How To Troubleshoot Common Defects Of Tablet Coating?

No one can reject the tablet coating as it is the most intelligent invention which makes great benefits for your medicine taking. Tablet coating is irreplaceable for many people and medicines. You cannot miss them for your medicine taking. But do you find the little defects on your tablet coating?

Why you need tablet coating? What are the types of tablet coating? What are the material used for tablet coating? What are the common defects of tablet coating? How to troubleshooting common defects of tablet coating? The all questions can be solved in this post. Come on and have a reading!

1.What Is Tablet Coating?

Tablet Coating-Sourced:rheonics

Tablet coating is the thin and sleek layer which covered on the outside of a tablet. It is used to benefit patient’s swallowing and also protects the active ingredients of tablets. In tablet manufacturing, tablet coating is the important manufacturing part and you may find the various machines and equipment applied in it.

There are tablets coating of various color and you may see the coated tablets for various medicine type. The tablet coating technique can be used in many industries and you may see its application in sugar manufacturing, tablets manufacturing and agricultural products manufacturing.

2.Why You Need Tablet Coating?

Why you need tablet coating? Why tablet coating is so important for medicine. Here you may find the reasons.

Bad taste covering

Bad Taste Covering-Sourced:science

The tablets with bad taste may lead the tablet taking problems. Tablet coating can help prevent the bad taste or smell of the tablet. You may sometimes taste the sweat taste of coating which helps the medicine taking.

Drug releasing control

Drug Releasing Control-Sourced:krka

Tablet coating can help control the releasing speed of your tablets. You body can be greatly protected with the drug releasing controlled. The releasing in a short period may lead the side effect for you.

Tablet stability

With the protect of tablet coating, the active ingredients of tablets and the tablet shape can be better proved. With the protection, you may have your tablets defect moisture, light and the many attack on transportation or storing.

Stomach protection

Stomach Protection-Sourced:pennmedicine

Tablet coating reduces the stimulation of medicine to your stomach and intestine. After the tablets are in the right position, the dissolution and releasing began. And this is the great protection for your body.

Attracting appearance

Attracting Appearance-Sourced:lfatabletpresses

Tablets coating makes the attractive color for your tablets. And its different bright color makes great benefits for patients to distinguish tablets. For patients purchase, the color also makes the difference.

3.What Are The Types Of Tablet Coating?

You may find the various types of tablet coating. But do you know the main types of tablet coating?

Sugar coating

Sugar Coating-Sourced:making

Sugar coating is the common tablet coating type. It formed the strong and thick sugar layer which avoids the bitter or disgusting favor. The thick sugar layer can also help protect your medicines.

Film coating

Film Coating-Sourced:kerry

Film coating is now the coating methods which takes more shares on tablet coating market. Film coating is composed of polymers, plasticizers, colorants, solvents and so on. The film coating is the great film which can improve appearance, protect medicines and also cover the bad taste.

Enteric coating

Enteric Coating-Sourced:osdmachinery

Enteric coating is the special coating which get dissolved in your intestine. With it, the active ingredients of tablets will be released easier and have the effect better absorbed in your blood.

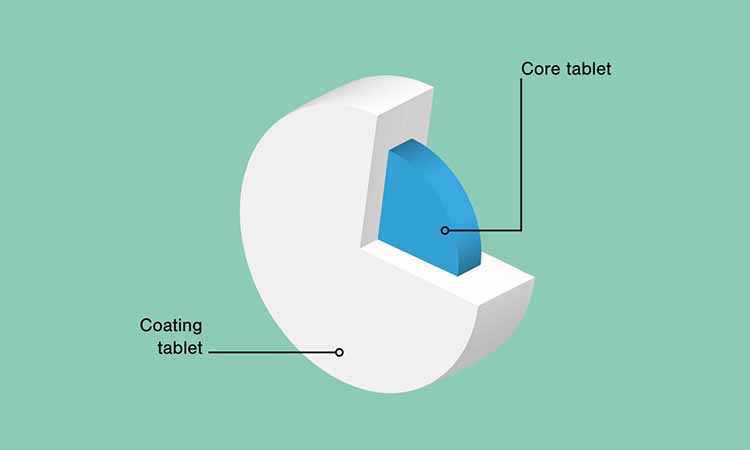

Compression coating

Compression Coating-Sourced:pharmaceutical-networking

Compression coating can make the coating with no bitter. It has low cost and makes little compliance of customers. The nice effect and low cost of compression coating make this coating type rather welcomed on market.

4.What Are The Material Used ForTablet Coating?

The material used for tablet coating is also varied. And you may find the below types as the common types.

Binders

Binders-Sourced:lfatabletpresses

You may find gelatin, acacia and cellulose derivatives as the represent binders for the common tablet coating manufacturing. It makes the sticky and sleek feature for your tablet products.

Fillers

Fillers-Sourced:medium

Fillers like talc, calcium carbonate and titanium dioxide make the main body of tablets. You may make your flexible choice from the various fillers type according to your tablet type and your budget.

Colorants

Colorants-Sourced:bathfizzandfoam

You should add color for your tablet coating to make them attractive and distinguishable. There are titanium dioxide, dye, iron oxides and the various colorants for your tablet coating coloring.

5.What Are The Common Defects Of Coating?

You may have found the defects of tablet coating in your medicine taking. Here are the common defects of tablet coating.

Pockmarks

Pockmarks-Sourced:pharmapproach

Pockmarks are the common defects of tablet coating. There are the irregular and raised spots on the superficial layer. The pockmarks make your tablet ugly and looked dirty. For your medicine taking, it may affect the smooth swallowing of tablets. Some customers may think the pockmarks make the unqualified products.

Crack

Crack-Sourced:colorcon

Crack is also the frequently appeared tablet coating defects. The cracks on tablet coat may affect the dissolution of tablet in your body. It may lead the earlier dissolution of tablets in your stomach.

Uneven coating

Uneven Coating-Sourced:colorcon

Uneven coating makes the rugged surface of your tablets. Compared with the smooth surface, uneven coating is slightly inferior in appearance of tablet. Besides, with uneven coating, there is also the dissolution of tablet in patient’s stomach which is also bad for active ingredients taking.

6.How To Troubleshooting Common Defects Of Tablet Coating?

For the various defects of tablet coating, here is your trouble shooting of tablet coating pockmarks, crack, uneven coating and the relative defects.

Coating materials

Material quality

Material Quality-Sourced:romaco

| Purity Issues | The insufficient purity and impurities in coating material may cause uneven coating surfaces and defects during the coating process. For example, using a polymer with tiny particulate impurities as the coating material can cause these impurities to form protrusions, resulting in surface defects, such as pinholes. |

| Poor Stability | Some coating materials are sensitive to environmental factors. If the coating material absorbs moisture, its physical and chemical properties may change. For instance, powdered sugar that absorbs moisture can cause rough patches on the coating surface due to the recrystallization of sugar. |

Material formulation

Material Formulation-Sourced:thepuresource

| Improper Proportion of Excipients | The proportion of excipients such as plasticizers and colorants can affect the coating quality. When hydroxypropyl methylcellulose (HPMC) is used as the main coating material, the plasticizer (e.g., glycerin) amount which is below the recommended range (usually 10-20g per 100g of HPMC)will induce the brittle and crack of coating film. |

| Ingredient Compatibility | Different components within the coating material might react chemically or interact poorly. For example, certain drug components may react with additives in the coating material and cause discoloration, defects and even affect the adhesion and integrity of the coating. |

Coating Process

Spraying process

Spraying Process-Sourced:fluidairinc

| Spray Speed | Uneven spray speed is the common cause for coating defects. If the spray speed is fast, the coating solution may dry on the tablet surface before it can be evenly spread, leading to local accumulation, rough surfaces, or defects. For instance, during fluidized bed coating, improper spray speed settings may cause some areas to have a thick coating while others have a thin coating, or even uncoated spots. |

| Spray Pressure | Incorrect spray pressure can also affect coating quality. Low pressure results in large droplet sizes, which can lead to droplet accumulation and surface defects. High pressure creates fine droplets that may be blown away by the drying air, resulting in an uneven coating and defects. |

| Spray Angle | An improper spray angle can cause uneven coating distribution on the table’s surfaces. For example, if the spray is directed at one side, the coating on that side will be too thick, while the other side will be insufficiently coated. |

Drying process

Drying Process-Sourced:jinlupacking

| Temperature Factors | The high drying temperature or long drying time may lead the quick shrink of coating layer. For instance, if hot air is used for drying and the temperature exceeds the glass transition temperature of the coating material, the coating will become brittle and crack. On the other hand, if the drying temperature is too low or the drying time insufficient, the coating may not fully dry, and residual solvent in the coating may cause bubbles and defects. |

| Ventilation Condition | Poor ventilation affects the solvent evaporation rate. The slow ventilation may cause the improper discharged which may lead soft and sticky coating layer. If ventilation is too fast, the surface solvent may evaporate quick which may cause drying surface while leaving residual solvent inside. |

Equipment factors

Equipment-Sourced:syntegon

| Equipment Cleanliness | If the coating equipment is not clean and contains residues from previous batches, it may cause the unqualified coating. These residues may mix with the coating material or adhere to the tablet surface. |

| Equipment Precision and Stability | Insufficient equipment precision, such as uneven nozzle apertures or unstable stirring speeds, can affect the spray quality and tablet movement during the coating process, leading to uneven coating, pinholes or cracks. |

Tablet condition

Tablet shape and surface

Tablet Shape And Surface-Sourced:pexels

| Irregular Shape | Tablets with irregular shapes or uneven surfaces will have an uneven coating effect. For instance, if the tablet has edges or depressions, the coating liquid may flow and spread unevenly in these areas which may lead defects. For tablets with scores, it can be difficult to control the coating thickness in the scored areas. |

| Surface Roughness | Tablets with excessively rough surfaces will result in uneven adhesion and spreading of the coating liquid which may increase the likelihood of pinholes and defects. |

Tablet Hardness and Brittleness

Tablet Hardness And Brittleness-Sourced:seppic

| Hardness Issues | If tablet is too hard, it may damage the coating layer during the coating process, causing cracks. If it is too soft, the coating solution may erode the tablet surface and make defects. |

| Brittleness Effects | Tablets that are too brittle may break under mechanical stress during the coating process which can compromise the integrity of the coating and result in defects. |

7.How To Make The High Qualified Coating?

How to make the high qualified coating? Here are the advice you should conform in your tablet coating manufacturing.

High qualified raw material

You should adopt the high qualified raw material for the tablet coating. The material with impurity and high moisture may lead the uneven tablets or rugged tablets. You should adopt the high qualified material for the tablet coating manufacturing.

Proper coating formulation

Coating Formulation-Sourced:malvernpanalytical

It is mentioned that coating is made with binder, filler and colorants. The different match and proportion of coating may lead the different condition in coating process. You should get the formulation which can make the coating with high quality.

Reliable equipment

Reliable equipment also decides the tablet coating quality greatly. The spraying speed and pressure is so important for tablet coating process. The high qualified coating machine can also make the great coating job. You should prove the high quality and clean station of equipment for coating work.

Suitable tablet condition

Suitable Tablet Condition-Sourced:pharmaexcipients

Tablet condition also makes the great effect on tablet coating. For the tablet with various shape and splitting in the middle, there is trouble in coating solution flowing and evenly covering. Besides, you should also check your tablet’s hardness. The hard one may improve the possible of tablet cracking.

8.What Are The Types Of Tablet Coating Machine?

Tablet coating machine has the various types. And here are the common types of tablet coating machines.

Standard coating pan

ALLPACK Standard Coating Pan

Standard coating pan is the common tablet coating machines applied in tablet coating process. It has the round shape and the tablets can rotate in the pan for the uniform packing or covering on tablets.

Perforated pan system

AIPAK Perforated Pan System

Perforated pan system makes the tablet coating in a partial or full perforated drum. The spraying mechanism makes the even coating of various types of tablets for you. The high efficient and great sanitary can always make great work.

Fluid bed dryer

AIPAK Fluid Bed Dryer

Fluid bed dryer is the efficient and advanced tablet coating equipment. It is the vertical cylinder which applies the fluidization of wind to make drying, granulating and coating. The fluid bed dryer can easily make the medicine breaking.

9.How About Tablet Coating Future?

Tablet coating takes the large share on market. So have you ever wondered its future. How about tablet coating future?

Advanced tablet coating technique

Advanced Tablet Coating Technique-Sourced:oharatech

There will be advanced tablet coating technique in future. Tablets coating will make the great advance on protection, function and beauty. The automatic and efficient tablet coating can also make the great change in tablet coating market.

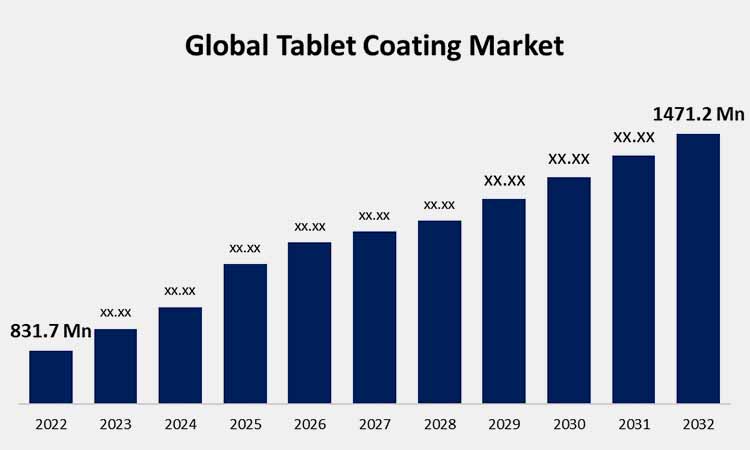

Growing tablet coating market

Growing Tablet Coating Market-Sourced:sphericalinsights

There is the growing tablet coating market. The increasing incidence of chronic disease makes the coated tablets important on market. The great demand of coated tablets makes the growing tablet coating market.

Customized tablet coating system

Customized Tablet Coating System-Sourced:colorcon

Customized tablet coating system takes customer’s profits and feeling at first place. Customized tablet coating makes the customer friendly service for patients of different need. The customized tablets for children, elders and different patients are more personalized.

Conclusion

What make tablet coating defects? How to troubleshooting common defects of tablet coating? You may have your own answers. Tablet coating is such an important part in tablet manufacturing. People will benefit more from tablet coating. If you have any questions on this subject, contact AIPAK right now.

Don't forget to share this post!

Tablet Coating Machine Related Posts

Tablet Coating Machine Related Products

Tablet Coating Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine