What Is Capsule-In-Capsule Technology?

Have you heard of capsule-in-capsule or dual release capsules? This is the interesting medical type which is applied in many places in various medicines for better medicine absorbing and taking. So how much you know about capsule in capsule technology? Will you choose this technology in your later use.

What is capsule-in-capsule? What is capsule-in-capsule technology? What are the features of capsule-in-capsule technology? What are the advantages of capsule-in-capsule technology? What are the machines applied in capsule-in-capsule? These questions can all be solved in this post. Come on and have a reading!

1.What Is Capsule-In-Capsule?

Capsule-In-Capsule-Sourced:contractpharma

In the field of pharmaceutical industry, capsule-in-capsule (CIC) technology involves embedding of one capsule inside another capsule. It offers unprecedented flexibility and control in the pharmaceutical industry, especially in terms of drug releasing and medicine stability.

Capsule-in-capsule has the special appearance of dual capsules for a segment. And the filling of the two capsules may be liquid or semisolid. You may find the capsule-in-capsule with various size, shape and color. This special medical form is intelligent and can fulfill the need of some special patients group and disease.

2.What Is Capsule-In-Capsule Technology?

Capsule-In-Capsule technology-Sourced:nutraceuticalbusinessreview

Capsule-in-capsule technology is an advanced formulation method where one liquid capsule contains another liquid or solid capsule. Unlike traditional liquid capsules, capsule-in-capsule technology uses a dual-capsule design to achieve multi-stage drug release within a single dosage form, allowing precise control for various therapeutic needs.

The core advantage of this technology lies in the ability to finely control the release of different drugs, allowing for multiple release characteristics within a single capsule. For example, one drug can be designed for rapid release, while another is designed for slow or targeted release for the meeting of personalized treatment needs.

3.What Are The Features Of Capsule-In-Capsule Technology?

Capsule-in-capsule technology is applied in more and more fields. For many medicine type, it can make the great conveying work. How much you know about the features of capsule-in-capsule. And here are the features of capsule-in-capsule technology.

Multiple release characteristics

Multiple Release Characteristics-Sourced:aarp

Capsule-in-capsule technology enables multiple drug release properties within a single dosage form. By carefully selecting the carrier materials for the inner and outer capsules, it can be designed for rapid release, delayed release or slow release.

This flexibility makes capsule-in-capsule technology ideal for drugs requiring controlled release, such as painkillers that need to act quickly and last long, or drugs that need to release at specific locations in the intestine.

Improved drug stability

Improved Drug Stability-Sourced:tamassohajda

Some drugs may be unstable in traditional capsules due to exposure to moisture, oxygen, or heat. Capsule-in-capsule technology can enhance drug stability by encapsulating the inner capsule, effectively isolating the drug from the external environment. For instance, liquid drugs are well-protected in capsule-in-capsule formats, preventing moisture and oxygen intrusion, thus extending their shelf life.

Drug compatibility

Different drugs may have variations in solubility, PH or other properties that make it difficult to combine them in a single capsule without adverse reactions. Capsule-in-capsule technology resolves this by placing different drugs in the inner and outer capsules, reducing potential interactions between drugs and improving the safety of multi-drug combinations.

Precise localized release

Precise Localized Release-Sourced:allucent

Capsule-in-capsule capsules can also achieve targeted release by incorporating enteric coatings or targeted membranes on the inner capsule. For example, the inner capsule can be designed to dissolve only in specific parts of the intestine, ensuring the drug acts at the intended site. This has significant potential for treating gastrointestinal diseases or drugs that require specific intestinal release.

4.What Are The Advantages Of Capsule-In-Capsule Technology?

Capsule-in-capsule technology benefits many medicines in a comprehensive way. And here are the advantages of capsule-in-capsule technology.

Improved bioavailability

Improved Bioavailability-Sourced:diginerve

Many drugs suffer from poor bioavailability, but capsule-in-capsule technology can significantly improve drug solubility and absorption by designing release properties of the carriers. For example, self-emulsifying systems or microemulsion carriers can help poorly soluble drugs dissolve and absorb better in the body, enhancing their therapeutic efficacy.

Meeting different release needs

Meeting Different Release Needs-Sourced:medicilon

Some treatment regimens require drugs to be released quickly for immediate effects, while others need slow, sustained release to maintain stable therapeutic levels. capsule-in-capsule technology can meet both of these needs within a single capsule, allowing patients to benefit from both rapid and sustained effects in one dose.

Enhanced patient compliance

Enhanced Patient Compliance-Sourced:pabau

For patients requiring combination therapy, traditional drug combinations often involve taking multiple medications, which can be burdensome. With capsule-in-capsule technology, multiple drugs can be combined into a single capsule, significantly reducing the number of doses a patient needs to take, improving adherence, and enhancing treatment outcomes.

Avoiding adverse drug interactions

Avoiding Adverse Drug Interactions-Sourced:masonicvillages

In the capsule-in-capsule manufacturing system, drugs are encapsulated separately in the inner and outer capsules, preventing interactions between them. For example, some drugs may become ineffective due to changes of PH or other physical-chemical reactions. The dual encapsulation minimizes such adverse effects.

Broad commercial potential

The flexibility and customizability of capsule-in-capsule technology make it suitable for a wide range of market needs, from prescription drugs to dietary supplements. It can be used not only for optimizing the release of a single drug but also for creating multi-drug combinations, offering extensive commercial opportunities. The potential for capsule-in-capsule technology is particularly significant in fields such as sports nutrition and aging-related diseases.

5.What Are The Machines Applied In Capsule-In-Capsule?

Capsule-in-capsule is the interesting and complex technology. The manufacturing of it involves the attending of many advanced and precise machines. And here are the machines applied in the capsule-in-capsule manufacturing.

Hard capsule liquid filling machine

AIPAK Hard Capsule Liquid Filling Machine

Hard capsule liquid filling machine is the advanced machine which makes the special manufacturing for capsule-in-capsule. Hard capsule liquid filling machine is capable of filling liquid, solid, solution, suspension or other objects in the hard capsules. The highly automatic and efficient work can help make the capsule-in-capsule with high quality.

The machine can corporate with filling sealing machine and make the hard capsule liquid filling and sealing production line. The strict and advanced sealing part of machine can help make the airtight sealing. A strip of gelatin seal will be applied at the middle of capsule. The great sealing is the prove of safe transportation and storing of capsule-in-capsule products. And it also assures the safety and stability of your capsule-in-capsule products.

6.What Material Can Capsule-In-Capsule Applied?

What material may exist in capsule-in-capsule? Can capsule-in-capsule contain liquid, solid or other material? Here are the common material applied in capsule-in-capsule.

Liquid and liquid

Liquid And Liquid-Sourced:vantage-nutrition

For the various fills, the combination of liquid and liquid is one of the most common one. You may fill the smaller capsule with liquid and the larger capsule with liquid too. The combination of liquid and liquid makes the different effect for much disease. The manufacturing of two liquid capsule apply the work of the advanced machines.

Liquid and semisolid

Liquid And Semisolid-Sourced:haosailscience

For the combination of liquid and semisolid, there is usually semisolid for the smaller one and liquid for the bigger one. And you may also make the exchange, as the bigger one can also take semisolid. The combination depends on the your different medicine type. This combination is also the common types for dual capsule manufacturing work.

Liquid and beads

Liquid And Beads-Sourced:lefancaps

For the combination of liquid and beads, there is usually beads in the smaller capsules and liquid in the larger capsules. By controlling the releasing of medical beads, the capsule-in-capsule makes the real effective work. For this type, you should also apply the granulation machine for the beads manufacturing and so on.

7.What Are The Carriers For Capsule-In-Capsule?

One important characteristic of capsule-in-capsule is to control the releasing of medicine. And the releasing time depends on carrier to achieve. Here are the common carriers for capsule-in-capsule.

Nonaqueous fluid

Nonaqueous Fluid-Sourced:qbios.gatech

Nonaqueous fluid is the common liquid carrier. You may apply the thixotropic agent to make it thickened. And you can also reduce the content to make the diluted liquid for your specific need. You may find its applying for the common capsule-in-capsule manufacturing work.

Thermosoftening excipients

Thermosoftening excipients has the features of various solution. And you may apply it to match the different releasing requirements. The changing of formulation or matching can make the releasing difference.

Self-emulsifying carriers

Self-emulsifying Carriers-Sourced:crodapharma

Self-emulsifying carriers man be nonaqueous solutions, suspensions, semisolid matrices or microemulsions. There are various types pf self-emulsifying carriers for you to apply and you should choose the one according to your medicine needs. Self-emulsifying carriers are suitable for the filling of various hard capsules.

8.What You Should Consider For The Capsule Manufacturing Of Capsule-In-Capsule?

Capsule-in-capsule manufacturing is the hard and precise work. It is easy to make mistakes or make the unqualified products. And in the manufacturing, here are some things you should consider for the better medical products.

Capsule shell material

Capsule Shell Material-Sourced:usvalidation

Capsule shell applied for capsule-in-capsule manufacturing should be hard capsule shell. You should apply gelatin or hydroxypropyl methylcellulose shells for the application. The soft capsule shell maybe shortened in its supporting force in containing and supporting the inner smaller capsules.

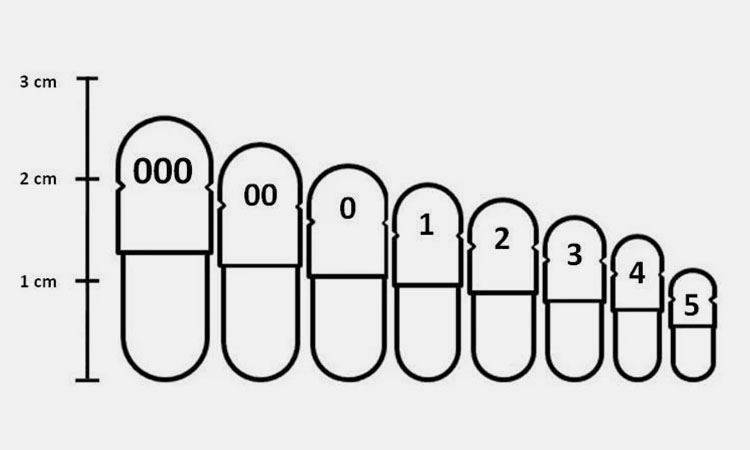

Capsule shell size

Capsule Shell Size-Sourced:buyemptycapsules

Capsule shell size has also the requirements for better suiting and supporting. Usually, the inner hard capsule should be two size larger than the outer hard capsules. For example, size 4 should fit in the size 2 outer shell for capsule-in-capsule manufacturing. For the size 2, it should fit the size 0. The wrong capsule shell size may make problem for your capsule filling work.

Coating

Coating-Sourced:caleva

In the consideration of capsule size, you should also take the coating into considering. The coating can also take the area and makes the filling of smaller capsule shell difficult. For different coating material, there is also the difference.

Carrier selection

You may select the carrier like aqueous solutions, glycerol, alcohol and some low molecular weight PEG may lead the quick breaking of capsule shell. For the balance content, you should select the carrier according to your medicine feature and type.

Transporting and storing

Transporting And Storing-Sourced:pharmapproach

You should consider the products feature and formulation feature to get the dissolving or relative change of your capsule-in-capsule products. The active ingredients and the excipients can also make difference for your products in their transporting and storing. For the great products transferring, you should adjust formulation or packaging.

9.What Are The Manufacturing Future Of Capsule-In-Capsule?

Future Of Capsule-In-Capsule-Sourced:ingredientsnetwork

Advanced capsule-in-capsule technology

Although capsule-in-capsule technology offers many advantages, its production process is more complex compared to traditional capsule formulations. Typically, the inner capsule must be filled using standard filling and sealing equipment, then embedded in the outer capsule using dual-station equipment.

This process increases production costs and limits manufacturing speed. However, with advancements in equipment and processes, the commercial production of capsule-in-capsule technology is gradually becoming more mature, and relevant patents have been approved globally.

Wide application

The capsule-in-capsule technology will be applied to more and more medicines and benefit more people. The precise medicine caring and the targeted medical work can improve the efficiency and help the quicker recovering of people. In future, with the low manufacturing cost and better technology, the capsule-in-capsule will be applied to more places.

Customized manufacturing

In future, to meet the need of different patients and improve the efficiency of medicine, there will be customized capsule-in-capsule technology which can help fulfill the need of different dissolving speed and targeted places. Customized capsule-in-capsule manufacturing will be booming in future.

Conclusion

What is capsule-in-capsule technology? You may have your own answers. Capsule-in-capsule technology is funny and intelligent. This new technology is now the trend in our current world. If you want to know more or have any questions about this technology, you should contact AIPAK at any time.

Don't forget to share this post!

Hard Capsule Liquid Filling Machine Related Posts

Hard Capsule Liquid Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine