Explore 6 Common Materials and 5 Factors of Pharma Packaging

How do your medications remain stable and active? It’s all about the game of pharma packaging that performs a significantly essential role across the globe when it comes to the safety and security of your medicines. Thus, it exerts a huge impact on public health positively. But the game is not stopped here! It has been observed in 2023 Grand View Research (GVR) that its market has been growing showing a worth of approximately $139.37 billion. Aren’t excited?

Come on readers! In this topic, we are going to ‘Explore 6 Common Materials and 5 Factors of Pharma Packaging’ which you will very informative and critical when it comes to shaping the pharma packaging plan.

1.What’s pharma packaging?

Pharma packaging- Picture Courtesy: Oliver Inc

This is an approach to enclose your medicines and keep them safe from environmental agents and biological pathogens. This packaging, also called drug packaging, consists of diverse procedures. The containers or materials utilized in protecting both raw drug formulations as well as facilitating the flexible way of handling, storage, shipment, delivery, and retailing.

It not only helps users in identifying medications but also in product advertising, along with brand promotion. Furthermore, with pharma packaging, you can have absolutely zero possibility of alteration in chemical composition. Nowadays, there is diversity in this packaging, ranging from temperature-controlled containers to aesthetic labels.

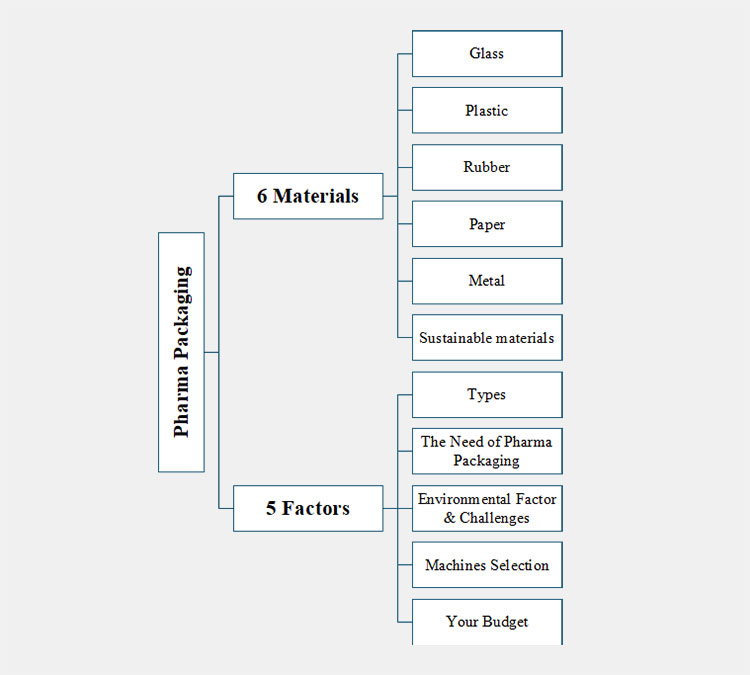

2.Can you Explore 6 Materials and 5 Factors of Pharma Packaging?

The basic classification of material and factors in pharma packaging

3.6 Materials in Pharma Packaging

This is an important section where you can explore the list of materials used for securing your medicines. See the details right below:

Glass

Glass- Picture courtesy: The Hungry JPEG

This is a very important packaging material that has been used for pharma packaging for a long time. Apart from its traditional values, glass as a packaging material is considered one of the safest ways to store medicines for a longer time. This is all because of exerting greater resistant properties against various unwanted gases and humidity. However, when you consider these all things, glass is known as the best material for preserving the integrity of the drug. This is mainly used for storage of injectable solutions, powders, and so much more.

The game is not just hooked to glass, but the colors of glass also impose effects on the materials stored inside. Yes, that’s the reason you see various colors of glass for medicines. For example:

Transparent and Amber glass- Picture Courtesy: Verified market research

| Transparent Glass | This is the clear color where you see the presence of any foreign particle inside the container. Moreover, this is mainly used to store vehicles that don’t get affected by physical factors and remain stable for longer. |

| Amber Glass | There are various materials in the medicinal world that are affected by the action of light and related factors. To avoid such factors, and make your product more potent, colored glass is used that possibly resists and reflects back the ray of light that tries to penetrate the medium. Therefore, you may observe various medicines available in amber glass packaging. |

Along with colors, the glass used for pharma packaging is also subdivided into various categories based on its structural composition and its property to resist the interaction of particles with its surface. In this case, you can see broad three ranges:

| Type I or Ultra-Resistant Borosilicate Glass | There are various medications and chemicals used in the pharma industry that are prone to degrade with changes in pH and acting so reactive. For their storage, this material is used and is known for being highly resistant to chemical interaction.

Additionally, it is highly resistant to thermal expansion and capable of withstanding warm and harsh environments or sudden changes in temperature. That’s why the same material is utilized in the process of sterilization of substances. Type I or ultra-resistant borosilicate material glass is mainly used in pharma packaging for the making of various ampoules, vials, etc. |

| Type II Surface Treated Soda Lime Glass | This type offers you specialized anti-alkalizing effects as it is treated with a procedure which is called dealkalisation.

In this process, the presence of alkali constitute in the glass is removed is making it more stable and less reactive. When you store various medications that are best known for alkali-sensitive elements, they remain stable for a longer time. As compared to type I, it does not offer more stability profile but can be used for storage of various infusions and syrups. |

| Type III Soda Lime Glass | The type III glass is prepared via treatment of soda lime silica. This type of glass is quite economical and safe for various pharma industry packaging purposes.

You can opt this glass when you’re packing those medicines that are not very sensitive to alteration in pH and not subjecting for long term storage. This is used in pharma packaging for various tablets, syrups, powders, etc. Moreover, you can use them for parenteral preparation solution as well as non-parenteral. |

Plastic

Plastics

You must have seen various medicinal products that are packed in flexible and effective molded packaging. Yes, these can be achieved by the utilization of plastic in the pharma industry. This is not only an affordable way of packaging but also gives you a high level of protective and barrier properties throughout the transportation and storage. Apart from its flexibility, it gives you aesthetic formatting by easily molding them in various patterns.

Just like glass, the plastic itself also has various types. See the brief discussion just below:

| Polyethylene or (PE) | The popular type of plastics used in the pharma packaging and available in various specifications such as density, hardness as well and various levels of transparency. |

| High-Density or Polyethylene (HDPE) | This is best known for its high durability. This type of plastic is mainly used to pack and store various tablets, pills, capsules, granules, and liquid dosage formulations. This is because it gives you greater strength and moisture-resistant properties. However, it is way more capable of resisting the absorption of UV light. Thus, your product is safe and promising if packed using HDPE plastics. |

| Low-Density Polyethylene or (LDPE) | This is a flexible form of plastic that can be squeezed easily. For example, you have seen various bottles and tubes, that can be pressed and squeezed to get substances of medicines. These types of packaging materials are mainly prepared from LDPE plastics and are mainly needed for materials packaging that urges flexible formats. |

| Polypropylene or (PP) | The type of plastic is a popular material that offers a greater degree of heat or temperature resistance properties. This characteristic, it is mainly used in sterilization methods as various temperature shocks can be given in that procedure.

Moreover, PP plastic is used in the pharma industry for caps, bottles, and syringes parts. This type of plastic is protective and gives high withstanding responsibilities against chemical interactions. That’s the reason various pharma packaging industry consider it as the most dynamic substance for storing and packing materials. |

| Polyethylene Terephthalate or (PET) | The safest, high clarity ratio, and most durable plastic-type which is mainly used for the manufacturing of plastic bottles, and various medicinal jars.

This material can play a significant role in striking back the oxygen penetration or other unwanted chemicals such as carbon dioxide to interact with inside materials. Therefore, it is used for pharmaceutical solid, liquid, and parenteral dosage formulation packaging. |

| Polyvinyl Chloride (PVC) | This type of plastic is mainly used in the packaging of tablets or capsules such as blister packaging.

It offers you easy-to-draw the medicine as well as great protection. Thus, when you used PVC packaging materials for medicine, it promises you that it will give a high shelf life to your product. Due to some environmental concerns, the utilization of PVC is decreased, and other types are used for packaging purposes. |

| Polycarbonate (PC) | This type of plastic packaging in pharma is used as it gives you a greater clarity ratio. This is mainly considered as a good option for ophthalmic preparations as it offers high resistance to physical factors and makes the materials to store for longer and more visible due to transparencies. |

Rubber

Rubber- Picture Courtesy: Fengchen

Where do you utilize rubber in pharma packaging? The answer it is mostly used for manufacturing stoppers and closures as it has excellent sealing characteristics. Rubber sealing components are vital in safeguarding the purity and integrity of pharmaceuticals, for example, injectable and parenteral preparations. Let’s look at the numerous uses of rubber in pharma packaging.

| Butyl Rubber | It is one of the most prevalent types of rubber in pharma packaging. Because it can encounter challenges of gas and vapor entry into packed products through its strong barrier against these agents. This makes it well-sought out for sealing vials and bottles. |

| Chlorobutyl and Bromobutyl Rubber | They are formed by adding halogen molecules (chlorine and bromine) to butyl rubber. This increases its resilience to harsh and highly reacting chemicals and extreme temperatures (both high and low). Thus, they are found in specialized pharma containers, for example, stoppers for freeze-dried vials. |

| Synthetic Rubber Stoppers | You’ll routinely observe them in vials and ampoules. They are popular for use with packaging of injectable formulations, owing to their ability to provide airtight seal. |

| Elastomeric Closures | You’ve guessed it right! These closures are known for their extreme elasticity, consequently, they can withstand numerous punctures by syringe needs. Therefore, it should come as no surprise that they can preserve the composition of medication even when the latter is retrieved many times. |

| Gaskets and O-rings | Although their utility is synonymous with pharma equipment, however, you’ll find it unbelievable, that they are best for sealing joints and connections in pharma containers. |

| Silicone Rubber | It is a rubber-like material that is formed with the reaction of silicon with other molecules-carbon, oxygen, and hydrogen. It remains stable even during abrasive settings, making it best for application in a syringe plunger and dropper bulb. |

Paper

Paper- Picture courtesy: Pakko

This oldest material for packaging is not used as a first covering for medications but you would’ve noticed that the second and third packaging layer is made with paper and associated materials- cardboard. Paper is very mainly obtained from the wood of trees. It is easily recycled and can be used in diverse ways like making labels, leaflets, and inserts.

Paper is easily printed; so, it is the best means to inform users about different facts about the product.

Metal

Metals- Picture courtesy: Robert Metal Packaging

They have made it at the top of the list of pharma packaging. The reason? Because of their extreme durability and barrier characteristics. In contrast with other materials, they are preferred by various pharma manufacturers due to their ability to completely shield pharma products from light, air, and, water content.

Numerous diverse materials are present in pharma packaging, such as:

| Aluminum | It's safe to say that most people are aware of blister packs, tubes, and aerosol cans. But are you familiar that they are made from aluminum? This metal is not only protective but also malleable. |

| Tinplate | It is a two-in-one alloy of stainless steel with a tinplate, as it combines the robustness of steel with the rust resistance of tin. It is highly regarded in the pharmaceutical industry because of its supreme chemical inertness and physical barrier. |

| Stainless Steel | It is the winner in metal pharma packaging. Because of its impressive toughness, corrosion tolerance, and easy cleanliness. It is often the go-to choice in specialty and high-purity applications that need more sterilization and sanitation. |

| Tin | Every now and then, you surely have spotted tin in pharma packaging. It is non-toxic in nature and like other metals, doesn’t rust. So, its thin coating layer is applied to other metals to make the latter suitable for holding products for a longer period. |

Sustainable materials

Sustainable Materials- Picture Courtesy: Healthcare Packaging

Now, people are becoming more and more environmentally aware because of active campaigns. So, the pharmaceutical world is actively seeking materials that are more eco-friendly and decompose by natural means. Let’s discover some promising sustainable materials:

| Polylactic acid (PLA) | This biodegradable material is created from plant-based sources, such as corn starch and sugarcane. Manufacturers have recently started using it for making blister packs and disposable packaging. How does it decompose? It easily decomposes in a composting environment. Therefore, it possesses less carbon footprint than plastics. |

| Recycled Plastics | They are becoming more and more common in the pharmaceutical arena. You can easily produce bottles, jars, and trays from post-consumer recycled (PCR) plastic. This approach has lots of potential benefits, for example, minimizing the need for virgin plastic and lowering plastic waste. |

| Bamboo and Other Natural Polymers | Have you heard that bamboo, hemp, and other materials found in nature are now used as alternatives to standard packaging materials? Yes, absolutely, because they grow more rapidly and don’t require much energy and water for manufacturing. |

4.V Factors in Pharma Packaging

Along with materials, there are various factors that impose high impacts on pharma packaging. For instance:

Types

The pharma industry packaging ensures that whatever type of formulation you’re filling or packing in materials are kept safe longer and it is up to your international settings. So, by this, there are around four major types of pharma packaging. For instance,

Primary Pharma Packaging

Primary packaging- Picture courtesy: PPMA Show

As its name shows, it has direct interaction with your formulation as the pharma medicines are straight packed into them. You can categorize them into the following sub-types:

| Blister and Strip Packaging

|

These are very popular and common types of pharma packaging. You can store medicines like capsules, pills, and tablets inside them. In case of a blister, pocket cavities formation is provided to store your product. Whereas in the case of a strip, a series of medicines can be packed by heat sealable and flexible packaging material.

Both modes are extremely important and known as primary packaging it offers an improved way of protection by providing extra barrier properties to your medicines. |

| Ampoules

|

This is mainly used to pack pharma sterile preparations. Ampoules are mainly made up of glass materials and sometimes plastics too.

You can store your formulation as a single serving dispensing and mainly used for parenteral products that ensure greater sterility proportion. |

| Vials

|

This is also known for packaging sterile products. Vials have the capability to store your product for a longer time and can be used more than one time.

Just like ampoules, they are prepared with glass or plastics but are facilitated with soft rubber hooked stoppers which are fixed with a cap. You can withdraw the medicines by inserting the needle into the soft rubber hook easily. Once it is used you can fix the cap back over the neck of the vial. |

| Bottles

|

Various syrups, lotions, topical, solid dosage formulations, and many liquid solutions are dispensed in bottles. This is a traditional packaging way in the pharma industries.

Today, bottles are designed in a way that provides high anti-tampering characteristics and child protection closing. They are available in plastic and glass materials and provide high shielding effects against external factors to preserve the medicine's properties. |

| Tubes

|

In pharma packaging, various semi-solid preparations are packed in tubes made up of either metal or flexible plastics. You can get your medicinal product simply by squeezing the tubes and applying it directly where it is required. |

| Aerosol Spray

|

These are unit containers that have medicines prepared in a mist formulation and can be dispensed by pressing the nozzle to get dispersed molecules of potent materials. This is an easy mode of primary packaging and is mainly used for medications that are present for treating asthma, allergic, or dermatological problems. |

Secondary Pharma Packaging

Secondary packaging- Picture courtesy: Khangthanh

After primary pharma packaging, the further protective packaging is addressed. This means that one more layer of packaging is provided where the primary packed materials are placed. This is known as secondary packaging. It is mainly used for marketing and distribution purposes. You can also categorise them into further sub types of packaging. For instance,

| Boxes and cartons

|

When you buy tablets or medicines, you find them in a box. This is used as a mean of carrying the primary packed products. The boxes are mainly prepared from card boxes which ensure the position of materials safely. |

| Shrink Wrap and Foil

|

Main primary packaging products are stacked and wrap around with a shrink wrap by utilizing the thermal energy. It gives you high protection and tamper resistant properties. Also, you can attain physical protection from moisture, light, or foreign particles. |

| Cold Seal Wallets

|

For heat sensitive products, the secondary packaging is done by applying the cold sealing wallets method. They are mainly attained by utilizing the laminated sealing wrapped and by inducing the high pressure a suitable sealing is formed. |

| Blister Wallets

|

For blister packaging and other medicines, the blister wallets are formed for giving extra protection. These are also provided with printed wallets that do not offer shielding effects but makes an aesthetic format to your products. |

| Injection Trays

|

Various ampoules, syringes, vials, related injectables are stored and packed in small and flat trays. These are known for easy transportation and safety. They are offering well-organized adjustments of the product and offering easy handling in clinical settings. |

Tertiary Pharma Packaging

Tertiary Packaging- Picture Courtesy: ROTZINGER

This is mainly popular for bulk packaging of pharma products. Yet, offering high security and easy distribution to the various regions of the world.

The sub- division of the tertiary packaging are discussed below:

| Bulk Containers

|

These are mainly prepared from either metals, plastic, or hard boards. It includes large containers, boxes or drum. You can store a large quantity of the material into bulk container and can be supplied for trading purposes safely. |

| Pallets

|

The containers or boxes are piled up and secured together in the form of pallets. This is considered as a robust and economical pharma packaging method. However, pallets are made up of either woods, plastics, and sometimes metal. |

| Stretch Wrap and Strapping

|

By its names, you can easily predict that either a plastic film, polyester film, or steel film, is responsible for wrapping the pharma products firmly. It facilitates an easy loading and unloading of the product and its throughout movement. |

| Barrels

|

Large quantities of liquid pharma products are stored in a barrel which is not only leakproof but offering protection for sensitive materials. You can transport liquid formulation from one place to other to store longer in a barrel without worrying for environmental hazards or contamination. |

Specialized Pharma Packaging

Specialized pharma packaging- Picture Courtesy: QR Tiger

Due to the emergence of high technology, today’s pharma packaging prefers specialized packaging for specialized groups of people. For instance:

| Child-Resistant Pharma Packaging

|

Children always needs greater monitoring when it comes to saving your medication. to solve this problem, child resistant pharma packaging is introduced that needs high pressure and tricks to open the lid of the medicine.

Such tricks can’t be used by children, so it is easy to manage their safety and make them safe from accidental ingestions. |

| Anti-tampering Pharma Packaging | Various different formats and specialized materials are used to make your pharma packaging featured with tamper evident properties. For instance, if anyone tries to alter the setting, one can easily identify tampering and avoid taking them. |

| Smart Pharma Packaging | In this century, smart pharma packaging has emerged with advanced ways for medication safety. It is included with infused labeling, utilization of QR scan codes, NFC or near field communication technology. Such packaging allows our mobile app to communicate and alarm you the time of taking dosage, with its indication, etc. |

| Sustainable Pharma Packaging

|

Due to high concern for ecological safety worldwide, sustainable pharma packaging has been introduced. This means, that whatever the ingredients are used in packaging, they have biodegradable and recyclable properties so you can reuse them by conserving the ecosystem. |

5.The Need for Pharma Packaging

Product contamination, spilling, information miscommunication, and tampering have been always sources of worry for manufacturers and users since the earliest times. Hence, pharma packaging is designed to nip these problems from the root. Are you curious about the significance of pharma packaging? Then, let’s explore its wide range of benefits together.

Stable Products

Stable medicine- Picture Courtesy: Types blog

The pharma industry prefers stable packaging as it plays an important role in maintaining stability. Pharma packaging is very effective in preventing chemical reactions and physical damage during the journey of products from factories to patients. By packaging, you can improve the life of your drug dosages.

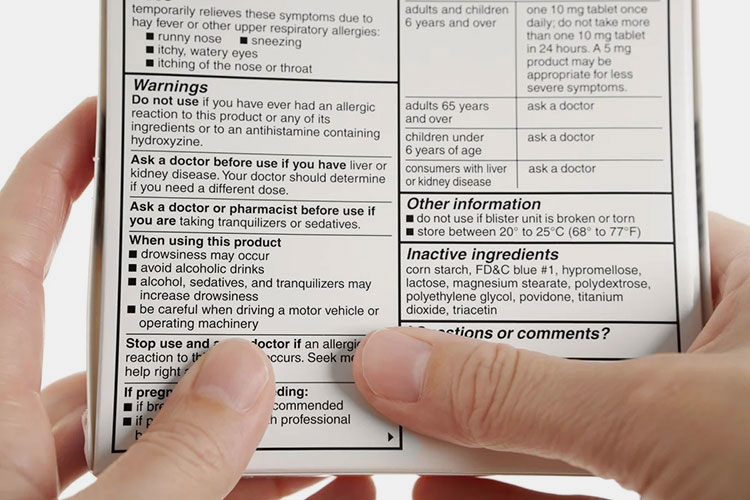

Educating User

Educating users- Picture courtesy: Healthy women

How to prevent accidental ingestion, the pharma packaging play a significant barrier role. While it allows the easy opening to elderly patients, at the same time, it prevents young kids from accessing medications. Moreover, manufacturers always welcome additional security by incorporating tamper-evident aspects in pharma packaging.

Promotion

Promotion- Picture Courtesy: label online

You can think of pharma packaging as a communication channel between pharmaceutical manufacturers and end-users or healthcare practitioners. Because it has a role in information dispensing. You must have noticed numerous facts, for instance, use instructions, storage suggestions, expiry dates, and drug interactions on the back of the treatment pack. So, users can avoid the misuse of drugs by reading these details.

Satisfaction

Your trust on medication

Your satisfaction, trust, and convenience are always at the front of the minds of pharma businesses. Studies show that pharma packaging with easy-to-use features goes a long way to establishing patient adherence to dose schedules. So, now you find dosing calendars printed over the blister packs, and unit dose containers to enable you to carefully monitor your medications.

6.Environmental Factors & Challenges

Nevertheless, there is high debate about maintaining pharmaceutical packaging and the environment. That’s why today pharma packaging is way more challenging. For instance,

Humidity

Humidity- Picture Courtesy: Wisesorbent

Moisture of humidity can shorten the life of medicines earlier. That’s why to combat this challenge, every pharma packaging deals with the insertion of desiccants. It has ability to penetrate the presence of moisture or water content progress inside the pharma packaging thus your product can stay longer.

Oxidation

Oxidation- Picture Courtesy: Technology network

Oxidation is a culprit behind rapid degradation of medicines. It induces the process chain of degrading the efficacy and potency of the active pharmaceutical ingredients. Side by side, the overall organoleptic properties are affected. Therefore, in pharma packaging, the greater preventive measures are taken. For instance, utilizing material that inhibits the process of oxidation, such as induction of nitrogen, removal of O2 moieties or air removal, vacuum induction, airtight packaging, etc.

Light

Light- Picture Courtesy: Pipeline packaging

Light is composed of some harmful rays in the form of UV radiation. Which is not only risky for your skin, but also for products. Therefore, just like sunscreen, pharma packaging minimizes the chances of entry of UV radiation inside the packaging. Thus, you have seen various tinted packaging and various color scheming that prevent your medications from unwanted radiation.

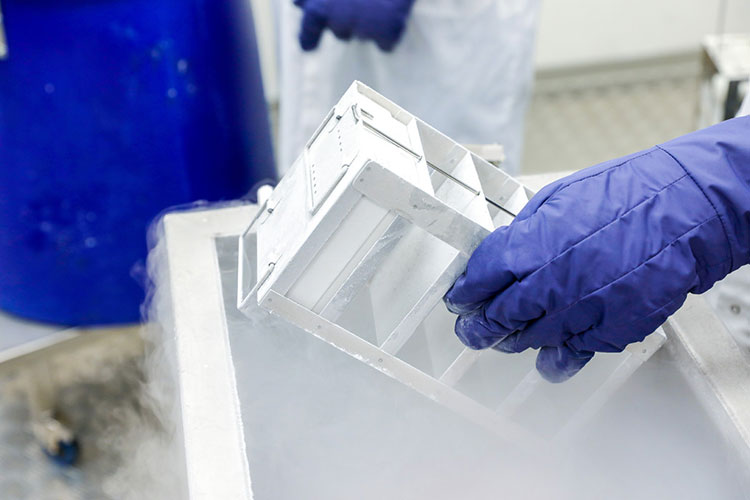

Temperature

Temperature- Picture Courtesy: World Pharma Today

Pharma packaging demands a stable material application that can make promising conditions inside. So, the environmental temperature fluctuations can be dealt significantly. That’s why various layers of packaging are implemented to assure you that the drug is safe inside from temperature alteration.

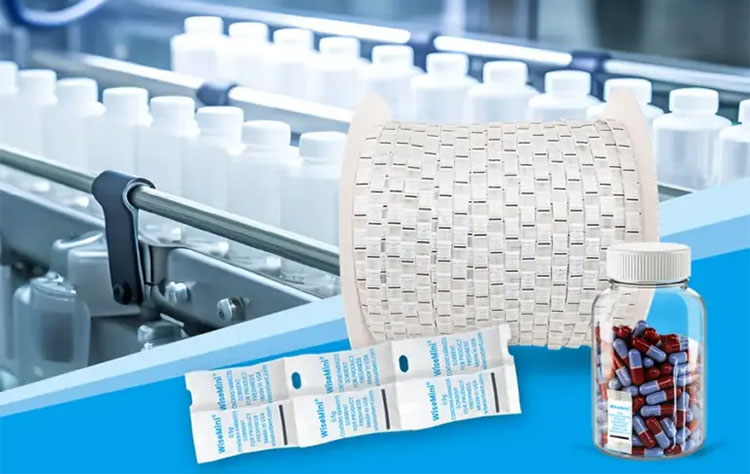

7.Machines Selection

AIPAK ENGINEERING Pharma Packaging Machine

The right choice of machine selection is an important factor that can impact on pharma packaging. Conventionally, there were simple and semi-automatic machines were high in demand. Today, everything has changed, machines are introduced with more innovation and advancement.

Every pharma packaging company looks for high tech packaging equipment with standard and affordable prices. Side by side, your production capacity, area space, environment safe, user-friendly, etc options must be seen before picking up the unit. Therefore, the right option can overall influence your business at a high ranking.

Your Budget

Your budget

This is an important factor one must keep in mind when designing the pharma packaging. Indeed, the investment in simple packaging comes under affordable limits than you spend on specialized packaging. Therefore, if you are formulating controlled drugs, sensitive medications, or reactive substances, or focusing a specialized group of people. The budget ranks come after that, but your patient safety should be the first priority.

Conclusion

After reading the article ‘Explore 6 Common Materials and 5 Factors of Pharma Packaging’, we hope that you will have good knowledge about the materials and factors relationship with pharma packaging. Here, you have evaluated various types of pharma packaging and how they play a significant role in the safety and stability of your medication. However, what kind of machines can be used for attaining the pharma packaging can be seen on our website. If you want further information and suggestions related to the machine; we would like you to contact our team. AIPAK is an excellent solution that offers an optimized and affordable series of pharma packaging machines under reduced unnecessary cost.

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine