Fluid Bed Dryer In Pharmaceutical Industry The Complete Buying Guide In 2024

Have you ever wondered the forming of the various granules or powder of your medicines? Why they are so cute and even? How to make the qualified granules? These are of course easy to deal for fluid bed dryer in pharmaceutical industry? How much you know about this machine?

What are the main function of fluid bed dryer in pharmaceutical industry? What are the main function of fluid bed dryer in pharmaceutical industry? How to choose your fluid bed dryer in pharmaceutical industry? Here is the complete buying guide of fluid bed dryer in pharmaceutical industry. Come on and have a reading!

1.What Is Fluid Bed Dryer In Pharmaceutical Industry?

AIPAK Fluid Bed Dryer In Pharmaceutical Industry

Fluid bed dryer is the equipment which is widely used in pharmaceutical industry, food industry, cosmetic industry and so on. If you have noticed the various particles or granules, you may know this equipment. This machine can transfer the loose powder into the strong, dry and even granules.

Besides the granule making, fluid bed dryer in pharmaceutical industry can also make the ideal job in drying and coating. The heat air stream makes the fluid processing of the various particles and granules. This machine makes the drying and granule making efficient, fluent and high qualified.

2.What Is The Importance Of Fluid Bed Dryer In Pharmaceutical Industry?

Fluid bed dryer in pharmaceutical industry is rather important and irreplaceable. Here is the outstanding importance.

Reduce the toxic dust

Reduce The Toxic Dust-Sourced:occupational-safety

Fluid bed dryer can reduce the toxic dust in its drying process. For pharmaceutical industry, it is a prove of products quality and sanitary standard. Its work in reducing the toxic dust is one reason it get so famous.

Reduce the drying time

Reduce The Drying Time-Sourced:shutterstock

For the traditional drying process, the whole process is long and complex. The fluid bed dryer makes the efficient drying way with the production of high quality products. You may have your energy and time greatly saved this way.

Improves granule feature

Improves Granule Feature-Sourced:renejix

Fluid bed dryer can improve the powder and granule’s flow and compaction which improve the quality of your products. The great quality of granule and particle is the prove of your high qualified products.

Make even work

Make Even Work-Sourced:indiamart

For traditional drying method, there may be many uneven work. And for fluid bed dryer, it can make the even and great work. The even work can help make the even distribution of ingredients for the further medicine manufacturing.

Multiple and flexible work

Multiple And Flexible Work-Sourced:proofhub

Besides drying, fluid bed dryer can also make the great work of coating and granule making. You may apply it to many different medicine products and the manufacturing of other industry. All in all, it can make the multiple and flexible work.

3.What Are The Use Of Fluid Bed Dryer In Pharmaceutical Industry?

What are the use of fluid bed dryer in pharmaceutical industry. There are three basic use of it.

Drying

Drying-Sourced:kerone

Drying is the basic use of fluid bed dryer in pharmaceutical industry. The heated air the machine produce and the long exposing of powder in the machine can make the quick and thorough drying. It can make the drying for granulation, active pharmaceutical ingredients and pellets.

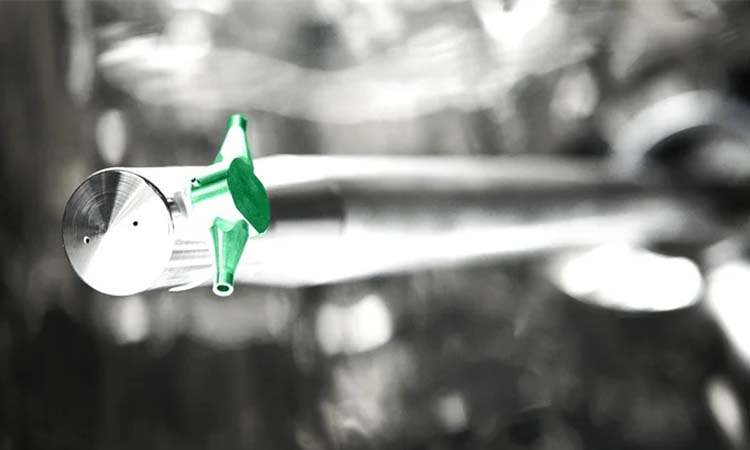

Coating

Coating-Sourced:bieglo

Coating is the special function of coating fluid bed dryer. In the fluidizing process, the coating solution can make the even and high qualified coating for various granules and pellets.

Granule making

Granule Making-Sourced:making

Fluid bed dryer is widely used in granule manufacturing. For the loose powder, the granulating is rather hard. Fluid bed dryer improve the uniformity and flow of the loose powder and makes great work for granule making.

4.What Other Filed CanFluid Bed Dryer In Pharmaceutical Industry Be Applied?

Is fluid bed dryer restricted in pharmaceutical industry? Of course not. Here are the field the fluid bed dryer in pharmaceutical industry can be applied.

Food industry

Food Industry-Sourced:hanningfield

Food industry is the industry which makes the wide use of fluid bed dryer. For chocolate powder, blood powder, tea, protein, soy, peanut, corn steep liquor, corn starch and the various powder can also be dried and deal from fluid bed dryer.

Agricultural industry

Agricultural Industry-Sourced:sudarshangroup

The pesticide and fertilizer of agricultural industry has the great demand for fluid bed dryer. It can be used for the manufacturing of granules, tablets, powders and so on which are all widely used for agricultural industry.

Chemical industry

Chemical Industry-Sourced:freepik

For chemical industry, there is various kind of powder or granule which requires the work of fluid bed dryer. Dye intermediate, formaldehyde silicic acid, polyethylene, polyvinyl chloride, urea resin, catalyst, sulfuric acid agents, amino acids and so much chemical products can be processed with this machine.

Metallurgical industry

Metallurgical industry-Sourced:hksieve

Metallurgical industry is the industry which made the metal production. And there of course exists the applying of powder and granules for metal production for the manufacturing of the reliable and qualified products.

5.How Can You Benefit From Fluid Bed Dryer In Pharmaceutical Industry?

There are so many advantages of fluid bed dryer in pharmaceutical industry. How can you benefit from fluid bed dryer in pharmaceutical industry?

High efficiency

High Efficiency-Sourced:lilyshop2020

Fluid bed dryer makes the high efficient work in dealing with pellets, powder and granules in pharmaceutical industry. It can save your time and energy in manufacturing the qualified products greatly.

Great mixing

Great Mixing-Sourced:paticheri

The great and even mixing and drying of products is the prove of your qualified products. And the fluid bed dryer is the secret to make the nice and great mixing for your further dealing in pharmaceutical industry.

Flexible work

Flexible Work-Sourced:forbes

Fluid bed dryer makes the flexible work. It can make the various work like drying, coating, granulating and so on. Its wide application field and various size make the application wider and more flexible.

Low maintaining cost

Low Maintaining Cost-Sourced:jimbuell

The maintaining of fluid bed dryer is easy as the operation involves little attending of its components and parts. The maintaining cost of the machine is also low and can help you make the better manufacturing.

Temperature control

Temperature Control-Sourced:vcrma

You can make the easy adjusting of the temperature of fluid bed dryer and make it suitable for the different material or products type. The temperature control of fluid bed dryer makes the drying process more intelligent.

Better quality

Better Quality-Sourced:corporatevision-news

The products from fluid bed dryer makes the products of better quality and higher reliability. It abandons the low-effective and low qualified method of the traditional drying methods.

6.What Are The Disadvantage Of Fluid Bed Dryer In Pharmaceutical Industry?

Fluid bed dryer makes so much benefits for pharmaceutical industry and other industry. Do you know the disadvantages of fluid bed dryer.

Large space

Large Space-Sourced:freepik

Fluid bed dryer will take the large space for you. And for the large production scale, the needed fluid bed dryer is bigger and takes the larger space for you. It is not the compact machine and requires your large space.

Material sensibility

Material Sensibility-petronaftco

Fluid bed dryer cannot be applied to all material or products. For some sensible material, it cannot make the great fluidization work. The stick of applying the sensible material may lead the degradation of integrity loss.

Complex maintaining

Complex Maintaining-Sourced:fleetmaintenance

Fluid bed dryer is easy to make the cleaning and the outer maintaining. But for the maintaining of its complex system, there will be the operational cost which ensured the great performance and digitization.

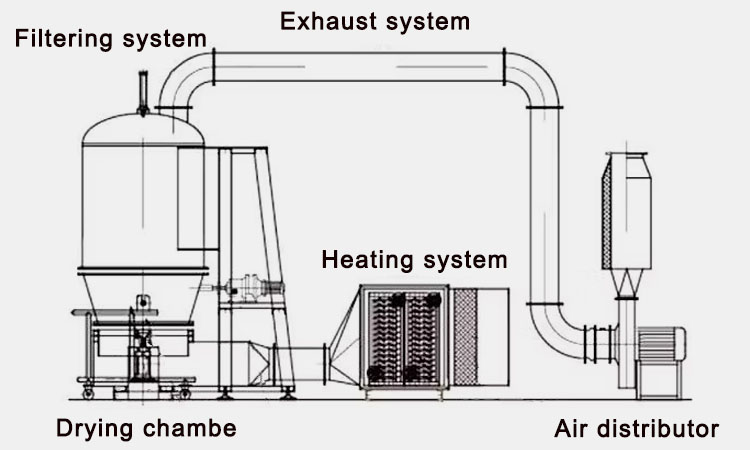

7.What Are The Main ComponentsFluid Bed Dryer In Pharmaceutical Industry?

Fluid bed dryer is not the complex machine and here are its main components you should know.

Main Parts Of Fluid Bed Dryer-Sourced:unitfine

Drying chamber

Drying chamber takes the large space of fluid bed dryer in pharmaceutical industry. It is the place where the material or products have the sufficient drying and fluidization. And it is the place where the equipment makes the main job.

Air distributor

Air distributor of fluid bed dryer in pharmaceutical industry is the place which proves the even heating process and efficient fluidization of the whole fluid bed drying process.

Blowing part

Blowing part is made from blower or fan. The airflow it provides makes the fluidization of particles or granules. You can have its strength adjusted to prove the adequate and efficient blowing.

Heating system

The heating system makes the heating and drying for fluid bed drying process. It usually apply the medium or high temperature to make the consistent and efficient heating. You may find the different heating way.

Exhaust system

Exhaust system is also the irreplaceable part of fluid bed dryer. It helps to exhaust the extra moisture or the exhaust dust or part from your material or products. It is the complex and precise equipment which makes sure the products quality.

Control system

Control system is the part where you can make the direct connection of the machine. There involved control panel, sensor and other adjusting system. You can make the relative setting and monitoring for the maintaining and operating.

Filtering System

Filtering system is the important accessory of exhaust system. It helps make the more fine and delicate filtering of the small particles and in some way prove the quality of your products better.

8.What Are The Processing Of Fluid Bed Dryer In PharmaceuticalIndustry?

Fluid bed dryer is the efficient machine and the working process is rather interesting and concise.

The Processing Of Fluid Bed Dryer

Panel setting

There are various material type and you should set the panel according to your need and material type. For the great results getting, you should make the research before to make the great drying work.

Material loading

There is the steel made chamber with a perforated bottom and you should place your material and products in the chamber. The begin of the machine will make the sudden and efficient heating and drying of material.

Air distributing and drying

The distributing air which comes into the chamber is strong enough to make the particles levitate and get the thorough heating and drying. It makes sure the even drying of every particles.

Moisture exhaust

In the drying process, there is the consistent moisture exhausting in this way. The extra moisture and dust comes out in the heating and drying process. The machine can thus make the consistent drying.

Cooling and getting

After the drying and heating process, the products are made well. You cannot get them immediately. After cooling for a second, the material will be discharged from the machine. And then you can make the later processing.

9.What Are The Types OfFluid Bed Dryer In Pharmaceutical Industry?

What are the types of fluid bed dryer in pharmaceutical industry The machine didn’t restrict themselves in one type and here are the types of fluid bed dryer in pharmaceutical industry.

Batch fluid bed dryer

Batch Fluid Bed Dryer-Sourced:fbddryer

Batch fluid bed dryer makes the batch processing. This types of machine is suitable for the small scale production. It can also make the intermittent and flexible producing.

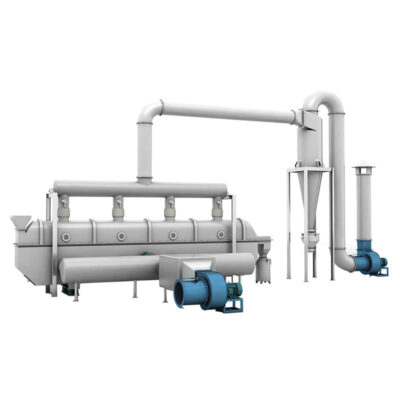

Continuous fluid bed dryer

Continuous Fluid Bed Dryer-Sourced:lbbohle

Continuous fluid bed dryer is suitable for the continuous heating and drying for the particles and material. And for the large scale production, it is more suitable and efficient.

Vibrating fluid bed dryer

Vibrating Fluid Bed Dryer-Sourced:griffinmachinery

For the viscous material and particles, the drying and heating may not that efficient. And the vibrating fluid bed dryer makes the outstanding job to separate the particles and make the even and efficient heating and drying.

10.What Is SFM Of Fluid Bed Dryer In Pharmaceutical Industry?

SFM Of Fluid Bed Dry-Sourced:coperion

SFM which has the full name as Solid Flow Monitor is the useful and advanced equipment which can make the reliable monitoring of fluidization. The monitoring is the prove of the stable and efficient working of particles flowing.

Besides the flowing monitoring, it can also help to check the bag failure or other problem in fluid bed drying process. SFM can save your cost and energy in dealing with the unqualified products or products loss.

11.What Is Fluid Bed Processor In Pharmaceutical Industry?

Fluid Bed Processor-Sourced:syntegon

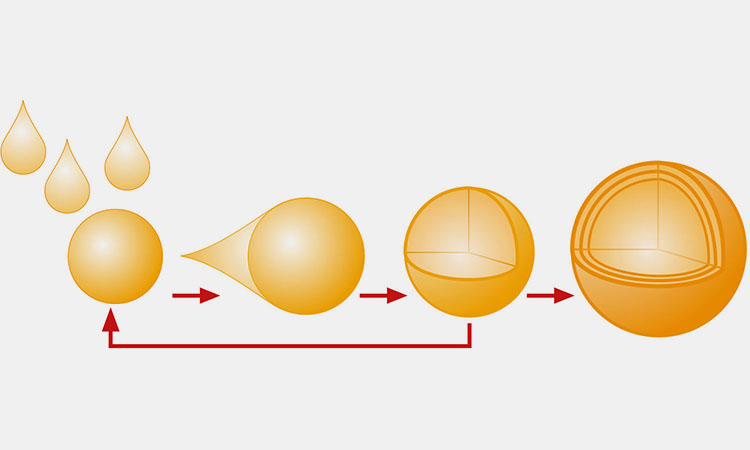

Fluid bed dryer is the important machine for pharmaceutical industry which makes the irreplaceable job in granule making. The drying and heating of fluid bed dryer makes the suitable particles for pharmaceutical use.

And for fluid bed processor, it can make the coating of granules with solution in the process of drying and heating. The fluid bed processor also integrate the function of spraying, coating, granulating and so on.

12.How To Choose Your Fluid Bed Dryer In Pharmaceutical Industry?

Fluid bed dryer in pharmaceutical industry is irreplaceable. And to get the real nice and suitable one you should take the below tips into serious consideration.

Budget

Budget-Sourced:universalfunding

There are various fluid bed dryer type and a wide price range. You should first make clear your budget and then select and get the machine according to your budget. The one suits your budget is the nice one.

Energy consumption

Energy consumption concerns to your later cost in drying process and your force to world environment protection. You should get the fluid bed dryer which has low energy consumption.

Performance

Performance-Sourced:primeum

The performance of your fluid bed dryer is one of the most important factor you should consider. Is the machine multi functional? Can it be used for the continuous or batch production?

Customization

How about your personal need? Can the machine adjust according to your need? Customization is also important for you to select the machine. You can contact the manufacturer to your suitable functional machine manufacturing.

Maintaining

Maintaining-Sourced:creativefabrica

The fluid bed dryer is mostly made from stainless steel. The cleaning of it is easy. But the different fluid bed dryer may require you different maintaining method and frequency. For the easier and more smooth maintaining, you should choose the one east to maintain.

Products need

The fluid bed dryer makes the work of heating, drying, coating, spraying and so on. What is the requirements of your medical products? You should get the machine which suits your pharmaceutical processing need.

Manufacturer brand

Manufacturer Brand-Sourced:lucidadvertising

Manufacturer is one factor which decides the machine quality, performance, after sale service and so on. The reliable manufacturer is the prove of the smooth and efficient fluid bed drying work. AIPAK makes the great job in providing the high qualified fluid bed dryer.

13.How To Prove The Stable Operation Of Fluid Bed Dryer In Pharmaceutical Industry?

Fluid bed dryer in pharmaceutical industry makes the efficient and stable work according to your various need.

Regular cleaning

Regular Cleaning-Sourced:workwave

The cleaning is one important maintaining method of fluid bed dryer in pharmaceutical industry. You should make the regular and deep cleaning after the using of machine. It can make the stable and efficient operation and can also prove the sanitary standard of your products.

Calibration

Calibration-Sourced:msasafety

Calibration should also be made regularly. The regular calibrating can prove the precise drying number and condition. The temperature, air flow and the relative number is all so important for the machine’s smooth operation.

Machine check

Machine check-Sourced:freepik

You should make the regular cleaning as well as the regular machine check. You should make the deep consideration for the heating part, filtering part, exhausting part and so on. For the worn parts, you should make the timely replacing.

14.What Are The Challenges You May Meet In Fluid Bed Dryer In Pharmaceutical Industry?

What are the challenges you may meet in fluid bed dryer in pharmaceutical industry? Here are the challenges which may occur frequently.

Hard discharge

Hard Discharge-Sourced:stock

The particles of granules may be hard to discharge from fluid bed dryer. And that is because the particles become electrostatically charged in the process of heating and drying. This is the challenge as it burdens your discharging way.

Material decomposing

Material Decomposing-Sourced:rts

For the unstable temperature in fluid bed drying process, the particles may get burned for the immediate drying. And you can avoid this condition by making the accurate adjust of temperature.

Filter blocking

Filter Blocking-Sourced:midwestinstrument

The filter may get blocked for the neglected cleaning of filter in this part. The blocked filter may lead the the strike of your fluid bed dryer. The blocking can be easily avoided as you make the regular cleaning.

15.What Are The Future Trend Of Fluid Bed Dryer In Pharmaceutical Industry?

What are the future trend of fluid bed dryer in pharmaceutical industry? Catch the trend and make the relative adjust.

Higher automation level

Higher Automation Level-Sourced:vecteezy

The advance in automation and intelligence makes the fluid bed drying more accurate and more efficient. Th automation level increasing is the future trend which suits the large, effective and qualified producing.

More focus on sustainability

More Focus On Sustainability-Sourced:tira

The developing of fluid bed dryer will be more energy effective and eco-friendly. The whole heating and drying process will be more sustainable and has less affect to environment.

Better coating capacity

Better Coating Capacity-Sourced:glatt

Coating is the great function of fluid bed dryer in pharmaceutical industry. The advance in coating can make the releasing of various pharmaceutical solution more efficient and even. This can save your energy and time better.

16.What Are The Main Granulation Method And The Method Of Fluid Bed Dryer In Pharmaceutical Industry?

Granulation is the important function of fluid bed dryer in pharmaceutical industry. Do you know the main granulation method and the method of fluid bed dryer in pharmaceutical industry.

Main granulation method

Wet massing

lWet Massing-Sourced:caleva

Wet granulation is the common granulation method. It involves the blending of powder and solution, massing the mixture and then shaping the granulation. It is the old manner and can still be used today.

Dry granulation

Dry Granulation-Sourced:lfatabletpresses

Dry granulation means the granulate making with dry powder or dry powder blend. It makes no involving of liquid or solution. It is also the granulation methods which is widely used.

Melt granulation

Melt granulation-Sourced:galaxysivtek

Melt granulation makes the powder or particles blending together with a kind of meltable blinders. In the temperature between 50°C to 90°C, it get melted or softened.

Granulation method of fluid bed dryer

Dryblending

Dry Blending-Sourced:aveka

Dry blending of fluid bed dryer involves the powder compacting by roller. The high pressure from compacting can promote the forming of powder. And that is the typical way of fluid bed dryer making granules.

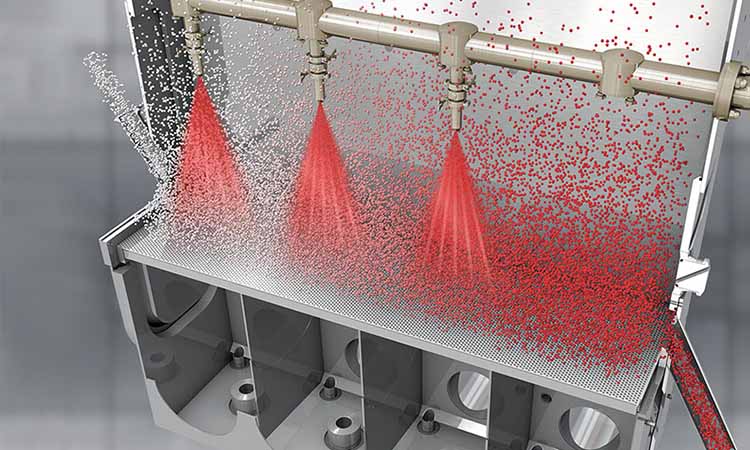

Fluidizingbed granulation

Fluidizing Bed Granulation-Sourced:thyssenkrupp

Fluidizing bed granulation is a kind of wet granulation. It applies the liquid or solution to make the granules in the heating and drying process.

Granulation spraying

Granulation spray-Sourced:foodfeedfinechemicals

Granulation spray is the high tech granulating method. It transfer the liquid to the flowing granules. And the spraying of the flowing granulates on the carrier can make the solid granules.

Conclusion

Fluid bed dryer in pharmaceutical industry is the irreplaceable, effective and productive machine for many industries. Hope the complete buying guide of fluid bed dryer in pharmaceutical industry may help you for your business. And if you have any questions, don’t hesitate to contact us.

Don't forget to share this post!

Drier Machine Related Products

Drier Machine Related Posts

Drier Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine