Fluid Bed Dryer Machine: The Complete Buying Guide In 2024

Drying is one of the important tasks which is carried out during the production of goods especially food products and medicines like powder and granules. However, safety comes along this need which is the prime concern of pharmaceutical and food industries. Due to this reason, a sophisticated and hygienic equipment is designed to facilitate the gentle drying of various products which is known as Fluid Bed Dryer Machine.

The machine has advance design structure with eclectic features and convenient operation. Together, these attributes enable the machine to function smoothly and generate quality production. Moreover, it is highly adaptable in terms of application and functions. So, if you want to get benefited from it, make sure to give this buying guide a thorough read!

1.What Is A Fluid Bed Dryer Machine?

AIPAK FL-60 Boiling Fluid bed dryer and Granulator

Fluid bed dryer machine can be simply defined as a compact machine made with eclectic features for the purpose of drying various powders and granules. It uses the process of fluidization for drying materials where hot air is passed through a loaded fluid bed causing the particles to flow in air and evaporate moisture.

The machine has simple operational procedure where entire process is carried out automatically. Overall, the structure is made up of quality stainless steel which is corrosion resistant. It can deal with range of substances in industries encompassing food, pharmaceutical, chemical, and agriculture industry etc.

2.Enumerate The Advantages Of A Fluid Bed Dryer Machine?

Fluid Bed dryer machine offers numerous benefits in terms of production, handling, as well as its design. Some of the notable advantages are enlisted below:

Precise Structure

Precise structure of a fluid bed dryer machine- Picture Courtesy: romaco.com

The foremost attribute of the machine is its precise body. Despite being able to process large volume of materials, fluid bed dryer machine has small footprint which makes it perfect for facilities with limited space and frequent mobilization.

Effective Performance

Effective drying & mixing of granules- Picture Courtesy: romaco.com

The machine has outstanding performance by effectively removing the moisture content of the material to desired level while retaining their originality and quality. Similarly, the moisture is evaporated through filter bags without carrying particles which ultimately helps in reducing waste.

Improved Safety

Fluid bed dryer machine has an enclosed structure without any dead corner. The body is made up of quality stainless steel with anti corrosive properties. These features demonstrates the machine's suitability for side range of sensitive and corrosive materials.

Simple Handling

Granules drying in fluid bed dryer machine- Picture Courtesy: trustar-pharma.com

The most trying thing about any machine is its handling whether it's the operation or maintenance. However, in case of a fluid bed dryer machine, the equipment follow simple operational procedure along with easy cleaning and maintenance schedule.

High Flexibility

Fine powder- Picture Courtesy: romaco.com

Another notable advantage of the machine is its flexibility and application. For instance, it can perform multiple functions of drying, mixing, and granulation. Similarly, it can deal with different types of substances including powders, granules, and pellets.

3.Why Fluid Bed Dryer Machine Is Important In Pharmaceutical Industry?

Pharmaceutical industry in world- Picture Courtesy: Getty Images

The manufacturing and processing in pharmaceutical industry revolves around grinding, mixing, drying, and granulation. In this way, the most popular dosage forms like capsules and tablets are made from powders or granules. Now, these substances are produced in a very safe way where the quality and consistency are well retained.

With these requirements, fluid bed dryer machine is always suitable for preparing material for drug manufacturing. Apart from this, the demand for high production of medicines has further enhanced the importance of machine in pharmaceutical industry which works automatically while giving high production output.

4.Explain The Working Principles Of A Fluid Bed Dryer Machine?

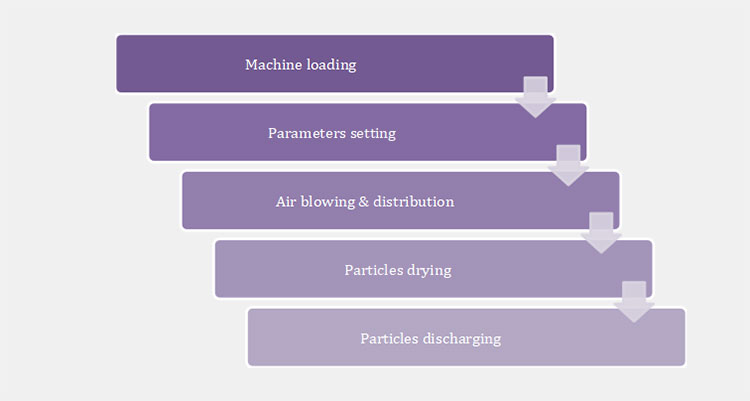

Fluid bed dryer machine works on the principle of fluidization where you can find hot air reducing the moisture content of the wet material. You can understand this process in a much better way by reading the following steps:

Machine Loading

Material loading into fluid bed dryer machine- Picture Courtesy: Gansons

The first working principle of a fluid bed dryer machine includes the loading of machine with material. Here, user should manually load the bulk of wet powder or granule mixture in the perforated bed, or a feeding unit can be used for intermittent loading of material.

Parameters Setting

Remember that setting up parameters is one of the important steps to be carried out for operating a fluid bed dryer machine. In this way, you need to use the control panel and touch screen interface to set the air pressure, temperature, and time for each round.

Air Blowing & Distribution

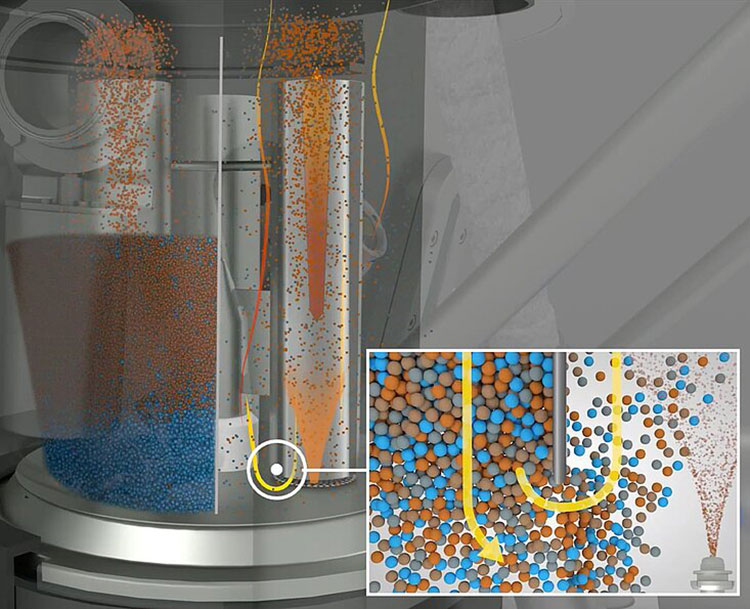

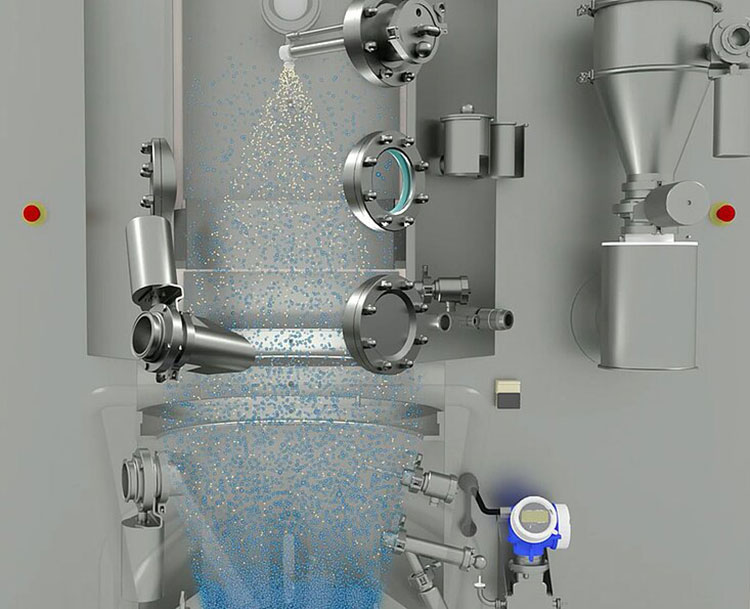

Aur blowing & distribution- Picture Courtesy: romaco.com

As soon as the machine is turned on, the air starts flowing from the inlet. This air is then passed through a heating system which turns the cold air into hot air for drying. This heated air is then passed through the material filled with fluid bed and distributed across the extension chamber.

Particles Drying

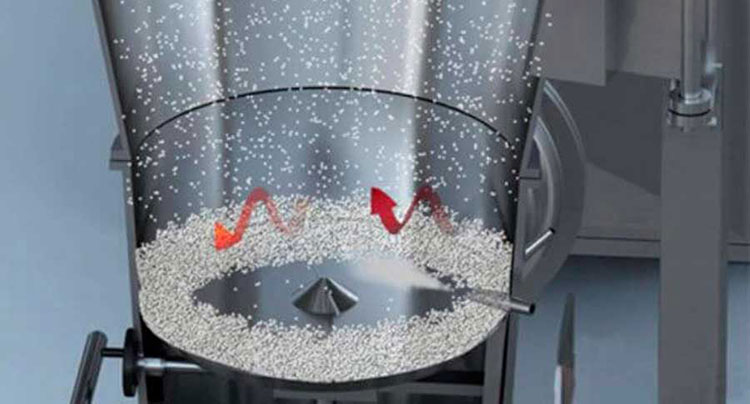

Particles drying- Picture Courtesy: Gansons

The excessive pressure of hot air causes the particles to flow inside the extension chamber. Consequently, the moisture is evaporated, and particles get dried. This entire process is termed as fluidization.

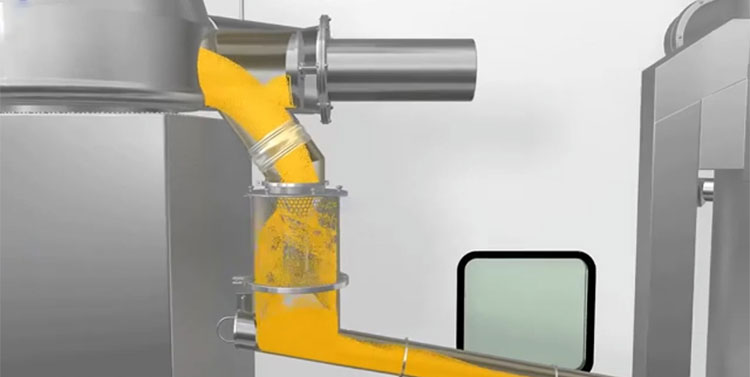

Material Discharging

Finally, the dried powder and granules particles are ready for outlet. They are discharged by unlocking the valves of fluid bed.

5.Describe The Components Of A Fluid Bed Dryer Machine?

Understanding a fluid bed dryer machine is necessary for its usefulness. In this way, the components play a significant role which constitute the overall body of the machine. These are described below:

Components of Allpack's GF Series High Efficiency Fluidized Bed Dryer

Air Outlet

It is located on the top of the machine. It is usually called exhaust system which is integrated into the machine for removing out the gases and air present inside the extension chamber in order to avoid their accumulation for effective drying of material.

Control Panel

Control panel is another instrumental part of a fluid bed dryer machine. It consists of various switches, sensors, and digital display. It is extremely useful in enabling the user to set, operate, and maintain the machine.

Air Inlet

It refers to the part where air blower or fan and heater are situated. The former provides air to the machine, while as, the latter enhance the heat of air from medium to high intensity in order to remove moisture.

Electric Cabinet

It is a large enclosure where the electric system of the machine is fitted in the form of fuses, wires, and boards.

Bowl

In fluid bed dryer machine, bowl is also known as fluid bed which is a large hollow perforated container for the placement of bulk material. Air passes through the holes of the bowl.

Filter Housing Chamber

In most cases, the powder particles are so tiny that they can also escape the machine and flow into the air which may cause product loss. For this purpose, the filter housing chamber is fitted into the machine which filters the air by keeping particles in filter bags and only allowing air to out.

Extension Chamber

Extension chamber is the core component of a fluid bed dryer machine where the actual process of drying occurs. The chamber has smooth corners with attached devices for spraying liquids or coating particles.

Main Frame

It refers to the support stand which is also made up of quality and durable stainless steel. It keeps the machine stable throughout processing.

Universal Wheels

The machine has multiple universal wheels making it easier for mobilization and placement.

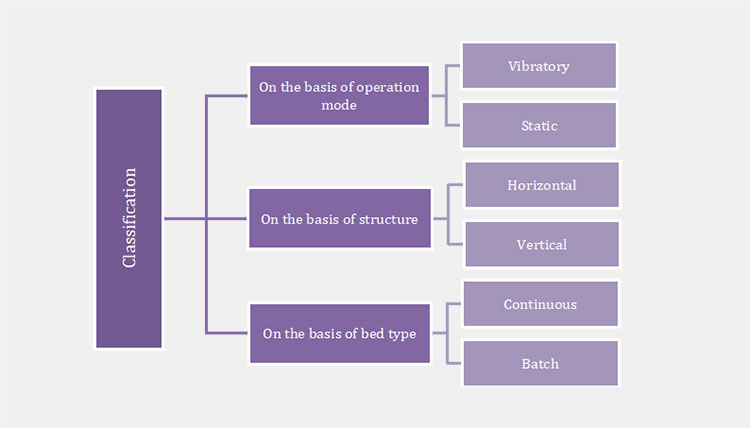

6.What Is The Classification Of A Fluid Bed Dryer Machine?

Fluid Bed dryer machine is available in different types depending upon their structure and the technologies they use for operation. Below, you will know this classification in detail:

On The Basis of Operation Mode

Vibrating Fluid Bed Dryer Machine

AIPAK FL-120 vibrating fluid bed dryer

Vibrating fluid bed dryer machine is a multi purpose equipment that can perform mixing, granulation, and drying in one go. This type of machine uses vibration technology which greatly assist in producing uniform particles. Similarly, it provides a safe and convenient way for material processing by increasing their flow. That's why, it is suitable for large size or heavy weight substances like granules and pellets in food and non food industries.

Static Fluid Bed Dryer Machine

Static fluid bed dryer- Picture Courtesy: temaprocess.com

Static fluid bed dryer machine is also known as shaking fluid bed dryer machine due to to its special design. The machine remains stationary during operation and perfectly process free-flowing bulk materials with good distribution of air across the bed. Such type of machine is available both in batch and continuous operation. Similarly, the structure can also vary from round to rectangular.

On The Basis of Structure

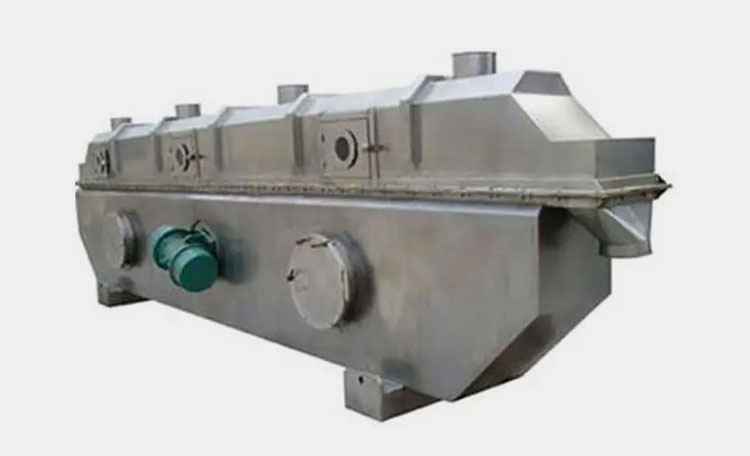

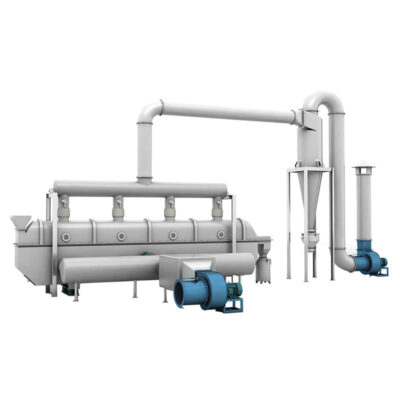

Horizontal Fluid Bed Dryer Machine

XF Series PLC Control Horizontal Fluid Bed Dryer for Desiccated Coconut

Horizontal fluid bed dryer machine is a complex machine with horizontal structure. It has a unique set-up for material drying in long horizontal fluid bed. The material is processed from one side to another. During process, there is a good contact between material and hot air as a result of which each cycle take less time for drying particles. Hence, this machine is a reliable choice for multiple industries with demand for speedy production like food, medical, and chemical industries.

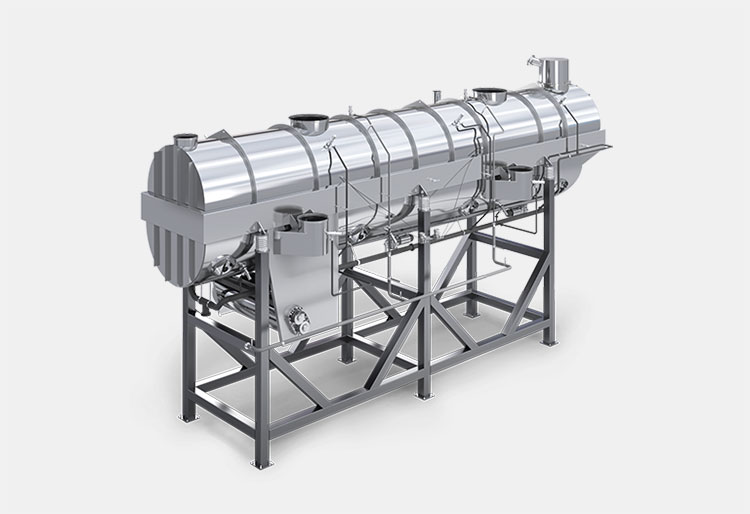

Vertical Fluid Bed Dryer Machine

AIPAK high efficiency vertical fluidized bed dryer

Vertical fluid bed dryer machine is the most common type of equipment utilized for drying powders, granules, and similar substances. It has precise vertical body which at the same time occupies less space while providing more room for material drying. The air flows from the bottom side via a perforated bed towards the top. Inside the extension chamber the actual process occurs. Excess air and moisture are removed through the exhaust system. It is a good choice for almost every industry dealing with related stuff.

On The Basis of Bed Type

Continuous Fluid Bed Dryer Machine

AIPAK FL-120 continuous vibrating fluid bed dryer

As the title illustrates, this type of machine is continuous in its operation. It features multiple sections for the drying of materials. Each chamber has its own temperature control and airflow system for meeting the drying needs of various substances lying inside. Similarly, the machine has high production output. This type of fluid bed dryer machine is best suitable for large scale industries requiring non-stop production.

Batch Fluid Bed Dryer Machine

Batch Boiling Fluid Bed Dryer- Picture Courtesy: griffinmachinery.com

Batch fluid bed dryer machine is a compact machine designed with distinct features to facilitate single cycle material drying. Unlike continuous fluid bed dryer machine, it uses single timing during operation. Due to this reason, it consume less energy while offering a safe and quality performance. These attributes make the machine compatible for eclectic materials and suitable for small to medium scale production.

7.Enlist The Applications Of A Fluid Bed Dryer Machine?

Fluid bed dryer machine is extensively applicable to every field where there is processing of powders and granules. Some of the key industries are as under:

Drug Manufacturing Industry

Various tablets & capsules- Picture Courtesy: istockphoto.com

One of the top sectors where the importance of a fluid bed dryer machine is realized is drug manufacturing industry. Here, the machine is utilized to decrease the humidity level of pharmaceutical powders and granules for making consistent medicine dosage form such as tablets and capsules.

Pet Food Industry

Pet food presentation idea- Picture Courtesy: sgs.com

The machine can also be used in pet food industry where most of the pet food is produced in form of pellets or granules for easy consumption of hens, cats, fish, and dogs.

Food Industry

Milk powder in bowls- Picture Courtesy: revala.com

Fluidized bed dryer machine is an effective machine whose presence is inevitable in food industry for reducing the moisture content of range of powdery substances. The common examples include cocoa powder, instant coffee, milk powder, sugar, cereals, and spices etc.

Chemical Industry

Various powder dyes- Picture Courtesy: thebluebottletree.com

Chemical substances like detergent powder, dyes, and pigments are free flowing and contain chemicals which are dangerous if inhaled or get into eyes. Therefore, a fluid bed dryer machine provides a safe room for the drying of such substances. It thus highlight another application of the machine.

Beauty Care Industry

Girl applying makeup on her face- Picture Courtesy: purplle.com

Being the users of smartphones and internet, it must not be surprising for us to know the long lasting list of cosmetic products used for beauty. Most of these items are commonly used and available in form of powder and granules like compact face powder, loose powder, eyeshadow, and glitters etc. Similarly, for their quality production drying is of the key steps which is carried out by a fluid bed dryer machine.

8.What Other Machines Can Be Used Alongside A Fluid Bed Dryer Machine?

It is good news for you that a fluid bed dryer machine can be used alongside other machines for enhancing the efficiency and quality of your production. So, let's explore what these machines are:

Tablet Press Machine

AIPAK HSZP series high-speed rotary tablet press machine

Tablet press machine is an important machine used for compressing powders into various sizes and shapes of tablets. It can be used alongside a fluid bed dryer machine to further process the dried powders and granules. Tablet press machine is an economical machine with range of designs and automation level. It is a key equipment being used in pharmaceutical industry.

Granulation Machine

AIPAK HLSG Series High Speed Wet Mixing Granulator

Granulation machine is another such equipment that can be integrated with a fluid bed dryer machine. It is a significant device employed for granules formation, however, in most instances the produced granules are not in desired condition. Hence, a fluid bed dryer machine can be used to remove out the excess moisture content.

Pulverizer Machine

AIPAK B Series Universal Crusher

Pulverizer or crusher machine is created to aid the crushing of hard and whole objects into powder or granule form. In this way, it play significant role to provide a fluid bed dryer machine with raw material for drying.

Mixing Blender

AIPAK DTH Series Post Bin Blender

Mixing blenders like bin blenders is useful for mixing powders and granules in a uniform way. As a fluid bed dryer machine is used for drying powders, mixing blenders can be used alongside it to enhance the efficiency of manufacturing.

9.What Is The Cleaning And Maintenance Requirements Of A Fluid Bed Dryer Machine?

Regular cleaning and maintenance is very important for a fluid bed dryer machine not only because it is safe against damage but also due to its efficiency, quality, and compliance to international standards. Here are some of the valuable tips for you to follow. These include:

Operator maintaining a fluid bed dryer machine- Picture Courtesy: technicpharma.com

Cleaning:Turn off the main switch and disassemble all the components of machine. Once done, take a clean cloth along with a brush and soak them in recommended detergent liquid. Remove the hard stains and spota by rubbing. For the rest of the machine's parts, you may use damp cloth.

Maintenance:It is also very crucial to keep your machine ready and maintained all the time. However, it requires your attentiveness and vigilance by properly adjusting the structural components, timely adding lubrication, and replacing the damaged parts with new ones.

10.What Quality Standards Should A Fluid Bed Dryer Machine Meet With?

In today's fast paced world, there is a dire need to establish checks on the products produced across the globe because globalization has made it very easy to sell and purchase products without considering how far it is located. When talking about a fluid bed dryer machine, this concern has been addressed by the international community by formulating rules and principles under some prominent organizations. Let's have a look at them!

International Organization for Standardization (ISO)

ISO is the most popular quality standards with largest representation from states in the world. It aims at regulating and applying safety policies for goods and machines. In this way, it is must for a fluid bed dryer machine to be certified by ISO.

Good Manufacturing Practices (GMP)

GMP is another significant standard that deals with the construction material of a fluid bed dryer machine and recommend 304 stainless steel which is safe against bacteria and corrosion.

Food and Drugs Administration (FDA)

American agency has established FDA to particularly focus on and ensure the safety of public health. Therefore, all the products and machines made for producing or processing food products must be certified by FDA

Conformate European (CE)

European Union is a big market for both production as well as sell. In case of a fluid bed dryer machine it must comply EU rules regarding safety of product, or else, it may not be accepted in any one of the country being parts of EU.

11.Factors To Look For When Choosing A Fluid Bed Dryer Machine?

There are several factors whose consideration can greatly help you in choosing the best fluid bed dryer machine. These include:

Production Capacity

Large capacity fluid bed dryer- Picture Courtesy: icf-welko.it/en

The first thing you need to check is the production capacity of a fluid bed dryer machine. It is important for the reason that machines come in various capacities. Similarly, the one with large size fluid bed will definitely be able to produce more output in less time and vice versa.

Type of Material

Dry powder- Picture Courtesy: romaco.com

Another factor to look for is the type of material you want to process. For instance, whether it is free flowing powder or granules or pellets and flakes etc. Once you have determined this, it will be easy to choose the machine with relevant specifications.

Machine Specifications

A fluid bed dryer machine is all dependent upon its specifications which include the volume of air flow, power source, and the number of revolution per minute. Knowing these specifications will assist you to find your requirements.

Cost

Cost calculation icon- Picture Courtesy: revnew.com

There are range of fluid bed dryer machines available in market and each has different design so as cost. Thus, when you intend to purchase a machine make sure to ask your vendor about the original price of the machine along with overall expenditure including operation and maintenance cost.

Conclusion

To put in a nutshell, Fluid Bed Dryer Machine is a tremendous equipment made with numerous features. It can transform your production in different ways by enhancing finishing quality as well as output. This is simply done by understanding its operational procedure and the function of various components. Similarly, it needs proper cleaning and maintenance for life long effective performance. Following these guidelines can help you take advantage of this machine. So, if you are interested in purchasing a fluid bed dryer machine then AIPAK is the best supplier you may consider. For further information please contact us!

Don't forget to share this post!

Drier Machine Related Products

Drier Machine Related Posts

Drier Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine