Orally Disintegrating Tablets: The Complete FAQ Guide In 2025

Why pharmaceutical manufacturing sector begin with delayed interest in orally disintegrating tablets? It’s all about patient demand and greater popularity about them! The orally disintegrating tablets are considered as the most patient-compliant medication among the various age group people. This form of modern medication has shown a large impact on the pharmaceutical business and is expected to be high in the coming years.

In this article, you’re going to explore the answers to various questions you have in your mind. This comprehensive blog is composed of simple to technical issues related to orally disintegrating tablets. So, without wasting your time, let’s start the scientific article.

1.What is the meaning of orally disintegrating tablets?

Orally disintegrating tablets- Picture Courtesy: Vitaquest

Orally disintegrating tablets or ODTs are a popular mode of oral medication that is flexible with more stability and proven compact packaging sizes. The fast mode of the delivery system melts once you put it inside your mouth.

By the action of your mouth’s saliva, it starts disintegrating slowly. Therefore, you don’t need to take water if taking orally disintegrating tablets.

It can be dissolved by the action of pregastric mucosal secretion and begins to melt. However, for this reason, it is mainly subjected to the patient who is either bedridden or paralyzed or suffering some emergencies. This type of formulation came into existence in the 1980s.

2.What are the other names or synonyms for orally disintegrating tablets?

Orally disintegrating tablets

This type of medication is referred to by different names or simply hooked to a broad range of synonyms. This is all because of its unique pharmacokinetic properties and is different from conventional or regular oral tablets.

For example:

- Orodispersible tablet

- Instant orally disintegrating tablets

- Rapid dissolving orally disintegrating tablets

- Quick-acting orally disintegrating tablets

- Melt in Mouth orally disintegrating tablets

- Mouth-dissolving or tongue-dissolving medications

- Solubilized tablets

- Fast dissolving tablets

3.What is the definition of orally disintegrating tablets according to FDA/EU/US Pharmacopoeia?

Going towards the more scientific definition of orally disintegrating tablets is provided by statements from international drug pharmacopeias and regulatory administrations.

FDA/EU/US Pharmacopoeia - Picture Courtesy: USP.org

Food and Drug Administration or FDA

The Food and Drug Administration or FDA stated it as ‘the fast-acting medication that melts rapidly in the matter of few seconds by the action of your tongue secretions’.

European Pharmacopoeia or EU

However, the European Pharmacopoeia or EU explained the definition as ‘an uncoated solid dosage formulation when placed over your tongue may be dispersed immediately prior to swallowing and these tablets must be integrated in 3 minutes’.

United State Pharmacopoeia or USP

The United States Pharmacopoeia or USP monographs exactly did not state the particular definition related to orally disintegrating tablets. Rather it mentioned the convenience and flexibility of orally disintegrating tablets by action of pregastric mucosal secretion just in the fraction of section upon administering them with improved bioavailability and low dosage intake.

4.Why are orally disintegrating tablets so popular?

The orally disintegrating tablets are possessed with so many benefits due the the following enlisted points.

Greater Ratio of Patient Compliance

High patient compliant- Picture Courtesy: supplysitej

As you know, some special populations in our society are facing challenges when it comes to administering oral tablets. For example, in geriatrics, children, and people with dysphagia. One of the most significant benefits of utilizing the orally disintegrating tablet is its user’s compliance as it dissolves conveniently in your body quickly.

Excellent Solution for Tablet Refusal

Excellent Solution for Tablet Refusal

Many patients reject the tablet dosage formulation due to related problems. For example, The medication is offering safe administration where problems like choking, medication smell, etc. According to scientific studies mentioned in The European Journal of Clinical Pharmacology, 30% of the population faces problems with taking regular pills and 10% population directly refuses to take them. So, it is the greatest alternative to conventional tablets.

Ease in Carry and Safe

Safe to carry

One of the major benefits of orally disintegrating tablets is that you don’t have to carry a water bottle or glass. This is a good solution for patients traveling most often and may need medication at any time under any circumstances.

Moreover, you don’t need to wash your hands whenever take them. Just open the medication and put it in your mouth without worrying about washing or hygiene-maintaining protocols. Whether it is a blister pack or jar, the orally disintegrating tablets offer easy and safe medication intake.

Faster Rate of Absorption and High Bioavailability

High Bioavailability

Whenever you take orally disintegrating tablets, they directly absorb in your system by using your oral mucosal tissues along with pre-gastric areas of your mouth. Remember, certain sites are known for a greater region of absorption and bioavailability of medication.

So, it promotes the fast absorption and efficacy of the drug as it reaches your blood circulatory system and makes tablets ideal for certain diseases. For example, in neurological problems (as the patient is not capable of taking medicine), such as epilepsy, psychological issues, cardiovascular diseases, body aches, etc.

Accurate and Pre-Determined Doses

Fast and accurate dose- Picture Courtesy: Egypt business

The orally disintegrating tablets are designed with pre-determined dosages that signify that you’re taking the correct and potent medication each time. Therefore, it lesser the chances of dose management in your emergency, you just need to choose the tablets and administer the patient with minor dose error. So, whether you require a frequent dose or a single dose, the orally disintegrating tablets are ideal to carry and administer.

5.What are the special groups of the population for orally disintegrating tablets?

The orally disintegrating tablets are mainly confined to a special group of the population and are recommended for use for certain categories as well as conditions. For instance,

Pediatrics

Better for children- Picture Courtesy: DentaGama

You know that children due to taste selection and small age can face challenges in swallowing conventional medications in the form of tablets and capsules. For them, orally disintegrating tablets are the new and easiest medication to use without the hassle and need for extra things such as water or juices. Moreover, they are more bioavailable and appealing to every young child associated with chronic illness.

Geriatrics

Geriatrics- Picture Courtesy: GP Online

Same as children, the older population also faces problems in accepting and swallowing the tablets or capsules. Therefore, orally disintegrating tablets are a useful way for medication widely accepted by the older generation. This mainly included people with cognitive decline, neurological problems, or psychological complications. This is a useful way of medication with rapid therapeutic action.

Animals

Animal Dosage- Picture Courtesy: animaldoc.au

These medications are also specially designed for the treatment of animals due to ease of administrating as well as fast action. Firstly, animals are non-cooperative and make you uneasy to give medicines, thus orally disintegrating tablets make an easy and quick mode of administration and attaining the therapeutic response in a shorter time.

6.What is the formulation of orally disintegrating tablets?

Almost every active pharmaceutical ingredient used in the manufacturing of orally disintegrating tablets is showing systemic effects rather than local effects.

Remember that the drug and excipients should not affect the therapeutic property of medication for the purpose it is utilized. Moreover, there are many types of orally disintegrating tablets making an acceptable and ideal dosage formulation.

Active Pharmaceutical Ingredients

Active Pharmaceutical Ingredients- Picture Courtesy: Verywellhealth

The tablet must be ionized and capable of penetrating inside the mouth significantly without leaving any particle of medication inside your mouth cavity.

Side by side it should be considered that the molecular weight of the active pharmaceutical ingredient must be lower than 500 Dalton.

Therefore, tablets with active pharmaceutical ingredients show a weight of less than 50 milligrams, with a compact half-life, possessing an acceptable smell and taste.

Excipients

Excipients- Picture Courtesy: Pharma Excipients

Excipients also have an essential and critical role in the formulation of orally disintegrating tablets. Therefore, the particular requirements such as solubility, and associated physical properties be considered.

The mannitol is particularly used as a diluent, but it is a little bit modified and shows suitable properties in orally disintegrating tablets. Such as increasing the surface size and large pore size can make a cost-effective product.

Look at the table below where we have designed the number of exhibits used in really disintegrating tablets with table courtesy of the National Library Of Medicine PMC.

Approved List of Excipients Utilized in Orally Disintegrating Tablets

| Excipients | Examples | Description |

| Super Disintegrants | Crospovidone,

Croscarmellose Sodium, Sodium Starch Glycolate, Sodium Carboxymethyl Cellulose, Microcrystalline Cellulose, Spray-Dried Lactose, Acrylic Acid, Alginic Acid, Sodium Alginate, Soy Polysaccharides, Ispaghula Husk With Pregelatinized Starch, An Altered Corn Starch, Ion Exchange Resins, And Gas Evolving Disintegrants |

These are specialized disintegrating agents used in orally disintegrating tablet formulation which swells and disperses in your mouth and is used in a small concentration as compared to traditional ingredients such as 1 to 10% of weight in formulation.

|

| Fillers | Sugar and Sugar-Based Derivatives Such as:

Dextrose, Fructose, Isomalt, Lactilol, Maltitol, Maltose, Mannitol, Sorbitol, Starch Hydrolysate, Polydextrose, and Xylitol |

It provides and improves the textural properties of tablets.

|

| Emulsifying agents | Alkyl Sulphates,

Propylene Glycol, Lecithin, Sucrose Esters, Sodiumdoecylsulfate, Sodium Lauryl Sulfate, Polyoxyethylene Sorbitan Fatty Acid Esters (Tweens). |

It acts as a dissolution accelerator and improves the bioavailability of immiscible molecules. |

| Sweetening agent | Various sugars and grapefruits. | The ingredients used in the tablets make it unacceptable. That’s why sweetening agents are incorporated to improve the taste. |

| Flavoring agent | Fruity flavors such as peppermint, vanilla, mango, strawberry, etc. | To make tablets patient-compliant. |

7.How to make orally disintegrating tablets?

The current approaches for making orally disintegrating tablets are described below:

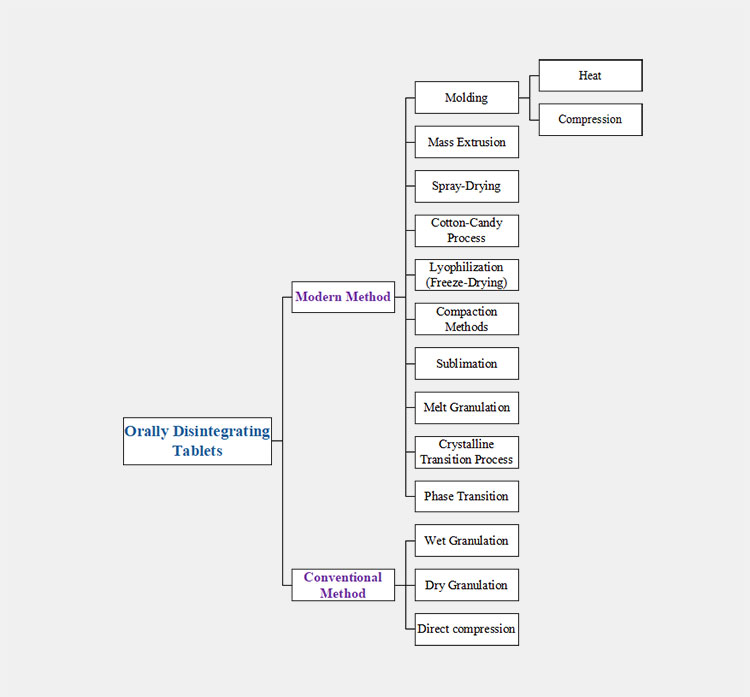

The methods for orally disintegrating tablets

Modern Method

The following content is about the methods used for manufacturing orally disintegrating tablets and best known for modern processing.

Molding

This is the most common technique used for preparing orally disintegrating tablets that are capable of disintegrating in five to fifteen seconds only. This is mainly achieved by following two important ways.

Orally disintegrating tablets from molding- Picture Courtesy: The medicine maker

Heating Molding

In this method, the molten solution of sugars or water-soluble substances is mixed with active ingredients to form a tablet. In this case, the sugar portrays binding effects which improve the good taste as well as sensory experience when you are taking the tablets. The prepared suspension is added into the specified molds and the water content is evaporated at 30°C under the high vacuum so the porous solidified mass is now prepared.

Compression Molding

This is low-cost and known as a simple method for producing orally disintegrating tablets. In this process, the powder mixture is prepared with hydro-alcoholic solvent and is compressed into the molding plates by using low pressure, and the formed tablets are dried with the help of solvent evaporation.

The final porous structured tablets are formed which are capable of disintegrating in your mouth rapidly with greater dissolution rates.

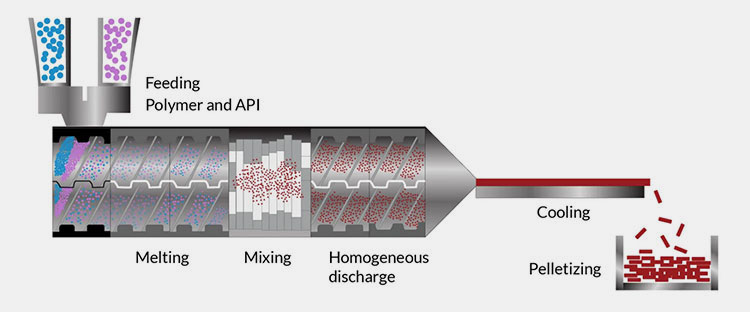

Mass Extrusion

Mass extrusion- Picture Courtesy: Fabtech technologies

In this process, the powder mixture is prepared by the action of water-soluble solvents such as polyethylene glycol or PEG, ethanol, or methanol. The mixture is passed through an extruder followed by the drying process to evaporate the content alcohol. It ultimately leaves the solidified substance which looks string like structure. Now it is crushed into small granule substances which are then mixed with the other components of the tablets and compressed by utilizing the compaction method.

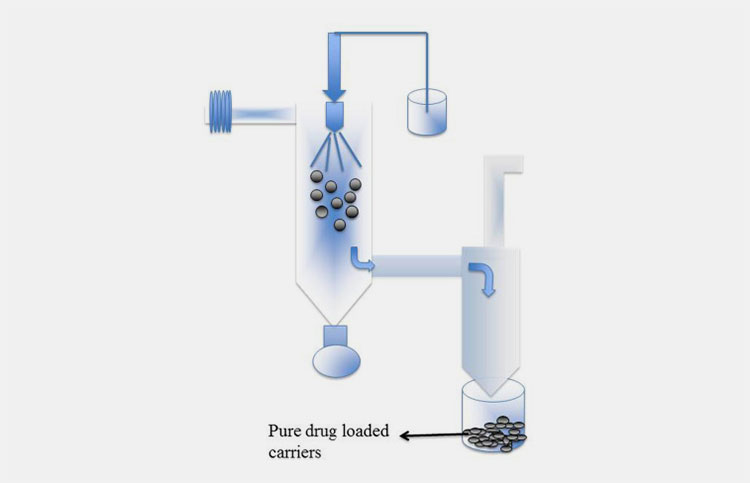

Spray-Drying

Spray drying for orally disintegrating tablets- Picture Courtesy: ScienceDirect

This is the common method used for producing orally disintegrating tablets simply by preparing the liquid solvent in combination with a solid formulation. The solvent mixture is first introduced into the hot chamber where it is subjected to evaporation due to high temperature which ultimately leaves microparticle substances behind. They are kneaded and utilizing distilled water to form granules then dried at 60 degrees for 2 hours.

The granules are sieved and blended. These substances are composed of high porosity micro-particles which are then combined with excipients to form a tablet by compression method. However as compared to the other preparing methods. It is comparatively expensive and requires a piece of specialized equipment for the evaporation of moisture.

Cotton-Candy Process

Cotton candy process- Picture Courtesy: CLE

This is a unique method to form orally disintegrating tablets where the spinning instrument is subjected to a form of a floss-like structure by utilizing polysaccharides. Here the sugar is subjected to an instrument which has temperature ranges from 180 to 266°C and helps in the formation of floss matrix and recrystallized. Then, it is crushed and mixed with active pharmaceutical ingredients and other substances of the excipients and compressed altogether.

This technique is unique and very useful for masking the bitter taste of your substances inside the tablet because the involvement of a large amount of sugar can improve the taste as well as patient compliance. However, due to the accumulation of large molecules of drugs, it is not suitable for thermolabile substances.

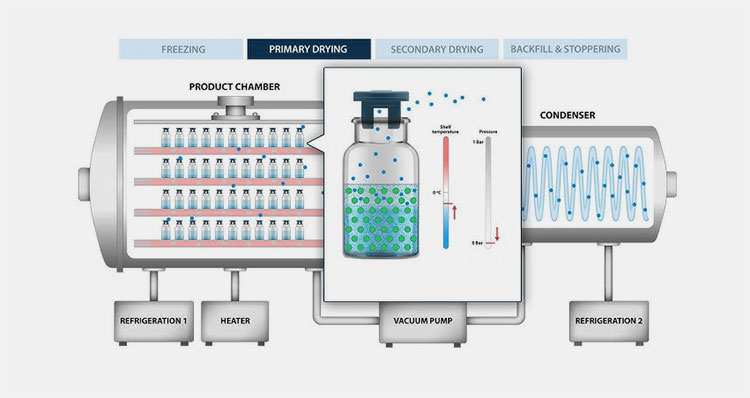

Lyophilization (Freeze-Drying)

Lyophilization or freeze drying

In this process, the thermolabile substances are mainly treated under reduced temperature. It is mainly done by application of a vacuum and the prepared mixture is known as lyophilizes. This mainly has a lighter texture and porous structure which is capable of fast disintegration. Moreover, this process is useful especially when dealing with reactive or toxic substances as you don’t need to face or encounter powders that are dusty in nature. Therefore, it is the safest way to form orally disintegrating tablets.

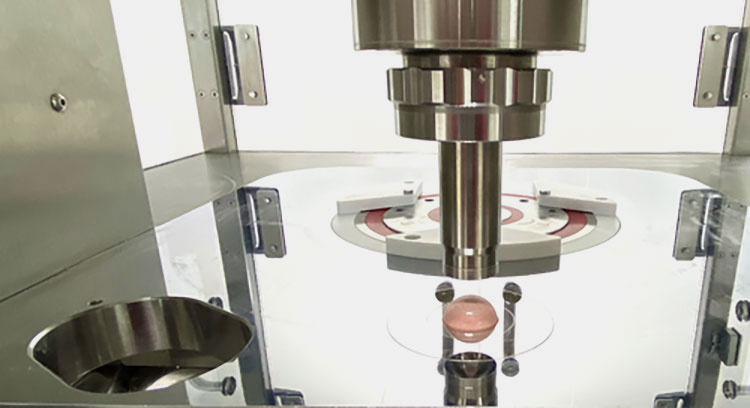

Compaction Methods

Compaction- Picture Courtesy: Korsch Tablet Presses

The compression equipment is mainly used which is subjecting greater pressure to APIs and excipients to form a tablet. In this method, you will need to use super disintegrant as the compression reduces the chances of forming porosity in tablets.

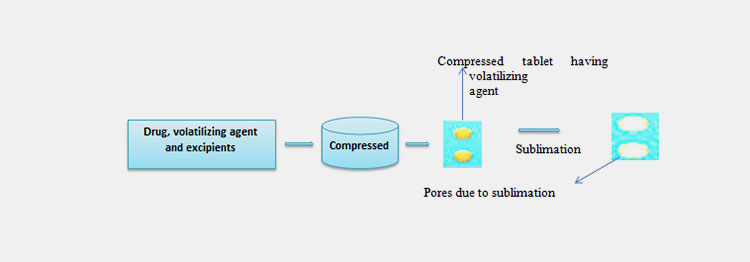

Sublimation

Sublimation method for orally disintegrating tablets- Picture Courtesy: ResearchGate

In this method, the mixture of volatile substances with APIs is formed using the tablet compression method. Under controlled temperature and pressure, you can induce the evaporation of such substances to form a porous tablet that allows flexible disintegration when you place it in your mouth.

Medication like captopril is mostly used in emergency situations requires fast action is mostly prepared by sublimation method.

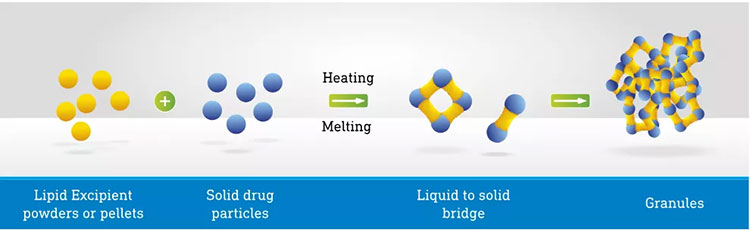

Melt Granulation

Melt granulation- Picture Courtesy: Gattefosse

This method is known as a solvent-free process where you can use a binder of low melting point with other ingredients of the tablets. Here the molten binder is a game changer with sticks the particles of the mixture and makes a granule that gets harder a room temperature, followed by grinding, sieving, and compression of the tablets.

This is quite a simple and cost-effective method that does not need drying as well as solvents and ensures high-quality tablet formation. That’s why it is mainly required for heat-sensitive materials or APIs.

Crystalline Transition Process

Crystal transition process- Picture Courtesy: loyal

This method is involved with the compression of two different compressibility indices of sugars where one is confined with high compressibility while the other with low. So, a tablet with suitable hardness is formed. The amorphous powder of sugar is transitioned into the crystalline phase. This transition is ideal for the desirable hardness of the tablets. This method is useful for various saccharides that are then formed by direct compression. Due to temperature and pressure parameters, it is not suitable for every type of saccharide or active pharmaceutical ingredient.

Phase Transition

Phase Transition- Picture Courtesy: Vadaya

The blending and compressing of powder with two sugar alcohols that are associated a high and low melting points. The compressed mass is heated with a temperature range of two sugar molecules. After heating the solidification of sugars takes place with required porosity. Here low compression force is utilized with heat treatment therefore not suggested for water-sensitive substances.

Conventional Method

An old and popular method where orally disintegrating tablets ingredients are directly subjected to the following processes.

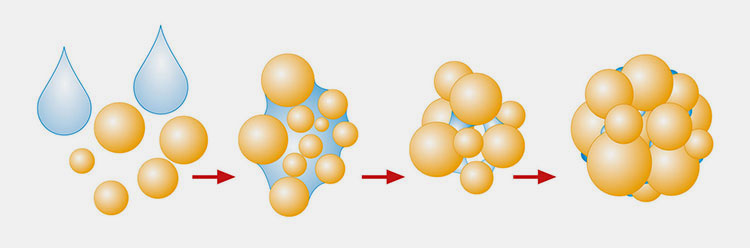

Wet Granulation

Wet granulation- Picture Courtesy: Glatt

The widely used method is where excipients and APIs are mixed utilizing a liquid granulation procedure to produce granules. The solution is dried, sifted, crushed, and compressed by utilizing various range techniques involved with wet granulation.

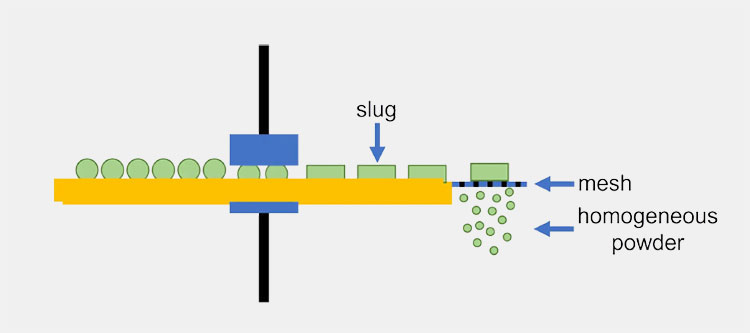

Dry Granulation

Dry Granulation

This is ideal for substances with high moisture sensitivity or heat. The excipients and APIs are mixed and passed through a compactor that forms a slug. It is further crushed into pieces to get uniform and small granules.

Direct Compression

Direct Compression- Picture Courtesy: Huada Pharma

This is a direct and straightforward way of forming tablets that involves three steps, mixing of excipients and APIs, compression, and ejection. This is the direct way of getting effective tablet production in the least complicated way.

8.What are commonly used manufacturing machines for orally disintegrating tablets?

To make orally disintegrating tablets, you will need the following essential instruments to carry out the task.

Blenders or Mixers

Blenders and mixers

The beginning of any process in pharma is not completed without blenders or mixers. The uniformity in mixed substances is attained by utilizing the mixing machines. There are a number of equipment available for hygiene and through mixing of excipients and APIs. For example: V blender, ribbon mixers, planetary mixers, high shear mixers granulator, etc.

Sifters or screening machine

Sifter or screening machine

The equipment significantly ensures the presence of uniformity in the particle size of the substances to be used in the orally disintegrating tablets. The screening and mesh size units are used to eliminate the oversized particles and ensure the particles are filtered out that are required to you. Moreover, the machine is designed with a micro-crusher that helps in the size reduction to produce the desirable shape and size.

Spray Dryer

AIPAK Spray dryer

This is a versatile solution to get dried powder particles from the solution or suspension formulation by the action of atomized spray and high degree temperature which induce the evaporation of moisture inside the mixture. A spray dryer is mainly used equipment for orally disintegrating tablets in order to form porous granules that are ideal for the production of these tablets.

Freeze Dryer

Freeze Dryer

This is also known as a lyophilizer and is broadly used in the pharmaceutical industry and others for the manufacturing of various products. For orally disintegrating tablets the highly porous substances can be achieved by utilizing the lyophilizer or freeze dryer. Here the machine works by reducing the temperature and inducing the high vacuum to eliminate the moisture content with the help of sublimation. This method is used for heat-sensitive APIs and materials and the action is taken place by primary and secondary drying.

Tablet Compression Machine

AIPAK tablet compression machine

Without a compression machine, it is not possible to produce orally disintegrating tablets. Whatever the method is used, all ingredients must be passed and pressed through this machine. For example, rotary tablet press, single punch pressing machine, double rotary tablet presses bi-layer, multi-layer, effervescent tablet press, etc.

9.How do orally disintegrating tablets work inside your body?

The orally disintegrating tablets work inside your body with a unique approach that is discussed in the following points:

The working of ODTs inside your body

The action of Saliva and Super disintegrants

The primary factors that act as the turning points are the action of our saliva and the specialized excipients such as super-disintegrants. The action of these two simultaneously produces an ideal action once to keep the tablet in the mouth which rapidly absorbs by using 15 to 60 seconds (depending on the type of tablet) and it is all about the highly porous structure of the tablets.

High Absorption in the Oral Cavity and Entering Blood Circulation

Upon absorption, it produces its therapeutic action by entering the circulatory system of the blood. This is mainly induced by the mucosal layer of the mouth that bypasses the inner lining of the GIT and escapes the action of various enzymes that may affect the properties of the APIs. For example, anti-emetic, hypertensive, anti-allergy, etc orally disintegrating tablets.

10.Can you chew orally disintegrating tablets?

Chewing orally disintegrating tablets- Picture Courtesy: MedPageToday

No, the designed quality for orally disintegrating tablets is meant for achieving its action simply by placing them on your tongue. If you chew the tablets, it may affect the properties of medicines related to inducing their action or quick absorption.

Therefore, it is not recommended to chew, crush, or dissolve these tablets. In fact, the dissolution of these tablets doesn’t urge water intake. Just place the tablets and observe their good therapeutic action. So do not cut, crush, or swallow the tablet as in return it may give adverse effects instead of benefits.

However, you can also talk to your prescriber for more guidance and the potential effects if you attempt chewing or crushing them.

11.Can you cut orally disintegrating tablets into half?

Cutting of orally disintegrating tablets

Generally, it is not suggested to cut the orally disintegrating tablets in half due to many reasons. First of all, by cutting can disturb the absorption properties of the tablets, the coating over tablets may also be unable to produce taste-masking effects as a whole. There won’t be assured in the dose accuracy in case of splitting the tablets.

In some cases, especially when subjecting the tablets to small children, you may require splitting the tablets. In this way, the prominent line mark is given by your manufacturer already. So, you can cut them in half. However, you must be cautious in handling them for example, maintaining hygienic tips properly. But it depends on the type of medication and manufacturer indication if the tablet is safe to cut.

12.What is the difference between orally disintegrating tablets and dispersible tablets?

The basic difference between orally disintegrating tablets and dispersible tablets is mentioned in a table.

Orally Disintegrating Tablets and Dispersible Tablets

| Orally Disintegrating Tablets | Dispersible Tablets |

| The fast-acting tablet disintegrates in your mouth by the action of saliva. | The fast-disintegrating tablets are dispersed rapidly when dissolved in any liquid. |

| Water is not required for orally disintegrating tablets. | Water is essential for dispersing the tablets. |

| It has the fastest onset of action ranging from a second to a minute. | It has delayed onset of action comparatively orally disintegrating tablet ( maybe 10 minutes to 15 minutes) |

| It involved super disintegrants to induce faster actions. | It contains effervescent agents to induce fast dispersion in water such as citrate. |

Conclusion

The orally disintegrating tablets are an excellent mode of drug delivery with greater user compliance and greater biopharmaceutical properties. These are the specialized formulations that are meant to decrease the choking hazards that are mostly associated with special populations. Today, due to its high benefits, this medication type is broadly manufactured as an over-the-counter product for the treatment of various general ailments such as allergies, body aches, etc. In this article, we have described the comprehensive steps involved in the processing and equipment involvement. If you’re planning to manufacture orally disintegrating tablets or looking to purchase any equipment. Then, we would suggest you contact our experts to avail the chance to explore an unlimited series of innovative machines under your budget.

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine