Pharma Blister Cartoner Machine: The Complete Buying Guide in 2025

Are you using medicine and wonder how your tablets and capsule are packed in silver and transparent strip? How they are packed in cardboard boxes? This simple yet precise process involves series of step that starts from packing capsule and tablet in aluminum packaging till the last stage of packing blister in cartons.

Either you are manufacturer and confused about which “Pharma Blister Cartoner Machine” you have to buy in 2025. We listened you. In this article, you will learn about pharma blister cartoner machine, which is used in different industries and its main features which you need to consider while purchase. Without any further due let’s start this informative article.

1.What is Pharma Blister Cartoner Machine?

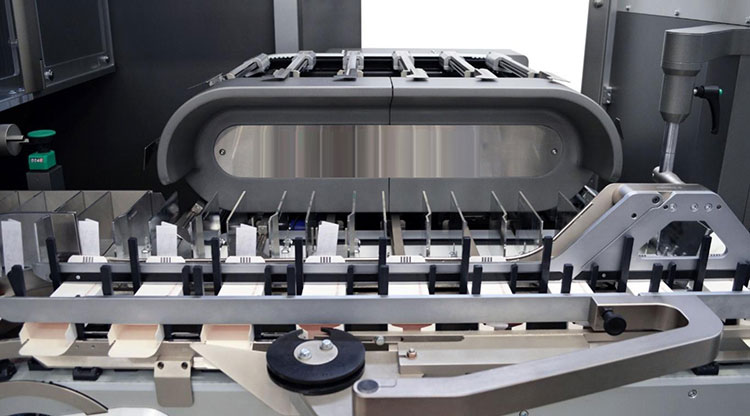

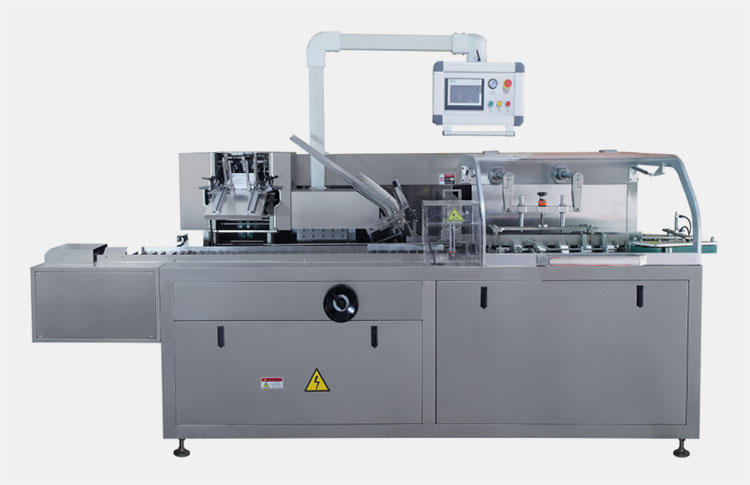

Pharma Blister Cartoner Machine- Picture Courtesy: Marchesini Group

Pharma blister cartoner machine is a specialized automatic machine use to pack each blister containing tablet and capsules in a cardboard box. Primarily, carton box acts as secondary barrier for medicine. This machine can pack anything as long as it in form of blister packaging.

Pharma blister cartoner machine can efficiently handle different sizes of product and pack them in different sizes of cartons. It is an advanced equipment which is widely used in pharmaceutical industry and an essential component in product line of pharmaceutical medicine packaging.

This equipment eases pharmaceutical manufacturer difficulties by efficiently fulfilling market demands and packed large quantity at very high speed. Now it becomes a staple component of pharmaceutical manufacturing unit.

2.Why Do You Need Pharma Blister Cartoner Machine?

Pharma blister cartoner machine has significant benefit in term of easy in transportation, protecting integrity of blister, handling different product and many more. Let’s get into this article, and learn some promising outcomes and benefits of using pharma blister cartoner machine.

Ease of transportation

Ease of Transportation

It helps to pack blister in safe carton, making it easier to transport for distribution and, can place in big cartons easily and can stack on each other. It also helps in transporting pharmaceutical product to different distribution units. In this manner pharma blister cartoner machine can benefit in transportation.

Reducing labor cost

Automation Reduces Labor Cost

Pharma blister cartoner machine is an efficient automatic equipment which can repetitively package medicine without any error. This machinery can be easily operated with very less number of people and, hence reduces need of manual labor and overall cost of packaging.

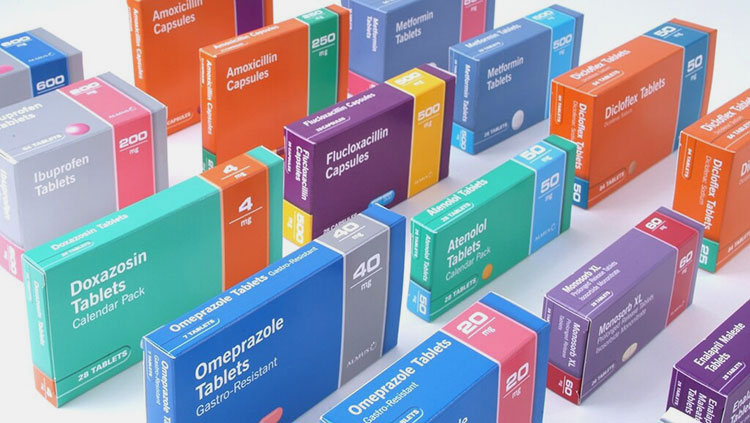

Handling different products

Handle Different Cartons –Picture Courtesy: Rotzinger Group

Pharma blister cartoner machine can easily handle different types and sizes of product so you can say that it is multifunctional and can easily installed with your desired specification. Hence, making it easy to operate for manufacturer.

Maintaining consistency and accuracy

Maintaining Consistency and Accuracy-Picture Courtesy: SiroSilo

As an automatic device, blister cartoner machine can ensure accurate packing in every carton. It also reduces misalignment and improper sealing of carton. In this way it enhances overall product presentation and branding of pharmaceutical product.

Increasing productivity

Increase Productivity-Picture Courtesy: Packaging South Asia

Pharma blister cartoner machine is high tech automated equipment which package blister packs in cartons at very high speed without any error. Hence, it will save you a lot time and increase packaging process of blister without need of extra manual labor.

3.How Other Industries Using Pharma Blister Cartoner Machine In Their Practices?

Other than pharmaceutical, you see can many other industries using pharma blister cartoner machine in their packaging line to increase overall production and functions in their industries. Now in this topic you will learn how other industries using same equipment?

Cosmetic industry

Cosmetic Industry-Picture Courtesy: Cosmetic Boxes Packaging

You can see all your makeup product whether it is cream or foundation, lip balm or lipstick all comes in a secure box packaging. So here you can see application of pharma blister cartoner machine, it makes packaging process much easier and efficient.

Food industry

Food Industry-Picture Courtesy: Hongkiat

It is largely used in food industry, where all your confectionary items, like chocolates or candies are packed efficiently by pharma blister cartoner machine. This machine also maintains quality and shelf life of product, and ensures that carton packaging makes distribution of confectionary items convenient without damaging its shape.

Herbal industry

Herbal Industry

All herbal medicines are come in box packaging. In this industry pharma blister cartoner machine is largely used to packed herbs in blister packaging and then placed them in carton box.

Hardware industry

Hardware Industry-Picture Courtesy: XiMan

In hardware industry, blister cartoner machine is diversely used to pack different product like hardware tools, energizer, wires and different products. It securely packed product.

4.What Is the Average Working Speed of Pharma Blister Cartoner Machine?

High Speed Blister Cartoner Machine-Picture Courtesy: Biaozan

The speed of pharma blister cartoner machine largely depend upon the type of machine you are using or complexity in packaging. But, on an average a semi-automatic blister cartoner machine packed 80-100 cartons per minute.

On the other hand, an automatic blister cartoner machine work on a very advance speed and efficiently packed large quantities. An automatic pharma blister cartoner machine packed an average of 200-400 cartons per minute.

The number cartons packed by blister cartoner highly affect the whole process of packaging. A high speed automatic pharma blister cartoner machine greatly reduces manufacturer stress and they can easily meet increasing market demand.

5.What Are the Main Components of Pharma Blister Cartoner Machine?

The pharma blister cartoner machine is complex structure machine which compromises of multiple component which work together for an efficient result. These are the main parts which you need to learn about

Control panel

Control Panel- Picture Courtesy: iPharmachine

This control panel use to install different specification in pharma blister cartoner machine according to your requirement. It consists of small screen and few buttons to enter instruction and to monitor the process.

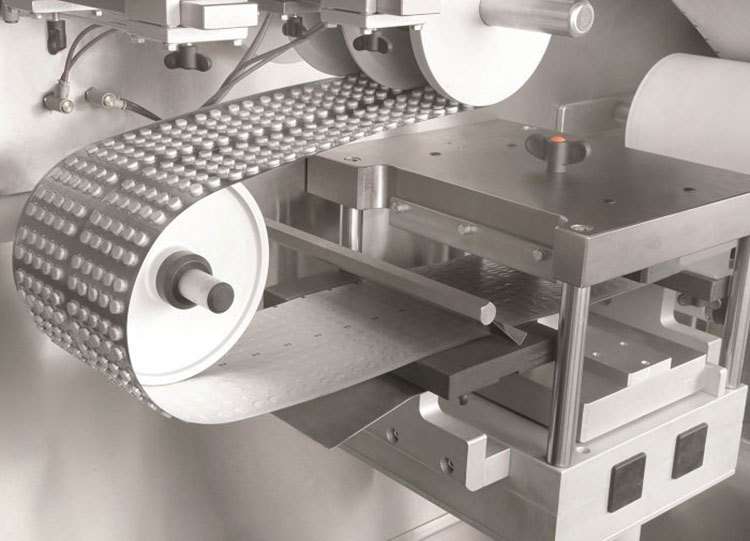

Carton tooling system

Carton Tooling System-Picture Courtesy: SiroSilo

This tooling system in blister cartoner machine is used to determine the required size and shape of carton. This system cut shape of carton according to the instruction which you entered through the control panel.

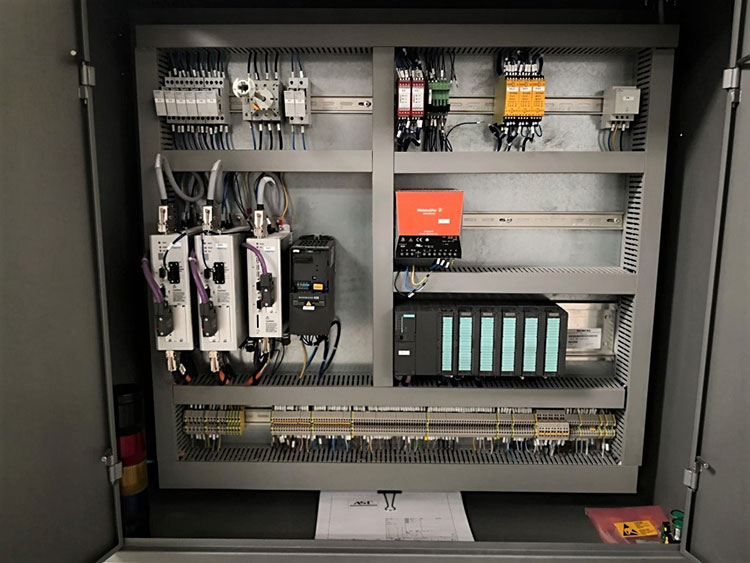

Electric or power panel

Electric or Power Panel- Picture Courtesy: Progitec MTP

The electric panel provides power to pharma blister cartoner machine and run the machine. In easy word you can say that it is switch on and off button of cartooning machine. It gives power to machine to run the process of cartoning product.

Ink printer jet

Ink Printer Jet- Picture Courtesy: Packaging Strategies

It is responsible for printing on carton which includes name product, specification or any information related to product. It can print anything which you install in pharma blister cartoner machine through control panel.

Lubricating system

Lubricating System- Picture Courtesy: Asset Packaging Machine

It allows oiling and greasing different parts of machine which make process smoother. It also helps to reduce friction in various parts of machine as well as protect parts from corrosion.

Safety system

It works as safety protocol for machine. It equipped with sensors that enhance safety of equipment. They also provide safety alarm to alert manufacturer about any malfunction in the pharma blister cartoner machine.

Transport system

Transport System-Picture Courtesy: PCT

This transport system consists of conveyer belts. Rollers and different guide rail which take product to different station. It is a crucial system because optimum speed of transport system ensure every step is precisely performed.

6.What Is the Working Principle of Automatic Pharma Blister Cartoner Machine?

Working Principle of Pharma Blister Cartoner Machine

Basic working principle of blister cartoner machine consist of mainly few steps which must be followed for accuracy.

Setting operating system

First you need to set blister machine according to your desired parameter like size, shape and printing data as well component are also assembled correctly.

Loading material

Loading Material- Picture Courtesy: Citus Kalix

Before initiating the process, it is important to load hopper with all required material like carton. Leaflet, printing data and also glue if hot sealing in done.

Blister making

Blister Formation

After loading material blister are formed by rolling blister film to molds of desired shape and shaped accordingly with the help of heat and pressure.

Filling of blister

Filling of Blister

After giving desired shape to blister. Each blister hole is filled with precise quantity of tablet and capsule making sure high accuracy and consistency.

Sealing

Sealing of Blister- Picture Courtesy: Ascend Packaging System

In this step, blisters are placed on conveyer belt and sealed with aluminum foil pressed on blister with help of heat and pressure. In this way, blister is completely closed.

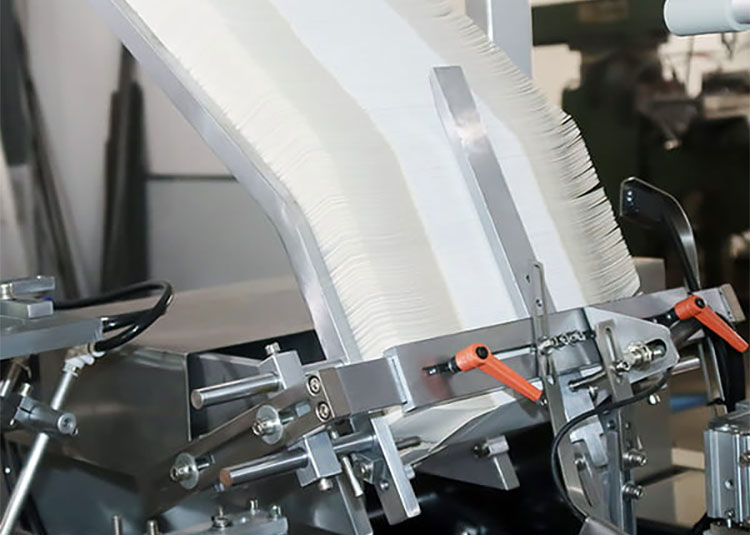

Carton forming

Carton Forming – Picture Courtesy: GTE- Engineering

Along with blister sealing, carton forming process is also started. Carton sheet are sucked through and placed on conveyer belt where carton pass through folding machine resulted in box formation of desired size which you feed in blister cartoner machine.

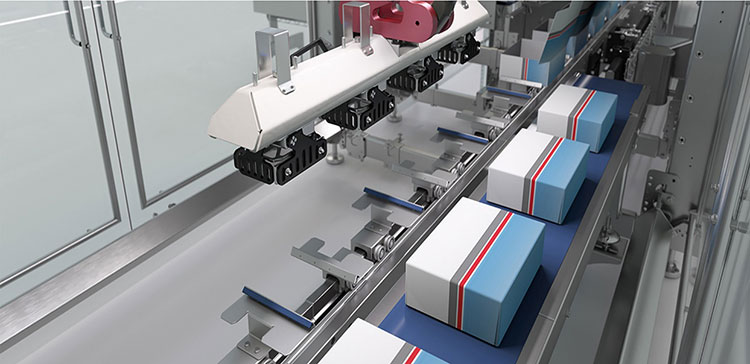

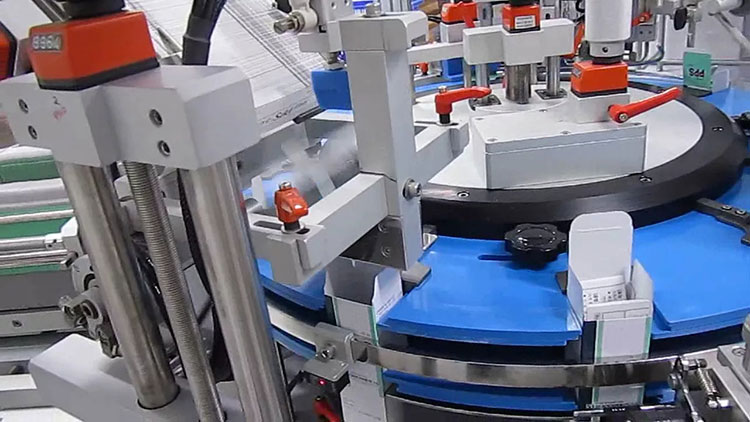

Blister inserting

Blister Inserting- Picture Courtesy: Process worldwide

After carton are formed they are arranged in this manner on conveyer belt and blisters are precisely pushed in to the box with the help of side tool. A counting system is paced which ensure accurate amount of blisters packed.

Closing carton

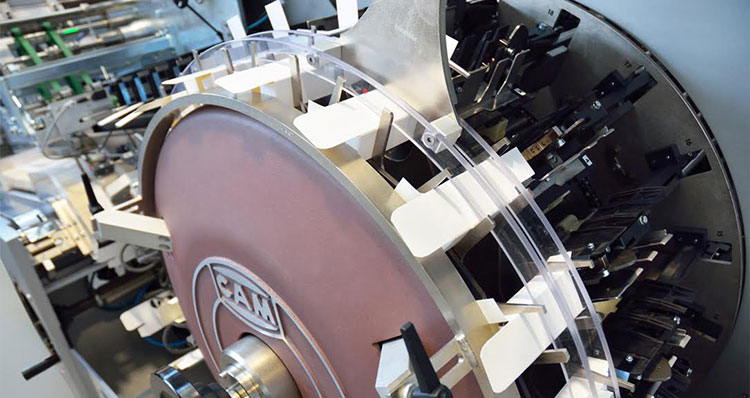

Carton Closing – Picture Courtesy: CAM Automatic Packaging Machine

After blisters are place inside carton boxes, boxes are sent to sealing station on conveyer belt where sealing machine close boxes with the help of glue or heat. Some boxes are closed without glue depending on the design of boxes.

Printing on carton

Printing on Carton-Picture Courtesy: Oliver Inc

After proper sealing of carton, they are sent to printing area where printing on boxes done with relevant information like medicine name, dosage or any information related to medicine which you specify through control panel to print.

Discharging boxes

Discharging boxes

After boxes are printed they ejected from blister carton machine through conveyer belt and further packed in big cartons.

7.What Are Different Types of Pharma Blister Cartoner Machine?

The pharma blister cartoner machine comes in different types depending upon structure modification and level of automation. Let’s discuss each for your understanding.

On the basis of automation

Semi-automatic pharma blister cartoner machine

Semi-automatic Pharma Blister Cartoner Machine

In semi-automatic, it works at fairly good speed. You need to hire manual labor to operate the semi-automatic machine. In some model, manual labor is required at different step like loading carton sheet or turning the sheet after each side fold.

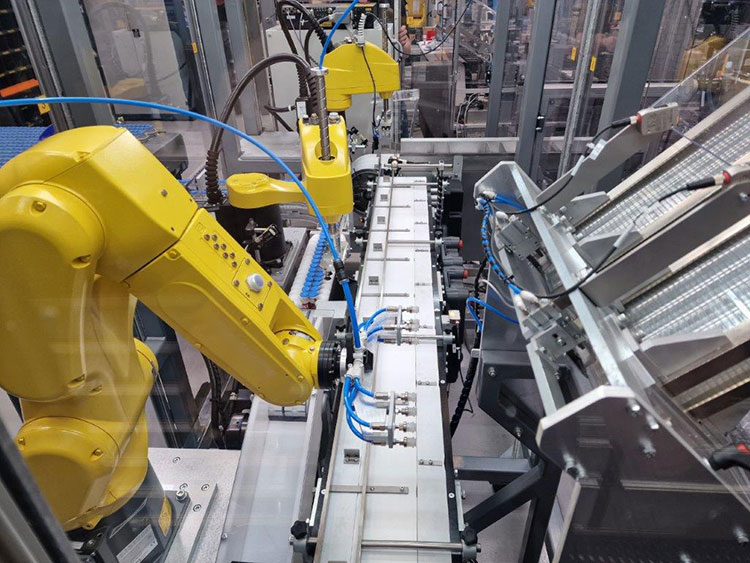

Automatic pharma blister cartoner machine

Automatic Pharma Blister Cartoner Machine

Automatic blister cartoner machine, you will find it more convenient to operate. It works at very high speed. You will not need additional human labor to operate it. In automatic blister cartoner, you need to set specification and instruction at beginning through control panel. Rest of the process done automatically without any manual efforts.

On the basis of structure modification

Vertical pharma blister cartoner machine

Vertical Pharma Blister Cartoner Machine

In vertical setting, material flow vertically into the carton box. It is suitable for packaging syrups, injectable and serums. It easier to operate and clean. It can easily install in compact spaces and can be customize according to production specification.

Horizontal pharma blister cartoner machine

Horizontal Pharma Blister Cartoner Machine- Picture Courtesy: SiroSilo

In horizontal cartoner machine, blisters are pushed through lateral drawer or horizontally. It is mostly preferred for blister packaging of tablet and capsule. It also suitable for large scale setup can easily installed in larger area.

8.Which Important Factor You Need to Consider Before Buying Pharma Blister Cartoner Machine?

If you are going to purchase pharma blister cartoner machine in near future, these are few most important factors you need to keep in mind.

Well-equipped safety measures

Well-Equipped for Safety- Picture Courtesy: Jochamp

You must look pharma blister cartoner machine is safe to use and equipped with emergency sensor which can promptly work without any life threatening situation. For this purpose, ensure that machine meet all safety standards and regulation.

Machine production outcome

Production Outcome

You should also consider production capacity of machine before purchasing so it can meet your production requirement. It can handle bulk material and can easily work different size of packaging. IT can also cope with the production capacity if you want to increase your production in future.

Compatible with other equipment

Compatible with Other Equipment- Picture Courtesy:

You should also look for pharma blister cartoner machine which can easily align with other machine in production line and can easily integrated. In this way, you do not need to change or add any other machinery.

Type of product

Type of Product- Picture Courtesy: Packaging Digest

It is also crucial factor to consider. You should select pharma blister cartoner machine which is applicable to pack your product or either purchase an upgraded version which can handle multiple type of product.

9.What Are Most Commonly Faced Malfunction In Pharma Blister Cartoner Machine?

Air leakage in suction tube

Air Leakage in Suction Tube- Picture Courtesy: Jochamp

Sometimes due to increase pressure leakage occur in suction tube of pharma blister cartoner machine which result in decrease suction force. This suction tube used to suck carton from storage area to conveyer belt and from there carton sheet is move to folding area.

Solution

Sometimes due to increase pressure, this problem arises. For this, you need to set pressure at optimum. You can also replace leaked sucker tubes to make process smooth.

Improper sealing

Improper Sealing-Picture Courtesy: Marchesini Group

This issue is crucial in packaging. It usually arises if glue is sub-standard, the glue temperature is not properly maintained or spray nozzles are jammed which result in improper sealing of cartons. The carton loses holding after time and causing harm to integrity of product.

Solution

To overcome this problem, you need to understand never compromise on quality of adhesive. Temperature must not be too high or low so it results in proper sealing. Always cleans nozzle with time because in long run nozzles get clogged with residue, causing uneven application.

Inaccurate folding

Inaccurate Folding-Picture Courtesy: Vipsport

Accuracy in folding method is crucial in packaging to enhances overall appeal of packaging. If boxes are not fold properly, it messes with look of boxes and slow down whole process. This issue occurs due to misalignment of conveyer belt of pharma blister cartoner machine or wrong material thickness.

Solution

To overcome this issue, you need to adjust conveyer belt to match with the dimension of carton and also choose material wisely. If the material is too thick or too thin, boxes will not fold properly. The folding pressure is also vital because too much pressure damage carton or less pressure result in improper folding. Proper adjustment ensures smooth working of pharma blister cartoner machine.

Damage of mechanical components

Damage in Mechanical Component- Picture Courtesy: iPharmachine

The continuous and regular use of machine in packaging can cause the damage of machine after the long use in production if you don’t check the regular maintenance of machine then it causes major problem of machine as well as decline the level production

Solution

If you need proper functioning of the machine, then you don’t skip the maintenance of machine with timeline which affect the production. Keep all the mechanical components lubricated. Check all parts of machine, if not functioning proper then replace the part. It must increase the life of machine; also timely maintenance of machine may control the lost or damage.

Conclusion

In conclusion, pharma blister cartoner machine is an essential part of pharmaceutical packaging line. It impacts overall product capacity as well as enhance appearance of packaging in many ways. In this article, you also learn how to overcome different malfunction and how to increase production capacity? After reading this blog, you are looking for a pharma blister packaging machine and still have some concern. Contact our expert right now. AIPAK team is expert at providing best customer service

Don't forget to share this post!

Cartoner Related Posts

Cartoner Related Products

Cartoner Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours