Chewable Tablet Making Machine: The Complete FAQ Guide In 2025

To be honest, you’ve taken chewable tablets, haven’t you? These tablets have a good taste and won’t contain much medication. Do you know how chewable tablets are made? Of course, a chewable tablet making machine is indispensable.

At present, this machine has been applied in many industries, such as the stomach strengthening and digestive tablets, vitamins, and dairy tablets we eat.

Do you want to learn about this machine? Next, let’s take a look at the complete FAQ guide of chewable tablet making machine.

1.What Is Chewable Tablet Making Machine?

Chewable Tablet Making Machine

Before we begin, let’s talk about what chewable tablets are. I believe everyone should have eaten various types of milk tablets when they were children, and these are called chewable tablets. This type of tablets generally have a better taste than swallowed pills and are more convenient to take.

A chewable tablet making machine produces this type of chewing tablet, also known as a table press machine. It compresses powdered materials into different tablets. These tablets come in different sizes and shapes. And after continuous development, its presence can be seen in many industries around you.

2.What Are the Applications of Chewable Tablet Making Machine?

You may have guessed that chewable tablet making machines have been applied to multiple industries such as pharmaceuticals. Let’s take a look at the specific industry applications together.

Healthcareproducts industry

Healthcare Products - Sourced: VitalAbo

Many health products, including vitamins and calcium tablets, are manufactured in the form of chewable tablets. Chewing tablets are made into various flavors with good taste, suitable for people of different ages. Therefore, you will definitely see the presence of chewable tablet making machines in your daily supplements.

Pharmaceutical industry

Chewable Tablets in Pharmaceutical Industry - Sourced: Online Pharmacy

Have you ever bought chewable tablets in pharmacy? In particular, many traditional Chinese patent medicines and simple preparations are made into chewable tablets, such as stomach strengthening and digestion tablets, which grind various materials such as orange peel, Chinese yam, hawthorn into powder and press them into tablets. In addition, some Western medicines are also made into chewable tablets.

Food industry

Chewable Tablets in Food Industry - Sourced: Medimex Sigapore

Have you ever eaten breast milk tablets? This type of food has a strong milky aroma, can be chewed, and has a better taste. In order to meet the diverse dietary needs of customers, this tablet press machine is often used in the food industry.

3.What Are the Types of Chewable Tablet Making Machine?

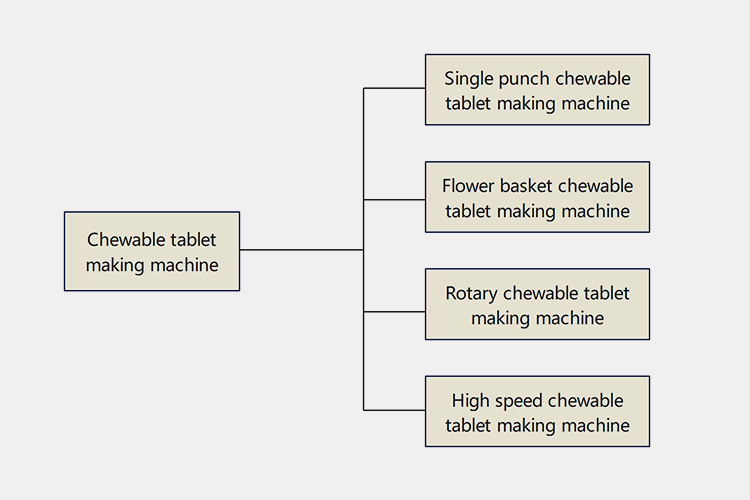

Types of Chewable Tablet Making machine

According to the above picture, you can see that there are currently several types of chewable tablet making machines.

Single punch chewable tablet making machine

AIPAK Single Punch Chewable Tablet Making Machine

With small volume, the single punch chewable tablet making machine can be put on the table, so it is easy to move and operate. However, this machine has a smaller scale and lower output, making it suitable for smaller manufacturers, laboratories, etc.

Flower basket chewable tablet making machine

AIPAK Flower Basket Chewable Tablet Making Machine

Shaped like a flower basket, AIPAK flower basket chewable tablet making machine can achieve continuous automatic tablet pressing. This machine can also be placed on a desktop for easy operation and can press tablets of various shapes and patterns. However, due to low production efficiency, it is not suitable for large-scale factory production.

Rotary chewable tablet making machine

AIPAK Rotary Chewable Tablet Making Machine

When using the AIPAK rotary chewable tablet making machine, you can adjust the speed of the turntable and other parameters. With various tooling system, this machine can also press dry particles into chewable tablets of various shapes. In addition, it also has many functions, such as overload protection.

High speed chewable tablet making machine

AIPAK High Speed Chewable Tablet Making Machine

With a large number of punches, the high speed chewable tablet making machine can operate at high speed. By adopting various new control technologies and equipment, efficient operation can be achieved while ensuring the interlocking protection function of each program. This machine can be used in various industries and is suitable for large-scale production.

4.What Are the Parts of Chewable Tablet Making Machine?

What components does this machine consist of? You must be very curious, right.

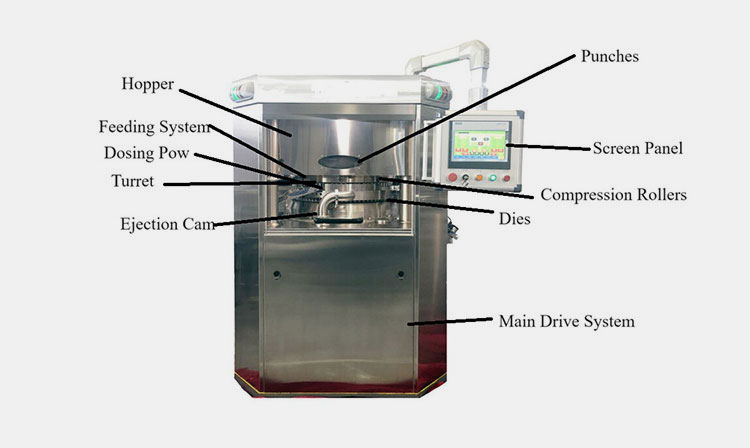

Parts of Chewable Tablet Making Machine

| Parts | Detail |

| Hopper | The hopper is the input port for materials. It is generally made of stainless steel material, which is sturdy, stable, and not easy to rust. According to the grinding quality, single, double, and multi-layer hopper can be selected to ensure uniform pressing. |

| Feeding system | This system transfers materials from the hopper to the mold cavity. It usually consists of a funnel and a rotating drum. |

| Turret | It has multiple tablet molds on it. During the pressing process, the turret brings the tablet mold between the upper and lower templates, creating pressure. |

| Dosing plow | This component is related to whether the material can be accurately filled into the mold cavity. |

| Punch | Punch is a key component for achieving material filling and compression. The upper punch and lower punch are respectively installed on the upper and lower sides of the turntable, and through precise mechanical linkage, the two move back and forth in the mold hole |

| Ejection cam | Ejection cam is a protruding part on the camshaft, and the number and shape of cams vary depending on the design of the tablet press. It can achieve different functions, such as tablet pressing, transposition, discharge, etc. |

| Die | The edge of the die is designed in a conical shape, making it easy to disassemble and replace with a new die. |

| Screen panel | This setting facilitates the adjustment of various parameters, such as pressure, tablet weight, etc. By adjusting the pressure of the upper punch on the material during the tablet pressing process, the hardness and density of the tablets can be controlled. |

| Compression roller | The movement of the rotating component is achieved by the action of the cam through the compression roller. The length and shape of compression rollers also vary depending on different designs, usually made of high-strength alloy steel. |

| Main drive system | The drive system is the source of power, usually consisting of an electric motor, a reducer, and a transmission mechanism. The electric motor transmits power to the central turntable through a reducer and transmission mechanism, causing it to rotate continuously. |

5.How Does Chewable Tablet Making Machine Work?

The chewing tablet making machine mainly compresses dry powdered substances into tablets. Do you know its specific operating process?

Working Principle of Chewable Tablet Making Machine

Feeding material

You should prepare the powder materials, and then put the prepared materials into the hopper and transport them to the mold through rotation.

Filling of compression chamber

There are multiple tablet pressing chambers in the tablet press, and there is a rotating wheel below the hopper. The material enters the rotating wheel of the tablet press through the hopper and is transported to each tablet chamber.

Tablet pressing

After the compression chamber is filled with material, the upper and lower pressure rollers are used for compression, and the pressure roller compresses the material into tablets through interaction with the die.

Tablet discharge

The lower punch rod moves upward after the compression is completed, pushing the tablet out of the mold hole. The pressure chamber rotates while moving the tablet to the discharge port and conveying it to the next step.

6.Can the Design of Chewable Tablet Making Machine Affect the Tablet Performance Characteristics?

The answer is: Yes. So, how does the design of the tablet press machine affect the performance of the tablets?

Affectingthe shape of chewable tablets

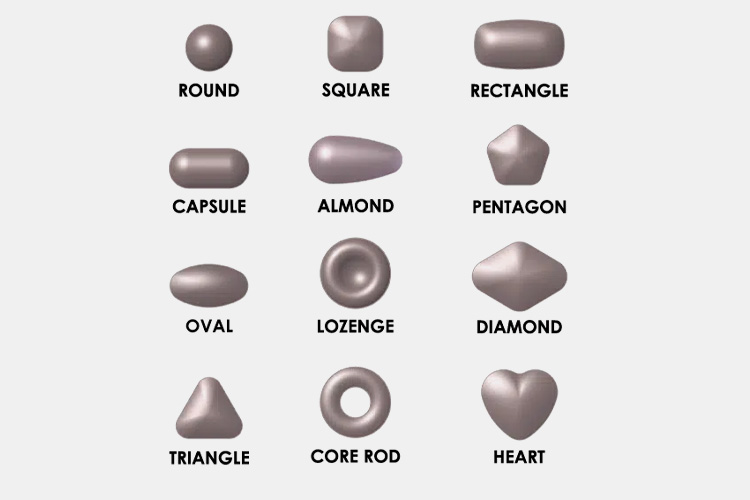

Shape of Chewable Tablets - Sourced: Kangmeihui

As is well known, the shape and size of tablets are determined by the design of the tooling system. If you choose different models of tooling systems, you will get different tablets.

Affectingthe quality of chewable tablets

Affecting Quality of Chewable Tablets - Sourced: Evoke Wellness

If your machine is not regularly maintained, or if the selected machine material reacts with the material, it will affect the quality of tablet production, such as tablet cracking and corrosion, ultimately affecting the effectiveness of the medication and even leading to ineffective treatment.

7.What Types of Chewable Tablets Can You Make Using a Chewable Tablet Making Machine?

You must have seen many shapes of chewable tablets. What types of tablets can you manufacture with a chewable tablet making machine?

Common Sizes and Shapes of Chewable Tablets

In fact, the size and shape of chewable tablets are mainly determined by the mold cavity and head radius of the tablet chewing machine punch. By replacing different accessories, different types of pills can be produced, such as round, square, and others.

8.Can a Chewable Tablet Making Machine Be Used to Make Carved Tablets?

The answer to this question is: definitely.

Carved Tablet - Sourced: Ackley Machine

Carving tablets of different shapes reflects the unique design of chewable tablets and represents the characteristics of the product. During the production process of chewing tablets, you can use the flat surface of the top punch to carve the tablets according to your own design.

9.How To Choose the Appropriate Tooling System for Your Chewable Tablet Making Machine?

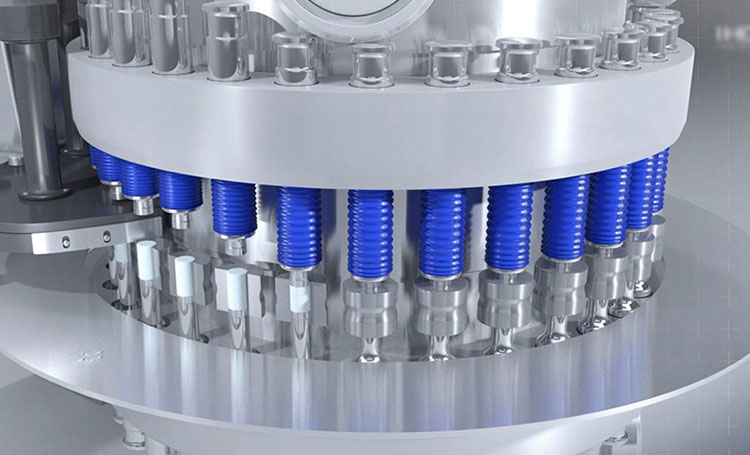

Tooling System - Sourced: VORTEX Sales Group

The tooling system includes molds and punches. How to choose the appropriate tool requires consideration of multiple factors.

Usage frequency

As the tool system is the core link in chewing tablet production, you need to clarify your usage frequency. The quality of the tool system is closely related to its frequency of use. If your usage frequency is high, you should choose a highly durable tooling system.

The shape of chewable tablets

The Shape of Chewable Tablets - Sourced: The Medicine Maker

The tool determines the shape and size of different chewable tablets, so shape and size are important considerations. Choose the appropriate tool system based on the shape of the chewing tablet you require.

Production demand

The choice of tooling system will vary depending on the demand for different production volumes. If the production demand is high, it is necessary to choose machines with multiple tooling systems.

10.What Is a Tooling Inspection System for Chewable Tablet Making Machine?

Tooling Inspection System - Sourced: LFA Tablet Presses

The tooling inspection system is a testing tool used to measure tablet grinding tools. There is currently an automatic tooling inspection system that can record the results of inspections.

This detection tool has many benefits, such as being able to record a lot of data and compare it with previous results. The use of automated programs greatly simplifies the process of measuring tool values.

11.What Is Maximum PressForce For Chewable Tablet Making Machine?

The pressure of the chewable tablet making machine is not fixed, but varies depending on the model and purpose.

Maximum Press Force For Chewable Tablet Making Machine

When you choose the pressure of a chewable tablet making machine, it is necessary to consider the properties of the material, such as particle size, humidity, etc., which can affect the tablet pressing effect. Different materials may require different pressures to achieve the best molding effect.

In addition, production scale should also be considered. Taking the rotary chewable tablet making machine as an example, its maximum tablet pressure can usually reach ranging from 60 kN to 100 kN which is suitable for large-scale production.

The pressure range of a single punch chewable tablet making machine is relatively wide, with a maximum pressure ranging from 15 kN to 60 kN.

12.How Does Auto Weight Control Work for Chewable Tablet Making Machine?

There is an automatic weighing control system in the chewable tablet making machine that can determine the weight of the produced tablets.

This device can automatically detect overweight and underweight unqualified tablets in the production line online, and eliminate products with unqualified weight. It use electronic sensors to detect the weight of the item being weighed, transmitting the weight data to a computer for processing.

13.Is There Any Active Ingredient in the Chewable Tablet Making Machine Interacts with?

Active Ingredient in the Chewable Tablet - Sourced: Health Innovations

You will definitely worry about whether the chewable tablet making machine will react with the active ingredients in the material, thereby affecting the quality of the final product. If you are concerned, you can use some materials to test whether a reaction will occur.

Stainless steel material has high corrosion resistance. In fact, many components of the tablet press are made of stainless steel, especially the parts in contact with the material, so they will not react with the active ingredients in the material and will not affect the characteristics of the material.

14.Which is the Best Material for Contact Parts of Chewable Tablet Making Machine?

In order to maintain the long-term operation of the equipment, the contact parts of chewable making machine should meet the specified quality standards and be able to withstand wear and tear. Therefore, when selecting materials for contact parts, sturdy and wear-resistant materials should be chosen to ensure the smooth operation of the machine.

Common materials include:

Tungsten carbide

Tungsten Carbide - Sourced: A&A Coatings

The hardness of tungsten carbide is second only to diamond and cubic boron nitride. It has high hardness, strength, and rigidity, and can effectively withstand heavy loads and wear during high-speed motion.

High chromium steel

High Chromium Steel - Sourced: www.wzlsgj.com

Chromium is the main alloying element of high chromium stainless steel, which can form a dense layer of chromium oxide and has strong corrosion resistance. It can work stably for a long time in harsh environments.

High carbon steel

High Carbon Steel - Sourced: Amazon

This material has excellent wear resistance and can be improved by adjusting the carbon content, adding appropriate alloying elements, etc., to make high wear resistant and high-strength materials. Moreover, this material has a long service life.

15.What Material Is the Shell of The Chewable Tablet Making Machine Made of?

The outer shell of a machine has many functions, which can prevent dust from entering and protect internal instruments from various interferences. The commonly used metal materials for the shell of a chewable tablet making machine are shown follow.

Stainless steel

Stainless Steel - Sourced: eBay

Stainless steel mainly consists of 304, 316, and 316L, which have chemical stability and corrosion resistance, suitable for use in humid environments, and are commonly used in the production of high-quality cheaper tablets.

Carbon steel

Carbon Steel - Sourced: Ulma Forged Solutions

Carbon steel is cheap and lightweight. The carbon steel used in rotary chewable tablet making machines is generally Q235, but it requires frequent rust prevention treatment and has a relatively short service life.

Aluminum alloy

Aluminum Alloy - Sourced: Gabrian International

Aluminum alloy is a lightweight and high-strength material. The aluminum alloys used in rotary tablet presses are generally 6061 or 7075, which have the advantages of light weight, high strength, and good thermal conductivity. However, this material has poor corrosion resistance and requires maintenance.

16.What Are Compliance Requirements for Chewable Tablet Making Machine?

cGMP

cGMP - Sourced: Sawgrass Nutra Labs

The production of chewable tablet making machine must strictly comply with cGMP standards in order to be safely put into use. This standard also requires the machine to ensure the use of safe raw materials during operation, strictly control the production environment, equipment, personnel training, and document recording.

ISO

ISO - Sourced: Zintilon

ISO specifies the requirements for the quality management system of chewable tablet press machine and other equipment to ensure that products can continuously meet customer and regulatory requirements in the design, development, production and other stages, and to ensure the safety and effectiveness of products.

FAT

FAT - Sourced: WATS

After the chewable tablet making machine is produced, it needs to undergo FAT, which means it will be operated at the manufacturer's location. The purpose of FAT is to verify whether the equipment can operate normally and whether it meets the designed parameters.

17.How Do You Determine the Right Chewable Tablet Making Machine for Your Factory?

I think you must want to choose a suitable chewing tablet production machine, but how do you make the selection? You must think carefully!

Production demand

Production Demand - Sourced: www.mdi.org

There are different models and scales of tablet presses, and their output also varies. For example, the production efficiency of a single punch chewable tablet making machine is generally 6,000 tablets per hour; The production efficiency of the rotary chewable tablet making machine can reach 20,000 tablets per hour.

Factory scale

Factory Scale - Sourced: Architectural Model Makers

The chewable tablet making machine can also be used together with other equipment to form a tablet production line. Therefore, when purchasing a chewable tablet making machine, you need to consider the size of your factory to ensure the applicability of the equipment.

Material

Clarifying your materials is of great help in choosing machines with different materials. If you make the wrong choice, it may affect the quality of the product. If your material contains pharmaceutical ingredients and is prone to chemical reactions with the material, you should choose a chewable tablet making machine made of corrosion-resistant materials, such as stainless steel.

18.What Maintenance Does Chewable Tablet Making Machine Require?

Everything needs maintenance, so you need to take good care of this tablet press. Regular cleaning and inspection are essential.

Regular cleaning

Regular Cleaning - Sourced: Samyx Cleaning

Due to the fact that some cleaning agents can undergo chemical reactions, you need to choose the appropriate one. You can use a damp cloth to clean the surface of the tablet press, removing dust and stains. In addition, you can also use a vacuum cleaner to clean the dust inside the machine.

Fastener inspection

When the chewable tablet press machine is operated for a long time, the fasteners are easily loosened. Loosening can cause equipment failure, so it is necessary to regularly check the degree of looseness of fasteners. During inspection, the operator should use a wrench to check the screws, nuts, and other fasteners on the equipment one by one. If looseness is found, it needs to be tightened to ensure the normal operation of the equipment.

Electrical maintenance

Electrical Maintenance - Sourced: Laxmi Associates

Especially for high-power tablet press equipment, electrical maintenance work is also very important. It is necessary to ensure good contact between the wires and plugs to avoid problems such as wire aging and poor contact, which may affect the service life of the equipment.

19.What Other Equipment Involved in the Production Line of Chewable Tablet?

Do you know how powder is turned into chewable tablets? The final chewable tablets require preparation of materials, mixing of materials, pressing, and coating, thus involving some equipment.

Crusher machine

AIPAK Crusher Machine

The crusher machine can crush the materials required for chewing tablets quickly and evenly. This machine can reduce energy consumption, improve work efficiency, and lower production costs. By cell level micro pulverization, the active ingredients are fully released.

Bin mixer

AIPAK Bin Mixer

The bin mixer can fully mix the raw materials and excipients, ensuring the stability and uniformity of the chewable tablet quality, and has efficient mixing and blending functions. This machine can achieve automated mixing, greatly improving work efficiency.

Granulator machine

AIPAK Granulator Machine

Granulator machine can effectively convert powdered or granular raw materials into uniform particles. Equipped with a simple and easy to understand operating interface and control system, this machine is convenient to operate. Besides, you can adjust the granulation parameters as needed to obtain the desired particle characteristics.

Drier machine

AIPAK FG Series Fluid Bed Dryer

Drier machine is an efficient drying device that utilizes the principle of fluid agitation to make materials fluidized in the drying medium, thereby achieving rapid drying. This dryer has fast drying speed, uniform temperature, and easy control

Grinding and granulating machine

Grinding and Granulating Machine

Grinding and granulating machine combines the two processes. It is mainly used to process solid materials, grind the materials into small particles under the action of abrasives and grinding bodies. In the compression system, the particles are squeezed and compressed to complete the formation.

Tablet coating machine

AIPAK Chewable Tablet Coating Machine

After the production of chewable tablets, in order to improve their appearance or prevent moisture and light, some tablets need to be coated, which requires the use of chewable tablets coating machines. This machine sprays plasticizer, solution, etc. onto the chewable tablet through a spray.

20.Why Choosing AIPAK Chewable Tablet Making Machine?

What are the advantages of AIPAK chewable tablet making machine worth choosing? Let’s learn about it together.

Using a glass cover

Using a Glass Cover

By using this transparent glass cover, operators can clearly observe the tablet pressing process and adjust parameters in a timely manner. In addition, the design of the glass cover reduces contamination of internal components, and it can also be opened for easy cleaning of internal components.

Equipped with different compression molds

Equipped with various tablet molds, the AIPAK chewable making machine can press granular materials or powders into circular, irregular, and chewable tablets with text and symbols.

Easy to use

Easy to Use - Sourced: Freepik

This machine does not require professional skills, so ordinary workers can operate it. The equipment adopts a PLC automatic control system, which can achieve automated production and reduce manual intervention. Meanwhile, the chewable tablet press machine is easy to clean and maintain, reducing production costs.

Unique mold diedesign

Unique Mold Die Design

The upper, middle, and lower mold plates are integrated. The middle plate is in direct contact with the material, made of 23Cr stainless steel with high hardness and wear resistance. Even if scratched, it can be polished once. In addition, this device is equipped with a lubricating oil guide groove and a waste oil groove.

Automatic lubrication system

Automatic Lubrication System

Molds of AIPAK chewable tablet making machine can be automatically lubricated, which can reduce machine wear and reduce manpower. In addition, it is equipped with a brush and can also be manually refilled.

Tablet thickness adjustment

Tablet Thickness Adjustment

The machine can achieve an adjustment range of 0-6 and has a scale display. If you want to make 8mm thick pieces, the adjustable range of machine thickness is ± 3, which means you can make pieces with a thickness of 5-11mm. The downward pressure wheel rises and rushes deeper into the middle mold, while the position of the upper mold remains unchanged, thus changing the thickness.

Fully enclosed forced feeder

Fully Enclosed Forced Feeder

This machine is equipped with 2 impellers, which are fixed and can evenly mix the powder. And the material filling speed is fast, which can maintain material flow and achieve uniform filling.

Upper punch protective track

Upon Punch Protective Track

It can protect the upon punch to prevent collision, and after the final filling measurement, perform a downward pull action to protect the downward punch and avoid throwing out the powder.

Conclusion

With the development of people’s needs and technology, the application scope of chewable tablet making machines has become increasingly widespread. This machine is also constantly being modified, with increasing efficiency and better performance and appearance. Do you have any questions about this machine? You are welcome to contact AIPAK at any time, and we will provide you with the most comprehensive answers.

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine