What Are The Different Types Of Pharmaceutical Powder?

Have you ever learned about the types of pharmaceutical powders needed in traditional pharmaceutical dosage forms, including powders, granules, capsules and tablets? Why is the pharmaceutical industry still based on powder dosage forms? How stable are pharmaceutical powder dosage forms? What are their preparation methods? In addition to oral administration, what other pharmaceutical powder dosage forms for external use have you seen?

Although pharmaceutical powder are not widely used for external use, they basically dominate oral medications. They are also often added to various ointments, pastes, suppositories, etc. Following this different types of pharmaceutical powders, you may get all you want to know about. Get started now!

1.What Is Pharmaceutical Powder?

What Is Pharmaceutical Powder-sourced: pharmapproach

Pharmaceutical powder refers to a solid dry preparation in the form of particles. It can be used as a medicine for internal and external use, and the dosage is strictly controlled. Pharmaceutical powder can be obtained through grinding, mixing and stirring. Generally, the size of pharmaceutical powder can range from 10 nanometers to 1000 microns. Compared with liquid preparations, pharmaceutical powder is more widely used.

2.What Are The Types Of Pharmaceutical Powder?

There are many types of drug powders. According to the use of drug powders, it can be divided into the following categories:

Bulk powder

Bulk powder-sourced: bulkconnection

Bulk powder is a very fine powder solid dosage form. Because it is used in large quantities, it has a wide range of uses, both for external and internal use.

Dusting powder

Dusting powder-sourced: burtsbees

This powder is often used as an external application drug. It can solve skin irritation problems very well. The components of dusting powder are generally clay, kaolin, talc or starch.

Douche powder

Douche powder-sourced: pharmasciences

Douche powder is usually a powder substance used in the private parts of the human body. It can be used to clean your vagina to solve your vaginal itching or bacterial problems.

Insufflation powders

Insufflation powders-sourced: nationalpharmacyrx

Insufflations is a powder specifically used for injection. It can be injected into the human body through a syringe or an extruder.

Divided powders

Divided powders are individually packaged in very small doses. The dosage of this powder is very precise, but the efficacy is generally strong.

Aerosol powders

Aerosol powders-sourced: opkill

Aerosol powders can be administered to patients with the aid of a respirator. This powder is generally used to treat patients with asthma or bronchial diseases.

Efflorescent Powder

Efflorescent Powder-sourced: srwproducts

Efflorescent powder is generally composed of crystalline powder. Its representative products are atropine, citric acid or alum and caffeine. This powder becomes viscous when exposed to air.

Effervescent powder

Effervescent powder-sourced: ester-c

This powder reacts chemically with water to release carbon dioxide to produce bubbles. Representative substances of this powder are sodium bicarbonate, citric acid or tartaric acid.

Powder sprays

Powder sprays-sourced: juvitus

It can effectively disperse powdered drugs on the injured part of the human body through a sprayer, so that it can be well absorbed by the human body.

3.What Are The Uses OfDifferent Pharmaceutical Powders?

Pharmaceutical powders are widely used in the pharmaceutical industry. They include:

Tablet press

AIPAK tablet press

Medicinal powders in the pharmaceutical field are usually used in tablet presses. This powder is made into tablets or pills by tablet presses, which can be swallowed or chewed by patients.

Granulation

Granulation-sourced: reitech

Many medicinal powders are made into pills by various fluidized bed granulators for patients to use.

Capsule filling

AIPAK capsule filling

Many medicinal powders filled by capsule filling machines belong to this type of powder. The fluidity and granularity of the medicinal powder can determine the type of capsule filling equipment and capsule model used.

4.What Are The Size Classification Of Pharmaceutical Powders?

Pharmaceutical powders have different size classifications. They include

Size Classification Of Pharmaceutical Powders-sourced: drinktrade

Extra fine powder

This powder is also called No. 80 powder. It is usually sieved with a No. 80 sieve.

Fine powder

Fine powder is usually called No. 60 powder. It is usually sieved with a No. 60 sieve.

Medium coarse

Medium coarse powder is also called No. 40 powder. Ideally, it is usually sieved with a No. 40 sieve.

Coarse powder

Coarse powder is also called No. 20 powder. It is usually sieved with a No. 20 sieve.

Very coarse

Very coarse powder is also called No. 8 powder. Because it uses the largest model, No. 8 sieve, to sieve.

5.What Are The Methods Of Pharmaceutical Powders Preparation?

Processing pharmaceutical powders is a very delicate matter. It requires many steps to refine. These include

Size reduction

Size reduction-sourced: horiba

This is the first stage of powder processing. It mainly grinds and shears all powders of different specifications through preliminary processing. Control the larger powder particles to a smaller unit and make the powder more uniform for the next step.

Sieving

ALLPACK powder sieving

Sieving is a very delicate process. It measures each ingredient and mixes powders with different functions. Sieve during the mixing process. Sieve out larger or coarser particles to make the powder particles uniform with powder sieving machine.

Weighing

Weigh the powder processed in step 2. This ensures that each ingredient in the sieved powder is a controlled dose.

Mixing

AIPAK powder mixing

Finally, mix all the different ingredients and all the powder ingredients of different doses with powder mixer. The mixed powder will be weighed and packaged at the end.

6.Are There Specialized Types of Pharmaceutical Powders?

There are also special types of powders that are not included in all the above types of powders. They are:

Eutectic powder

Eutectic powder-sourced: castolin

Eutectic powder is a mixture of many special and different ingredients. Its formula is extremely special and very valuable. This powder usually contains ingredients that can relieve local pain, including menthol, camphor and balifen.

7.What Is The Granulation Of Pharmaceutical Powders?

Granulation of pharmaceutical powders is a tedious process and involves several different methods. These include

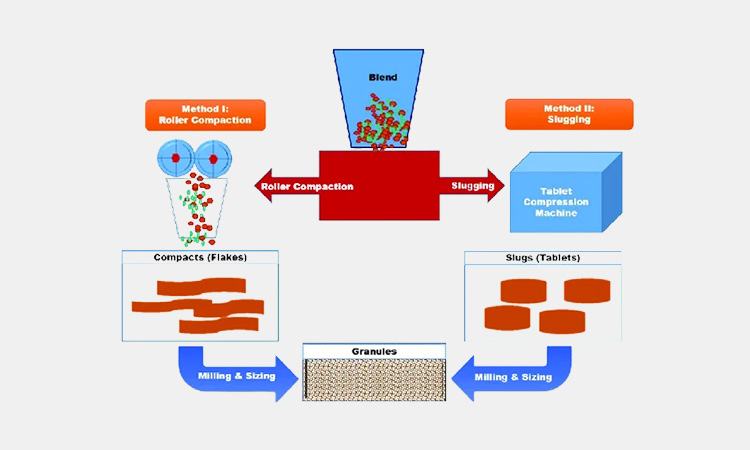

Dry granulation

Dry granulation-sourced: ipharmachine

Dry granulation is an innovative method. It is mainly through rolling and proprietary air classification methods to produce powders with excellent fluidity and compressibility. The powder can also flow during the compression process. The particles can be uniformly granulated during the atomization process driven by airflow.

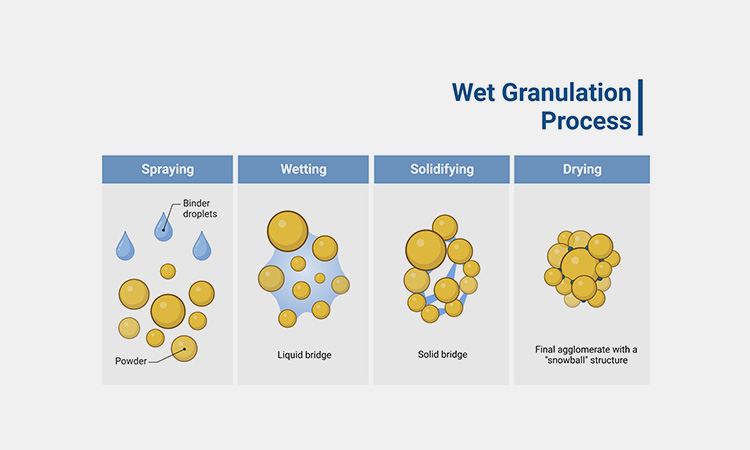

Wet granulation

Wet granulation-sourced: biorender

Wet granulation refers to the process of adding excipients and other active ingredients to powder particles and then agglomerating them through a binder. Compared with conventional dry granulation, wet granulation mainly undergoes steam granulation and thermal bonding fusion granulation.

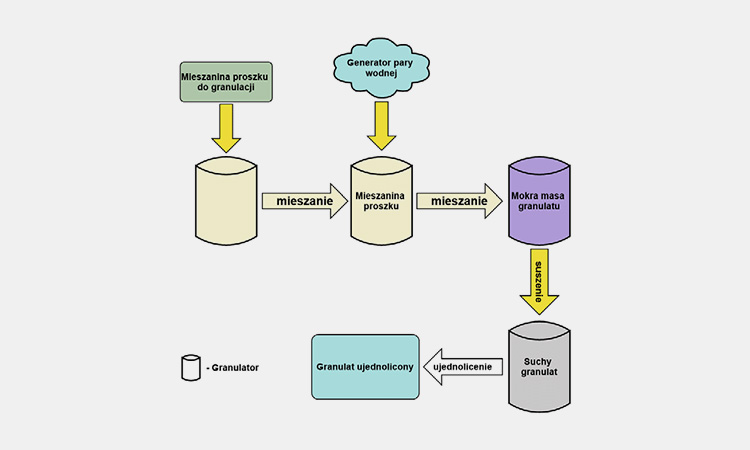

Steam granulation

Steam granulation-sourced: researchgate

Steam granulation refers to the granulation of pharmaceutical powders by using steam instead of water as a binder. Its advantage is that it can make the distribution between particles more uniform. The particles can be more efficient in the subsequent dissolution process and better absorbed by the human body.

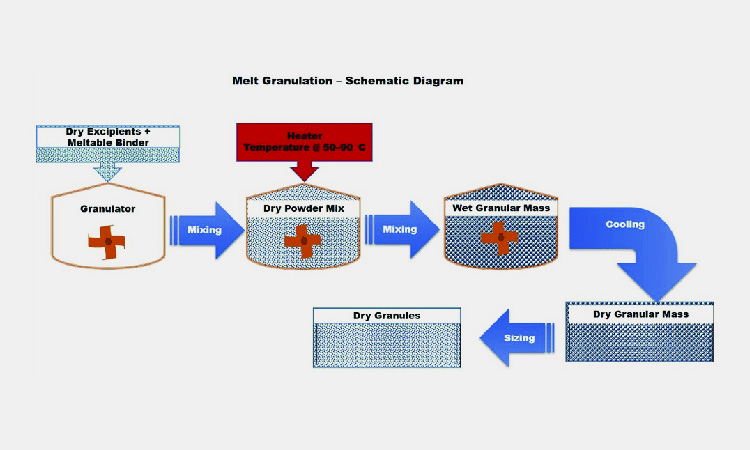

Melt granulation

Melt granulation-sourced: researchgate

It is mainly achieved by adding a plastic binder to the powder. Let the particles fuse under a temperature change of 50~80 degrees. The powder is then granulated using a binder.

8.How Pharmaceutical Powders Are Mixed and Handled?

The powder processing process is mainly carried out through the following steps:

Powder processing process-sourced: cms

- First, you need to choose a suitable and efficient powder mixer.

- Then send the materials you need to process or mix into the powder mixer or equipment that can process.

- The powder mixture you choose will pre-liminarily process your materials through various grinding, mixing and stirring methods.

- When the powder is pre-liminarily processed and reduced to the particle size you need, you can divide the powder into different sizes by sieving.

- When you get the powder of the required or expected particle size, you can mix other active ingredients and the excipients or adhesives you need.

- After mixing, you can use a desiccant or dry it at room temperature to remove the fluidity of the powder and its internal moisture.

- The dried powder will be packaged in the next step, which is convenient for you to store or transport better, as well as for the use of patients in the later stage.

9.How Is The Particle Sizes Of Pharmaceutical Powders Reduced and Measured?

Different powders may have different particle sizes. So what steps are used to achieve different particle sizes of powders? You can refer to the steps below:

Grinding

Grinding-sourced: researchgate

The first step of processing pharmaceutical powders is grinding. It can be used to initially crush larger powder particles, making it easier to mix and granulate later.

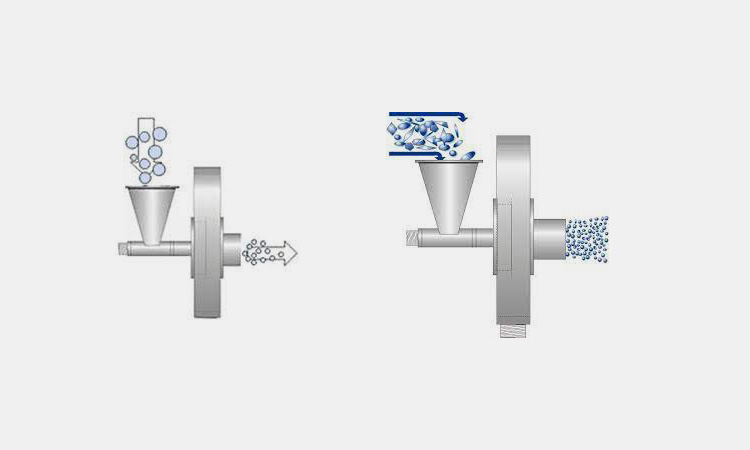

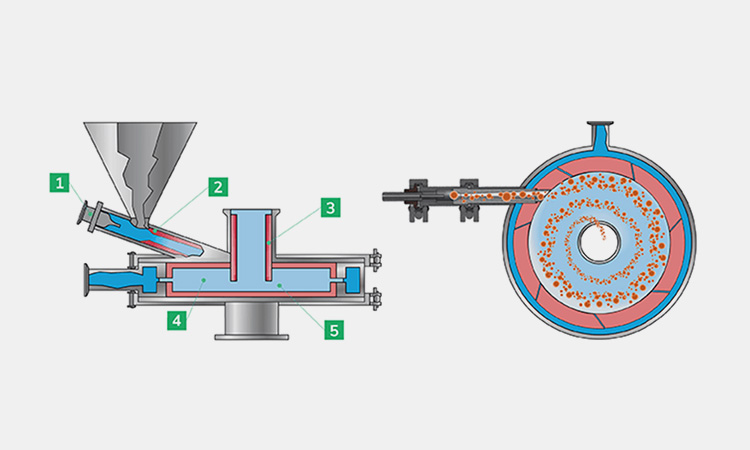

Micronization

Micronization-sourced: themedicinemaker

You can use a fluidized bed or a device with high shear force to micronize your powder and further process it to micron size.

10.What Are The Parameters To Be Considered Of Pharmaceutical Powder?

So what goals does the medicinal powder need to achieve to be called qualified medicinal powder? And put into use? Its specific standards are:

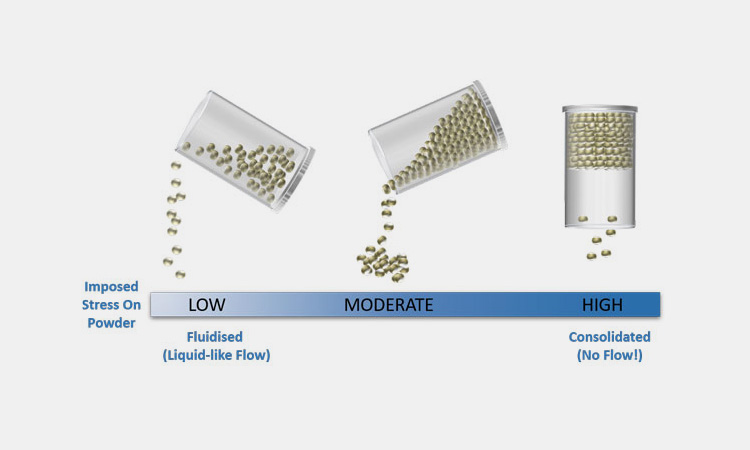

Flowability

Flowability-sourced: freemantech

After being processed, high-quality medicinal powder will definitely have good fluidity. It is not only convenient for the addition of other materials and the processing of the formula, but also more convenient for the use of patients later.

Solubility

The solubility of excellent medicinal powder must be the best. Because different medicinal powders may need to be combined with water for later use. Medicinal powders with poor solubility will affect human absorption.

Purity

Purity-sourced: taniobis

For high-quality medicinal powders, the purity of the active pharmaceutical ingredients or adhesives and additives inside must be the highest. Because this can ensure the safety of human use later.

Stability

Stability is the most important characteristic parameter for medicinal powders. For medicinal powders that are not stable, the powder may be atomized and lose activity during transportation and storage.

11.What Are The Grades Of Pharmaceutical Powder?

The grades of pharmaceutical powder mainly include:

Grades Of Pharmaceutical Powder-sourced: bigcommerce

| Coarse powder | The diameter of coarse powder is about 1.7 mm. It can only pass through the sieves with mesh size of No. 10 and No. 44 on the market. |

| Medium coarse powder | The diameter of medium coarse powder is about 350 microns to 710 microns, and it can usually pass through the No. 60 sieve. |

| Medium fine powder | The diameter of medium fine powder is about 180 cm to 350 cm, and it can basically pass through the No. 44 sieve and the No. 85 sieve. |

| Fine powder | The particle diameter of gas powder is about 180 microns and below. It is considered fine powder because it can only pass through the No. 85 sieve. |

| Ultra-fine powder | The particle diameter of ultra-fine powder is about 125 microns and below. It can only pass through the No. 120 sieve. |

12.What Are The Advantages Of Pharmaceutical Powder?

What are the advantages of pharmaceutical powder? What benefits can it bring to you in specific applications? It includes:

Wide range of applications

Wide range of applications-sourced: syntegon

Pharmaceutical powder can be taken orally or externally. New formulas can be generated by adding different other ingredients. It is also very convenient to control the dosage.

Stable chemical properties

Stable chemical properties-sourced: hanningfield

Pharmaceutical powders usually do not need to be stored in the dark. They are very stable. Compared with liquid drugs, pharmaceutical powders are not afraid of deterioration and loss during transportation and storage.

Easy to swallow

Pharmaceutical powders are usually compressed into tablets or filling capsules for patients to swallow. This can greatly cover up the unpleasant smell of the drug itself, and it can also be well absorbed in the human body.

Can be mixed

Can be mixed-sourced: hanningfield

Many dosage forms in liquids cannot be mixed casually because the stability of the liquid is not strong enough and chemical reactions may occur.

Economical and affordable

Compared with liquid dosage forms, pharmaceutical powders are ground and mixed in the early stage and packaged and stored in the later stage. The equipment used and the use of manpower in the process are more economical and affordable than liquids.

13.What Are The Disadvantages Of Pharmaceutical Powder?

Of course, pharmaceutical powders also have their own disadvantages. Its disadvantages are:

The powder smells bad

The powder smells bad-sourced: marthastewart

Many pharmaceutical powders have a very bad smell because functional ingredients are added. This reduces patient compliance.

Easy to be diluted

If the pharmaceutical powders is not packaged well, it is easy to absorb moisture in the air and become sticky in an open storage environment with sufficient oxygen, thus affecting the active ingredients of the drug.

Conclusion:

Through this post of "what are the different types of pharmaceutical powder," you may know that pharmaceutical powders have diverse applications in different industries. Its importance cannot be overstated. When handling pharmaceutical powders, you need to pay attention to all kinds of details. If you have more needs, don't forget to contact AIPAK now!

Don't forget to share this post!

Powder Filling Machine Related Products

Powder Filling Machine Related Posts

Powder Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine