Small Scale Gummy Making Equipment: The Complete FAQ Guide In 2025

Are you worried about small-scale gummy production? According to the survey, the current market is dominated by large-scale gummy production lines. They target large output and high energy consumption. If you want to find a small-scale gummy making equipment to improve your product quality, then this post is worth your in-depth study.

The guide will explain you the details about small scale gummy manufacturing equipment and its related auxiliary equipment. And it will also introduce you a series of ingredients, production, packaging and maintenance, etc. information. Why not take a try?

1.What Is Small Scale Gummy Making Equipment?

AIPAK Small Scale Gummy Making Equipment

The small scale gummy making equipment is a small-scale equipment specially used for producing various gummies. It is specially designed for the production of gummies with low production demand, fine processing and high added value. In addition to producing traditional gummies and candies, this equipment can also produce various vitamins, minerals, supplement gummies, etc.

2.What Are The Ingredients You May Need With Small Scale Gummy Making Equipment?

Ingredients You May Need With Small Scale Gummy Making Equipment-sourced: sugargeekshow

The main ingredients of gummies are gelatin, sugar or sweetener, coloring, flavoring, active ingredients (optional), citric acid, pectin, glucose syrup, coating (optional), etc.

| Ingredients | Description |

| Gelatin | It makes the gummies chewy and elastic, and adds flavor to the gummies. |

| Sugar or sweetener | Increases the sweetness of the gummies, and at the same time increases the viscosity, which is convenient for the subsequent molding. |

| Coloring | It can provide a colorful effect to your gummies. |

| Flavoring | Add more flavor to the gummies. |

| Citric acid | Adds sourness to the gummies. |

| Pectin | Pectin is a thickener that makes it easier to mold the gummies later. |

| Glucose syrup | Adds more flavor to the gummies. |

| Active ingredients (optional) | Active ingredients are optional, and they include vitamins, minerals, etc. |

| Coating(optional) | Coating is an optional option. You can choose a variety of powders or granules you like as coating. |

3.Which Industries Are Inclined To Use Small Scale Gummy Making Equipment?

The small scale gummy making equipment has long been used in the food and health care products industries. They:

Food industry

Food industry-sourced: blendhub

Most of the gummies and candies in the food industry are made and processed by small scale gummy making equipment. It includes various gummies for children, adults and pets. As people pay more attention to health, more zero sucrose added gummies and candies are also being developed and produced.

Health care products industry

Health care products industry-sourced: healthline

The demand for functional gummies is also growing for children with swallowing dysfunction and those who cannot swallow pills. It not only has a sweet flavor, but also can provide you with a variety of nutrients needed by the body, becoming a substitute for many pills.

4.What Contributes The Small Scale Gummy Making Equipment For Your Gummy Manufacturing?

Compared with gummy manufacturing line, the small scale gummy making equipment has the following advantages:

Better quality control

Better quality control-sourced: somafina

Compared with gummy manufacturing line, small scale gummy making equipment can better help you control product quality.

Consistency

Consistency-sourced: labmanager

In addition to better product quality control, the small scale gummy making equipment can provide you with better product consistency and improve production efficiency.

High added value

High added value-sourced: vice

In the saturated gummy market, unique and high value-added products are now more favored and gain more market share. The small scale gummy making equipment can provide you with more sophisticated and distinctive product production, increasing the added value of your brand.

Efficient use of resources

Small gummy making machine can better utilize resources and avoid waste.

5.What May The Small Scale Gummy Making Equipment Limit You?

What May The Small Scale Gummy Making Equipment Limit You-sourced: smallbizclub

Inevitably, using a small gummy making machine will also bring you some limitations. It includes:

Small scale

The small scale gummy making equipment cannot be applied to large-scale gummy making production lines. It cannot meet your large production needs.

Unable to expand

The small gummy machine cannot be integrated into high-level and grade production lines to expand to larger levels and scales of gummy manufacturing and production.

6.How To Learn The Main Parts Of Small Scale Gummy Making Equipment?

The main parts of small scale gummy making equipment include:

Gummy molds

Gummy molds-sourced: future4200

It includes molds of various sizes and shapes. Most of the gummy molds on the market include gummy bears, animals, fruits, flowers, worms, toys, etc. The materials of the molds mainly include silicone gummy bears, metal molds, teflon molds, plastic molds.

Cooking pot

AIPAK cooking pot

The cooking pot is specially used to prepare gummy syrup and solutions. During the production process, attention should be paid to the temperature and stirring of the syrup. Maintain the temperature and fluidity of the syrup, etc. The processed syrup will be automatically transferred to the storage tank.

Storage tank

AIPAK storage tank

The prepared gummy syrup and solution will be directly transferred to the storage tank for subsequent deposition and pouring.

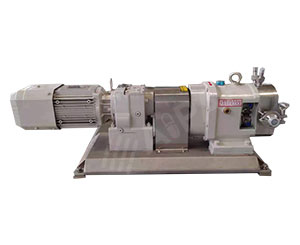

Syrup delivery pump

AIPAK syrup delivery pump

The syrup delivery pump is specially designed for transferring cooked syrup and gummy solution from cooking pot to storage tank. It mainly adopts pneumatic method, which can easily help you transfer syrup with high efficiency and energy saving.

Gummy depositor machine

AIPAK gummy depositor machine

The gummy depositor machine is mainly used for the deposition of gummy solutions and the production of gummy candies. The prepared gummy solutions will be deposited and poured into the mold. The depositor machine can accurately control your pouring amount and time, etc.

Cooling tunnel

AIPAK cooling tunnel

The gummy solution poured into the mold will be demolded after standing and cooling, and then transferred to the cooling tunnel. It allows your prepared gummies to cool down and become chewy afterwards.

7.What Is The Manufacturing Process Of Small Scale Gummy Making Equipment?

The manufacturing process of small scale gummy making equipment is syrup preparation, syrup storage, additive mixing, pouring, cooling and molding.

What Is The Manufacturing Process Of Small Scale Gummy Making Equipment-sourced: AIPAK

- Syrup preparation. Add the required raw materials into the cooking pot one by one according to the formula, and stir evenly to avoid overheating and uneven mixing. The mixed syrup will be automatically sent to the storage tank.

- Additive mixing. The syrup sent to the storage tank will be added with various additives.

- The prepared gummy solution will be sent to the gummy depositor machine. The gummy depositor machine will pour the gummy syrup into the mold you need.

- The poured gummy mold will be cooled and left for a period of time to wait for solidification and molding.

- The cooling gummies will gradually take shape and will be demolded then.

8.What Are The Auxiliary Manufacturing Equipment For Your Small Scale Gummy Making?

The small scale gummy making equipment can be integrated with other auxiliary equipment to form a small gummy production line. They are:

Gummy coating machine

Gummy coating machine-sourced: ZWJABYY

Gummy coating is an optional part. If you have requirements for coating of gummy candies, this equipment can provide you with a perfect coating solution. After the gummies are made, it can add an extra layer of good flavor and texture to enhance the flavor of the gummy candies.

Sugar sanding machine

AIPAK industrial oil sanding machine

Sugar sanding machine is designed and made out according to the special jelly candy processing technology. It is used for coating the sugar granules out side of the jelly candy or the jelly gummies. Made of stainless steel, the machine can prevent candy and gummies from sticking after being manufactured.

Drying tray

Drying tray-sourced: tgmachine

Gummy drying trays are now widely applied for holding the produced gummies. There are many holes in the middle of the tray, which is convenient for dehumidification and drying of soft candies. It can be stacked with many trays, which can save space and facilitate your movement and drying.

Carts

Carts-sourced: sinofudetechs

The gummy tray moving carts are important equipment in the gummy candy drying process. They are mainly composed of wheels, bolts and other parts. One cart can hold up to 50 trays. It is convenient for you to move and clean, hygienic and simple.

Gummy packaging machine

AIPAK gummy packaging machine

The gummy packaging machine is a device specially used to pack the gummies and candies that have been made and passed quality inspection into bags. It can automatically complete the feeding, quantitative weighing, bagging, heat sealing, date printing, etc. of various gummies and candies. This equipment can complete the packaging of gummy candies in various 3-side sealing bags, 4-side sealing bags, flat bags, small bags and other packaging bags.

Gummy counting machine

AIPAK gummy counting machine

Gummy counting machine is a very important machine. It can help you count the gummies accurately and then bottle them. It provides accurate counting effect and can help you bottle the gummies. It is a good gummies terminal machine. The success rate is greater than 99.99%, which can provide you with high-efficiency gummy candies.

9.Small Scale Gummy Making Process VS Large Scale Gummy Making Process

Whether it is small scale gummy making equipment or large scale, they can complete your gummy production and making, but they also have similarities and differences.

| Small Scale Gummy Making Process | Large Scale Gummy Making Process | |

| Images |

AIPAK Small Scale Gummy Making Equipment-sourced: endosemolds |

AIPAK Large Scale Gummy Making Equipment |

| Flexibility | Obviously, small scale gummy making equipment has significant advantages in this regard;

Using small equipment, you can easily experiment with the production and quality control of various fudge types; |

Strict adherence to the recipe is required;

In order to maintain the consistency of finished products and high output, poor flexibility; The flavors and styles of gummies that can be provided are relatively single; |

| Customization | Able to provide customized services;

Customized products are diverse and complete; |

Generally, customized services are not provided;

The product is relatively simple; |

| Efficiency | Average efficiency;

Certain manual services need to be provided; Long production cycle; |

High efficiency and low manual dependence;

generate economies of scale; Shorten production cycle; |

| Quality control | Quality control is strong and more precise;

Focus more on manual production and refined production; |

Quality control challenges;

Focus more on mass production and efficiency; |

| Cost | Low cost, less consumables, less waste, high material utilization, and more environmentally friendly; | The cost is high, there are many consumables, there is a lot of waste, and the material utilization rate is average; |

10.Small Scale Gummy Making Equipment VS Commercial Gummy Making Equipment

The small scale gummy making equipment and commercial gummy making equipment have different purposes and scopes of use. They:

The small scale gummy making equipment:

Small scale gummy making equipment-sourced: tg

- Suitable for smaller scale gummy making;

- The equipment is small in size, generally a single machine or a small line;

- The automation level is average and it relies heavily on manual labor;

- The speed is slow, the efficiency is average, and it is suitable for small scale production;

Commercial gummy making equipment:

AIPAK commercial gummy making equipment

- Suitable for large scale gummy making;

- The equipment is large in size and generally a complete line mode, which can complete the production, molding, quality inspection and packaging of gummy;

- The automation level is high, and it relies less on manual labor;

- The speed is fast, the efficiency is high, and it is suitable for large scale production;

11.Will Small Scale Gummy Making Change The Gummy Production Process?

The small scale gummy making will not change the gummy production process. Whether it is a small scale or large scale gummy making machine, it will not change the process and all the steps they perform would be the same way. They all need to go through three basic stages:

Small Scale Gummy Making Process-sourced: gummymakingmachine

Syrup preparation

The syrup solution is prepared by adding different raw materials through boiling, stirring and storage.

Pouring and cooling

The prepared syrup solution is directly poured into the mold, then cooled and formed.

Coating and quality control

The cooled and formed gummies will be demoulded, undergo quality inspection and then coated.

12.What Are The Specifications of Small Scale Gummy Making Equipment?

The specifications of small scale gummy making equipment involve many aspects. It includes:

Equipment size

AIPAK gummy equipment size

Equipment size is related to your site requirements, as well as the production capacity and cost of the equipment. The size of the small scale gummy making equipment is generally smaller than the gummy production line.

Productivity

Productivity-sourced: jochamp

Productivity is related to the frequency of use of your equipment and the planning of production efficiency.

Pneumatic requirements

The pneumatic requirements of the gummy making machine are very important, which is related to the overall operation effect and smoothness of the equipment.

Temperature and humidity requirements

Temperature and humidity requirements-sourced: thehealingcanna

The temperature and humidity of the gummy making are very important. If the humidity and temperature are not properly controlled, the final product effect will not achieve the expected effect.

13.How To Keep Your Small Scale Gummy Making Equipment Running Smoothly?

In order to keep your gummy making production in good condition, you need to clean and maintain your equipment regularly. It includes:

Replace the engine oil

Replace the engine oil-sourced: wieelz

The operating life of the machine depends on the lubrication and replacement of the engine oil. Regular inspection and timely replacement of the engine oil can ensure the smooth operation of the machine and extend its life.

Regular cleaning

Regular cleaning-sourced: capplustech

Regular cleaning of the machine can timely check for leaks and defects, find loopholes and wear of the machine, etc., which is also a kind of maintenance for the machine.

Trial run

After maintenance, you also need to test run to see if the equipment runs smoothly, so as to greatly improve the effect of your formal use.

Daily inspection

After daily use, you need to conduct daily inspections, including several items such as damaged parts, noise failures, loose screws, etc.

14.How To Make The Check List Once Your Small Scale Gummy Making Equipment Breaks Down?

Check List Once Your Small Scale Gummy Making Equipment Breaks Down-sourced: is

What if the machine crashes? If you check and adjust according to the normal procedures? You can refer to the check list below to troubleshoot and make adjustments.

- If the gummy machine does not work normally as before, first, you can check whether the power switch is displayed normally;

- Then check whether there is a problem with the fuse of the device. If the fuse is blown, you can replace it with a new one;

- If there are no problems with the above two items, you can restart the machine to see if the machine runs normally;

- If the problem is still not solved, the motor and gearbox of the device may have failed;

- Replace and adjust the motor and gearbox, and then check whether the device is overheating.

15.What Is The Factory Acceptance Test For Small Scale Gummy Making Equipment?

Factory Acceptance Test For Small Scale Gummy Making Equipment-sourced: is

In order to complete your equipment requirements, all small scale gummy making equipment needs to obtain factory acceptance test to ensure the efficiency and safety of the equipment. It includes:

- Complete the factory acceptance test of the equipment with the help of user requirements specification to verify whether the equipment meets the standards;

- You need to ensure that the entire test plan and procedure are planned in advance and there are no loopholes;

- Prepare the materials and tools required for the actual test process;

- Arrange the test personnel and conduct relevant training;

- Start the relevant system and start the test;

- Finally, it is best to record, evaluate the results, and form a report.

16.How To Choose Your Own Small Scale Gummy Making Equipment?

After understanding the details of small scale gummy making equipment, how to build a relevant gummy production line for yourself? You can design it by the following methods.

Determine your own products

Determine your own products-sourced: candyconceptsinc

Before choosing equipment, you need to consider the type, material, style, scale, production volume, production efficiency and time of the products you want to produce. After determining these factors, you can consider the equipment below.

Choose the right production equipment

Choose the right production equipment-sourced: AIPAK

After determining your production scale and efficiency, you can choose the equipment that suits you in the small scale type.

Invest in related equipment

Before choosing the right equipment, you need to consider price, cost, production energy consumption, equipment maintenance, etc.

Choose the right drying and cooling system

The right drying and cooling system is also an important part of gummy making and manufacturing. This involves whether the final product can achieve the effect you expect.

Coating and packaging options

If you have requirements for coating, you also need to equip the relevant gummy coating machine. And improve the relevant gummy counting and packaging machine.

Quality control

Not all gummies made can be packaged and sold directly. You also need to use quality inspection equipment or relevant staff to conduct quality inspection.

Conclusion:

When choosing small scale gummy making equipment, you need to consider all aspects of the production process to ensure the subsequent production quality. Through this complete FAQ guide of small scale gummy making equipment, you may know how to choose a good gummy machine. If you do not know who to choose to cooperate, do not hesitate to contact AIPAK now!

Don't forget to share this post!

Gummy Making Machine Related Posts

Gummy Making Machine Related Products

Gummy Making Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine