Medical Powder Sachet Machine: The Complete Buying Guide In 2025

Is the use of medical powder sachet machine a niche? Does the use of this type of equipment require very high costs? Compared with other types of medical powder packaging equipment, why is the use rate of medical powder sachet machine higher and longer lasting? If you are engaged in the business of filling small bags of medical powder, then you may have a strong demand for this type of machine.

In order to meet your medical powder sachet filling needs, you may be very eager to learn about this type of equipment and make corresponding equipment type selection and maintenance. This post is about the complete guide of medical powder filling and packaging. Let's take a look now!

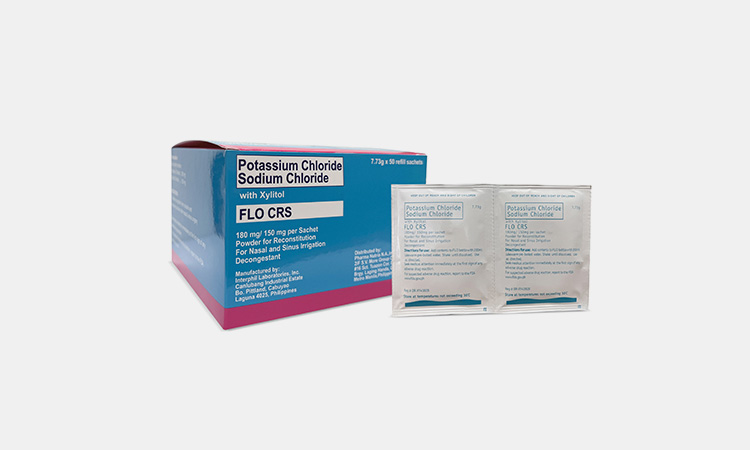

1.What Is A Medical Powder Sachet?

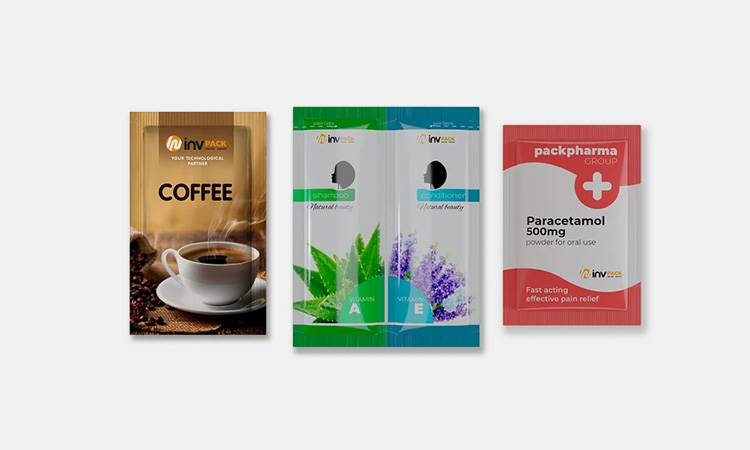

Medical Powder Sachet-sourced: svmoregroup

There are many medical powders that are packaged in sachets with fixed dosages. Through sachet packaging, patients can use the same dosage of different medicine conveniently and ensure the freshness and validity. Medical powder sachet refers to the medical powders are filled and sealed with different sachets that you need with good sealing effects.

2.What Is The Medical Powder Sachet Machine?

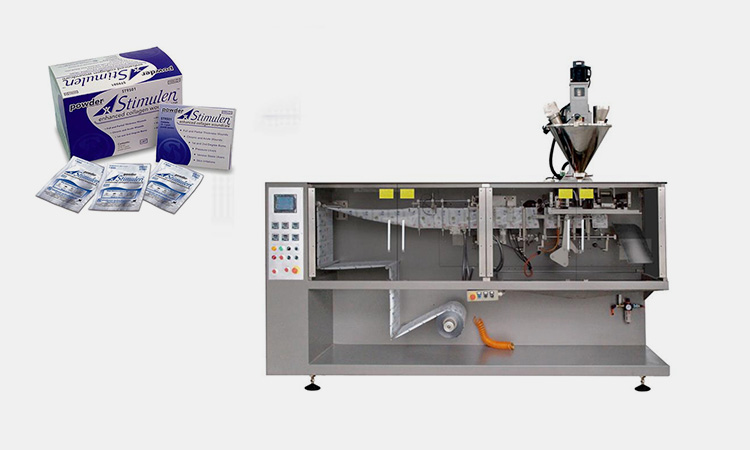

AIPAK Medical Powder Sachet Machine

Medical powder sachet machine distributes powder into different small bags according to certain dosage and weight, and then seals and packs them using three-sided or four-sided sealing. In addition to the pharmaceutical industry, it is also used in various food, chemical, skin care, cosmetics and other industries. Among them, the most common materials are coffee powder, protein powder, milk powder, etc.

3.What Can Medical Powder Sachet Machine Fill?

Medical powder sachet machine is mainly used for filling these two materials:

Powder

Powder-sourced: avemar

This sachet machine can be used for filling and sealing chemical powder, pharmaceutical powder, food or skin care powder, nutritional powder, infant formula milk powder, coffee powder, beverage powder, etc. It can cleanly, neatly and efficiently pack the materials you need in the small bags you need.

Granules

Granules-sourced: vitaminqatar

In addition to powder products, you can also fill granular products into sachets you like or need. It can pack the same particle size and different particle sizes separately to improve efficiency and output.

4.What Are The Sachet Packaging Formats That Medical Powder Sachet Machine Can Offer You?

There are different sachets that can be offered for your choice:

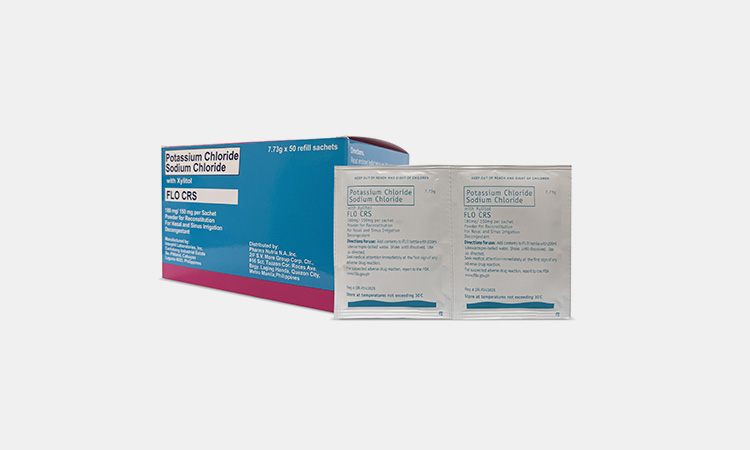

Flat sachets

Flat sachets-sourced: cystopurin

This packaging is also called a three-sided sealed sachets. It allows you to lay your product flat. Add a hole to display or hang the product. It is very suitable for filling and sealing various nutritional supplements or pharmaceutical powders.

Stick sachets

Stick sachets-sourced: dottortili

Stick sachets are also sachets. It is mainly used for single-dose packaging of pharmaceutical powders or nutritional powders. It can divide your single-use dose into several parts for your convenience.

Twin sachets

Twin sachets-sourced: svmoregroup

Twin sachets are mainly composed of two sachets connected together without being separated. It is often used to package two different products that need to be used together, such as hair dye and hair mask.

Triple sachets

Triple sachets-sourced: quartz

This packaging is very similar to twin sachets. It consists of three different sachets that are connected together without being separated. This packaging method is also suitable for different products to be used together, such as salad dressing, mayonnaise or ketchup.

Strip sachets

Strip sachets-sourced: ghfruit

Strip sachets are mainly used for display and hanging. They are a single-dose sachets that can be connected together in different quantities without being separated. They are usually found in department stores.

Irregular shaped sachets

Irregular shaped sachets-sourced: kefai

Irregular shaped sachets are very personalized and fit your promotional content and methods. They are suitable for filling different materials, thereby increasing your customer appeal and improving your sales rate.

5.What Are The Types of Sachets Based On Materials For Your Medical Powder Sachet Machine?

The materials commonly used in medical powder sachets are as follows:

Plastic

Plastic-sourced: adorefem

Plastic is one of the raw materials commonly used in sachets. Plastic materials such as polyethylene or polypropylene are processed to make film rolls for sachets. Then, when filling the drug powder, the film is made into sachets to package the material.

Paper

Paper-sourced: oasisfloralproducts

Paper is an environmentally friendly sachets packaging material. It can reduce your production costs and improve production efficiency. However, the disadvantage is that it is easy to break and does not completely block moisture, oxygen and light.

Non-woven fabric

Non-woven fabric-sourced: biobombs

Non-woven fabric is a new type of sachets packaging material. It is mainly used in the food industry for instant coffee and tea sachets. This packaging material is more environmentally friendly and has strong barrier properties.

Multi-layer laminated film

Multi-layer laminated film-sourced: bestsuppliers

Multi-layer laminated film refers to the combination of plastic, aluminum foil and paper through coating to provide a new type of material with high-quality moisture, oxygen and light barriers. The disadvantage is that it may be more expensive.

6.What Scenarios Are Medical Powder Sachet Machine Suitable For?

Medical powder sachet machine is widely used in various industries. These include:

Pharmaceutical industry

Pharmaceutical industry-sourced: avemar

Various nutritional supplements and medicinal powders are packaged in sachets. Patients can use the same dosage when using them. And it can ensure the freshness and high quality of medicinal powders.

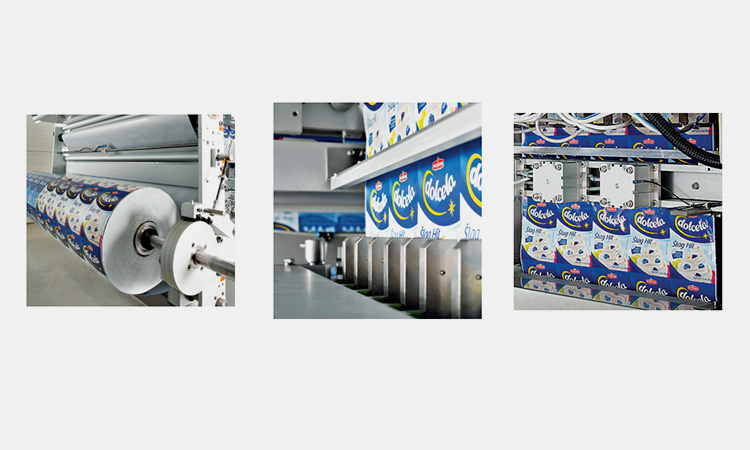

Food industry

Food industry-sourced: supermarketperimeter

Medical powder sachet machine can also be used for packaging in the food industry, including various condiments, sauces, snacks and beverage powders, etc. It can be packaged in various unique small bags to meet customer needs and brand marketing requirements.

Cosmetics industry

Cosmetics industry-sourced: violette

Various cosmetics trial packs and travel packs are filled and packaged by medical powder sachet machine. It can provide small bag packaging and sealing for various skin care products such as lotions, essences, hand soaps, shower gels, shampoos, etc.

Chemical industry

Chemical industry-sourced: porta pak

Medical powder sachet machine can be used for various chemical products, such as small bag packaging of detergents, pesticides, fertilizers, acid agents, etc. This packaging method is convenient for manufacturers to transport, store and distribute.

Agricultural Industry

Agricultural Industry-sourced: farmsquare

Various pesticides, seeds, nutrients, fertilizers and nutrient-rich soil can all be packaged using the medical powder sachet machine. It can provide you with more precise dosage packaging, thus avoiding waste during use.

7.What Are The Benefits of Medical Powder Sachet Machine?

Using medical powder sachet machine can bring many benefits to the enterprise, including:

Improve efficiency

Improve efficiency-sourced: aihr

The medical powder sachet machine adopts an automated working mode throughout the whole process, which can save you more labor and time, improve production efficiency and production volume.

Improve packaging quality

Improve packaging quality-sourced: vikingmasek

This equipment can accurately fill and measure each sachet of materials and tightly seal them, which can keep the freshness of the materials for a long time. To avoid the influence of oxygen or light, different packaging materials are used for packaging.

Filling accuracy

Filling accuracy-sourced: syndapack

The powder materials of sachet packaging machine are accurately packed, which can reduce waste and improve your production efficiency.

Flexibility

The medical powder sachet machine can handle materials of various products and various packaging materials. It is flexible and can be put into various filling lines.

8.What Are The Types Of Medical Powder Sachet Machine?

According to the different appearance designs, medical powder sachet machines can be divided into horizontal, vertical and rotary sachet machines.

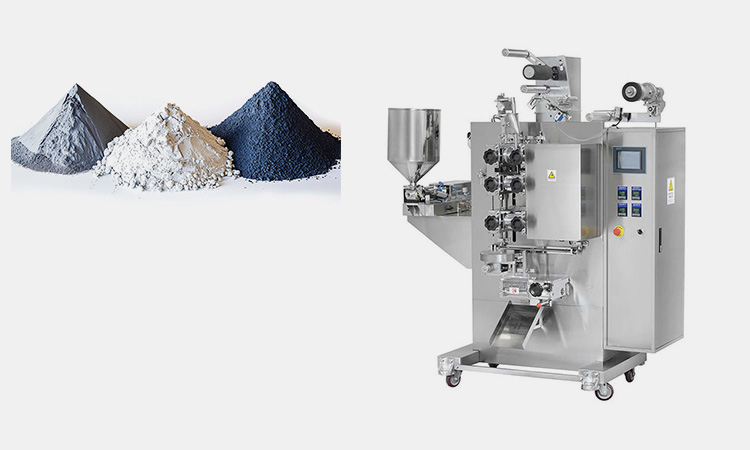

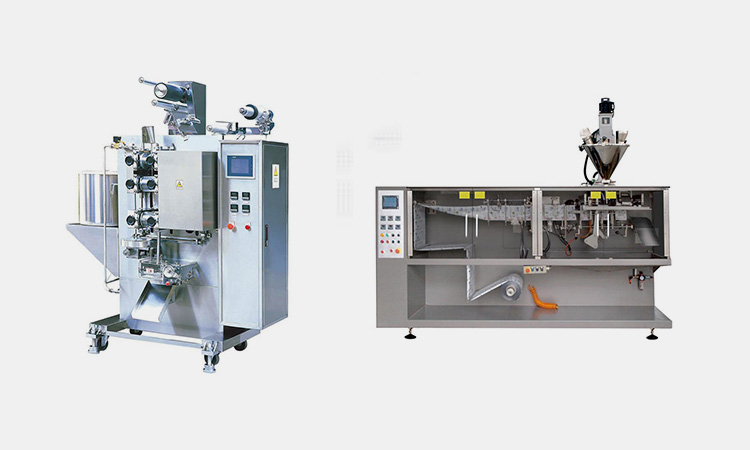

Vertical medical powder sachet machine

ALLPACK vertical medical powder sachet machine

The vertical medical powder sachet machine mainly adopts semi-automatic design. It requires you to manually load the materials. There is no way to connect with other auxiliary equipment. It can only simply fill and seal the sachets of the drug powder materials you need.

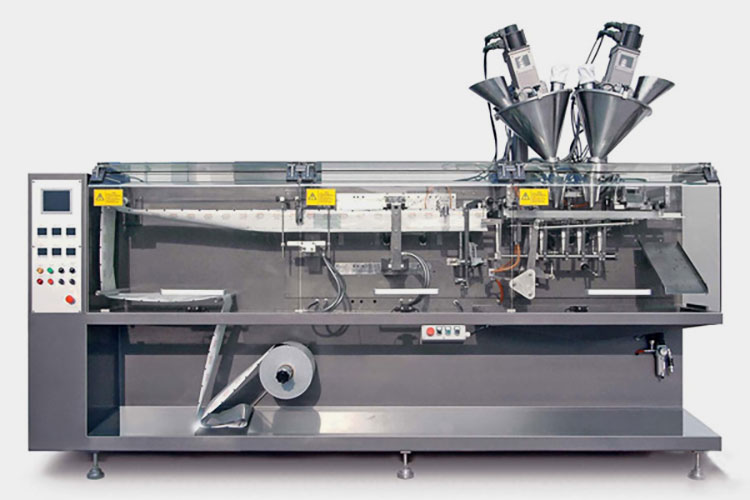

Horizontal medical powder sachet machine

AIPAK horizontal medical powder sachet machine

The horizontal medical powder sachet machine is more efficient and automated than the vertical one. It adopts a fully automatic filling method and can be connected with other auxiliary equipment, including the subsequent boxing and packaging.

9.How To Know The Main Parts of Medical Powder Sachet Machine?

The main parts of medical powder sachet machine are:

Main Parts of AIPAK Medical Powder Sachet Machine |

|

| Material loading system | After medical powder has been loaded into the feeding hopper, it can pump and transfer them to the filling system. |

| Bag forming system | After materials have been loaded into the hopper, the films will be stretched and vertical folded, then sealed into sachets with the top open. Sachets will be formed. |

| Weighing system | It can accurately dispense the correct amount of powder, making it easier to fill later. |

| Filling and sealing system | After being weighed, the dosed powder is filled into the prepared sachets. When the sensor detects that the filling is complete, the sealing bar is directly heated to heat-seal the open mouth. |

| Printing unit | The heat-sealed sachets will be printed with relevant information, such as production batch number and expiration date. |

| Cutting blade | The cutting blade will cut the sealed and printed sachet rolls into individual small packages. |

10.How Does Medical Powder Sachet Machine Work?

Working principle of AIPAK medical powder sachet machine

The operation of the medical powder sachet machine is complex and precise. It includes:

Medical powder feeding

First, you can manually or automatically feed the material you need to fill into the feeding hopper.

Sachet forming

When the material is distributed to the feeding hopper, the film roll will be stretched and elongated. It will fold the film longitudinally or transversely according to your settings to form a tube or a sachet. After the sachet is formed, the edges of the two sides or the bottom will be sealed to facilitate the filling of the material later.

Medical powder filling

When the sachet is formed, the material will be automatically and evenly distributed into the sachet in a fixed dose.

Sealing

When the sachet is filled with the same dose of material, the machine sensor will detect the sachet and then heat-seal it to form a sealed packaging bag.

Cutting

When the sachet is filled and sealed, the machine sensor will detect it and start the cutting part to heat-cut the sachet on the same film into individual packages.

Ejection and collection

After the individual bags are cut and detected by the sensor, they are ejected from the machine and fall into the collection basket at the back.

11.What Are The Common Challenges And Solutions That You May Met During Medical Powder Sachet Packaging?

There are many challenges in the filling and filling process of small bags of pharmaceutical powder. Its corresponding measures include:

Common Challenges And Solutions-sourced: eraofkashmir

| Challenges | Solutions | |

| Dust control | Powder filling and sealing may cause dust. This will cause pollution and harm to equipment and workers. | Exhaust extra powder or minimize the powder in the air through additional ventilation or dust collection system;

Relevant operators also need to wear appropriate personal protective equipment, such as respirators or masks; |

| Poor material flowability | If the material you need to fill has poor flowability, the material filling process will be very difficult. | Before filling the powder, you need to apply the corresponding mixing, stirring and drying equipment to appropriately reduce the moisture in the material to enhance the flowability of the powder;

Control the temperature and humidity level of the environment and the material; |

| Sealing problem | If the product packaging bag leaks or the seal is not complete, it is likely that there is a problem with the sealing clamp. | Before starting the equipment, you should check whether the sealing jaws are clean and intact;

Whether the temperature control of the equipment is optimal; Whether the sealing pressure and residence time are set appropriately; And different materials use different sealing temperatures and pressures; |

| Blocking or leakage | If the material frequently blocks or leaks during the filling and sealing process, there may be wear defects between the equipment parts. | Before filling, you need to thoroughly check the auger, seals, hoppers and other parts of the equipment; |

| Inconsistent filling dosage | If the dosage is different or uneven, it may be because the volume setting of your equipment is incorrect; | Before starting the equipment, carefully confirm whether the material filling weight and volume settings you set are correct and calibrated. |

12.How To Prevent Clogs Or Leaks During Medical Powder Sachet Packaging?

Prevent Clogs Or Leaks During Medical Powder Sachet Packaging

How to avoid material clogs and leaks during the use of the equipment?

- Firstly, ensure the dryness of the material you need to fill and seal, reduce its humidity, and avoid adhesion during the subsequent filling process;

- Secondly, you need to check the speed and pressure level of the filling. If the speed is too fast or the pressure is too low, it may cause material clogs and leaks.

13.What Are The Maintenance Tips For Your Medical Powder Sachet Machine?

Good equipment maintenance can provide the greatest benefits for your production.

Cleaning

Use mild or neutral detergent to clean the surface of the medical powder sachet machine to prevent damage to the machine. You need to clean the dust, residue, and the sealing or labeling parts marked in the equipment.

Lubrication

Lubrication-sourced: nexxis

According to the instructions or the manufacturer's requirements, use professional lubricants to regularly lubricate the parts that need lubrication to ensure the smooth operation of the equipment.

Replacement

You need to regularly replace the sealing tape or cutting blades of the sachet machine and check their wear. If you find that the parts are severely worn, they need to be replaced in time to ensure product quality.

Calibration

Calibration-sourced: spacskmachine

After cleaning, lubricating and replacing all parts, you need to perform a final calibration of the equipment. This will allow you to adjust the final weight and size of the sachet packaging, and ensure the efficiency and accuracy.

14.What Is The Troubleshooting For Your Medical Powder Sachet Machine?

There will be more or less problems when using the equipment. The solution is:

Troubleshooting For Your Medical Powder Sachet Machine-sourced: ramotion

| Problems | Troubleshooting |

| Dust problem | Purchase high-quality dust control system, such as vacuum cleaner or integrated bag, etc.;

Ensure good ventilation in the filling area; Provide protective equipment for workers, such as respirators or masks, etc.; |

| Material flow problem | Improve powder density or reduce humidity;

Use stirring or mixing equipment to pre-treat the powder; During the filling process, use vibrators or pre-press boxes to promote material flow; Adjust the temperature and humidity during the powder filling process to improve the fluidity of the powder; |

| Sealing problem | Confirm the temperature or pressure of the sealing strip before sealing;

Considering that different packaging materials require different temperatures and pressures; Choose the ideal sealing material; Regularly check the degree of wear of the sealing components; |

| Frequent blockage or leakage | Regularly clean, inspect and lubricate the equipment;

Check the equipment feed mechanism to minimize the pressure level of the material; Use filters or screens to prevent other foreign matter from entering the equipment. |

15.How To Choose A Medical Powder Sachet Machine?

According to your own needs, you can choose the medical powder sachet machine according to the following standards:

Material characteristics

Material characteristics-sourced: majestic

Choose the equipment that suits you according to the material characteristics. Medical powder sachet machine is mainly used for filling powder and granular materials, not suitable for filling liquid, viscous or paste materials.

Packaging requirements

Packaging requirements-sourced: invpack

Determine the size, weight, quantity, shape, color, sealing method, appearance design or whether it includes label seals or additional packaging functions of sachet materials you need.

Compatibility of packaging materials

Different materials may need to consider different packaging materials. Therefore, the sachet packaging machine you choose needs to have strong compatibility and be able to adapt to the packaging of most materials.

Flexibility

Flexibility

In the later stage, if you want to integrate it into other production lines, your equipment needs to have a certain degree of flexibility.

Speed and capacity

Considering the filling speed and volume that the equipment can achieve, you can choose according to your own production needs. Different speeds and production volumes can meet different customer needs.

Cost

When making relevant equipment selections, you must consider the budget. If you need to purchase a single machine, the cost may be lower. If you consider the later connection of machines, boxing and even packaging, your budget cost may be higher.

16.What Are The Future Trends For Medical Powder Packaging?

In the future, medical powder sachet packaging trends are:

Integrated monitoring

Integrated monitoring-sourced: em4

In the future, there will be more advanced sensor detection that can monitor the filling speed, weight, and sealing integrity of the powder as a whole. In addition to real-time monitoring, integrated monitoring can also make overall adjustments to the equipment.

Artificial intelligence

Artificial intelligence-sourced: zeroeyes

Equipment will have more artificial intelligence added. It can not only predict the operating status of the entire filling system in advance, but also make a dynamic adjustment or visual inspection for different materials. The system can help you immediately troubleshoot equipment failures and minimize costs and downtime.

Higher degree of automation

Higher degree of automation-sourced: tm-robot

Reduce manual intervention to a greater extent and improve your efficiency. In each part, realize automation functions to a greater extent. This not only improves accuracy, but also increases your output and ensures product quality.

Conclusion:

Medical powder sachet machine is your best choice. Through this complete guide of medical powder sachet machine, whether it is its high flexibility, adaptability, wide range of use, or the ability to achieve high-efficiency sachet packaging and sealing, it can provide you with a satisfactory solution.If there are more that you are not clear, find AIPAK for help now!

Don't forget to share this post!

Sachet Filling Machine Related Posts

Sachet Filling Machines Related Videos

Have you ever seen how Sachet Filling Machine works?

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest Sachet Filling Machines buying guide, tips and trends sent straightly to your box? Sign up for Aipak’s monthly newsletter, we’re free for your consultation and offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply to you ASAP within 24 hours.