What Are the Difficulties in the Manufacturing Process of Tablet Film Coating?

Many drugs have a layer of tablet film coating on their surface, which can protect the drugs inside. In addition, some coatings have a sweet taste, which can reduce the bitterness of the drugs.

In recent years, due to its advantages such as shortened coating process, simple operation, and low amount of coating material, film coating technology has been increasingly widely used in the pharmaceutical market.

However, there are many difficulties in the process of tablet film coating, and precise control of each link is required to ensure the quality of coating. Therefore, this article analyzes the common problems in the process of tablet film coating.

1.What Is the Tablet Film Coating?

Film Coated Tablet - Sourced: Thomas Processing

Coated tablets are tablets that are coated with a layer of film on the surface of regular tablets. It’s like putting a coat on ordinary tablets, which can be divided into three types based on the style of clothing: sugar coated tablets, enteric coated tablets, and film coated tablets.

Tablet film coating refers to the use of atomization to spray some polymer coating on the core of the tablet, thereby forming a certain thickness of molded film layer. After drying, the film coating is formed. The function of film coating includes the ability of the core to absorb moisture, reducing water evaporation, and masking unpleasant odors.

2.What Is the Process of Tablet Film Coating?

How many processes do tablet film coating go through? Let’s take a closer look.

Preparing coating materials

Mixing some polyacrylic acid resin II and other film coating materials in a stainless-steel batching bucket to make coating powder. Dissolving the coating powder in ethanol with a concentration of 75%, stirring for 40 minutes to make the solution concentration 7%, and preparing the coating solution

Feeding tablet core

Feeding Tablet Core - Sourced: Syntegon

Sifting out the fine powder of the drug to be coated and placing it in the equipment to ensure even distribution of the drug. Activating the exhaust and dust collection device to further adsorb the fine powder attached to the tablets, preheat with hot air at 50℃, and start the coating pot at intervals of one minute.

Spraying coating solution

Spraying the prepared coating solution evenly onto the surface of the medicine through a nozzle to form a thin film. During the spraying process, it is necessary to control the spraying speed and amount to ensure that the coating layer is uniform and the thickness is appropriate.

Drying

After spraying the coating solution, drying it to solidify the coating layer on the surface of the drug. In order to avoid problems, such cracking, you should control the temperature and time.

Cooling

After drying, cooling the drug to room temperature for subsequent packaging and storage.

3.Which Industry Can You Use Tablet Film Coating Machine?

The tablet film coating machine is mainly used in the pharmaceutical industry, but it can also be applied to other industries.

Pharmaceutical industry

Tablet - Sourced: Adinath International

The tablet film coating machine is used for coating various types of drug particles or tablets, such as antibiotics, vitamins, antipyretic analgesics, etc. It can mask the bitterness of drugs and help them dissolve better in the body.

Health products industry

In order to improve its taste and appearance, and enhance product quality, tablet film coating machine is used for coating treatment of health food, nutritional supplements, etc.

Food industry

Candy - Sourced: Wholesome Provisions

In order to increase the stickiness and aesthetics of food, tablet film coating machines are also used for coating some foods, such as candies, chocolates, cookies, etc.

4.What Are the Methods for Tablet Film Coating?

There are several methods for tablet film coating, and the common methods are as follows.

Spray drying

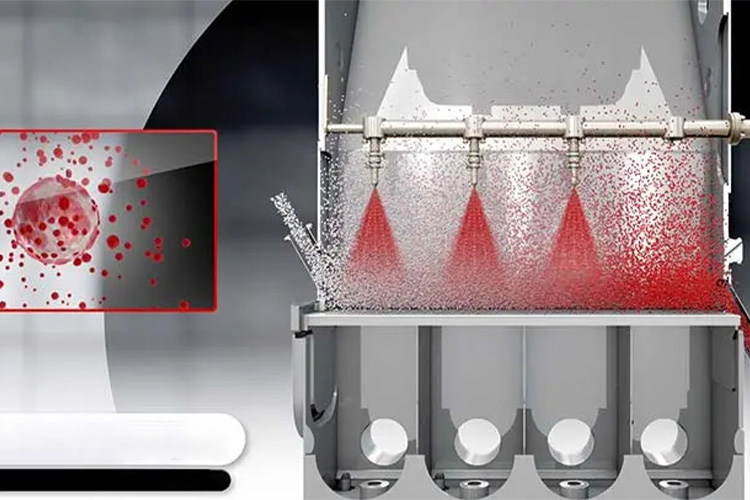

Spray Drying - Sourced: AVEKA

The principle is that the drug powder is dispersed in the coating solution, and then the solvent is atomized and evaporated by the spray device, which causes the coating material to precipitate on the drug surface to achieve drug coating.

This method has a short operating time, is suitable for coating unstable drugs, and has low material costs, making it suitable for industrial production. However, the instrument cost is relatively high.

Spray condensation

Similar to the spray drying method, the spray condensation method is to dissolve or disperse the drug in the coating system first, and then solidify it through the spray device to achieve drug coating.

The spray drying method relies on solvent evaporation to form the coating, while the spray condensation method is to achieve coating by condensing and curing the coating material in the molten state, which is similar to the principle of the melt dispersion method. The spray condensation method used for coating also has the advantages of speed, low cost, and controllable particle size of coating particles.

Dry coating technology

The dry coating technology without solvent system is receiving increasing attention, which can be mainly divided into liquid assisted coating method and hot melt coating method. The entire process of dry powder coating requires the layering, cross-linking, delamination, and solidification of the coating material.

Airflow suspension coating technology

Airflow Suspension Coating Technology - Sourced: Glatt Group

Due to the poor flowability and strong wetting properties of the powder, it is prone to adhesion. Therefore, high requirements are placed on the fluidization state and drying efficiency of the powder during the powder coating process. So, people modified fluidized beds according to their needs and derived various coating technologies, such as various airflow suspension coating technologies.

5.How to Adapt the Tablet Core And Coating Materials?

The shape, hardness, surface properties, etc. of the tablet core have an impact on the quality of the coating. Therefore, it is necessary to choose suitable tablet core and coating materials.

Choosing the appropriate tablet core

Choosing the Appropriate Tablet Core - Sourced: Outsourced Pharma

Irregular shaped tablet cores make it difficult for the film to be evenly distributed at the corners and depressions during coating. If the hardness of the tablet core is improper, it will be difficult for moisture to penetrate, and the drying time is long.

If the tablet core is too soft, it is prone to deformation under pressure, resulting in problems such as cracking and peeling of the coating. In addition, the surface of the tablet core being too rough or smooth can also affect the adhesion and uniformity of the coating.

Selecting suitable tablet coating materials

Tablet Coating Materials - Sourced: Chemstock Specialty CHemical Sourcing

Different film-forming materials, plasticizers, light blocking agents, etc. have significant differences in properties and need to be reasonably matched. If the amount of plasticizer used is too high, it will make the film too soft and prone to adhesion, while too low will make the film brittle and prone to breakage. If the materials are incompatible, delamination, crystallization, and other phenomena may occur, affecting the quality of the coating.

6.What Are the Challenges In the Preparation And Stability of Tablet Coating Solution?

In the process of coating production, the preparation process of coating solution is relatively complex, and storage after preparation should also be very careful.

Complex preparation for tablet coating solution

Tablet Coating Solution - Sourced: iPharmachine

The preparation of coating solution requires precise control of the proportion of each component and dissolution conditions. Insufficient dissolution of film-forming materials can result in particles in the coating solution, affecting the atomization effect and coating uniformity. In addition, improper order of addition, such as adding plasticizers first and then adding shading agents, may result in uneven dispersion of shading agents, affecting the appearance and performance of the coating.

Storage stability is difficult to control

When storing coating solution, component precipitation, polymerization, or degradation may occur due to temperature and humidity changes. For some coating liquids containing polymer materials, long-term storage may cause changes in viscosity, affecting the quality of the coating. Therefore, strict control of storage conditions and a certain period of use are required.

7.What Parameters Should be Regulated in the Process of Tablet Film Coating?

During the process of tablet film coating, many parameters need to be noted.

Temperature and humidity synergy

During coating, temperature and humidity interact with each other. High temperature, low humidity, and rapid solvent evaporation may cause the coating surface to form a crust and internal solvent residue, leading to film foaming and peeling; Low temperature, high humidity, slow drying, and easy moisture absorption of the tablet core can affect the quality and production efficiency of the coating. Different coating materials and tablet cores have different temperature and humidity requirements, which require precise control.

Spray and drying balance

Spray and Drying Balance - Sourced: Merck KGaA

The spray speed and drying speed need to be matched. Spray the liquid quickly but dry slowly, the surface humidity of the chip is too high, and it is easy to adhere; Slow spraying and fast drying, long coating time, low efficiency, and may cause uneven coating thickness. In addition, during the drying process, different stages have different requirements for drying strength, which needs to be dynamically adjusted.

Equipment parameters

Different coating equipment, such as high-efficiency coating pots and fluidized bed coating machines, have different parameter settings. The rotational speed of the pot body and the airflow velocity of the fluidized bed affect the movement state of the tablet core and the uniformity of the coating.

Even for devices of the same type, there may be differences in parameters due to specifications and manufacturers, and it is necessary to explore based on actual conditions.

Nozzleparameters

Nozzle Parameters - Sourced: Fluid Air

When using the tablet film coating machine, it is necessary to adjust the nozzle diameter, spraying pressure, gas-liquid ratio and other parameters of the spray gun to control the spraying effect of the coating liquid and the liquid receiving amount of the tablet core.

8.What Are the Common Quality Problems and Solution of Tablet Film Coating?

Due to various reasons during the tablet coating process, there may be some issues with the final produced tablets.

Problem1: Tablet sticky

Tablet Sticky - Sourced: Yenchen Machinery

Adhesive punching refers to the adhesion between the surface of a tablet and a punch or mold, resulting in a rough, uneven or residual surface of the tablet. The phenomenon of sticking and flushing may be caused by various factors, such as raw material properties, particle moisture, insufficient lubricant dosage, or uneven mixing.

Solution

(1)Adjusting the properties of raw materials for tablet film coating, such as changing raw materials or adjusting raw material ratios.

(2)Regularly cleaning and maintaining the mold to ensure a smooth surface.

(3)Controlling the moisture content of the particles to ensure sufficient drying.

(4)Increasing the amount of lubricant used to ensure even mixing of the lubricant.

Problem 2: Mottling

Mottling - Sourced: iPharmachine

Mottling refers to the color difference of spots or stripes on the surface of a tablet, which affects the appearance and quality of the tablet. The appearance of petals in tablets may be due to uneven distribution of pigments, differences in raw material color, etc.

Solution

(1)Screening and preprocessing the coating raw materials to ensure consistent color.

(2)Adjusting the amount and type of lubricant to ensure good lubrication effect and not affect the color of the tablets.

Problem 3: Crack

Crack - Sourced: iStock

The cracking of the film coating around the tablet may be due to poor quality of the core, low brittleness or hardness, and the edge of the core caused by punch wear. It is also possible that during the coating process, the atomization speed of the coating solution is too slow to protect the edges of the tablet core in a timely manner;

Solution

(1)Improving the quality of tablet core.

(2)Correctly designing the coating solution formula and selecting tablet core excipients with low expansion coefficient.

(3)In the initial stage of coating, reducing the speed of the coating roller appropriately and increasing the atomization amount of the coating solution appropriately.

(4)Selecting the appropriate solid content in the coating solution, adjusting the speed of the coating roller and the size of the spray appropriately.

9.What Quality Test for Tablet Film Coating?

The produced tablet film coating still needs further quality testing to ensure the integrity of the product's appearance.

Checking appearance and weight

Checking Appearance And Weight - Sourced: Konica Minolta Sensing

In order to maintain consistency in weight, you can use precision quality instruments to weigh the tablet film coating. Then observing whether the color of the tablet coating has colored spots and whether the color is consistent. It is also necessary to check whether the surface is smooth and rough.

Thickness detection

You can use appropriate measuring tools, such as thickness gauges, to measure the thickness of multiple parts of the tablet and compare the measured data with standard tablets.

Disintegration detection

Disintegration Detection

You should take a few tablets and place them in a six tube disintegrator, record their disintegration time. Placing one in each tube and distributing it in a circular basket shape. Each pipe is equipped with a 2mm mesh at the bottom. The suspended basket moves up and down a distance of 55mm in a medium at human body temperature (37℃), simulating gastric peristalsis, and moves up and down at a constant frequency of 30 times per minute.

If the tablet does not remain on the sieve after the specified time, it is considered to have passed the test. Typically, regular tablets take 30 minutes.

10.What Can AIPAK Tablet Coating Machine Bring for You?

AIPAK film coating machine is a solution for high demand tablet coating. In addition, this series can also be used for coating drug forms such as capsules and pills, as well as for coating ordinary film tablets.

AIPAK Tablet Coating Machine

High efficiency

The fully automatic film coating machine can automate the film wrapping process of drugs, greatly improving production efficiency. Compared to traditional manual operations or semi-automatic equipment, its work efficiency is significantly improved.

Easy to achieve intelligent and information-based management

Modern fully automatic film coating machines can integrate advanced sensor technology and network communication functions to achieve precise data monitoring and control, as well as remote services, making it easier for enterprises to manage information and make operational optimization decisions.

Reducinghuman errors and operational risks

There are many errors or mistakes that are prone to occur during manual operation and are difficult to avoid. Automated equipment can greatly reduce the probability of such situations occurring, thereby reducing the risks and losses caused by misoperation and negligence.

Conclusion

Film coating is the most commonly used type of coated tablet. The film coating technology is advanced and very complex, sometimes requiring the use of multiple coating techniques to achieve the expected results. Therefore, there are many difficulties in the process of film coating. After reading this article, do you have any understanding of these difficulties? If you have any other questions, please feel free to contact AIPAK at any time.

Don't forget to share this post!

Tablet Coating Machine Related Posts

Tablet Coating Machine Related Products

Tablet Coating Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine