What Should Be Cared When Using Fluid Bed Dryer?

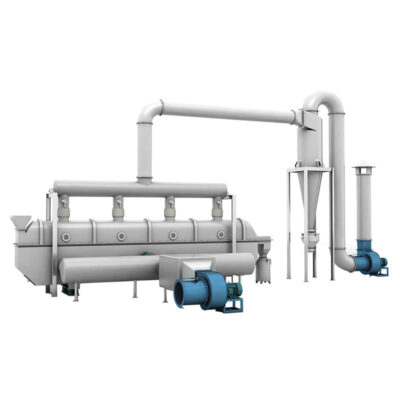

Have you ever heard of fluid bed dryer? Fluid bed dryer makes the irreplaceable work in many industries. It can make a series of work like drying, coating and so on. You may have applied it in your business. This machine is a complex and powerful machine. For use, here are the tips you should paid attention to.

What are the application of fluid bed dryer? What should be cared when using fluid bed dryer? How important fluid bed dryer is to pharmaceutical industry? What are the disadvantages of fluid bed dryer? How does fluid bed dryer work? All this questions can be answered here in this post! Come on and have a reading.

1.What Is FluidBed Dryer?

AIPAK Fluid Bed Dryer

Fluid bed dryer is the advanced and intelligent machine which is widely used for powder drying, fluidization and coating. You may find its use in pharmaceutical industry, food industry, cosmetic industry and so on. It can make great handle of moisture for particles and powder of various kinds.

For the fluid bed dryer work, there will have hot air introduced in the cabinet for the powder or granule drying. And the wasted liquid will be taken away with air. It can also used to make the even coating for tablets and so on. The versatile machine can save you money and energy in manufacturing.

2.What Are The Application Of FluidBed Dryer?

Fluid bed dryer makes the great affect on fluid bed dryer. The application of fluid bed dryer is wide. And here are the industries which make the frequent use.

Pharmaceutical industry

Pharmaceutical Industry-Sourced:anton-paar

Pharmaceutical industry makes the frequent adopt of fluid bed dryer. You may find its use in making powder and particles for tablets, capsules and various medical dosage. The high sanitary and great efficiency of fluid bed dryer can make the great help in dealing with the various medical materials.

Food industry

Food Industry-Sourced:hanningfield

In food industry, there are various powder and particles which require the professional work of fluid bed dryer. You may find flour, fruit powder, vegetable powder and so many powder which requires the deep processing from fluid bed dryer.

Supplementary industry

Supplementary Industry-Sourced:newhope

In supplementary industry, there is the trend of powder in supplementary products. You may find vitamin powder, protein powder, probiotic powder and so on as the welcomed supplementary powder.

Metallurgical industry

Metallurgical Industry-Sourced:gknpm

Metallurgical industry covers a wide range of metal material. And for metal production and metal products manufacturing, it is essential to have the fluid bed dryer for the fine and even powder and particles production.

3.WhatShould Be Cared When Using Fluid Bed Dryer?

The work of fluid bed dryer isn’t that easy. For the smooth and successful fluid bed dryer work, here are the tips you should pay attention to.

Temperature-related

Temperature-Sourced:upsite

Inlet Temperature

Inlet temperature determines the material drying rate, which varies for different materials. For heat-sensitive materials, such as certain bioactive ingredients, the inlet temperature should be set at 60 - 80°C to prevent ingredient deactivation. For non-heat-sensitive materials, 80 - 120°C can accelerate drying.

The high temperature dries the surface of the material quickly, forms a crust and makes it difficult for moisture inside to escape, which may even lead to deterioration of the ingredients. If the temperature is too low, the drying process becomes too slow, affecting efficiency, and the particles may stick due to high moisture content.

Outlet Temperature

It reflects the degree of drying of the material and the thermal balance inside the equipment, generally 20 - 50°C lower than the inlet temperature. If the outlet temperature is too low, the material may contain excess moisture and spoil easily during storage.

If outlet temperature is too high, the material may be excessively dried, causing the particles to become brittle and break easily. The temperature should be kept stable during operation, with fluctuations controlled within ±5°C.

Airflow-related

Airflow-Sourced:goldmedalindia

Fluidizing Airflow

This is a key parameter for fluidizing materials, determined by the material's properties and equipment size. For materials with low density and small particle size, less airflow is needed.

If the airflow is too small, the material will not fluidize properly, leading to dead zones and uneven mixing and granulation. If it’s too large, the material may be blown out, causing particle wear and breakage. Airflow can be adjusted by observing the fluidization state, such as the uniformity of the material’s movement and the evenness of the surface.

Spray Pressure

This affects the atomization of the binder and the size of the droplets, which in turn determines the particle size and uniformity. The pressure is typically in the range of 0.5 - 3 bar.

Higher pressure produces finer droplets and results in smaller, more uniform particles. Lower pressure produces larger droplets, leading to uneven particle sizes. Practical operation requires multiple tests to determine the optimal pressure while ensuring stability with fluctuations controlled within ±0.1 bar.

Material-related

Material-Sourced:gknpm

Material Particle Size

This influences the fluidization and granulation effect. If the particles are too coarse, the material will be difficult to fluidize, and particle formation will be slow. If the particles are too fine, they may agglomerate or fly off, causing unstable fluidization. Typically, materials are pre-treated to a particle size of 20 - 200 mesh. The more precise control is needed for special materials.

Material Moisture

High initial moisture content increases drying time and may cause particle sticking. Before the material enters the fluidized bed, its moisture should be controlled within a certain range, such as 5% - 15%, depending on the material’s properties.

Binder-related

Binder-Sourced:azom

Binder Concentration

The concentration affects particle strength and size. A high concentration results in harder, larger particles, while a low concentration leads to loose, fragile particles. For example, a starch slurry typically uses a concentration of 5% - 15%, and the optimal concentration needs to be determined through preliminary testing.

Binder Amount

Excessive binder leads to overly hard or clumped particles, while too little results in poor particle formation. The binder amount should generally be adjusted based on observation during the granulation process and testing of the finished product.

Spray Speed

The spray speed should match the drying speed. If the spray is too fast, the surface moisture of the material becomes too high, causing severe particle sticking. If too slow, granulation efficiency is low, and particle sizes may be uneven. The spray speed can be adjusted based on the fluidization, drying, and particle formation conditions.

Spray Gun Position and Angle

Spray Gun-Sourced:pittsburghsprayequip

These affect the distribution of the binder within the material. Improper positioning may result in uneven receiving of binder in some areas, leading to uneven granulation. A poor angle can result in some areas receiving too much or too little binder. The spray gun should be positioned above the center of the fluidized bed, ensuring the binder is sprayed evenly.

Granulation Time

If the time is too short, the particles won’t grow and dry sufficiently. If too long, the particles may be over-dried, broken, or reduced in size due to prolonged fluidization and collisions. The time should be determined based on the material properties and particle requirements, with regular sampling and testing during the process.

4.How Important Fluid Bed Dryer Is ForPharmaceutical Industry?

Fluid bed dryer makes the important affect for pharmaceutical industry. And here are its outstanding advantages for you to check.

High efficient

High Efficient-Sourced:businessimprovementexpert

Fluid bed dryer makes the efficient work of drying. Compared with the traditional drying way, fluid bed dryer can make a more efficient work and save your time and energy greatly. The high efficient manufacturing of fluid bed dryer can help your business greatly.

Homogenous drying

The work of fluid bed dryer is high qualified. You may get the even and homogeneous drying from fluid bed dryer. The high qualified drying makes the high qualified material and the high qualified products.

Heat-sensitive products

Heat-sensitive Products-Sourced:sofrigam

For heat sensitive products, the normal drying methods isn’t adoptable as it may destroy some elements of medical products. The fluid bed dryer can make the great control of the heat and won’t let your products contact the extreme temperature.

Stable feature

For some medical elements, the heat wavering may lead the change of its features. Fluid bed dryer can make the drying in relative low temperature which avoid the affect to your products. Your products can have their features safely conserved.

5.What Are The Disadvantages Of FluidBed Dryer?

Fluid bed dryer isn’t perfect. You may always find the small mistakes of it. Do you know the disadvantages of fluid bed dryer.

Electrostatic charge build-up

Electrostatic Charge Build-up-Sourced:incompliancemag

In the fluidizing process, there may be the continuous motion in the cabinet. And the electrostatic charges may build up. For your smooth and safe fluid bed drying process, you should avoid the condition.

Not suitable for sticky products

Fluid bed dryer isn’t flexible enough for any products. And for the sticky products, the fluid process may be interpreted. The great work of fluid bed dryer won’t make the separate particles.

Dust emissions

In some condition, there may exist dust emission in the fluid bed drying process. And for most condition, the dust emission in the manufacturing process isn’t adoptable and may even lead the trouble in the manufacturing process.

Product damage

Product Damage-Sourced:everydayhealth

Fluid bed dryer makes the mild manufacturing process. But there is possibility of products damage in the manufacturing process. For the avoiding of product damage, you should adopt the suitable products and make the suitable panel setting.

6.How Does Fluid Bed Dryer Work?

Fluid bed dryer isn’t a complex machine. And the work of fluid bed dryer isn’t difficult. Here is the manufacturing process of fluid bed dryer.

The Working Process Of Fluid Bed Dryer

Hot air generating

The first step of fluid bed dryer is to generate the hot air. The hot and heat air which covered the every corner of cabinet makes the great preparation for your later step. Hot air generating is the first step of your fluid bed dryer.

Fluidization

The adding of powder in hot air makes the fluidization. The wet powder comes from one side of your bed. And after the process of fluidizing, it comes out from the other side and becomes the dry powder.

Moisture removal

In the heating and fluidizing process, there are moisture which is extract from the powder. The evaporated moisture won’t stay in the fluid bed dryer. In reverse, it will get out the dryer in the process.

Drying

The particles and powder don’t dry in a second. For the nice quality prove, you should make the heating of multiple stage. The wavering of temperature makes the comprehensive dealing of your powder or particle’s various parts.

Cooling

After the drying, fluid bed dryer makes the quick cooling by inducing the cold air. It makes the efficient cooling for your powder products. The cooled products benefit your storing and packaging in later process.

Exhaust air managing

In the manufacturing process of fluid bed dryer, there produces the exhaust air or fine powder. For the quality prove of your products, the last step of fluid bed dryer is to make the elutriation and prove the great quality.

7.What Are The Common Trouble Of Fluid Bed Dryer And Its Relative Solutions?

In the work of fluid bed dryer, there may be problem or trouble. For your smooth manufacturing, here are the problem you should pay attention to and solution you may adopt.

Poor fluidization

Poor fluidization is the common phenomenon in your fluid bed dryer. The poor fluidization shows in the material clumping and channeling of bed. For the solution, you should make the special care about material feature. The nice material dealing is the key of your smooth fluidization.

Excessive material loss

Excessive Material Loss-Sourced:rjginc

In the moisture exhuasting process, there may be unexpected material loss. The excess material loss may lead the low efficiency and products damage. For the avoiding of this condition, you should first make the careful treating of your products. You may also upgrade your system for better and more precise material filtering.

Over drying material

Over drying material may lead the problem in your later products dealing and lead your products damage. Besides the material dealing, you should also make the frequent test for the suitable panel for your certain material type. You may also consider the air speed, fluid bed dryer design for your solution.

Temperature control

Temperature Control-Sourced:flaticon

The temperature control problem may lead the over dried, burned product, product quality or color change. The excessive fluctuation may lead the great damage for your products. For this problem, you should check your machine’s monitoring system, sensor, control loop and so on. You would better to equip with the precise temperature control system for the further temperature monitoring.

Material stick

The sticky products make great challenge for your drying process. The sticky material comes from the material feature, moisture problem or certain technique. To avoid this problem, you would better to make the precise control of moisture and temperature.

Air distribution problem

Air Distribution Problem-Sourced:constructionspecifier

Air distribution problem may lead the varied quality in fluctuation and drying. This leads the material product quality problem. The possible result of blocked distributor plate can make the various problems. To avoid this, you may avoid jams and add baffles for the air distribution.

Weeping

Weeping refers to the falling of solids on the distributor plate. The dealing with flammable material makes manufacturing process dangerous when it comes to weeping. To avoid this condition, you should adopt the fluid bed dryer with nice design.

8.How To Make The Professional Maintaining For Your FluidBed Dryer?

Fluid bed dryer is the complex and delicate machine. The great maintaining of it makes the longer life and better performance. Here are the maintaining of your fluid bed dryer.

Regular cleaning

Regular Cleaning-Sourced:systemcleaners

You should make the regular cleaning for your fluid bed dryer. The cleaning should be comprehensive and careful and covers the various parts of your machine. The dust or unclean machines may lead the low efficiency and short lifespan of your fluid bed dryer.

Parts lubrication

You should make the regular lubrication of the various parts of fluid bed dryer. The parts lubrication can take the best performance of your machines and also the great state of your machine.

Parts maintaining

Parts Maintaining-Sourced:hitachienergy

Fluid bed dryer is the machines which made with various parts. You should make the comprehensive maintaining for its various parts. Bearings, bag, wire rope, airbag, ground wire, here are so many parts of fluid bed dryer which need your careful concern.

Professional operating

Professional Operating-Sourced:cflowapps

You should make the professional operating of your fluid bed dryer. You should make the careful control of tension and pressure of the parts. Besides, the material loading limits should also be cleared for your machine safety.

9.What Are The Essential Quality Standard Of Fluid Bed Dryer?

How to prove the great quality of your fluid bed dryer? Here are the essential quality standard you should pay attention to in your fluid bed dryer purchase.

FDA

FDA-Sourced:digicomply

FDA refers to the food and drug administration. It makes the clear request on medicine, food, cosmetic, machine and various products on market. It makes sure the safety, efficiency and guarantees the machine quality.

CGMP

CGMP-Sourced:arenasolutions

GMP means the good manufacturing process and CGMP refers to the current good manufacturing practice. The two standard makes the clear and strict request on the manufacturing process and facilities.

ISO

ISO-Sourced:blog-qhse

ISO refers to international organization for standardization. For manufacturing process, it is essential to have the standard for your manufacturing business. And ISO makes the clear and comprehensive request.

Conclusion

What should be cared when using fluid bed dryer? You may have your own answers. For the smooth and reliable manufacturing of fluid bed dryer, there are so many useful advice for you to consider. And if you have any problem or question about this post or fluid bed dryer, you may have no hesitate to contact AIPAK now.

Don't forget to share this post!

Drier Machine Related Products

Drier Machine Related Posts

Drier Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine