there are fewer binding points inside the tablet, resulting in lower hardness and susceptibility to cracking and loosening. It is also prone to breakage during transportation and storage, which affects the quality and stability of the product.

Particles with low porosity can form more binding points during compression, but due to their excessive density, the elastic recovery force is greater. After the pressure is removed, the stress inside the tablet is released, which may cause small cracks to appear inside the tablet, thereby reducing the overall hardness of the tablet, and in severe cases, cracking may also occur.

Fragility

Fragility - Sourced: Erin Everett

The internal structure of tablets with high porosity is loose, and when subjected to external forces such as vibration or friction, the particles on the surface of the tablet are prone to detachment, leading to an increase in brittleness. This not only affects the appearance quality of the tablets, but may also cause changes in the active ingredient content of the tablets, affecting the efficacy of the drug.

Although tablets with low porosity have higher hardness to some extent, they may have internal defects due to the influence of their elastic recovery force.

Disintegration time

Disintegration Time - Sourced: VectorStock

The high porosity of tablets makes it easy for moisture to quickly enter the interior, allowing the disintegrant to quickly take effect and thus shorten the disintegration time of the tablet. If the disintegration time is too short, it may lead to rapid release of the drug in the gastrointestinal tract, which may affect the absorption and efficacy of some drugs that require controlled release rate.

A low porosity will hinder water from entering the interior of the tablet, making it difficult for the disintegrant to function and prolonging the disintegration time of the tablet.

Appearance

Appearance - Sourced: Thomas Processing

During the compression process, particles with high porosity may not form a smooth surface due to insufficient compression, and the surface of the tablet may have problems such as pitting and roughness, which affect the appearance quality of the tablet.

A small particle porosity may result in uneven internal stress distribution during tablet compression, leading to the formation of subtle cracks or unevenness on the surface of the tablet, which can also affect its appearance.

4.How to Determine the Porosity of Compressed Particles?

Porosity is a key quality attribute for drug disintegration, dissolution, and bioavailability, and there are multiple methods for measuring porosity.

Mercury intrusion method

Mercury Intrusion Method - Sourced: www.grad.hr

Mercury intrusion porosimetry is a commonly used method for measuring the porosity characteristics of drugs, which can measure the percentage of open pore volume connected to the outside world in the total volume of the sample.

The principle of mercury intrusion method is based on the fact that mercury does not wet most solid materials, and the interfacial tension will resist the entry of mercury into the pores. To allow mercury to enter the openings of the material, external pressure needs to be applied.

Weighing method

The principle of weighing method is to determine the pore volume of a material based on the weight change before and after it is wetted by a liquid (such as water).

Density method

The basic principle of the density method is similar to the weighing method, as only the density and apparent density of the raw material need to be known to calculate its porosity.

5.What Other Factors that Affect Tablet Quality?

Tablets are affected by many factors during the compression molding stage, such as melting point, moisture content, etc.

The melting point and crystal form

A lower melting point of drugs is beneficial for the formation of “solid bridges” and increases the hardness of tablets. However, if the melting point is too low, it is prone to sticking and impact during tablet compression.

Scaled or needle shaped crystals are prone to form layered arrangements, and tablets are prone to fragmentation; Dendritic crystals are prone to deformation and interlock with each other, with good compressibility and easy forming, but extremely poor fluidity.

Adhesives and lubricants

Adhesives and Lubricants - Sourced: Atlas McNeil Healthcare Community

Generally speaking, the larger the amount of adhesive used, the greater the bonding force between particles. However, it is important to avoid difficulties in disintegration and dissolution caused by excessive hardness.

Lubricants cover the surface of particles and have little effect on the formation of tablets within the commonly used concentration range, just like magnesium stearate. However, excessive amounts can affect the bonding force between particles, resulting in a decrease in tablet hardness.

Water

Water - Sourced: iStock

The appropriate amount of water is squeezed onto the surface of the particles during compression to form a thin film, which acts as a lubricant, making it easier for the particles to approach each other and form a cohesive shape. In addition, the water squeezed onto the surface of the particles contains soluble components. When the tablets are dried, recrystallization can occur and “solid bridges” can be built between adjacent particles, which tends to increase the hardness of the tablets.

Pressure

Under normal pressure, the greater the pressure, the closer the distance between particles, the stronger the binding force, and the greater the hardness of the compressed tablets. However, when the pressure exceeds a certain range, the impact of pressure on tablet hardness decreases and fragmentation is more likely to occur. Extending the compression time or reducing the compression speed is beneficial for increasing the binding force of the tablet.

6.What Are the Common Types of Tablet Press Machines?

Due to different needs and budgets, there are various types of tablet presses, as detailed below.

Single punch tablet press machine

Single Punch Tablet Press Machine

If you want to do some small experiments, you can choose this one. This small single punch tablet press machine can be manually operated. It is equipped with a die that can adjust the filling depth and tablet thickness of the material. Although this machine is compact, it has strong applicability and easy operation.

Flower basket tablet press machine

Flower Basket Tablet Press Machine

This machine is also very small, making it convenient for conducting small experiments. If you are in a hospital or laboratory, you can use this machine. Although this machine is also very small, it can be used for different materials such as coffee chips, pills, agricultural fertilizers, etc.

Rotary tablet press machine

Rotary Tablet Press Machine

Rotary tablet press machine is mainly used to compress various granular raw materials into tablets, but is not suitable for the compression of semi-solid, moist powder, and non granular ultra-fine powder. This machine has adjustable batch tablet pressing parameters and is made of all stainless steel material to prevent tablet breakage and ensure production quality and efficiency.

High speed tablet press machine

High Speed Tablet Press Machine

If you need large-scale production, you can use this high-speed machine. Equipped with advanced pressing technology and automated control systems, high-speed tablet press machine can greatly improving production efficiency. The high-speed tablet press is suitable for pressing various materials and specifications, and has strong versatility and flexibility. Both large pharmaceutical companies and small laboratories can choose suitable high-speed tablet presses for production according to their actual needs.

7.How to Solve the Common Issues During Tablet Pressing?

There may be some problems during the tablet pressing process, and we need to carefully identify the reasons and prescribe the right medicine.

Problem: Fragmented tablets

Fragmented Tablets - Sourced: Telegraph

Solution:

The main reason for cracking may be that the pressure of the tablet press is too high or the speed is too fast, and the pressure should be appropriately reduced or the operating speed of the machine should be slowed down.

Problem: Sticky flushing

Solution:

This problem may occur due to the high moisture content of the particles or insufficient lubricant material. Therefore, it is necessary to adjust the drying time and temperature appropriately, or increase the amount of lubricant appropriately.

Problem: Uneven weight

Uneven Weight - Sourced: Wikiwand

Solution:

It may be caused by uneven distribution of particle size, so it is necessary to mix or sieve the particles to excess fine powder. If it cannot be resolved, it should be re pelletized.

8.What Things Should Be Consider When Choosing Tablet Press Machine?

There are various types of tablet press machine on the market, how can you choose your favorite product from them?

Performance

Choosing a tablet press depends on its performance, such as tablet pressing speed, accuracy, and materials used. Choosing this high-performance tablet press also has fewer problems and can achieve twice the result with half the effort.

Price

Price - Sourced: Better Proposals

As a high-speed rotary tablet press machine, not only its selling price, but also its subsequent use cost, quality stability, and other aspects are important components of the overall cost composition. The different choices of accessories will naturally result in price differences, and of course, the different options determine the continuity and stability of instrument operation, which in turn determines the overall cost.

Brand and reputation

Brand and Reputation - Sourced: Aim Technologies

For friends who are not familiar with the market, they can look for brand manufacturers whose tablet presses have guaranteed quality and good after-sales service. Of course, you also need to conduct research on these brand manufacturers.

Conclusion

The porosity of tablets is one of the important quality indicators of tablets, which reflects the ability of tablets to resist damage. Tablets are also affected by other factors, so it is necessary to choose a suitable tablet press to improve the quality of the product. If you still want to learn about tablet pressing, you can contact AIPAK at any time.

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine